Multicolor 3D printing has evolved significantly over the years, moving beyond simple filament swaps to more advanced multi-material systems. It’s not just about aesthetic multicolor decorative prints; users can also combine rigid and flexible materials or incorporate dissolvable supports with the help of mult-material units.

As multicolor 3D printing becomes more accessible, we’re also seeing a lot more DIY open-source add-ons as well. While commercial solutions like Bambu Lab’s AMS and Prusa’s MMU offer plug-and-play functionality, DIY multi-material units provide a cost-effective and customizable alternative for those willing to tinker. The only catch is, many of these add-ons are only compatible with 3D printers that run Klipper firmware.

In this article, we’ll be exploring some of the most popular DIY multi-material printing options – and one of them is firmware agnostic.

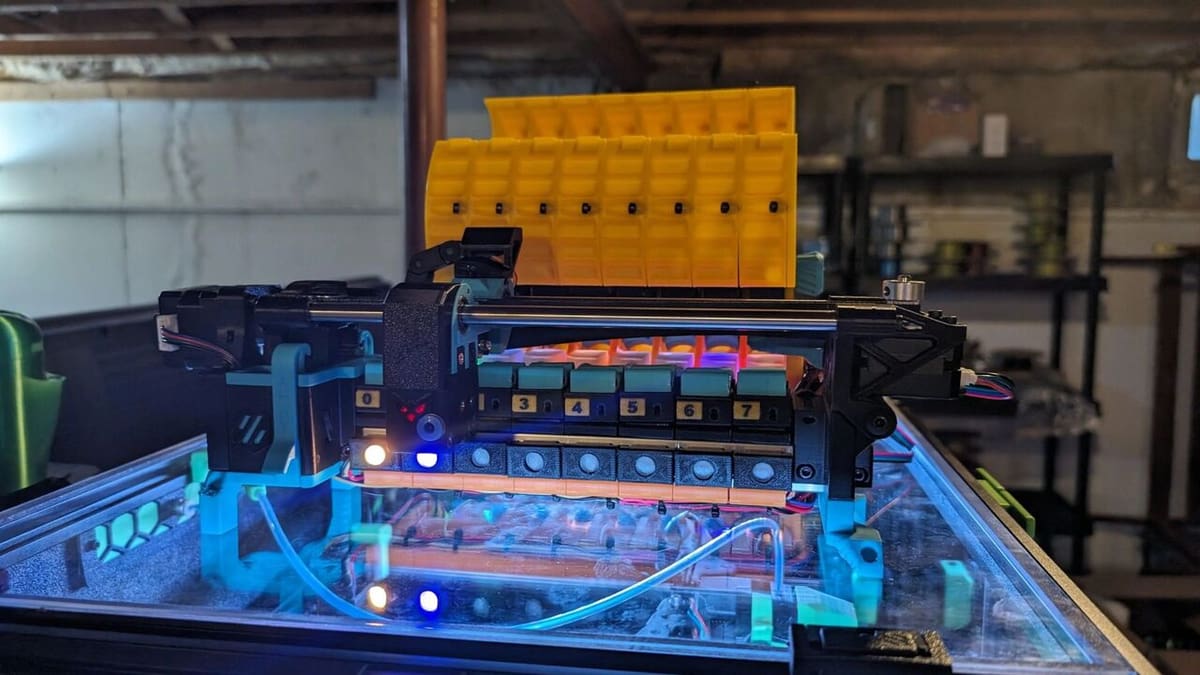

Enraged Rabbit Carrot Feeder

The Enraged Rabbit Carrot Feeder (ERCF) V2 is a popular DIY multi-material feeder, especially within the Voron community. It allows Klipper-based 3D printers to handle multiple filaments without requiring expensive proprietary solutions.

The first version of ERCF was designed by its founders, while the second version emerged from community contributions and fixes a lot of the V1’s design issues. It’s fully 3D-printable, so users can make most of the parts themselves.

The required hardware components must be sourced separately. Kits are available, which makes the sourcing pretty convenient.

Although ERCF does have a learning curve when it comes to dialing in the settings, it has excellent community support and extensive documentation. Users comfortable with Klipper firmware configurations and mechanical assembly will find it a fun build!

- Project page: GitHub – V1, V2

- Printer compatibility: Only works with Klipper-based 3D printers and is not compatible with Marlin. Most commonly used with Voron printers but adaptable to other setups.

- Ease of assembly: Requires moderate to high effort, as users must source various mechanical components, print parts, and carefully calibrate the system for reliable operation

- Additional support: A dedicated ERCF support channel on Voron’s Discord server, various YouTube guides for assembly and troubleshooting

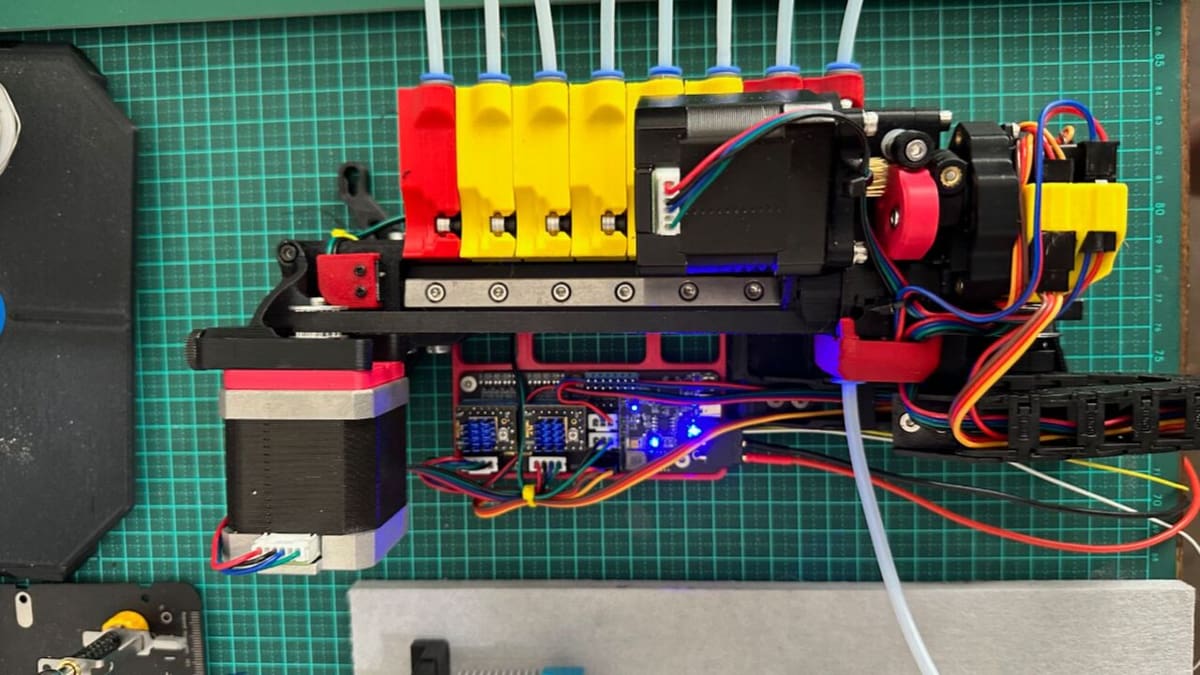

TradRack

TradRack is a compact, cost-effective multi-material feeder system developed by Annex Engineering, which is well-known for their high-performance printers and extruders. Although it’s not as widely adopted as the ERCF, it has gained a dedicated following due to its lower cost per material addition, faster filament loading and unloading, and smaller footprint – which is especially appealing for users with limited space.

One of TradRack’s biggest advantages is its simpler design. It’s easier to build, troubleshoot, and calibrate compared to more complex multi-material unit solutions. While the ERCF relies on multiple drive gears for better filament grip, TradRack uses a single-drive gear. This works well for rigid filaments like PLA, PETG, and ABS, but it may struggle with flexible materials like TPU. Once calibrated, users report that the system is quite reliable and maintenance is straightforward.

TradRack is easier to assemble than ERCF. As no complete kits are currently available (only hardware kits from Triangle Lab), users will have to 3D print their own parts.

- Project page: GitHub

- Printer compatibility: Klipper-based 3D printers

- Ease of assembly: Intermediate difficulty, as users must print their own parts. However, building and troubleshooting and maintenance is relatively simple.

- Additional support: Annex Engineering’s Discord server

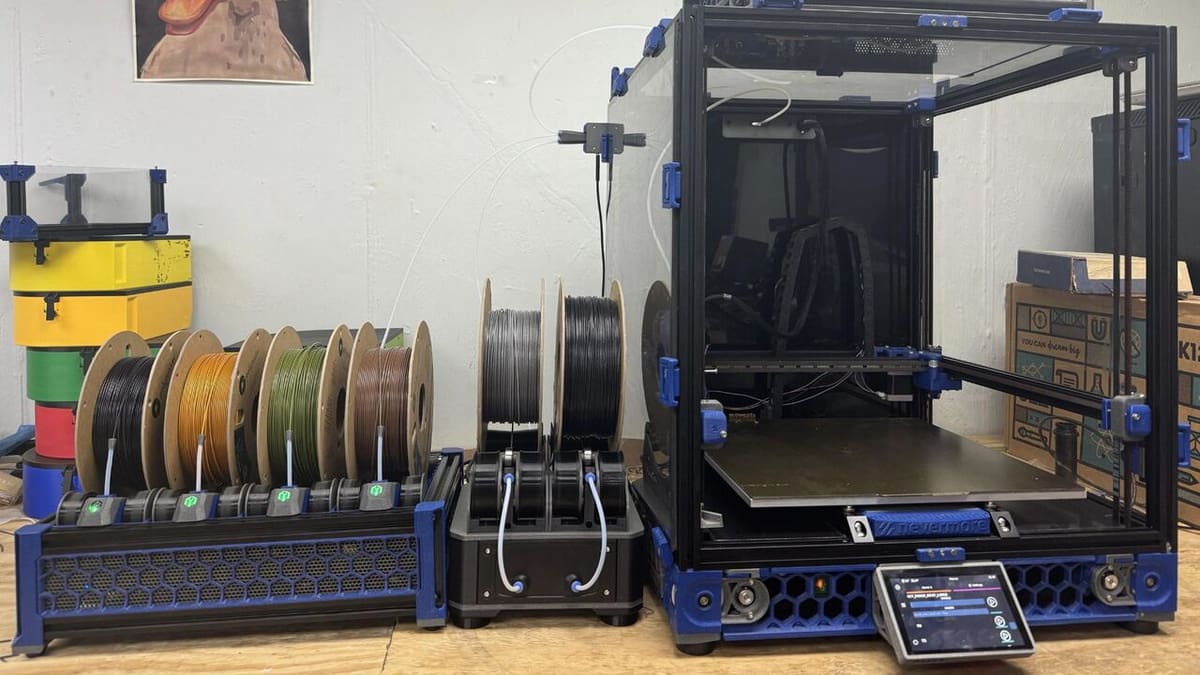

BoxTurtle

BoxTurtle is one of the most popular open-source multi-material units. Unlike other DIY solutions, it uses a dedicated stepper motor per filament lane, which improves reliability but also increases cost as more channels are added.

It has an active community, regular updates, and excellent documentation, making it easy to assemble and integrate with Klipper’s AFC plug-in for automated filament management. Sourcing parts is straightforward, as LDO offers a hardware kit.

While the current design is open and modular, an enclosed version is in development and expected to release soon. This could make it possible to print materials that need to be kept in a humidity-controlled environment while printing – Nylon, for example.

Given its decent user experience, reliability, and strong community support, BoxTurtle is a pretty good choice for Klipper users looking for a well-documented and actively maintained multi-material system.

- Project page: GitHub

- Printer compatibility: Klipper-based 3D printers

- Ease of assembly: Easy, as the documentation is thorough and well-structured

- Additional support: Armored3D’s Discord server

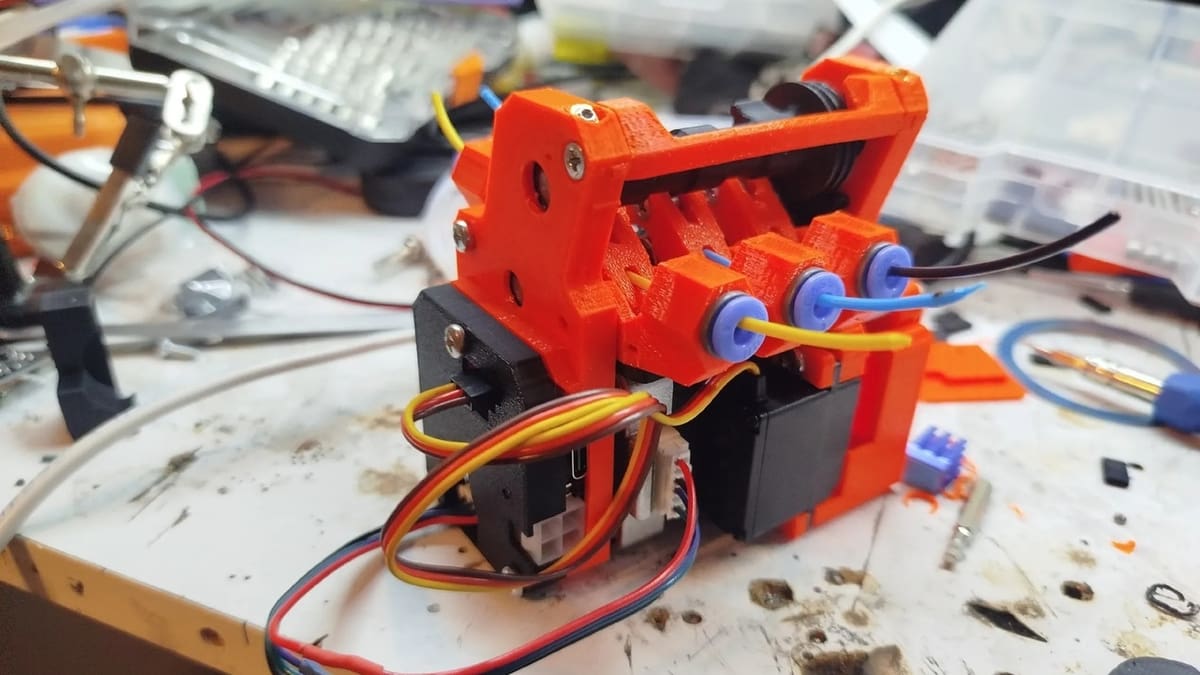

PicoMMU

As the name suggests, PicoMMU is an MMU with a small footprint. It only uses a single stepper motor and a servo motor to switch up to four filaments while printing.

While it doesn’t include a filament buffer by design, filament changes are handled in about 20 seconds, which is on par with most other MMUs on the market. Filament buffers allow for a more flexible filament routing setup, as it provides some extra movement range. But for this one, you’ll have to make sure the filament path is well-aligned and free of excessive bends.

The design keeps the mechanical complexity low, and once properly set up, it provides reliable filament swaps with minimal intervention. No kits are available yet, so users will have to source the hardware and print the parts by themselves. All in all, it’s a great MMU for users with space constraints, as long as the lack of a filament buffer isn’t an issue for you.

- Project page: GitHub

- Printer compatibility: Klipper-based 3D printers

- Ease of assembly: Very easy, requiring only a few components and straightforward assembly

- Additional support: Discord server

3D Chameleon

3D Chameleon is one of the few printer-agnostic MMU solutions, meaning it does not require firmware modifications and can work with any FDM printer that supports extruder movements via G-code. This makes it compatible with Marlin, Klipper, and even proprietary firmware. Instead of using complex electronics, it relies on a simple mechanical push-pull mechanism to switch filaments, making it an affordable and easy-to-maintain option.

While the design is open source, documentation is limited; getting it to work reliably requires extensive calibration. Many users report frustration with tuning, particularly with filament retractions and load positions, but some have had success after a lot of tweaking. This video series from Chris Riley is very informative, especially for assembly and tuning tips. Nero3D – a trustworthy name in the 3D printing space – has touted the project as well.

After the project went open source in 2024, LDO Motors hinted that they may produce a kit for it. At the time of writing, they haven’t released any further information yet, but we’re certainly looking forward to it.

The project has mixed feedback due to its complexity and lack of information available online. But now that it’s fully open source, there’s potential for the community to refine and enhance its design!

- Project page: GitHub

- Printer compatibility: Any FDM printer running Marlin, Klipper, or proprietary firmware

- Ease of assembly: Moderate, as it doesn’t require firmware changes but demands careful alignment and calibration for reliable performance. Not recommended for beginners due to the amount of tuning required.

- Additional support: A community forum exists, but the user base is relatively small, making troubleshooting more difficult

License: The text of "Make Your 3D Printer Multi-Material Capable with a DIY MMU" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.