Nozzles play a critical role in achieving high print speed and quality on FDM 3D printers. If the nozzle’s thermal conductivity is too low, the filament can’t be melted quickly enough to print at high speeds. A worn or misshapen nozzle tip gives inconsistent extrusion that leads to a number of surface defects.

The current standard for nozzles, brass, has an acceptable thermal conductivity but is soft enough that abrasive filament will easily erode away the nozzle tip, widening the nozzle diameter. At that point, the nozzle is effectively destroyed, as it will no longer extrude a consistent line diameter.

To combat this, nozzle manufacturers have been producing nozzles out of alternative materials, such as steel, carbide, and even artificial ruby. ChampionX is one of the businesses offering their unique take on a durable and precise nozzle: the DiamondBack. Their lineup consists of brass nozzles tipped with polycrystalline diamond (PCD), with the claim that the diamond nozzle tip is so hard that no abrasive filament available will be able to wear it down.

In this article, we’ll take a closer look at DiamondBack nozzles and what users are saying about this little treasure.

Features

Nozzles are very small parts of a 3D printer, but they’re jam-packed with technological innovations that make precision printing possible. The DiamondBack nozzle’s distinct features give it three primary advantages:

Broad Filament Compatability

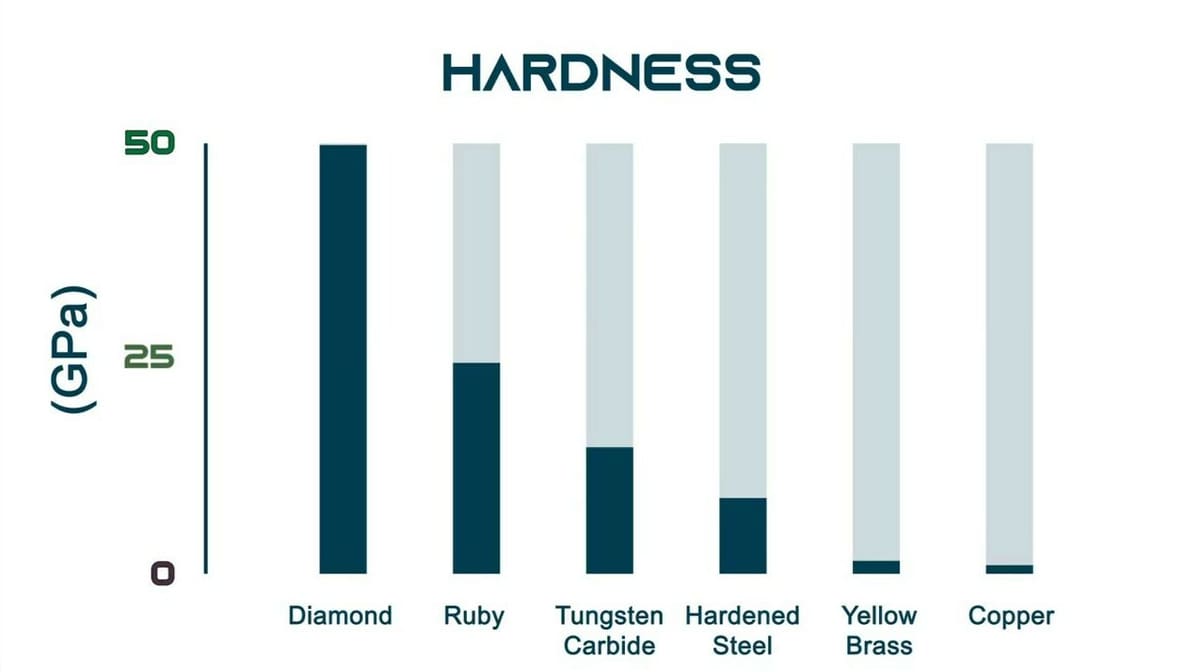

The dark grey PCD (polycrystalline diamond) tip of the DiamondBack nozzle is a solid piece of artificial diamond that is meant to prevent abrasive filaments or debris from undermining nozzle diameter integrity over time. It does this by being harder than any material that could potentially pass through it (as long as diamond-composite filament never becomes a thing).

ChampionX also claims that the PCD material has a coefficient of friction lower than that of copper or steel by an order of magnitude. This means that viscous or sticky materials will more easily flow out of the nozzle, reducing the need for higher heat.

Long Lifespan

The company stresses, for good reason, that their nozzle has a solid PCD tip, not a diamond coating. This means that it’s more durable than a coated nozzle, much like a solid metal part is much more durable than an electroplated one.

PCD has a hardness that is almost that of diamond, the hardest known natural material. Good luck trying to wear that down!

Since the tip of the nozzle is the only part significantly exposed to abrasives in filament, a brass body will not severely affect printing capabilities, nor will it significantly affect the nozzle’s useful lifetime.

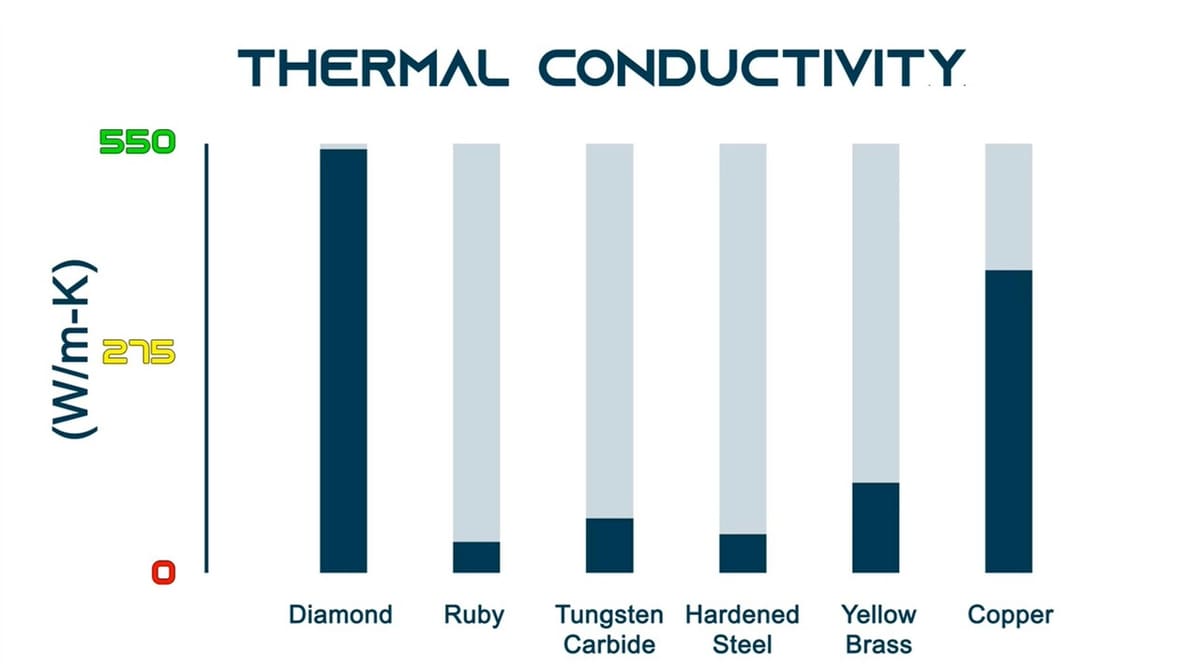

High Thermal Conductivity

Lastly, ChampionX clarifies that DiamondBack nozzles’ thermal conductivity is competitive with conventional nozzles. PCD actually has better heat transfer characteristics compared to other ceramic tip materials like artificial ruby, but more on that later.

Apart from the PCD tip, the rest of the DiamondBack nozzle, called the body, is made of brass. PCD is expensive, and an entire nozzle made out of PCD would be prohibitively expensive to both make and purchase. The brass body makes this nozzle more financially feasible. Brass also has similar heat transfer characteristics to PCD, so its use does not detract from the heat transfer advantage of PCD.

Reviews

People who have already purchased the DiamondBack Nozzle have left overwhelmingly supportive reviews of the product. Around 75% of Amazon reviewers have rated it 5 out of 5 stars. One happy customer noted in a review that flyaway strands of first-layer filament will not stick to the nozzle’s PCD tip, increasing the quality of the first layer.

Other sites and forums have seen similar reactions from customers. In one Prusa forum, forum users discuss a video posted by ussynthetic, the parent company of DiamondBack, where a technician is seen grinding down nozzles using a carbide grinding wheel. The grinding wheel is shown disintegrating brass, steel, carbide, and ruby nozzles before the technician applies the grinding wheel to the tip of the DiamondBack nozzle. Amazingly, the DiamondBack nozzle wears the grinding wheel down to the spindle, and pictures taken of the nozzle after the test show only minor damage to the PCD tip.

After switching to a DiamondBack, many users found, that they had to lower their nozzle temperature because the thermal characteristics of the nozzle transferred much more heat to the filament than their previous equipment. An important tip from users is to calibrate your printer before the DiamondBack nozzle is installed, as the nozzle is so hard that it has the potential to dig into certain build plates if the 3D printer’s Z-axis is homed incorrectly or the build plate is raised too high.

Tech Specs

Probably the most crucial information that consumers look for is, “Can I use this with my own 3D printer?” Here are the technical specifications for the DiamondBack nozzle series at the time of publication:

- Nozzle Material: Brass body, PCD polycrystalline diamond nozzle tip

- Filament Options: PLA, ABS, PETG, PC, nylon, flexible (TPE), composite-fill (carbon fiber, glass-fill, boron carbide, etc.), and more

- Available Nozzle Diameters: 0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm, 1.0 mm

- Available Filament Sizes: 1.75 mm

- Thread Compatibility: V6, MK8, Volcano, Ankermake M5 and M5C, M6

Price

While PCD is an expensive material to produce (and therefore to buy), the brass body of the nozzle helps keep the price tag approachable. Considering the long lifespan that these nozzles promise, you may find them to be a great deal.

You can find DiamondBack nozzles at Amazon and MatterHackers, the primary resellers, for around $100 for a single nozzle or a three-pack for around $260.

All of the threading options are available on MatterHackers and are typically well-stocked. Amazon hosts most of the popular threading options as well.

Similar Nozzles

The DiamondBack isn’t the only option when it comes to high-end nozzle options. There are a couple other nozzle types that stack up against the DiamondBack in a variety of characteristics:

- The Olsson Ruby nozzle, an artificial ruby nozzle, has near-similar hardness characteristics, though DiamondBack nozzles outperform them in terms of heat transfer. While both the Olsson and DiamondBack nozzles are very difficult to wear down even after a lifetime of abrasive filaments, they both have hefty prices, approaching $100 per nozzle.

- Tungsten Carbide nozzles demonstrate similarly high thermal conductivity, though DiamondBack nozzles outperform them in terms of tip hardness. Tungsten carbide nozzles will last longer than steel nozzles with abrasive filaments, and their melting temperature is so high that they can, at times, be unclogged with a torch. Although, such properties inevitably come at a premium price.

License: The text of "DiamondBack Nozzle: Specs, Price, Release & Reviews" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.