High-speed 3D printing is all the rage these days. Manufacturers are constantly innovating to bring ever-faster offerings, while still keeping print quality high and prices low.

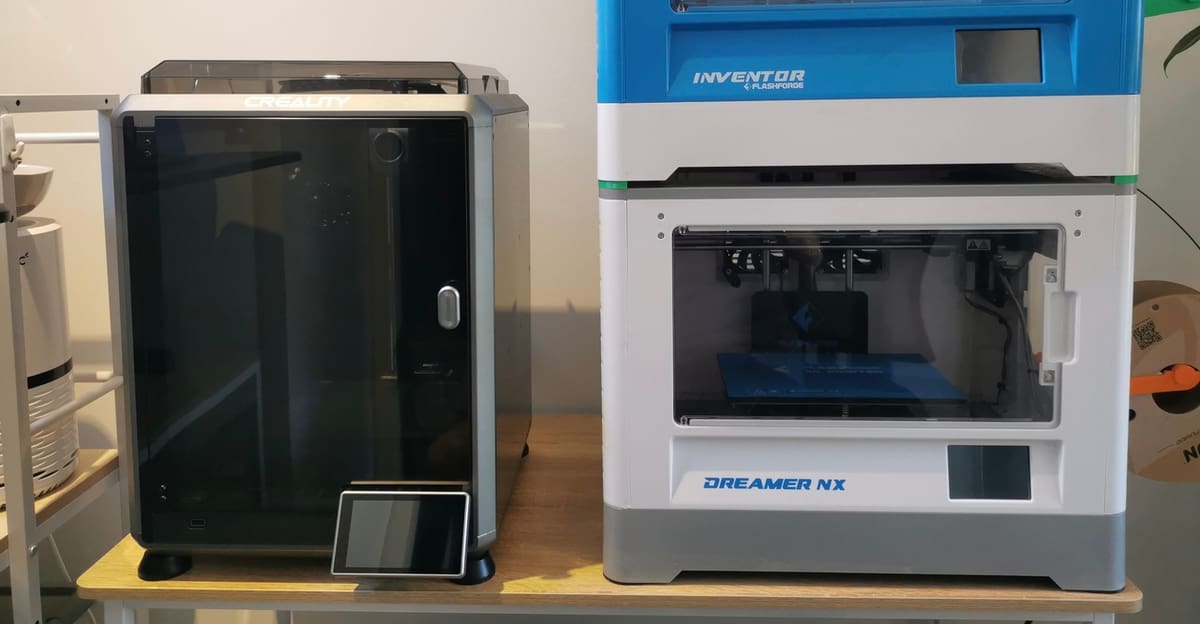

Creality’s K1, K1 Max, and K1C are all a part of the company’s entry into this age of high-speed printing. All three machines are capable of blazingly fast speeds, while still being affordable and obtainable for the average consumer.

But, the three do have some noteworthy differences that should be considered if you’re interested in getting your hands on one. Let’s take a look at which K1 is the one for you!

At A Glance

Design

All three printers look very similar visually. Each sports a die-cast frame made from aluminum alloy, acrylic and glass enclosure panels, and of course a touchscreen to top it all off.

All of the printers are CoreXY machines, and their print beds are supported by three lead screws. All in all, the three machines are built sturdy and for speed.

Build Volume

The K1 and K1C share the same typical, but adequate, 220 x 220 x 250 mm build volume found on many other printer models across the market, such as Creality’s own Ender 3 series.

The K1 Max stands out with its 300 mm3 volume, arguably one of its most defining features. This spacious print area might be useful if you find yourself frequently printing larger objects; you won’t need to split large models into multiple parts to fit a smaller print area.

Build Plate

All three models utilize PEI-coated, magnetic, and flexible steel sheets. Creality refers to the coating as “frosted” PEI, and it shares many similarities with a typical smooth PEI build plate. This build surface works quite well overall, with good adhesion, and a bit of glue stick can always be used if things aren’t adhering quite right.

If you want to switch up your build plate, Creality does sell other varieties, including textured PEI, in both the 220 x 220 and 300 x 300 varieties for the K1(C) and K1 Max, respectively. Some third-party build plates have also begun to come onto the market, offering new types of surfaces.

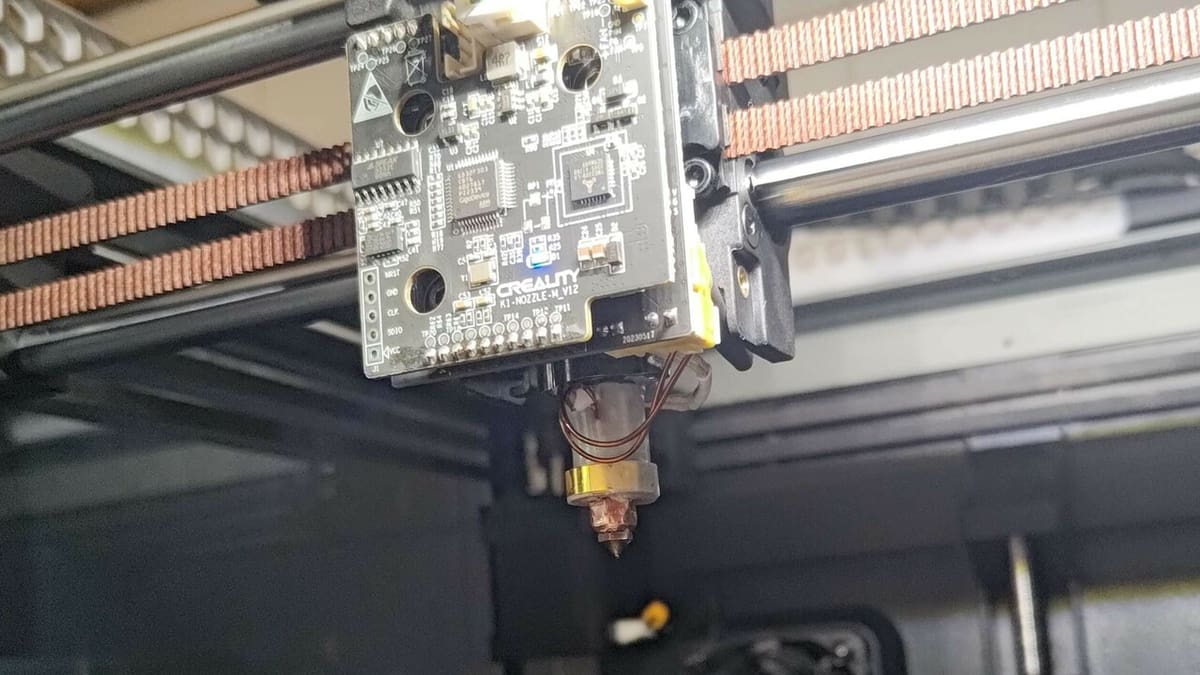

Extrusion

Each model has a similar extrusion setup, consisting of a simple geared stepper motor as well as a breakout board at the toolhead, which makes replacing components quite a lot easier. Extrusion issues haunted the K1’s initial launch, and as we noted in the update to our initial review of the machine, Creality made design changes to the hot end to resolve the issue.

The company has made further design modifications to the extrusion system in the K1C. According to Creality, the extruder on the K1C includes a side spring and ball plunger for the purpose of improving the performance of the extruder’s gears. In a seeming nod to 3D Printing Nerd’s critique of the K1 Max’s nozzle situation, the K1C’s hot end assembly now features an integrated nozzle and heat break – which, in theory, should decrease the likelihood of filament jams.

Users’ experiences, however, have been mixed. Jonathan at the YouTube channel The Next Layer reports overwhelmingly positive initial experiences, whereas Nathan over at Nathan Builds Robots experienced a severe filament jam within the first few test prints. And Nathan is not alone; Reddit users Kunfuscious and Sure_Cream_69 have shared their challenges as well.

As best we can tell, the issues didn’t originate at the hot end, but the new hot end design wasn’t immune from clogging either. In all three mishaps, the makers had stepped away from their printers, and all hell broke loose in their absence. It was also the case that the lack of spare parts and the printer’s incompatibility with existing nozzle designs exacerbated the issue.

All of that is to say, we’ll have to wait and see whether the K1 series’ extrusion woes are behind them.

Under the Hood

Mainboard

The K1 and K1 Max utilize very similar mainboards. They contain all of the necessary hardware to run the K1, including TMC2209 stepper motor drivers, a fully Linux-capable CPU, Wi-Fi, USB, and some extra hardware to control the K1’s fans, heaters, screen, and more.

As mentioned previously, not all of the K1’s controlling hardware is present on its mainboard, and hardware is instead split up across the printer. For example, hardware to control the printhead fans and heater is present on the printhead itself and not the mainboard, and hardware that controls the bed leveling is present on the bed itself.

The K1 Max’s board provides wired Ethernet functionality, whereas the K1 and K1C do not. The K1C’s mainboard has been slightly updated to make the printer quieter, but all is still mostly the same.

Firmware

All three models utilize Klipper firmware behind the scenes. They make a user interface accessible both on the printer itself (through the touchscreen) and through the network, which can be used to start and stop prints, set temperatures, change filament, and the like.

Creality also allows root access to the Linux system behind all models and has made the software open source. This allows anyone to tinker with their printers at will – something that isn’t allowed by all manufacturers.

Quality of Life Features

Bed Leveling

All printers use their nozzle to probe a grid pattern on the bed, which contains an array of strain gauges to detect the nozzle’s pressure. A full probe is only done during the first-time setup and is only briefly checked before each print to save time.

The K1C comes with a silicone strip built into the bed to wipe the nozzle before probing. This can be more reliable than the other models’ method of wiping, which simply consists of pushing the nozzle against the bed.

UI

Many users have praised the large color touchscreen present on all models, which provides a much more fluid interface than a typical click wheel. The touchscreen can display lots of useful information at a glance, such as a graph of current temperatures and a preview of the print. It can also simply provide an easier way to interface with the printer and execute simple tasks, with a decently intuitive and responsive interface.

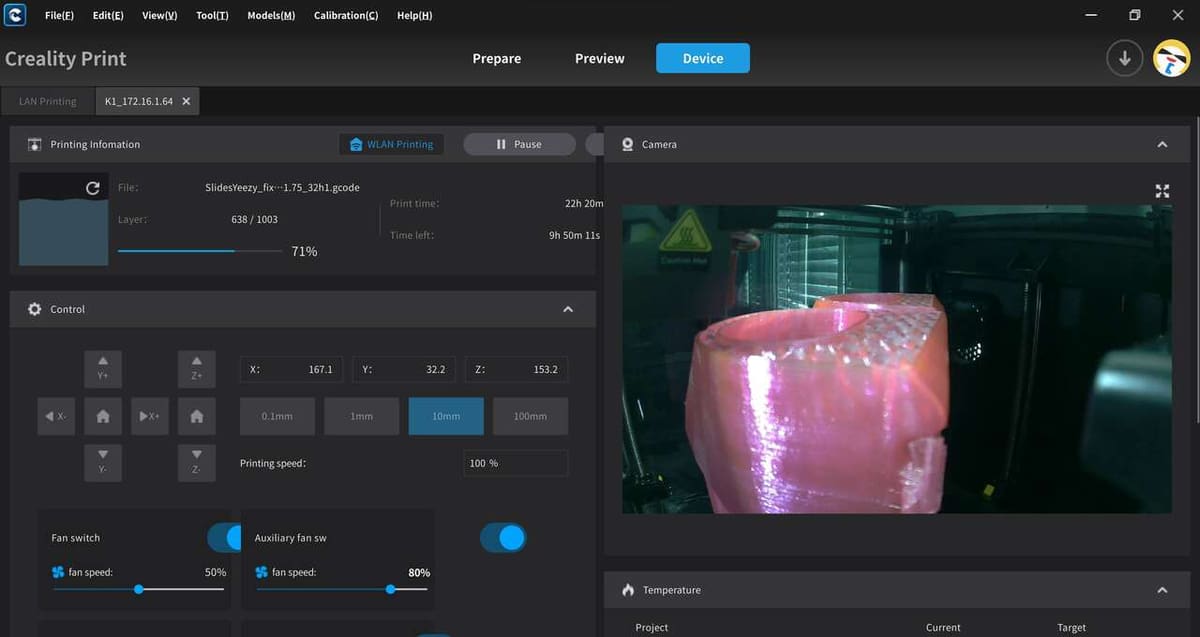

The printer can also be controlled using a web application over the local network. This application can do much of the same tasks that can be done from the printer’s screen, but you don’t have to be standing in front to access it. You can view a live feed from the camera (if installed), control movement and temperatures, start and stop prints, and more.

Software

Creality’s own slicer, Creality Print, supports all three printers. However, Creality Print has received some criticism from users regarding its somewhat confusing interface and its use of an older version of the Cura slicing engine, which may not produce the best results.

Thankfully, the community has developed some great profiles for popular slicers, such as Cura and PrusaSlicer, for all three printers.

Additional Features

It’s worth noting that both the K1C and K1 Max come with Creality’s AI camera preinstalled, which provides print failure detection, remote monitoring, and automatic timelapses, among other features. But on the regular K1, this camera must be purchased as an add-on but is fully supported within the software.

The K1 Max also comes with an AI lidar module that’s used to calibrate flow rates on the fly, as well as the ethernet port mentioned earlier. Both of these features are only present on the K1 Max and are not available as an upgrade for other models at this time.

Price

Price can be a big deciding factor when picking up a new printer. Fortunately, Creality frequently offers sales on their printers. The regular K1 is the cheapest of the bunch, mainly due to the lack of some of the more advanced features found on the higher-end K1C and K1 Max.

The K1C is usually around $50 more expensive than the K1. For that slight price bump, you get a camera (AI features included), wider filament support, quieter printing, and a generally more reliable and polished experience over the K1.

The K1 Max is a hefty ~$300 increase over the K1. That being said, having a much larger build volume could be a big deal, along with some of the features that can only be found on this model, namely lidar and Ethernet support.

As for a reference point, the K1 and K1C stack up well against Bambu Lab’s P1 series printers, with similarly kitted specs. Price-wise, the K1s are easier on the pocketbook, though with an arguably somewhat less seamless experience than Bambu provides.

Verdict

And the verdict is… there’s no best printer for everyone! The best model is one that serves your wants and needs.

If you’re looking to get into high-speed printing on a budget, the K1 might be right up your alley. But if you’re willing to spend a little more, the K1C gives you some extra features and a more refined experience.

And if you want to go big or go home (literally), you’re looking right at the K1 Max.

License: The text of "Creality K1 vs K1 Max vs K1C: Which to Choose?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.