Nowadays, 3D printing is all about speed. We’ve seen many releases from high-profile manufacturers in recent years that push the limits of what we previously thought possible for stock machines.

The Creality K1 and K1 Max are two such machines, designed from the ground up for speed. Creality makes impressive claims regarding the printers’ performance, such as 600 mm/s printing and 20,000 mm/s2 accelerations. But are these numbers just for show, or does the K1 series have what it takes to get high-quality prints in an ever-decreasing amount of time?

In this article, we’ll take a closer look at what performance can realistically be expected out of the K1 series, compare it to other popular high-speed offerings, and investigate the effects of variables such as material on print speeds and quality.

Design

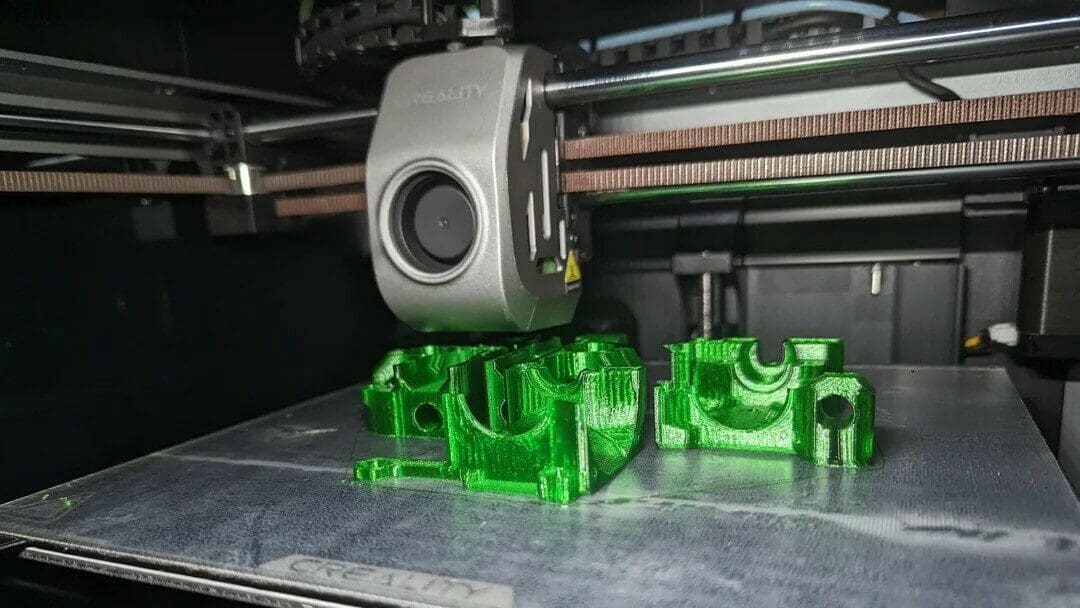

The K1 series, as with many modern printers, sports a CoreXY motion system. This minimizes the load that the toolhead is dragging along with it while it prints by placing critical motion components, such as the stepper motors, in the frame rather than the moving gantry.

There’s also no heavy bed to move back and forth, as there is on bed slinger printers. In a CoreXY design, the Z-axis moves up and down a lead screw, which makes it more stable and keeps vibration-related defects at bay when printing quickly.

To complement the sturdy frame, the K1 series has been fitted with a high-flow hot end system. This allows the printer to melt plastic fast enough and keep up with the impressive speed of the motion system. It’s also equipped with two cooling fans (one on the toolhead and one on the frame) to efficiently cool molten plastic and avoid artifacts such as drooping bridges.

While the K1 Max is significantly larger than the K1, they don’t differ too much when it comes to print speed. They’ve got the same printer design and are equipped with the same hardware. The main difference as it relates to print speed comes down to some luxury calibration tools that can help prevent the loss of quality at high print speeds. We’ll take a closer look at this and other under-the-hood features coming up, but first let’s check out the stats.

Stats

Creality has claimed some impressive statistics regarding the K1’s speed. To give some context to the numbers, printing was being done in Surface mode, which excludes infill and supports, at a layer height of 0.1 mm.

Here’s what they say:

- Max printing speed: 600 mm/s

- Max acceleration: 20,000 mm/s2

- Max flow rate: 32 mm3/s

- Bed heat-up time: 60 °C in 180 seconds

- Nozzle heat-up time: 200 °C in 60 seconds

Note that the max printing speed reported comes from the “typical” printing speed and the travel speed, which were reported to be 300 and 800 m/s, respectively. That said, the K1s won’t be clocking in at these speeds consistently, as it’ll depend on the model and your desired settings. Nevertheless, the speedy heating is a nice touch.

Quality

While those numbers are without a doubt impressive, they don’t tell the full story. Pushing plastic at a high rate is one thing, but getting a nice, usable part at the end of the day includes additional challenges.

The speed-quality tradeoff is why the K1 rarely runs at these aforementioned limits, and most users choose to pick a balance between speed and quality, as do many slicer profiles created by both Creality and the greater community. But since we’re on the subject of speed, the K1 series does have other features beyond its physical design to prevent typical defects that occur from printing too fast.

The K1 series utilizes Klipper firmware behind the scenes. Klipper is known for powering many high-speed printers, and sports tried-and-true features to keep both quality and speed high. Most notably, input shaper helps prevent ringing and ghosting, and pressure advance keeps blobbing and stringing at bay.

The K1 Max comes with an AI-powered lidar sensor for automatically tuning pressure advance and flow settings to make it easy for users to get a quality print on the first run. There’s been buzz about Creality selling this lidar sensor as an add-on for K1 owners, but it’s not on shelves yet.

It should be noted that some of these quality-focused features can eat into print time, such as auto-bed leveling and flow calibration. The K1 runs a leveling routine before each print, and the K1 Max can also run the flow calibration; while these typically only take a few minutes, they still need to be considered.

Other Considerations

While a printer’s design and features play a big part in how fast it can print, they don’t have the only say.

Factors like filament brand and type can greatly affect print speed. Filament materials such as PETG, ABS, and especially TPU all need to print slower than a basic PLA to obtain good-quality prints due to a higher risk of defects like stringing or clogging the extruder. Some brands of filament can attain higher flow rates than others so it’s important to run calibration tests with each new material you use.

Model geometry can also play a role in speed. Models that include small details or high infill densities will print slower than models that are less detailed and have less infill.

How the model is sliced will influence the total printing time. For example, Creality Print has two default profiles for PLA, High Quality and Normal, both of which use the same print speed (300 mm/s) but the latter prints drastically faster. The major difference is the layer height being 0.1 and 0.2 mm, respectively. The profiles can be pushed even faster using tricks like reducing the shell count or reducing supports.

However, this increased speed can come with quality consequences (noticing a pattern?), the most common of which (stringing, blobbing, drooping bridges) come from cooling too slowly where layers get printed on top of still-molten layers that are not yet structurally sound. Other artifacts, such as ringing, layer shifting, and skipping, can be caused by vibrations of the printer as it shifts its weight around during the printing.

Comparison

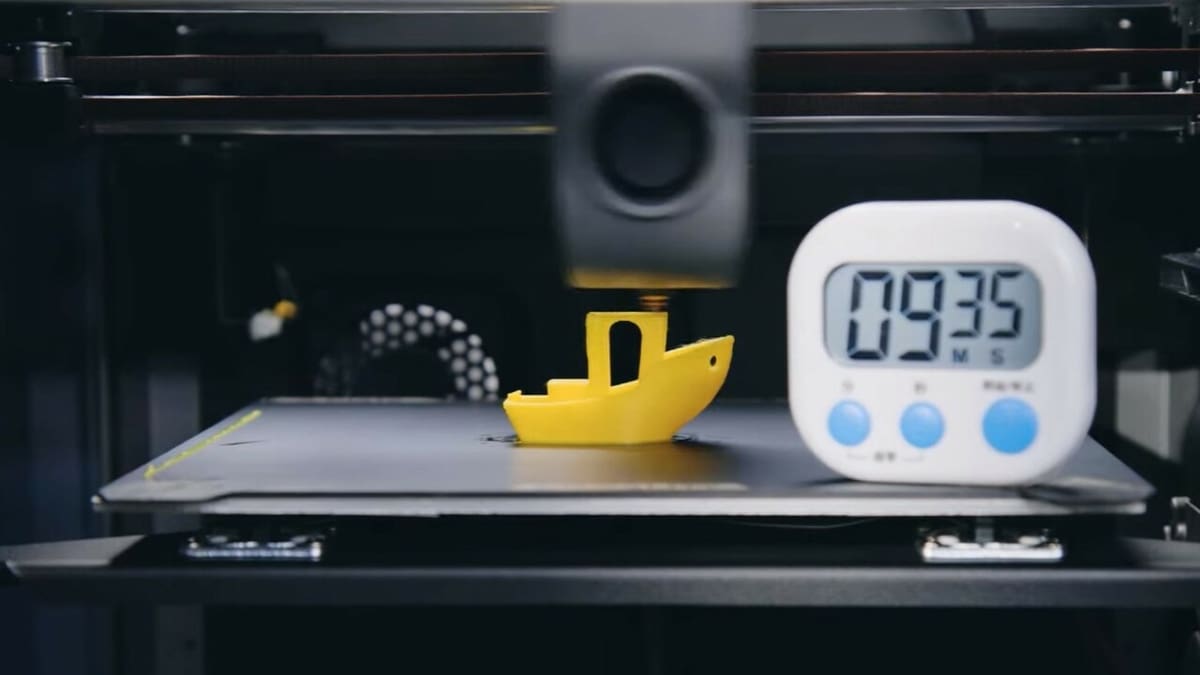

The K1 comes out of the box with a pre-sliced 3DBenchy, clocking in a bit over 17 minutes. Creality posted their own K1 speed test according to the SpeedBoatRace guidelines that showed the K1 printing a SpeedBenchy in just 11 minutes 40 seconds; however, commenters were quick to point out a few cosmetic flaws of the print.

Since fast printing is not that useful if the print you end up with needs extra post-processing cleanup (if usable at all), we’ll make comparisons using more realistic settings that give quality prints. It’s also relevant to note that the reported times often exclude pre-print calibration procedures.

So let’s see how the K1 stacks up to other recent high-speed offerings from other manufacturers:

- Bambu Lab X1 Carbon: 12 minutes and 38 seconds

- Creality K1: 17 minutes and 22 seconds

- AnkerMake M5: 17 minutes and 41 seconds

- Prusa MK4: 19 minutes and 11 seconds

For a quick reminder on how fast these printers are, our good old friend the Ender 3 takes about 1 hour and 4 minutes to print a SpeedBenchy.

License: The text of "Creality K1 (Max) Speed: How Fast Can It Go?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.