Unless you’re just recently getting into 3D printing, chances are you’ve heard about Creality, the 3D printing company famous for the Ender 3 and many other machines. Creality’s initial success was largely built on the popularity of the Ender 3, but their CR-10 printer was also a major hit in the consumer 3D printing industry. Both the Ender 3 and CR-10 gained a large following because of their relatively low price, expansive lists of features, and upgradability.

Since then, Creality has expanded their Ender and CR printer series, adding new printers like the Ender 5 and CR-20. On top of this, Creality has continually released new versions of their most popular printers. In addition to the Ender 3, Creality now sells the Ender 3X, Pro, V2, and Max, while the CR-10 range now includes the CR-10S, V2, Max, S5, Mini, 10S Pro V2, V3, and the new CR-10 Smart.

Today we’ll focus on the Ender 3 V2 and the CR-10 V3, both of which are enhanced versions of the original printers, inspired by community feedback. Although these two printers contain many similarities, their price points reflect their differences, with the Ender 3 V2 costing around $260 and the CR-10 V3 about $510.

We’ll go over a few differences concerning each machine’s printing style, extruder, electronics, and more. Before we get into those differences, though, we’ll go over the specifications of each machine; enjoy!

Specs

The Ender 3 V2 and CR-10 V3 are both similar printers, especially at first glance. Both printers are FDM machines, meaning that they intake filament, melt it, and lay it out layer-by-layer into the form of the desired part. Below, we’ve compiled a list of specifications for each printer:

Ender 3 V2

- Style: Cartesian XZ head (i3)

- Build volume: 220 x 220 x 250 mm

- Materials: PLA, ABS, PETG, TPU

- Extruder: Bowden drive; Creality stock plastic extruder

- Hot end: Creality stock hot end

- Connectivity: MicroSD card, Micro-USB

- Build plate: Textured glass (silicon carbide)

- Motherboard: 32-bit; available ports for BLTouch

- Stepper motor driver: TMC2208 (silent)

CR-10 V3

- Style: Cartesian XZ head (i3)

- Build volume: 300 x 300 x 400 mm

- Materials: PLA, ABS, PETG, TPU

- Extruder: Direct drive; E3D Titan extruder

- Hot end: Creality E3D V6 clone with circular heat sink

- Connectivity: SD card, Mini-USB, ISP

- Build plate: Textured glass (silicon carbide)

- Motherboard: 8-bit; available ports for BLTouch

- Stepper motor driver: TMC2208 (silent)

Basics

Let’s start with the basics. Both printers follow in the footsteps of the Original Prusa i3, with the printhead moving along the X-axis carriage. This carriage moves up and down the Z-axis, and the build platform moves along the Y-axis.

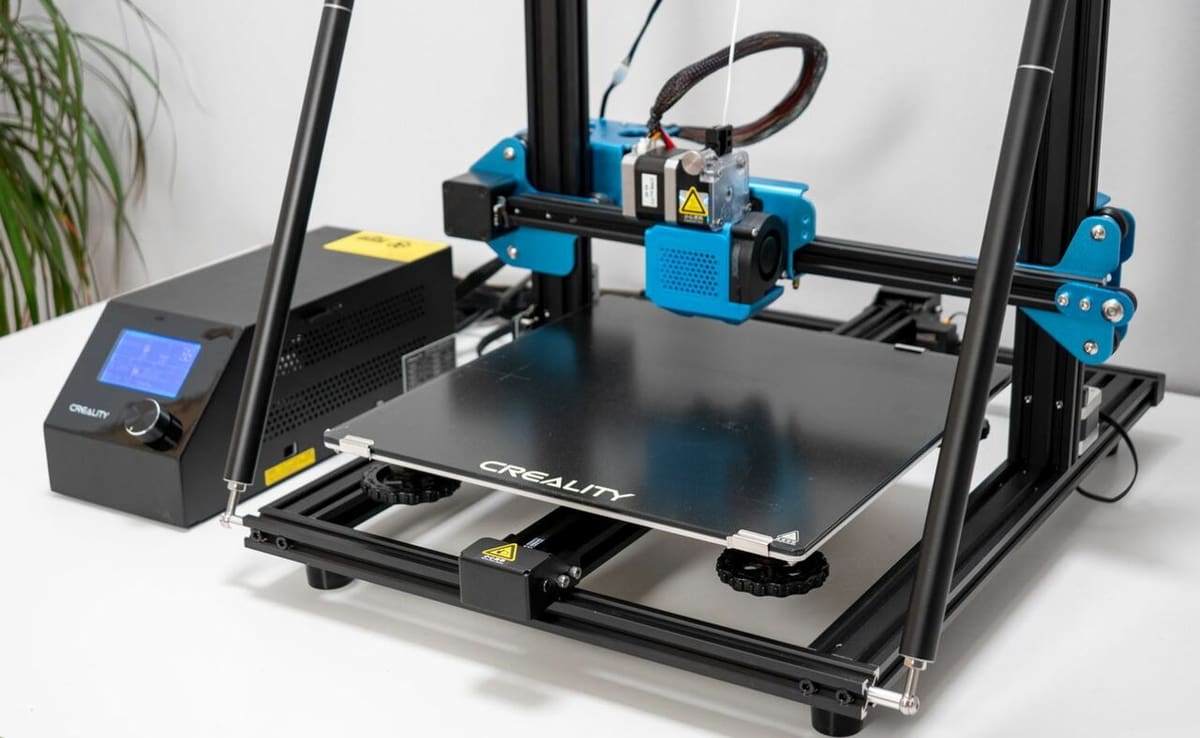

Perhaps the most obvious difference between the two machines is the size, as the CR-10 V3 is a good bit larger than the Ender 3 V2. The CR-10 V3 has an impressive build volume of 300 x 300 x 400 mm, while the Ender 3 V2 is a respectable 220 x 220 x 250 mm.

Although you get more build space on the CR-10 V3, this means that it will take longer for the heated bed to reach higher temperatures. Additionally, the extra Z-axis space on the CR-10 V3 makes the top of the printer pretty unstable, so Creality has added support rods to make the frame more structurally sound. While the support rods serve their purpose, the CR-10 V3’s frame is still not quite as stable as the Ender 3 V2’s, but this is the price you pay for a large Z-axis build space.

Another difference between the two printers is that the CR-10 V3 comes almost completely assembled. Despite Creality’s claims that assembly is super speedy for the Ender 3 V2, for an inexperienced or new user, it will probably take at least an hour and a half to set up the printer.

Regarding the extruder configurations, the Ender 3 V2 utilizes a Bowden system, while the CR-10 is equipped with a direct drive mechanism. This is a significant disparity between the two printers, so let’s dive a bit deeper into the differences.

Extrusion

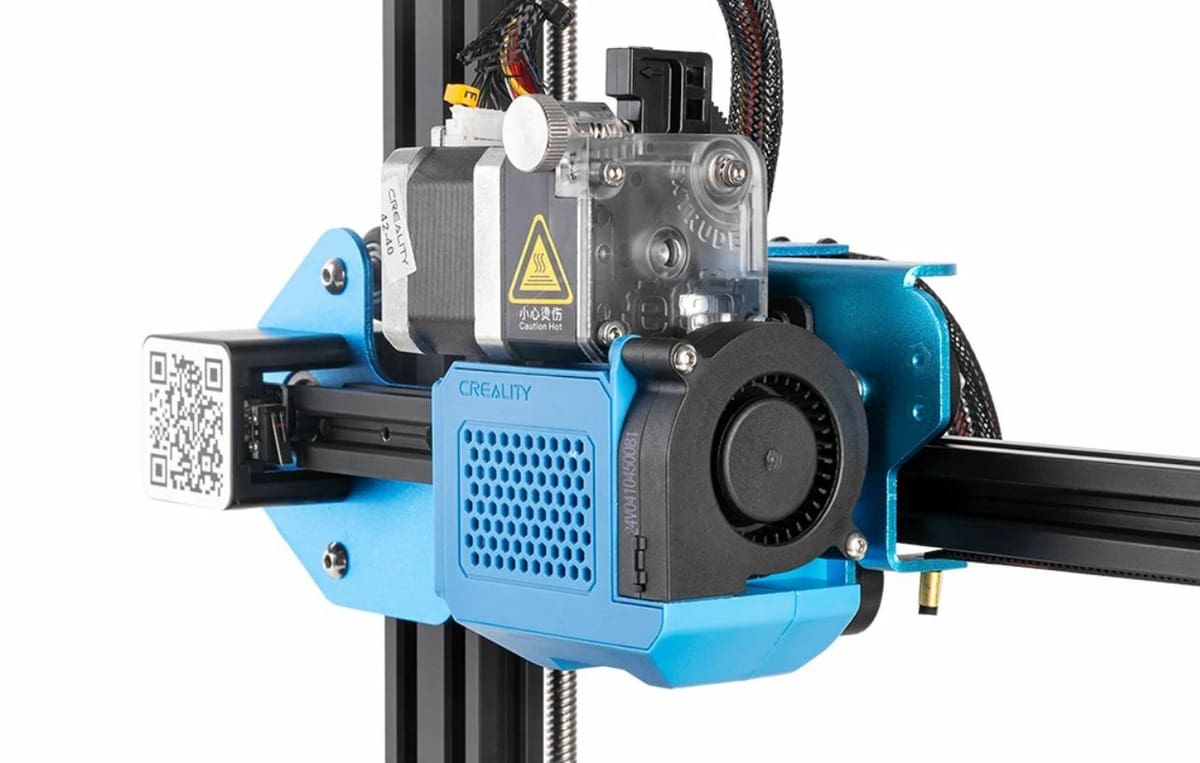

The extruder is a vital component of any 3D printer, as poor extrusion can cause issues like under-, over-, or inconsistent extrusion. The extruders on different Creality printers are usually very similar, but not in the case of the CR-10 V3, which uses a premium extruder from E3D, a manufacturer of high-quality hot ends and extruders.

The CR-10 V3’s E3D Titan extruder is a direct drive setup. This single-drive extruder (one drive gear and one idler wheel) uses an all-metal drive gear and a 3:1 gear ratio that increases extrusion torque. The Ender 3 V2, however, uses a standard Creality extruder with a metal drive gear but a plastic construction. The v2’s extruder uses no gear ratio, and some users have experienced under-extrusion due to insufficient pushing force. The plastic can also wear out on one side due to the friction of the material being fed through, so this extruder isn’t ideal in the long run.

Direct drive systems, like on the CR-10 V3, have the extruder positioned directly on top of the hot end, so there’s minimal transfer distance between the two. On the other hand, the Ender 3 V2’s Bowden setup has the extruder attached to the frame, so there’s a gap between the extruder and the hot end, spanned by a PTFE tube.

The CR-10 V3 will require smaller retraction distances for 3D prints because it doesn’t have to correct for any slack in the PTFE tube. It’s also the safer choice for printing flexible filaments because the short travel distance means the material is less likely to be stretched.

In spite of the advantages, the direct drive setup means that the CR-10 V3 has a larger, heavier printhead than the Ender 3 V2, and it can be more difficult to fix extruder or hot end jams because the printhead is crowded and compact. The Ender 3 V2 also has a useful extruder handwheel, a feature the CR-10 V3 is lacking. This handwheel makes loading and unloading filament easier, especially when you don’t want to touch your filament and potentially add moisture to it.

Electronics

The mainboard is the microcontroller board responsible for controlling the motors, reducing the motor noise, running the firmware, and performing other tasks. The Ender 3 V2 uses the 32-bit Creality V4.2.2 mainboard, while the CR-10 V3 uses an older 8-bit Creality mainboard.

The Ender 3 V2’s mainboard’s 32-bit framework and increased storage size allow it to run more advanced firmware packages, like Marlin 2.0, which the CR-10 V3’s 8-bit mainboard can’t entirely handle. On the Ender 3 V2, you can easily update the firmware on the mainboard simply by inserting a microSD card with your desired firmware. This isn’t possible on the CR-10 V3’s mainboard, and you have to use the board’s ISP port to make any firmware changes.

Both printers’ mainboards use terrific TMC2208 stepper motor drivers that do a great job of keeping the noise from the motors to a minimum. Also, both mainboards have dedicated ports for an automatic bed leveling (ABL) sensor, specifically a BLTouch device, even though the printers don’t come with one installed in their stock form. This makes upgrading to ABL a breeze because you don’t need to use an external component, like a pin-27 board, to add the device.

Another difference is that the CR-10 V3 uses an authentic Mean Well power supply unit (PSU), which the Ender 3 V2 doesn’t have. Although you probably won’t notice this difference, Mean Well PSUs are typically considered more reliable and safe.

Next, the CR-10 V3 has a filament runout sensor in the printer’s stock form, and although the Ender 3 V2’s mainboard has a dedicated port for one, the printer doesn’t come with a sensor. A filament runout sensor makes printing large objects with a close-to-empty filament spool a stress-free experience. Especially with a large-format printer like the CR-10 V3, having this feature is a nice reassurance.

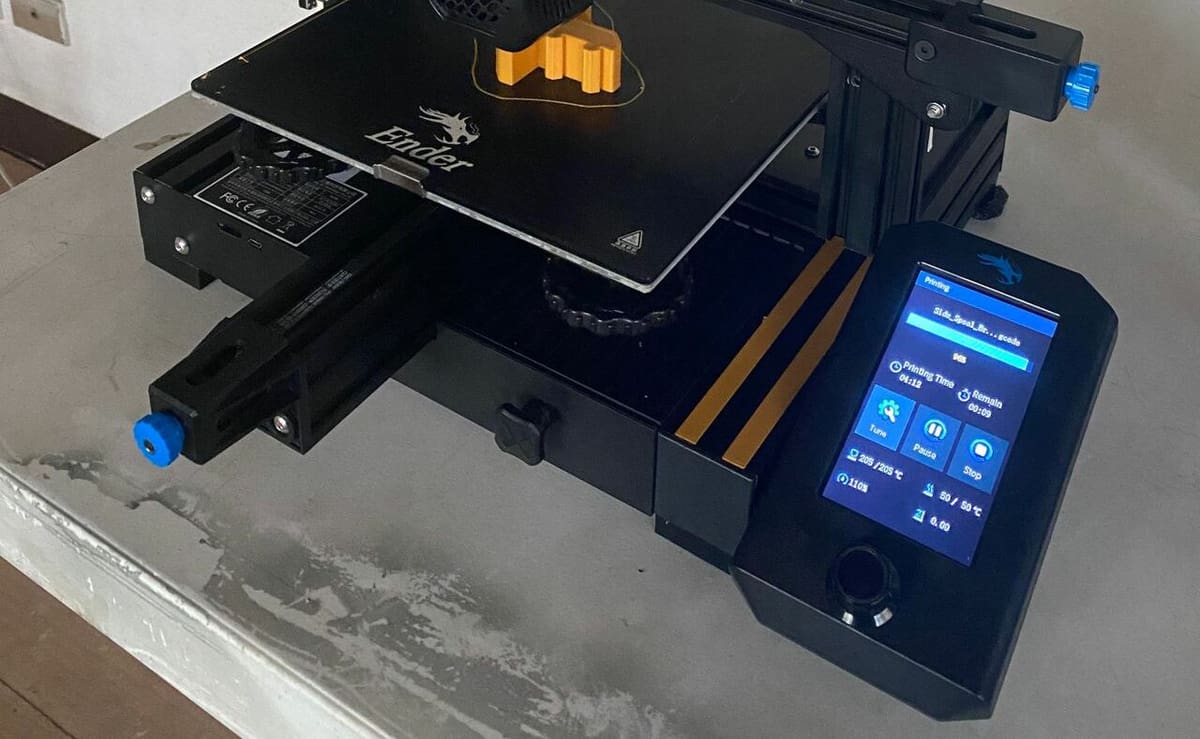

Lastly, the Ender 3 V2 has a color LCD screen and smooth user interface (UI). Conversely, the CR-10 V3 uses the standard CR-10 blue light display, which is perfectly functional but just doesn’t look as cool and isn’t as fun to use.

Other Features

Finally, we have some small, miscellaneous elements and enhancements of these printers that are easy to overlook but play a crucial role in the printers’ ease of use and performance.

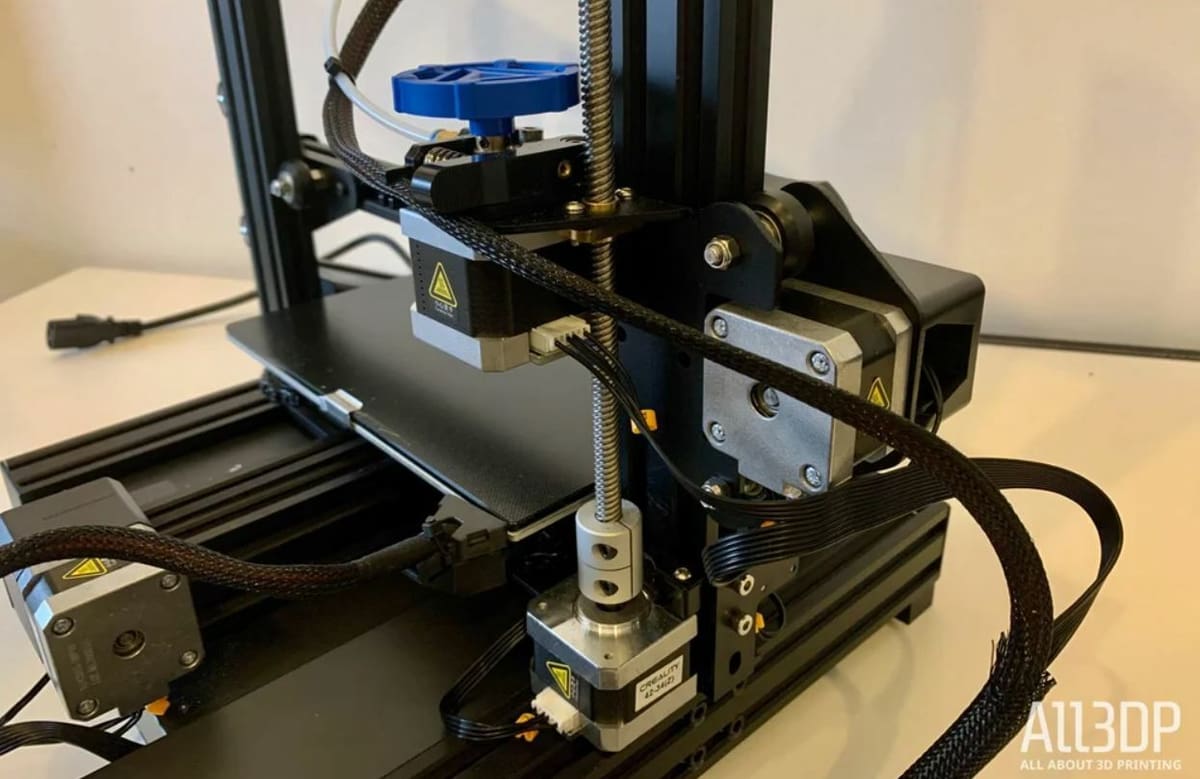

First, the CR-10 V3 has two Z-axis stepper motors and Z-axis lead screw stabilizers, which further contribute to the performance of this printer. The dual Z-axis stepper motors make the movement of the Z-axis carriage more stable and prevent one side from sagging, which is a problem for the Ender 3 V2. Moreover, the Z-axis lead screw stabilizers reduce the chance of the Z-axis lead screws bending over time.

The Ender 3 V2 makes up for lacking these features, though, with the included tool storage drawer and the adjustable belt tensioners. The former is just a convenience, but the belt tensioners can actually save you some time and can make it easier to solve printing issues like layer shifting. On the CR-10 V3, to tighten your belts, you would have to loosen the belt pulley component, move it back, and tighten its position.

Which One Is Right for You?

Overall, both the Creality CR-10 V3 and the Ender 3 V2 are phenomenal 3D printers, each with a long list of useful components and features. While they’re both great machines, they have their fair share of differences and are perhaps best for different types of people.

The CR-10 V3 has more build volume but a stable frame for its size, with dual Z-axis stepper motors, lead screw stabilizers, and a powerful extruder. For these reasons, the CR-10 V3 is probably best if you’re looking for a large format 3D printer and aren’t worried about the price. This printer is also the better choice for those looking to print flexible materials.

On the other hand, the Ender 3 V2 has great electronic features such as a color LCD, a powerful 32-bit mainboard, and an easy firmware update process. The Ender 3 V2 also has other handy extras such as a storage drawer and built-in adjustable belt tensioners. For this reason, the Ender 3 V2 is perhaps best for those who have a tighter budget, want to tinker with the firmware, and appreciate the small features that the V2 offers.

However, both printers are ripe for upgrades, so whether you settle on the Ender 3 V2 or the CR-10 V3, the parts that come stock don’t have to be forever.

License: The text of "Creality CR-10 V3 vs Ender 3 V2: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.