E3D is one of the largest manufacturers of 3D printer hot ends that serves individual consumers as well as businesses. The company is best known for its V6 hot end, which has become one of the most popular 3D printer hot ends on the market.

Released in 2014, the E3D V6 is an all-metal hot end that’s relatively inexpensive and provides exceptionally reliable extrusion. Since the debut of the E3D V6, the company has gone on to make many other hot end products.

Most recently, E3D unveiled their RapidChange collection of products, including the Revo Six, Revo Micro, Revo CR, Revo Voron, Revo Prusa MK3, and Revo Hemera XS. The Revo hot end series is touted as E3D’s next generation of hot end products, and they’re super easy to use and also provide amazing extrusion quality.

In this article, we’ll go over E3D’s Revo series of 3D printer hot ends. We’ll discuss their features, how they compare to other products on the market, and more.

Features

E3D’s new RapidChange Revo hot ends are packed with next-gen features that make using the hot ends a breeze. Below, we’ll go over some of the important features found on all of the Revo hot ends.

RapidChange Technology

Perhaps the most important feature on a Revo hot end is the integration of E3D’s RapidChange technology. RapidChange is E3D’s name for the new hot end design that allows for quick-and-easy nozzle changes.

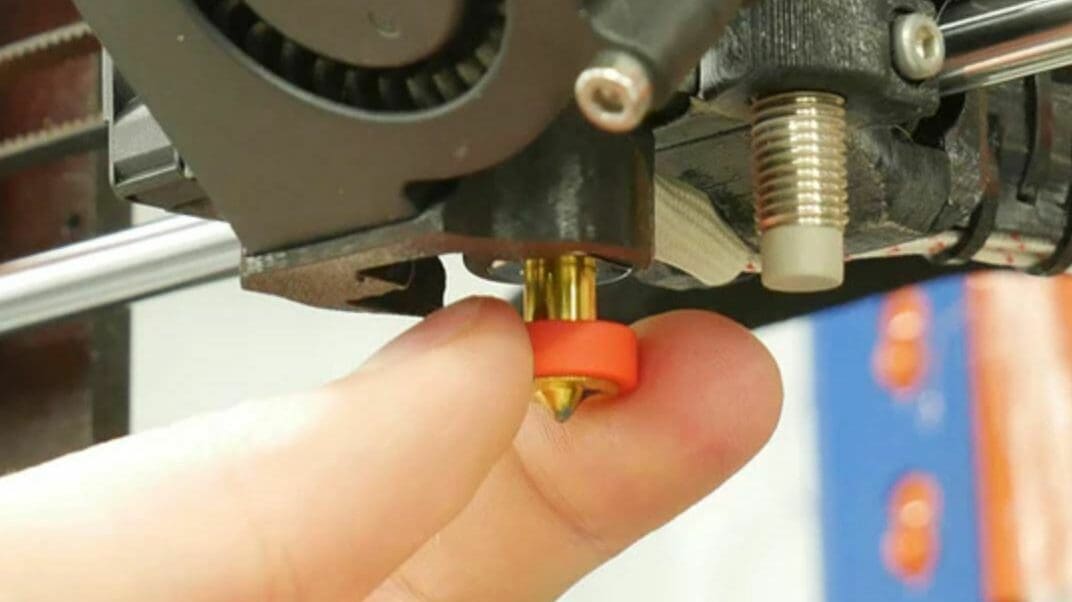

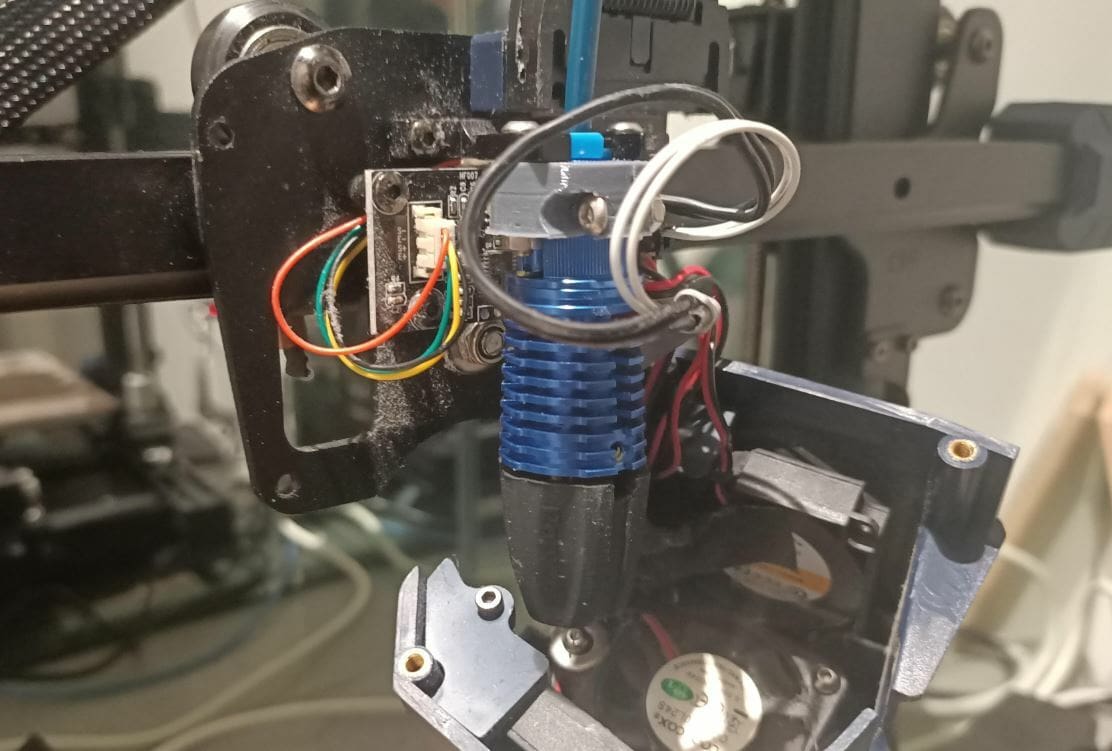

As seen in the image above, this entails using a nozzle with a built-in heat break. While using this proprietary nozzle structure means that you can’t use third-party nozzles (at least for right now), the technology makes nozzle swaps much easier.

That’s because, with an integrated heat break, the filament will only stay in the nozzle rather than touch any other part of the hot end. As such, swapping the nozzle is an adequate solution for solving both nozzle clogs as well as hot end jams.

RapidChange technology also makes changing the nozzle much easier because you don’t have to heat up the hot end to remove the nozzle from the assembly. There’s also a quick-release spring that allows you to install or remove the nozzle with your hands instead of having to use some special tool.

Heater Cartridge

Another difference between Revo hot ends and their V6 counterparts is the design of the heater cartridge. On older E3D hot ends, like the V6, the heater cartridge is called the HeaterBlock and has a rectangular shape. But on the Revo series of hot ends, the heater cartridge has a smaller cylindrical shape and is known as the Revo HeaterCore.

The current version of the Revo HeaterCore, present on all E3D Revo hot ends, is capable of reaching up to 300 °C, the same maximum temperature as the HeaterBlock. However, E3D has stated that they’re also working on a high-temperature variation of the HeaterCore so that Revo hot ends can also handle higher-temperature materials.

Additionally, the E3D Revo HeaterCore has a built-in heater and thermistor wire. This means you won’t have to deal with tightening any cables as you do with the V6’s HeaterBlock. This reduces the chances of breaking the HeaterCore during the installation process, and it also makes wiring the device easier.

It’s also worth mentioning that E3D states that the HeaterCore is made out of a material that has a positive temperature coefficient (PTC). This means the HeaterCore won’t melt, even if it accidentally heats up too much, improving the safety of your machine.

Models

As we’ve mentioned, there are a few different hot end models within the E3D Revo series. All of the Revo hot ends are equipped with E3D’s RapidChange technology, but each model has a unique shape and offers slightly different features to give you certain benefits or ensure compatibility across a certain set of printers. The following is a list of the models available at the time of writing:

- Revo Six: The Revo Six is the model meant to serve as a replacement for the original E3D V6 hot end. It’s practically identical in size and shape to the E3D V6. So, it should work with any assembly or mount for the E3D V6, and you get the benefits of RapidChange.

- Revo Micro: The Revo Micro isn’t specific to a particular set of 3D printers, but it features E3D’s smallest heatsink ever. It has the smallest footprint of all the Revo series hot ends as well as E3D’s entire collection. At only 30 grams, the Revo Micro is also very lightweight, making it a great option for direct extrusion printheads because it won’t limit your print speed as much as other hot end options (heavier = slower).

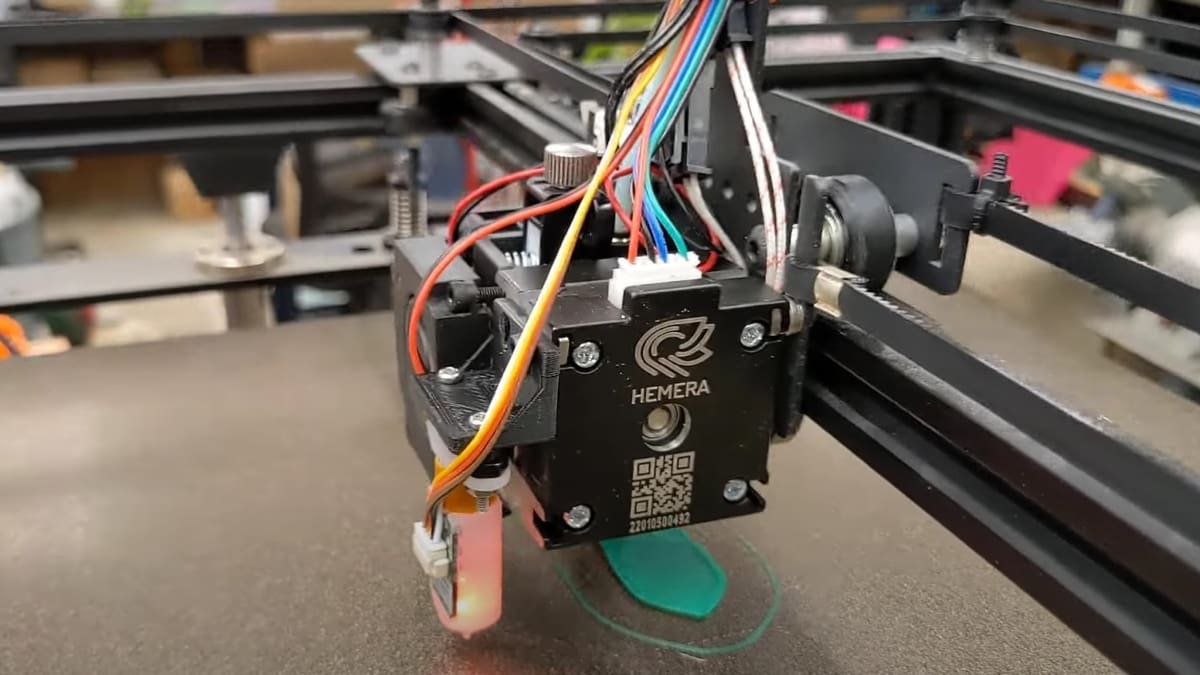

- Revo Hemera XS: The Revo Hemera XS is perhaps the most distinguishable model in the Revo series because it’s both an extruder and a hot end. The Revo Hemera XS is basically the E3D Hemera extruder but fitted with an E3D Revo hot end to enable quick-and-easy nozzle swaps. It also has a smaller footprint and lighter weight.

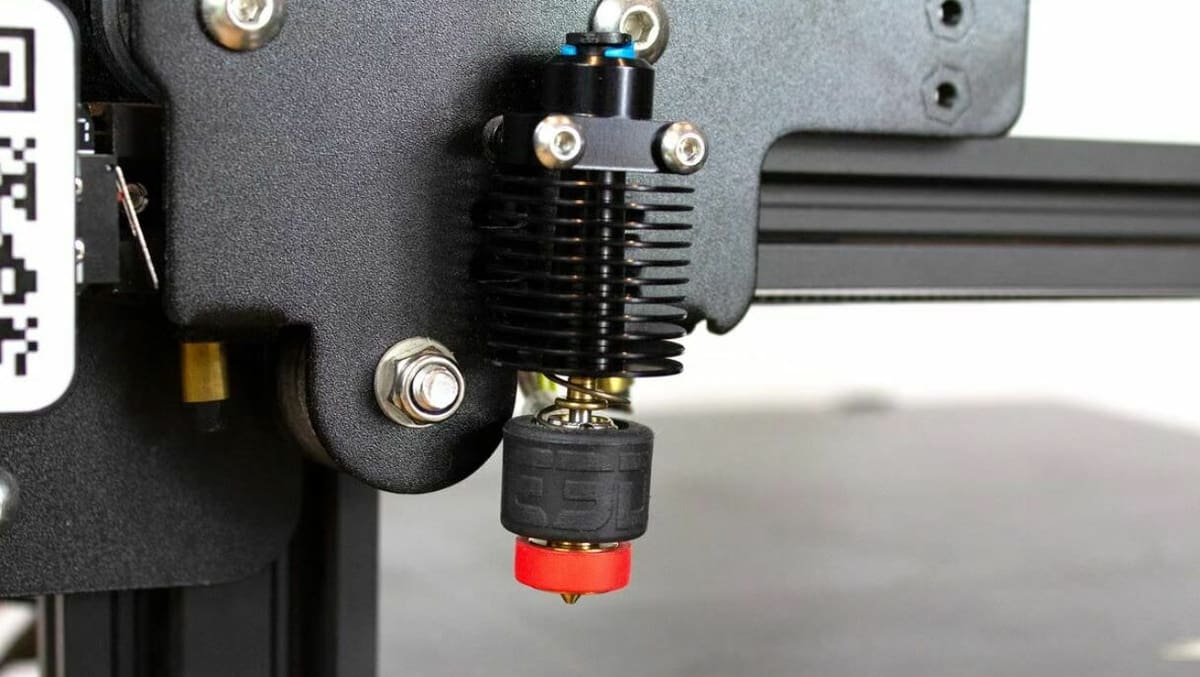

- Revo Voron: The E3D Revo Voron was developed in collaboration with the team behind the Voron project and is a great option for a hot end if you’re building a Voron 3D printer, like the Voron 2.4. Following the typical Voron theme, the Revo Voron’s heat sink is red, and the hot end is meant to be compatible with most Voron 3D printers’ printheads.

- Revo CR: The E3D Revo CR is a Revo hot end designed for Creality 3D printers, specifically the different versions of the Creality CR-10 and Ender 3. The Revo CR features the same mounting holes as the stock CR-10 and Ender 3 hot ends, making installation on these Creality printers a breeze. And, unlike other E3D hot ends, the Revo CR has a Creality-specific thermistor wire, so no changes to the firmware are necessary for installation on compatible Creality printers.

- Revo Prusa MK3 Edition: This E3D Revo hot end was designed specifically to serve as a drop-in replacement for the Prusa i3 MK3 printer as well as the MK3S and MK3S+. On top of having the same mounting holes as the stock hot end, the Revo Prusa MK3 Edition also features a Prusa-specific thermistor extension cable to ensure 100% compatibility and an easy installation process.

Reviews

Although the Revo series of 3D printer hot ends are fairly new to the market, they’re pretty well-liked by the community. Many users have mentioned that the ability to swap nozzles without heating up the hot end is super convenient. However, the other benefits of the Revo nozzle, such as the smaller and more efficient HeaterCore haven’t been super noticed by the reviewers, likely due to their smaller effects on the printing process.

It’s also worth mentioning that some have been reluctant to switch to Revo hot ends due to the current limitations of the nozzle. While E3D’s ObXidian Revo nozzle, an abrasion-resistant nozzle for Revo hot ends, is on pre-order right now, it’s not expected to fully release until next year. As such, the only Revo options you currently have are made of brass.

Overall, the Revo series of hot ends seem to be a great option for 3D printers. It just might be a few months until they start to gain more traction in the 3D printing community.

Price

When it comes to picking out a Revo hot end for your 3D printer setup, you have a few options.

First, you have to choose between 12 V and 24 V, which is a decision that should be based on the voltage of your printer’s motherboard. Most are 24 V, and Prusa MK3 Edition only comes in 24 V. You don’t have to worry about the price, though, as the voltage option you choose for your Revo hot end won’t affect that.

However, what will change the price of your order is whether you pick the single nozzle kit or the fully-loaded kit for your Revo hot end. The former comes with your chosen hot end and one compatible 0.4-mm Revo brass nozzle. On the other hand, the fully-loaded kit brings you a full set of diameter options – 0.25 mm, 0.4 mm, 0.6 mm, and 0.8 mm – at an added cost of about $55 across all Revo hot end models.

The total price of your hot end, though, will depend on what model you choose. Of course, the final price of your order depends on the constantly-fluctuating exchange rate between US dollars and pound sterling, so we’ll use the current rate to estimate the price of each model.

On one end of the spectrum, the Revo Prusa MK3 Edition is the least expensive Revo hot end model, with a base cost (single nozzle kit) of about $85. On the other hand, the Revo Hemera XS has the highest price tag, with a starting cost of just above $170. The Revo CR, Revo Micro, and Revo Six hot ends all have the same starting price of around $95, and the Revo Voron isn’t far behind, with a base price several dollars cheaper.

Finally, if you want to use the Revo Hemera XS in a Bowden extruder configuration, you can purchase a little E3D adaptor piece to make it work. The part costs about $5 and comes in both 1.75 and 2.85-mm sizes to cater to both filament diameters.

Tech Specs

Below, we’ve provided some general technical specifications of Revo hot ends:

- Maximum temperature: 300 °C

- Compatible filament: 1.75 mm

- Available voltages: 12 V, 24 V

- Heater cartridge: HeaterCore with integrated wiring

- Heat sink shape: Cylindrical (or semi-cylindrical)

- Compatible nozzles: Official E3D Revo nozzles

- Available nozzle diameters: 0.15, 0.25, 0.4, 0.6, 0.8 mm

- Weight: 25 g (Revo Voron) – 256.25 g (Revo Hemera XS)

- Price range: $85-170

Similar Devices

Now that you know all about the Revo hot ends, you might be curious about similar 3D printer hot ends. In the sections below, we’ll go over two other hot end options that offer similar features to the Revo series.

Slice Engineering Mosquito

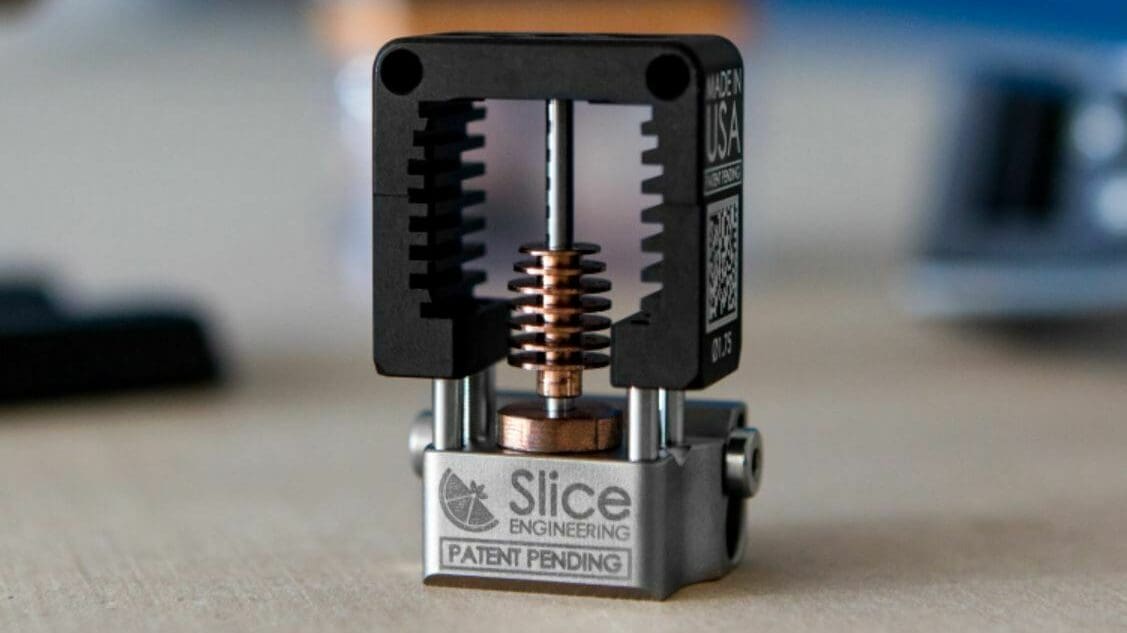

Slice Engineering is a company that specializes in making high-end 3D printer hot ends, and the Mosquito is one of their flagship products. The first thing you’ll notice about the Slice Engineering Mosquito, as seen in the image above, is its unique design. It has a low-footprint outer heat sink and a special bimetallic heat break.

According to the manufacturer, this unique design allows the Mosquito to conduct 85% less heat than a typical hot end, reducing the likelihood of issues related to poor heat management, like heat creep. Slice Engineering also advertises how the rigidity of the Mosquito hot end assembly allows for one-hand nozzle changes. Many in the community are fans, especially those who print materials that require higher temperatures.

If your main focus is extrusion quality and high-temperature printing, the Mosquito is probably the better option compared to E3D Revo hot ends. However, if you want to save money or are looking for a hot end that will make nozzle changes a breeze, an E3D Revo hot end is probably more your speed.

Phaetus Rapido

Phaetus is another company that specializes in making 3D printing accessories, including hot ends and nozzles. The Phaetus Rapido is one of the company’s latest hot ends, and it’s designed to provide high-flow extrusion to enable fast print speeds.

The Rapido comes in two versions: high flow (HF) and ultra high flow (UHF). The latter can handle a higher volumetric filament flow (75 mm3/s), meaning you’ll be able to use faster print speeds. But, according to Phaetus, the regular Rapido HF can still be used with above-normal print speeds.

This is possible due to the Rapido’s ceramic heating unit, which can go up to 290 °C. While this is pretty high for a maximum nozzle temperature, it’s not quite as high as the E3D Revo hot ends’ 300 °C maximum temperature. But, as it’s pretty close, it’s unlikely that you’ll run into many filaments that a Revo hot end can print, but the Rapido cannot.

Another special part about the Phaetus Rapido hot end is its unique design. The nozzle screws into a sub-assembly that attaches to the hot end’s cylindrical heat sink via three titanium alloy screws. Compared to a typical hot end assembly where the nozzle screws directly into the heat sink, the Rapido’s design makes it easier to swap nozzles. And, while Phaetus mentions that swapping nozzles can be done with one hand, you’ll still need to heat up the nozzle and use the right tool. On any E3D Revo hot end, however, you can make nozzle changes without turning on the heat or using any special tools – just your bare hands.

Overall, the Rapido hot ends are a very great option if you’re looking to use faster print speeds. But, if you don’t care as much about how fast you can print as you care about the nozzle changing process, an E3D Revo hot end would probably be a better choice.

License: The text of "E3D Revo Hot Ends: Specs, Prices, Release, & Reviews" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.