Creality has been busy. In a relatively short amount of time, they’ve produced some of the best affordable 3D printers. The Ender 3 is a perennial favorite, while the Ender 3 V2 is worth keeping if it’s already in your setup. The Ender 3 Pro also continues to be a strong machine for its price, despite the bold marketing decision to include “Pro” in its name.

With the Ender 3 series as well as its other lines, Creality has taken the 3D printing community by storm by supplying it with cheap, reliable machines. Part of the reason they’re able to produce reliable printers for such reasonable prices is that they tend to use simplistic designs with the same components across a range of machines. The hot end assembly is one such component.

The standard Creality hot end is simple and, for most tasks, capable. However, especially when printing with specialty filaments that require more consistent or higher temperatures, the stock hot end can reach its limits.

Let’s first take an in-depth look at the hot ends on the Ender 3s, then consider some alternatives that would make excellent upgrades. And the good news is, that all are compatible with the Ender 3 as well as the Pro and V2 models.

The Stock Option

The default Ender 3 hot end is very simple. A Teflon (PTFE) tube meets a metal heat break in the center of a metal heatsink. This construction screws together with an aluminum heater block (or an alternative material of your choice). The hot end takes 1.75-mm filament and reaches a maximum temperature of 260 °C. If you wanted to replace your stock Ender 3 hot end, it would set you back around $20.

Pros

- Cheap

- Easy to replace and install

- Teflon tube resists clogging

Cons

- Low maximum temperature

- Non-metal components require more frequent maintenance

- Loose connections between components can easily cause leakage and clogs

A true upgrade should resolve the above cons. Therefore, better hot ends will have higher maximum temperatures, require less maintenance, and be engineered so that there are fewer loose connections – which is exactly what we considered when making this list.

Just be aware that if you plan on printing with materials that require printing temperatures higher than 260 °C, you’ll need more than a new hot end. You also have to edit the temperature restrictions in your Ender 3’s firmware as well as upgrade the thermistor.

So, now that we know how the stock option can be improved upon, let’s look at some hot-end upgrades for the Ender 3s!

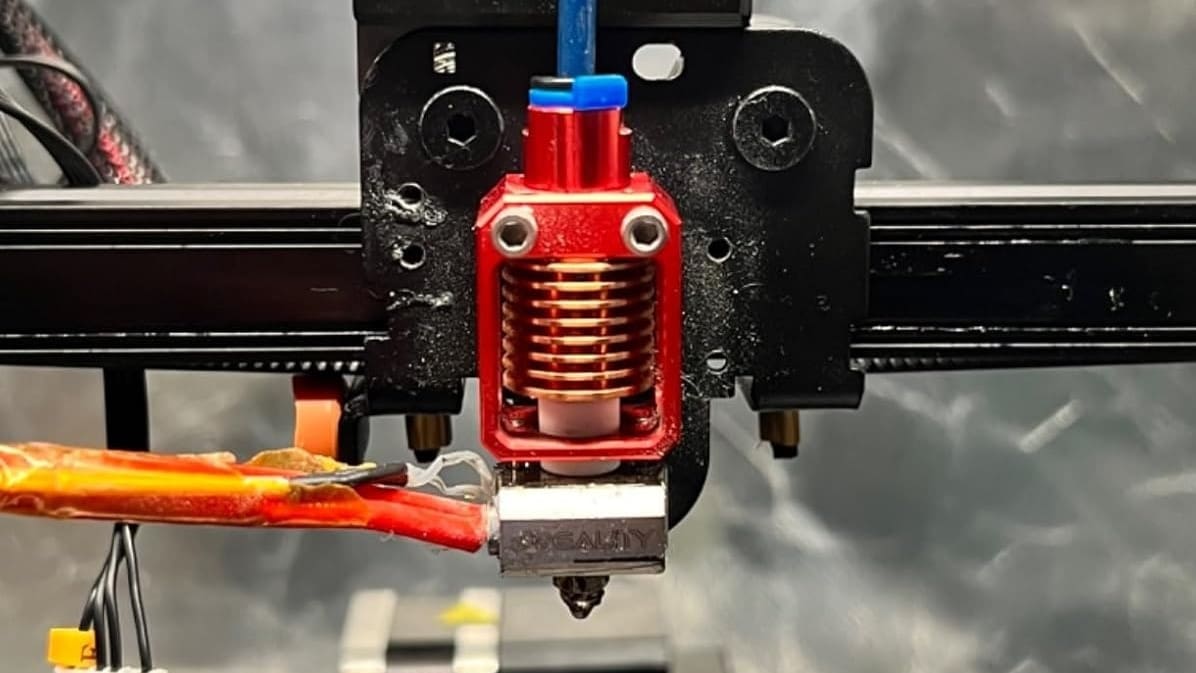

Creality Spider V3

Creality originally launched the high-performance Spider hot end as an upgrade to the stock hot end of Ender 3, which could reach a higher temperature and had an all-metal construction. Although the V1 had issues with heat creep and clogging, such design flaws have been fixed in V3, making it better than ever.

Since the hot end can handle a temperature of up to 300 °C, you can easily print higher temperature materials such as ABS and ASA (with an enclosure). If you pair it with a CHT-styled nozzle and have a powerful enough extruder, you can expect to get a flowrate of 35 mm3/s or more as well. The higher flowrate is made possible by the 30% larger melt-zone in the hot end.

As for installation, the V3 model is a drop-in replacement for the stock hot end and requires no further modifications to be set up. However, if you would like to print hotter than 260 °C, as mentioned, the firmware will also need to be updated. The hot end takes standard MK8 nozzles, so you can install any MK8-spec nozzle on it.

All in all, it’s a great choice for printing higher temperature materials at fast speeds. If that seems to match your criteria, definitely go for it!

- What’s the max temperature it can reach? The Spider V3 is capable of reaching up to 300 °C, which is on par with high-end consumer-grade 3D printers these days.

- Is it anti-leak & anti-clog? The Spider V3 isn’t an unibody design, so in theory there’s still a possibility of leakage if the heating block and the heatsink aren’t assembled properly. Moreover, a user noted that the Spider V3 clogs often with a Bowden setup and PLA (which would make TPU even more likely to clog). According to them, a direct extrusion setup is necessary to avoid clogging.

- How much does it cost? ~$60

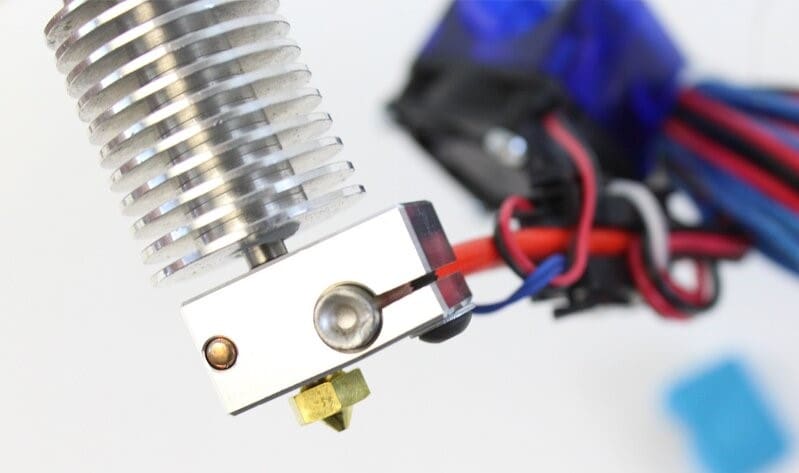

E3D V6 All-Metal

E3D is one of the most popular 3D printing companies, and for good reason. This British company strives to create top-notch, super reliable 3D printing parts that have become the standard on many machines.

One of the unique points of V6 is that it has an all-metal construction, and the PTFE tube for routing the filament is distanced from the heater block with a stainless steel heat break. Since the PTFE tube will never receive any heat, the chance of it melting is virtually zero. This is such a low-maintenance and reliable hot end that even Prusa’s MK3S+ comes stock with it.

But is the E3D V6 all-metal hot end a true upgrade to the default Ender 3 hot end? You bet it is.

The E3D V6 All-Metal Hot End is a fantastic choice for an Ender 3 hot end replacement. It’s durable, reliable, and a joy to use. Tutorials and 3D printable mount files for installing the E3D V6 are readily available to help you out.

If you’re looking for a popular hot end that’s compatible with a lot of community-designed toolheads, you should consider the E3D V6.

- What’s the max temperature it can reach? The V6 can easily reach 285 °C with the stock thermistor. However, according to E3D, the temperature is bottlenecked by it. So, if you switch to a thermocouple (which may require additional electronics) or a PT100 thermistor, you can reach over 400 °C. This, in addition to a few more upgrades and an enclosure, would let you print a wider range of materials such as polycarbonate, nylon, and even PEEK.

- Is it anti-leak & anti-clog? Due to the design, the heat break heats up much faster and needs to be actively cooled with a fan. Otherwise, the filament can soften and clog inside it. It’s not a design flaw per se, but users need to make sure the printer isn’t turned off right after the print is finished. Leaving it on for a few minutes should allow the hot end to cool down enough, alleviating any chance of clogging.

- How much does it cost? $55-$85 (depending on which version and whether preassembled or not)

E3D Revo

The Revo hot ends are among E3D’s best known hot ends. The Revo series improves upon the V6 hot end, with a compact assembly featuring E3D’s RapidChange technology. This system makes it super easy to swap nozzles on the hot end to minimize your printer’s downtime.

The E3D Revo was initially released in three versions. The Revo Six is the same size and shape as the E3D V6, and you can replace your old V6 with a Revo Six very easily. The Revo Micro is the lightweight version, only weighing 30 grams and featuring a smaller 20 x 20 mm fan. Both the Six and Micro retail for about $90. Lastly, the Revo Hemera is a remix of E3D’s Hemera extruder hot end combination (which we’ll come to later), but it uses a Revo hot end rather than a V6 hot end. This is a significant upgrade with a price to go with it, starting at about $170.

The E3D Revo Creality ceramic hot end kit is one of the more recent additions to thee Revo ecosystem. It’s designed to be a drop-in upgrade for Creality’s Ender 3 and CR10 series. The ceramic heater lets the hot end heat up to 200 °C in only 43 seconds, which is three times faster than traditional hot ends. For the Ender 3 series, this is the version that we recommend.

Reliability and maintenance-wise, they’re all great as well. The Revo hot ends are known to be fine even when printing with flexible filaments, such as TPU. And, if the nozzle wears out, you can get your machine back up and running quickly thanks to the RapidChange System that allows the nozzle to be changed cold without any tools. The hot end is also pretty easy to disassemble for further maintenance.

If you’re looking for a low-downtime hot end that provides reliable extrusion, the Revo options are worth your consideration.

- What’s the max temperature it can reach? Like most hot ends in this article, the Revo hot ends have a maximum nozzle temperature of 300 °C. That should be sufficient for most regular filaments such as PLA, PETG, ABS, ASA, and nylon.

- Is it anti-leak & anti-clog? The sophisticated design of E3D Revo is significantly less likely to leak or clog. It also has a circular heatsink that dissipates the heat better in the heat break, further reducing the chance of heat creep.

- How much does it cost? ~$130 (E3D Revo Creality Ceramic)

Micro Swiss All-Metal

If you’re looking for a super easy hot end upgrade, the Micro Swiss all-metal hot end is just what you need. There’s a version compatible with all Ender 3 printers, and it requires no extra brackets.

To talk about maintenance, the design of the hot end distances the PTFE tube from the heater block with a titanium heat break (similar to the E3D V6). Hence, there’s minimal chance of PTFE tube’s deterioration and a need to replace it. It also comes with nickel composite-coated brass nozzles that will make the nozzle last much longer than regular brass ones. Moreover, you can also print abrasive filaments, such as carbon fiber and metal-filled.

The installation process for this hot end is extremely straightforward, and Let’s Print 3D makes it even simpler with their tutorial.

If you want a drop-in upgrade for the hot end but don’t want to go with the Creality offerings, this would be a great choice.

- What’s the max temperature it can reach? Since there’s no PTFE tube to worry about in the all-metal construction, the hot end can go up to 300 °C comfortably.

- Is it anti-leak & anti-clog? The titanium heat break also stops heat from creeping beyond the heater block, so you don’t have to worry about the filament melting, cooling, and forming clogs in the cold zone.

- How much does it cost? ~$65

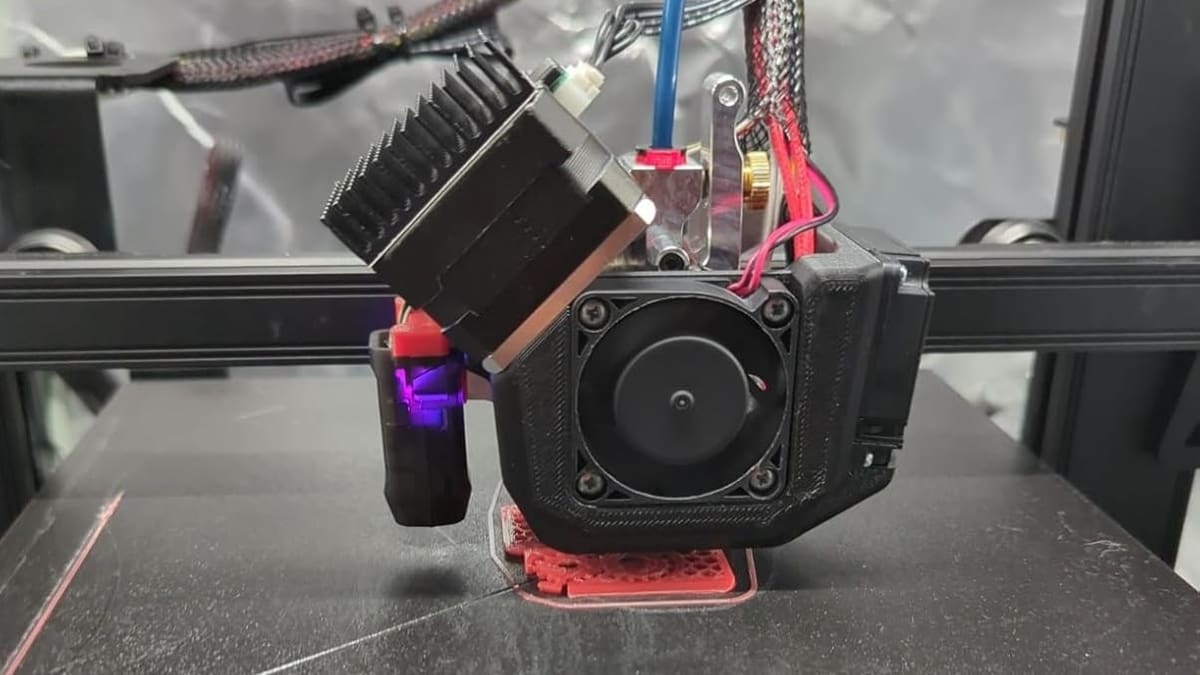

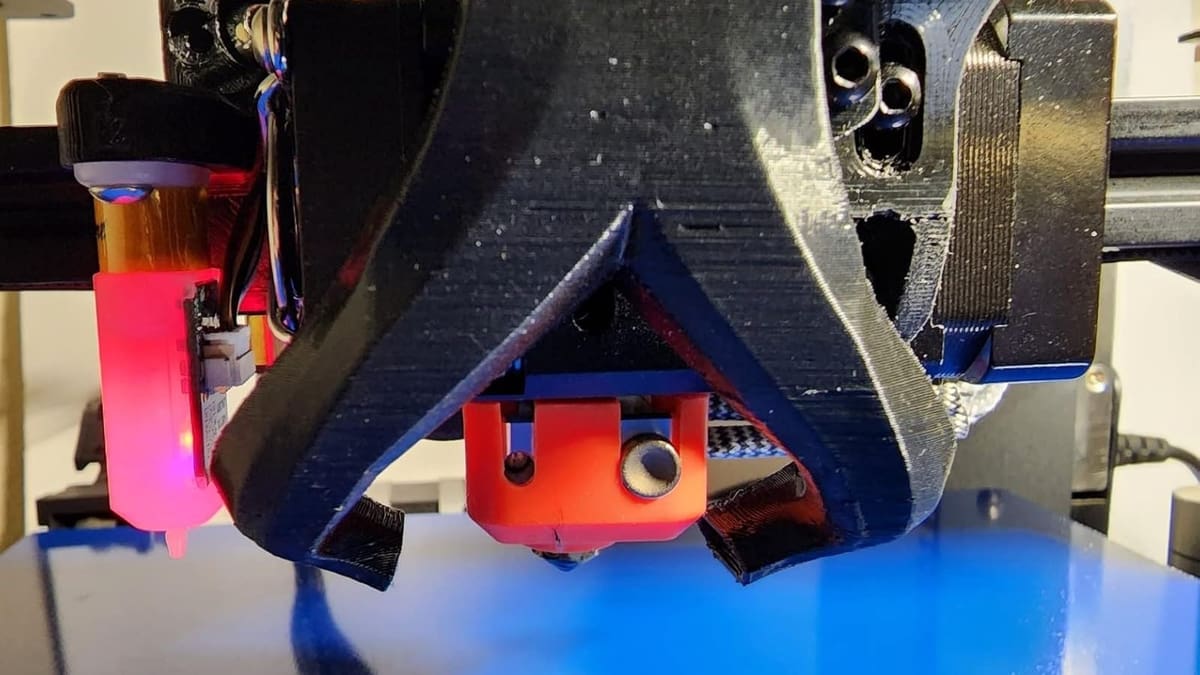

Creality Sprite Pro (Direct Extruder)

Both the Ender 3 V2 and Pro come stock with a Bowden setup. This works fine, but filaments like PETG and TPU can be really tricky to tune for without a direct extrusion setup. While you can convert your machine by reusing some components, you can also upgrade both the extruder and the hot end.

That’s where the Creality Sprite Pro comes in: It’s a direct extrusion setup that incorporates both the extruder and the hot end into one unit.

The extruder has a 3:5:1 gear ratio with twin drive gears that is capable of pushing a lot of filament through the hot end. It also comes with quality-of-life features, such as a release lever that allows you to swap the filament quickly and effortlessly.

The hot end is also capable of handling a variety of materials, ranging from flexible filaments like TPU to high-temperature filaments like ABS.

Thanks to the compact design, there’s minimal distance between the hot end and the extruder assembly. That, combined with the two drive gears in the extruder, prevent even the softest filament from getting jammed. Since everything – including the drive gears – is made of metal, nothing’s likely to wear out, making maintenance as minimal as it gets. The Sprite Pro is attached to the carriage with only three screws, so even disassembly for cleaning is a breeze.

So who should buy it? Any Ender user who’s looking for a simple, easy to install direct-extrusion solution that just works right out of the box!

- What’s the max temperature it can reach? The Sprite Pro comes with an all-metal hot end that can heat up to 300 °C.

- Is it anti-leak & anti-clog? Due to the combined assembly, there aren’t many places for the filament to leak out from. As long as you tighten the nozzle properly while the hot end is heated up, there should be no leakage. The Sprite Pro also features a high-performance heatsink and a powerful hot end fan that makes clogging or heat creep very unlikely.

- How much does it cost? ~$110

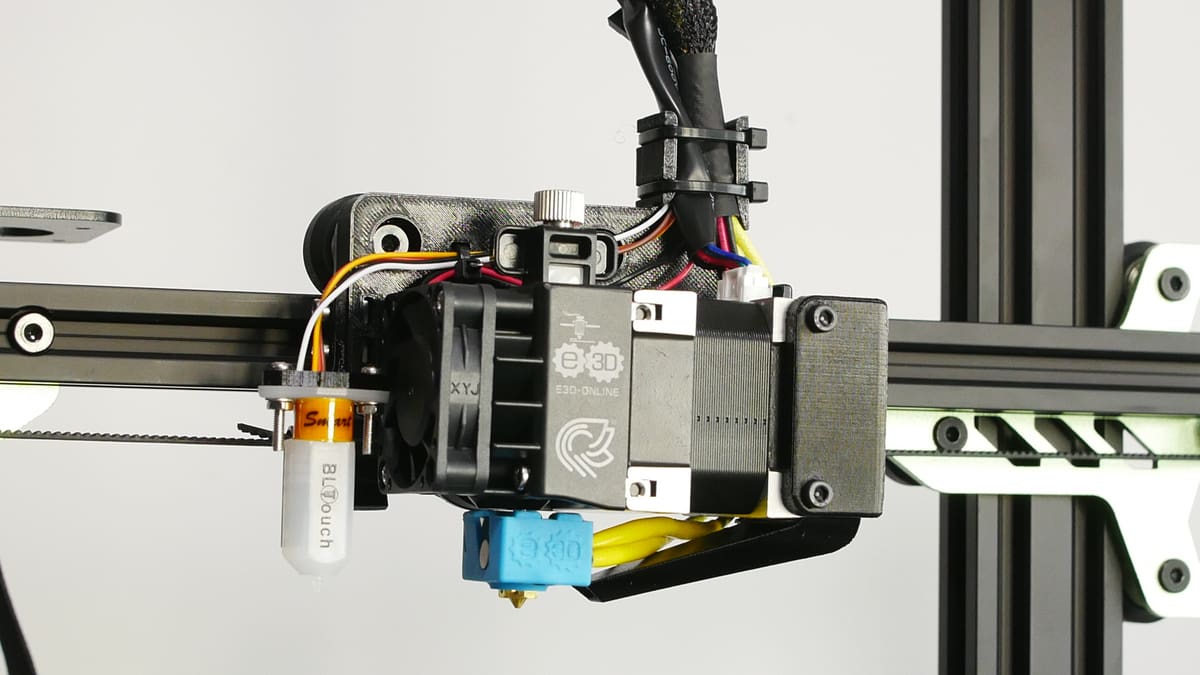

E3D Hemera (Direct Extruder)

The E3D Hemera is another two-in-one option, converting your Ender 3 to direct extrusion while upgrading the hot end at the same time.

According to E3D, the hot end and extruder assembly constrain the filament to ensure consistent extrusion of filament and minimize the chances of clogging. The PTFE tube is well-protected in the metal construction and doesn’t degrade over time. Setting filament tension is done by simply twisting a thumbscrew, and it’s designed for effortless filament loading and unloading.

In the rare case that you ever need to take it apart, the core of the setup can be easily accessed by removing the fan and two bolts.

With the Hemera, you’ll definitely upgrade your Ender 3, getting an excellent hot end paired with an excellent extruder for around $120. If you need a step-by-step tutorial, check out Teaching Tech’s YouTube guide. For those of you with the Ender 3 V2, you’ll want to check out this guide from Dan Rock.

Is it worth it? If you can afford it and want a high-performance hot end with an even higher potential, we would say yes. However, for average users, this might be a bit of an overkill.

- What’s the max temperature it can reach? With no modifications, the E3D Hemera is capable of reaching up to 285 °C, which is more than enough for ABS, ASA, and nylon. The temperature is only limited by the thermistor, which if replaced with a PT100 thermocouple (and additional electronics), and the standard heater block is replaced with nicked-plated copper block, you can reach up to 500 °C!

- Is it anti-leak & anti-clog? The really powerful extruder does an amazing job at pushing filament through the hot end. That, paired with the constrained filament routing system, makes sure even flexible filaments won’t clog up inside the hot end or extruder. The unique heatsink design also handles heat creep issues well.

- How much does it cost? ~$200

Micro Swiss NG (Direct Extruder)

Like Creality and the Sprite Pro, Micro Swiss integrated an all-metal hot end with their well-engineered extruder in the Micro Swiss NG.

What differentiates this from the other contenders is its unique design. As Micro Swiss says, the beveled-gear design allows it to have the industry shortest filament path (lower than 41 mm), which can be highly useful for printing filament that can be fussy with retraction, such as TPU. Simply put, the shorter the filament path is from extruder to hot end, the lower the retraction it would theoretically need. As a bonus, it also comes with a high quality LDO stepper motor, which is widely regarded for its reliability and superior performance.

As for the construction, everything inside the assembly including the gears are made out of hardened steel. It also comes with a Micro Swiss All-Metal hot end, so printing high temperature filament shouldn’t be an issue either.

If you like what comes with Sprite Pro but mainly print flexible filament, we would highly recommend this one. The other features are similar to the Sprite Pro, but the shorter filament path will definitely come in handy for soft filament.

- What’s the max temperature it can reach? The Micro Swiss NG is capable of going up to 300 °C with ease. That means, you should have no issues printing materials like ABS, ASA, nylon, and PC.

- Is it anti-leak & anti-clog? Since the hot end is integrated with the extruder with minimal distance in between, it’s safe to say there will be no leakage issue with the Micro Swiss NG. While users haven’t reported any major issues with clogging, do note that it’s sort of troublesome to take it apart if it does clog.

- How much does it cost? ~$120

Biqu H2 500 °C (Direct Extruder)

These days, it’s fairly common for hot ends to support as much as 300 °C for printing ABS, ASA, and nylon comfortably. But Biqu’s H2 definitely surpasses them all with its ability to reach as high of a temperature as 500 °C!

What would you need it for? Well, printing exotic materials like PEEK and PEI requires a nozzle temperature of 350 °C to 400 °C, for which this would be useful. However, printing those on an Ender would require upgrading pretty much everything but the frame. So, it’s not really a major advantage for most users.

What’s useful though is its 70-watt heater, which would reduce initial heat-up time significantly and allow it to maintain temperature even during printing fast at a high flow rate. Paired with all-metal heat break made out of titanium and copper, and the nozzle being made out of hardened steel, it’s a great combination made with rigidity kept in mind.

The hot end seems to be highlighted the most by Biqu as they don’t really go into much details about the extruder. However, according to users, the extruder is lightweight and works just fine. One added advantage is that the stepper motor used in the extruder can withstand up to 180 °C. Therefore, printing in a heated enclosure (50-60 °C for ABS, ASA, and nylon) should be a smoother experience with this extruder as well.

In a nutshell, the Biqu H2 is a terrific choice for printing extremely high temperature filament (such as PEEK and PEI) in a high temperature environment. If you see yourself printing such exotic materials at some point and want a future-proof extruder and hot end capable of handling those, the H2 is perfect for that.

- What’s the max temperature it can reach? It can go up to 500 °C.

- Is it anti-leak & anti-clog? Since the heat break is made out of titanium and copper, the even heat dissipation makes it way less likely to clog.

- How much does it cost? ~$65

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.