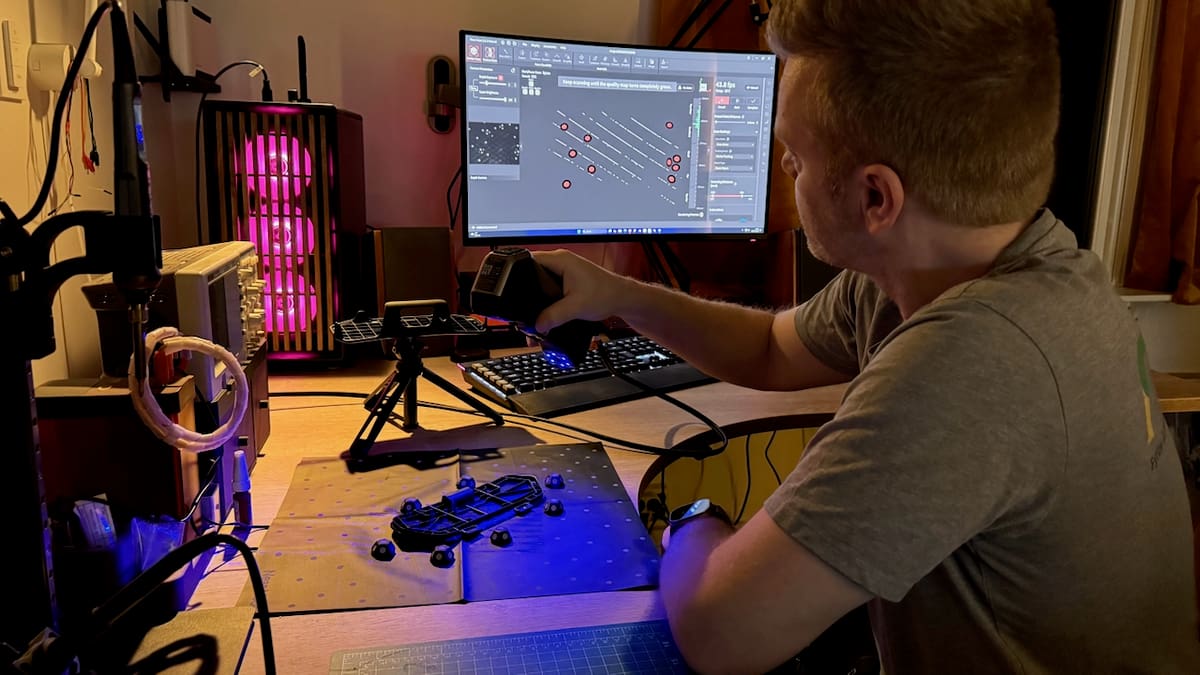

As we’re getting to know some of our favorite designers, this week’s Designer Spotlight shines a light on Tim Ellis from Fyrby Additive.

With over 160 models shared on Printables, you’ve more than likely come across Fyrby Additive’s designs. From a variety of Prusa XL mods and upgrades to a range of V-Spooler options, including string art and cool lamp ideas, you’re bound to find a model or two you’ll want to add to your workspace or home. Plus, there’s a poop for every occasion.

Let’s find out a bit more about Tim’s creative and production process, and what he’s learned along the way.

Q&A

All3DP: Tell us a little about yourself – what’s your background?

Tim Ellis: Originally from the UK, I now reside in rural Sweden with my wonderful wife and dog. I’ve always been fascinated by technology, which led me to pursue various tech jobs and hobbies throughout my life. It was only natural for me to gravitate towards 3D printing.

How do you get the ideas for your designs?

My ideas are often born of a need to create something new or extend an existing thing in a practical way, with a lot of designs being functional rather than artistic. Equally often things just pop into my head!

How much does the technical side of 3D printing (e.g. supports, a design that requires assembly or one that’s printable in one piece) come into play when you’re designing? Or is your designing entirely independent from 3D printing and you later figure out how they work together best?

Designs are usually considered at length by the time they are finally put into CAD and typically everything is designed for 3D printing at the outset. Minor details may require adjustment in terms of complicated assemblies or moving parts, and sometimes a small re-work for better supports or fitment for example.

Of all the things you’ve created, which are you most fond of and why?

V-Spooler was conceived as a filament re-spooler that used less space than existing solutions, it pushed me to learn more about gears and tolerances, and it was my first trending model. This happened after a close family member passed while I was sick and helped pick me back up again.

If you could step back in time and give yourself some advice from the beginning, what would it be?

Investing in better CAD software earlier would have boosted my productivity and quality of work sooner in my early days. Now there are many different tools available and something to fit everyone – there has never been a better time to get into CAD and 3D printing!

Rapid Fire

- Favorite CAD software? Shapr3D

- Favorite slicer? (Out of the printer vendor slicers) PrusaSlicer

- Favorite 3D printer? Prusa XL (it’s big and does everything)

- Favorite filament material to print with? Matte and/or CF

- Favorite filament brand? Extrudr

Find Him On

Do you want to be reminded of the next designer profile? Sign up for our newsletter.

License: The text of "Designer Spotlight: Tim Ellis (Fyrby Additive)" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

Stay Informed, Save Big, Make More

Stay Informed, Save Big, Make More