Many products available on the market today are at least partly made of items created with injection molding. It’s one of the most efficient manufacturing methods available, thanks to its ability to mass-produce plastic objects for a low cost. From bottle caps to outdoor furniture, products manufactured via injection molding are everywhere.

The concept of injection molding is fairly straightforward. A mold is created, either cast from metal or 3D printed for small production batches. Then, molten plastic is forced into the mold and allowed to cool. Once the plastic has hardened, the mold is opened and the part is removed. The mold is then ready to be reused. With larger molds and machines, each mold often creates multiple items at once, thereby creating an incredibly fast and efficient way to reproduce parts.

Hobby-grade injection molding machines are beginning to rise in popularity due to the exploding popularity of resin 3D printing, making the molds easier to create. With a bit of elbow grease, DIY options are also becoming available. In this article, we’ll present our favorite DIY injection molding machines. But before we get to our picks, we’ll share what you should be looking for to decide which ones fit the mold!

Considerations

When it comes to buying or building your own injection molding machine, there are a few things to consider:

- Cost: Injection molding machines can be quite pricey, but DIY options have certainly made them more accessible for hobbyists. The cost of the machines we’ve included ranges from $200 to $2,500.

- Shot size: The maximum size of an injection mold is defined by the amount of plastic it can hold in its heating element, also known as the “shot size”. Essentially, this is the maximum volume of plastic your machine can use to produce one batch of molds. The larger the shot size, the larger the injection molding machine as well as the capacity of the molds. (The amount of energy required is also greater.)

- Ease of use: Injection molding is inherently simple: Heat up the plastic and shoot it into the mold. The machines should be just as simple to use. Here, we have a selection ranging from automatic machines to manual ones.

- Temperature range: The temperature range of an injection molder determines the types of plastic that are suitable to use for a machine. All machines in this list will have a maximum temperature of at least 400 °F (~205 °C), which is suitable for PE, PP, PS, acetal, acrylic, EVA, TPE, PLA, and ABS. Other plastics can only work with higher-temperature machines.

So, now we know what to look for, let’s see some machines!

Buster Beagle 3D

For those looking for a well-documented and reliable option, the Buster Beagle 3D build was inspired by the LNS 150A and the Galomb B100. A fully DIY solution, the first version of the company’s injection molder, the MK1, is built around a drill press frame using common off-the-shelf components to deliver a sturdy injection molding experience.

The project evolved, and now, they have two other versions. Similar to its predecessor, the MK2 is also a manual machine but with a stiffer structure and a bigger injection volume. The MK3 is a pneumatic machine, meaning it employs compressed air and a piston to load material into the mold, offering a more controlled and efficient molding process.

A good thing is that many of the parts are common to all three versions, so you can start with an early version and upgrade later. Buster Beagle 3D’s online store sells part bundles, injection molding chambers, and pneumatic cylinders for all three versions. Nevertheless, BOMs are provided for all versions, so you can explore what best fits your needs.

In terms of instructions and safety considerations, the company’s YouTube Channel has plenty of information on the projects. The videos are not organized in playlists or by machine kind, so you might need to dig through them, but BOMs and build plans on Thingiverse are an excellent start. There’s also a community on Facebook for anyone who’s interested in creating this machine, has questions, or wants to share their build.

- Cost: ~$700 for parts (MK1), ~$800 (MK2), ~$1,200 (MK3)

- Shot size: 1.3 in³ / 21.3 mL (MK1), 1 in³ / 32.7 mL (MK2), 3 in³ / 49.1 mL (MK3)

- Maximum temperature: 500 °F (~260 °C)

- Project pages: Thingiverse, Buster Beagle 3D

Precious Plastic

Precious Plastic is a group dedicated to reducing plastic waste. Their injection molding machine has an impressive capacity, with a very large shot size of 146 grams of PP. At nine times the shot size of the other machines on this list, this press can produce much larger items, such as phone cases and plant pots. For such a large shot size, four independent heaters are used to maintain a stable temperature throughout the entire heating chamber.

Building this machine does require some welding and angle grinding, and it assumes you have some experience working with metal. For that reason, this machine isn’t the most beginner-friendly project. However, Precious Plastic does have a community bazaar for you to purchase parts or even the entire machine. The Precious Plastic community is very friendly and is happy to help you start a plastic recycling station in your own community.

- Cost: ~$500 for parts

- Shot size: 9.1 in³ / 149.12 mL

- Maximum temperature: 600 °F (~315 °C)

- Project page: Precious Plastic

Action Box

Action Box is a company known for providing kits – both mechanical and electronics – to engineers, hobbyists, and small machine shops, granting access to otherwise unattainable desktop machines. Although they generously showcase their creations on their YouTube channel, it’s worth noting that the plans for these machines are not shared.

The Injekto 2.0 desktop plastic injection machine is a promising addition to their lineup, offering an opportunity for DIY enthusiasts and small-scale manufacturers to effortlessly craft plastic parts and prototypes. While the lack of shared plans might be disappointing for some, Action Box’s offerings remain a valuable resource for those seeking access to niche machinery.

- Cost: ~$2,500,00 for parts

- Shot size: 2.68 in³ / 44 mL

- Maximum temperature: Under 464°F (240 °C) recommended, although the Injekto is capable of higher temperatures

- Project page: Action Box

Clifford Mfg

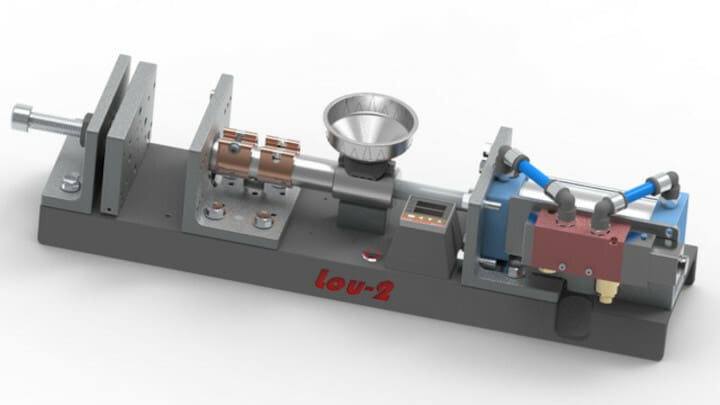

Scott Clifford has engineered the Lou2, a compact pneumatic air-actuated desktop molding machine. Clifford generously documents the entire construction process on YouTube, and for those interested in a hands-on approach, he offers PDFs and 3D CAD files for building the machine.

The Lou2 distinguishes itself with its straightforward and user-friendly design, making it accessible to a broad audience. The pneumatic feature adds an extra layer of precision and reliability to the molding process. Overall, the machine is an attractive option for those seeking a cost-effective and efficient solution for their molding needs.

- Cost: ~$200 for CAD files, ~$2,500 for parts

- Shot size: 1-1.5 in³ / 16.4 – 22.9 mL

- Maximum temperature: Varies according to your build – usually around 600 °F (~315 °C)

- Project pages: YouTube, Clifford Mfg

Scratch Build

For the seasoned maker who relishes hands-on projects and customization, a scratch build could be right up your alley. Inspired by Vincent R. Gingery’s book Secrets of Building a Plastic Injection Molding Machine, Jim Hannon shares his DIY injection molding machine creation process in Make: Magazine. This project basically consists of a hand press with a heated block into which you insert molds to produce your parts.

It’s essential to note that this endeavor demands a certain level of skill and experience, so it falls into the intermediate to advanced difficulty level. However, for those up to the challenge, this custom-built molding machine offers a unique opportunity to craft plastic components tailored to your specifications.

- Cost: ~$200 for parts

- Shot size: Varies according to your build

- Maximum temperature: Varies according to your build

- Project page: Make:

License: The text of "The Best DIY Injection Molding Machines" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.