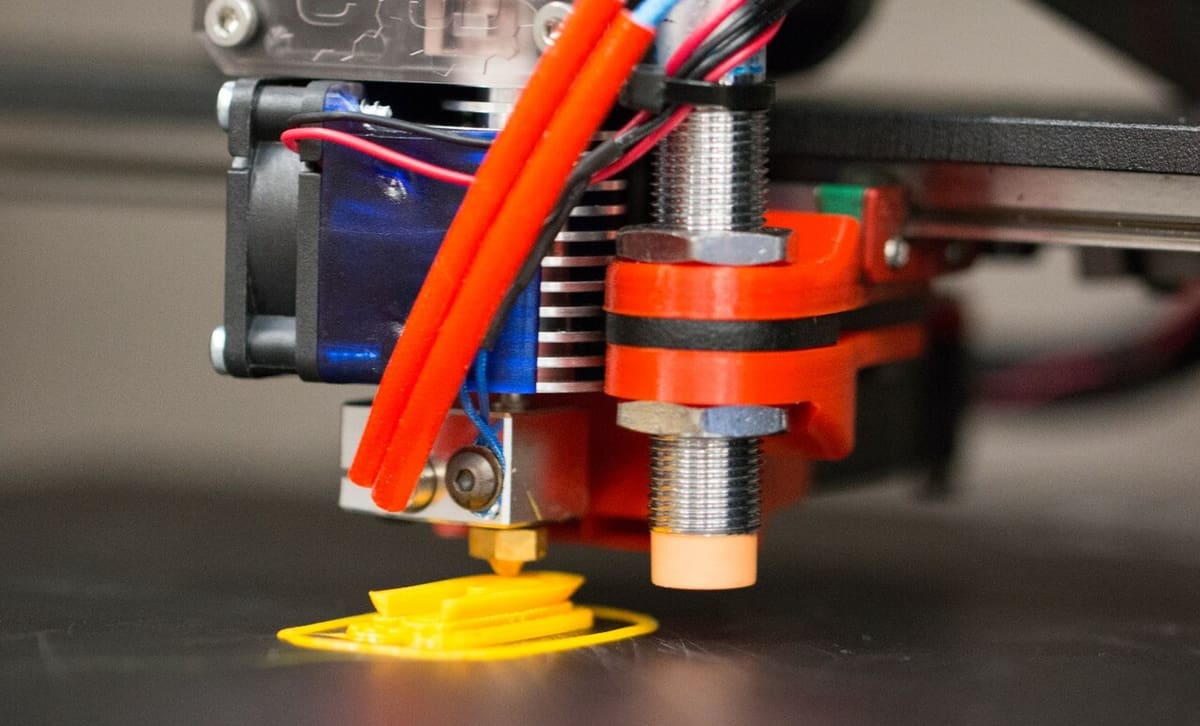

Hot ends are arguably one of the most important parts of a 3D printer. They’re responsible for taking in stringed filament, melting it, then letting it pass through the nozzle. If the hot end is low-quality, the extrusion of your print will also be poor, resulting in print quality issues such as over or under-extrusion or even full jams where the print stops entirely.

In the 3D printer hot end market, E3D is one of the biggest players, with a reputation for making high-quality hot ends catered to everyday 3D printing enthusiasts. The company makes a number of different hot ends, such as Volcano, Cyclops, Hemera, and more. The V6 is undoubtedly the company’s most popular product, with high-quality and consistent extrusion at a reasonable cost.

In 2021, E3D finally released an update to their famed V6 hot end: the Revo Six. In this article, we’ll compare both hot ends to help you determine which one is best for you. We’ll discuss each product’s hardware, printer compatibility, and installation requirements.

Let’s dive in!

Meet the Contenders

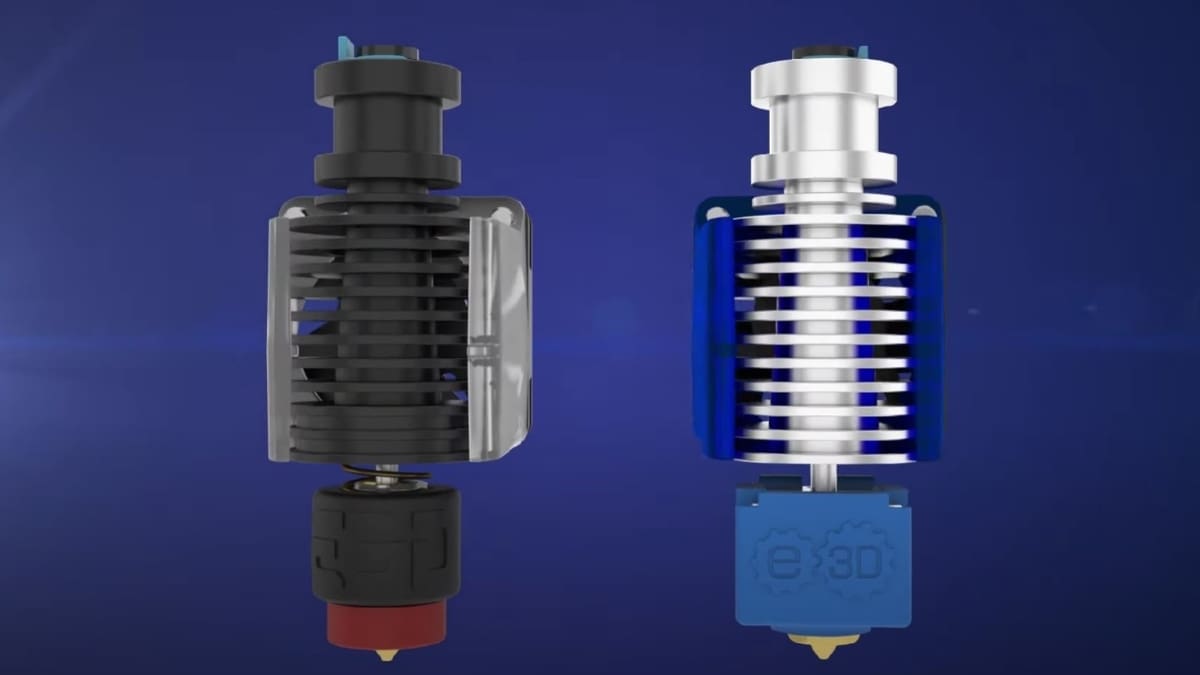

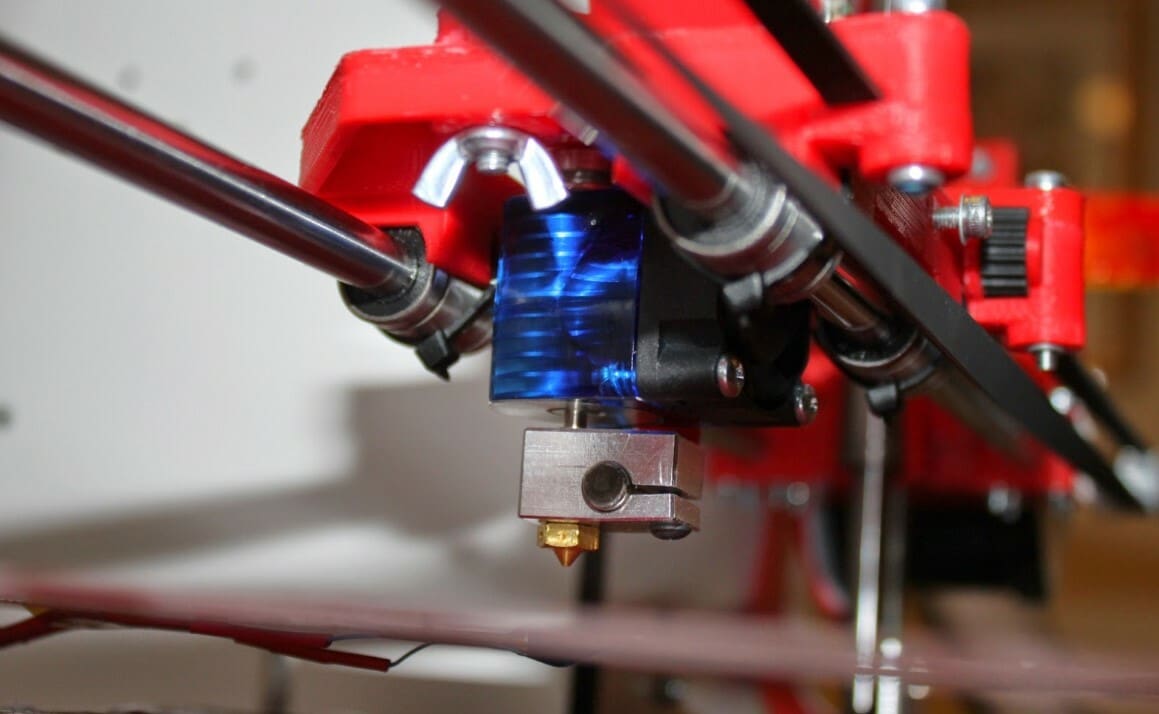

As the V6 is the incumbent, it only makes sense that we start with it. Released in 2014, the V6 is an all-metal hot end (no PTFE liner) catered to 3D printing enthusiasts who want reliable extrusion and the ability to use a wide assortment of materials. The hot end is also distinguished for its cylindrical heat sink, a feature not seen in many hot ends before the V6.

The Revo Six was released seven years after the V6 and looks very similar to the original V6: It also has an all-metal construction and a cylindrical heat sink. However, the Revo Six is unique because of its RapidChange technology, which allows for quick and easy nozzle changes. It also has a few other notable features, which we’ll get to in later sections.

Now that you know some background about these two E3D hot ends, let’s dive into their differences. We’ll split up our comparison into a few categories, including hardware, compatibility, and installation.

Hot End Structure

Our first subject of comparison is the hardware, specifically the hot end structure, which is extremely important for a hot end. While the V6 and Revo Six look similar from the outside, what’s inside is very different.

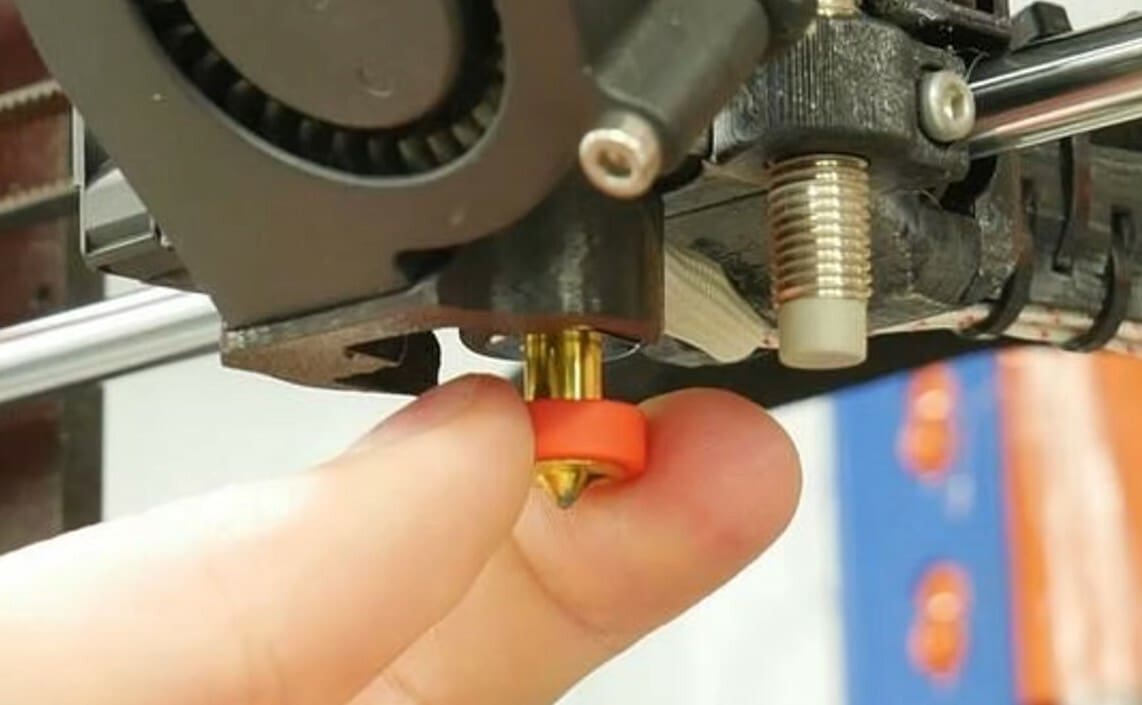

The V6 follows a regular hot end construction, with a nozzle that screws into the bottom of the heater block and a cylindrical heat break (also known as the “throat”) that goes through the heat sink. With this assembly, you can remove and install any regular-sized nozzles by simply screwing them into the proper threads on the bottom side of the heat block.

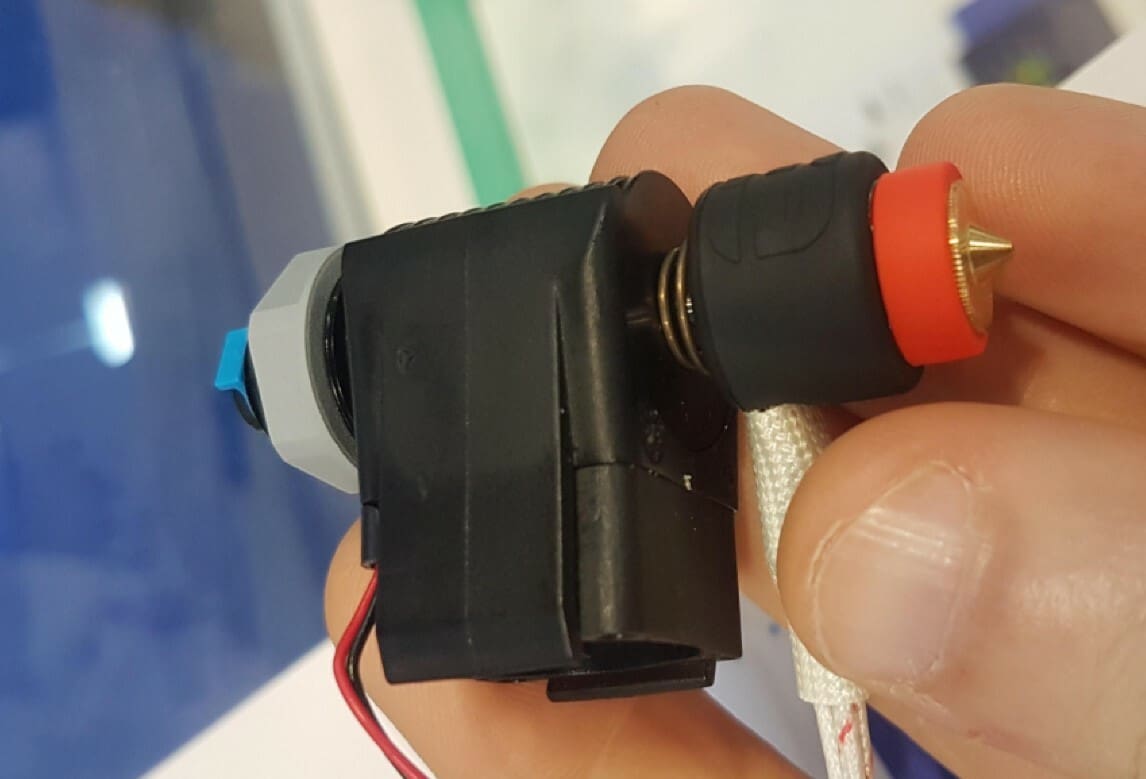

On the other hand, the Revo Six uses a specialized nozzle and heat block design, which E3D calls their “RapidChange” technology. With RapidChange, E3D integrated the heat break design into the nozzle, so the nozzle has a long shaft attached to it that goes up through the cylindrical heat sink. Additionally, rather than being rectangular like most heater blocks, the Revo Six’s heater block is cylindrical and has a spring that separates it from the heat sink.

But why all these changes? Well, the spring compression, along with the specialized nozzle design, allows you to quickly change the nozzle and remove any hot end clogs or jams in the process. This is much easier than having to both replace the nozzle and clean out the hot end as you would have to do on the regular V6.

On top of this, RapidChange also allows you to replace your nozzle when it’s at room temperature, so there won’t be any risk of burning your fingers off during the process. With the V6, though, you have to keep the hot end hot to change out the nozzle in most cases.

Electronics

Although hot ends may look like a small hunk of metal, they contain a few important electronic components: a fan, heater cartridge, and thermistor wire. Both the Revo Six and the V6 use a standard 3010 fan – a small blower that should adequately cool your heat sink to prevent problems such as heat creep. The rest of the electronic components, however, are different.

The Revo Six uses a heater-and-thermistor package called the “Revo HeaterCore”, while the V6 uses an aluminum heater block. While these two heating structures can both reach temperatures up to 300 °C, E3D states that the Revo HeaterCore can achieve temperatures much faster than the V6’s heater block. The HeaterCore has a positive temperature coefficient (PTC) heating element, which allows it to reach target temperatures faster while also reducing the likelihood of thermal runaway.

Compatbility

We’ve already mentioned that changing nozzles on the Revo Six is much easier than with the V6, but it’s also worth covering the compatibility of the hot ends. By “compatibility”, we mean what nozzles can be used with each hot end as well as what printers can use each hot end.

Largely due to the age of the V6, it’s no wonder that there are many more 3D printable mounts designed specifically for it than for the Revo 6. Yet, because the Revo 6 is a drop-in replacement for the V6, the former can fit any hot end mount meant for the latter. So, although there currently aren’t too many mounts meant for the Revo 6, due to the hot end’s interchangeability with the V6, it’s still compatible (or can be made compatible) with many 3D printers.

The V6 also takes the cake over the Revo Six when it comes to nozzle compatibility. That’s because there are tons of third-party V6-style nozzles that you can buy online, but very few alternatives to the official Revo Six nozzle exist yet because it’s so specialized. Like with printer compatibility, this could change for the Revo Six later down the road, but for right now, if you want more options for nozzles, the V6 is perhaps the better option.

Which One Is for You

After reading about the differences between the V6 and Revo Six, you’re probably wondering which one is better for you. Well, there isn’t one right answer for everyone, as both hot ends have their fair share of benefits and disadvantages. But there are users that will benefit more from one hot end over the other.

The V6 hot end is probably best for users who want the most compatibility for nozzles and printers. This hot end is also much less expensive to maintain because replacement nozzles are a lot less expensive than a new Revo Six nozzle.

On the other hand, for the easiest user experience and improved printing performance, the Revo Six is likely the better choice. While not many mounts for it have come out, the RapidChange technology onboard the hot end makes it super easy to replace the nozzle and get rid of clogs. Additionally, the Revo Six is equipped with a more powerful and safer heater cartridge that will reach printing temperatures faster than the V6 and ensure that the heat never gets out of control.

License: The text of "E3D Revo Six vs E3D V6: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.