With reasonable prices and high-quality filament, you’ve probably heard of eSun already if your a 3D printing fan. They’re well known for their own line of filaments as well as filament they’ve made for other companies.

eSun was founded in 2002, and at first, they focused primarily on researching and developing biodegradable polymers such as PLA and PCL. It wasn’t until 2007 that they looked at the applications of those materials in the 3D printing space. These days, they have one of the most extensive filament catalogs in the industry, ranging from PLA to PEEK, with so much in between.

What makes eSun stand out is their quality filament for a cheap price. While they don’t produce filament with remarkably high tolerances like Fiberlogy or Prusa, eSun still complies with the industry standard of +/-0.05 mm. Indeed, it’s one of the few brands that come recommended when people ask about affordable filament. Their quality is not sacrificed by the low price tag.

They’ve raised the bar, not so much for the premium brands, but for those competing on the lower end. With that in mind, let’s dive into what they have to offer!

PLA

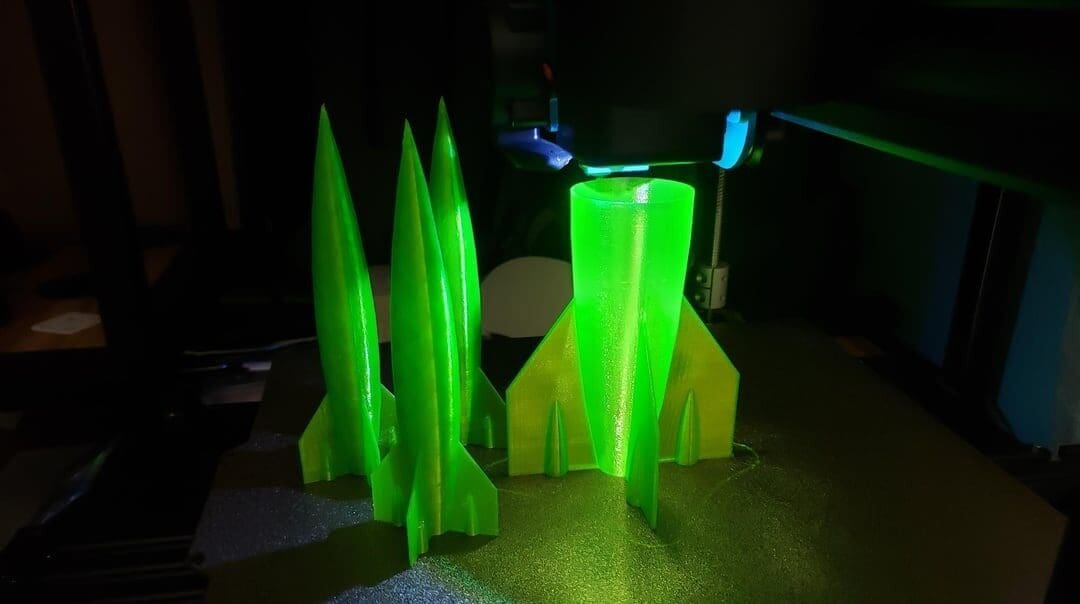

PLA is already a popular and abundant printing material due to its lower printing temperatures and minimal warping or stringing issues. This is the kind of filament that you can just hit print and let your machine run without having to dive deep into settings and printer tuning. PLA prints will look great with a smooth surface finish and even color. However, for more structural parts, such as load-bearing brackets, another material might be a better choice.

eSun’s PLA+, their own improved version of PLA, is the go-to filament for general 3D printing purposes. It boasts stronger mechanical features and even smoother prints compared to regular PLA.

PLA+ is eSun’s most popular material because of its price, performance, and wide range of colors. YouTuber Think Making, who reviewed and tested the PLA+ filament, echoed the community’s view, calling it a great choice for a budget filament with some desirable mechanical properties.

- Colors: 26, including three different hues of white, fire-engine red, and pine green

- Recommended settings: Hot end 200-230 °C, optional heated bed 45-60 °C

- Sizes: 1.75 mm; 1 kg

- Price: ~$24 for PLA+, $20-$50 for variants

Variations

- Refilament: PLA+ filament comes without a spool, meaning it’s simply spun into a roll and secured in place. These rolls can then be placed on reusable spools that the user can buy or print.

- Glass: This clear filament is the only remaining “normal” PLA offering, perhaps because PLA+ is only available in color options.

- eSilk PLA, Metal Silk: eSilk PLA is a filament that combines the ease of PLA printing with a silky and smooth finish, resulting in elegant and visually appealing prints. For a smooth metallic finish, check out Metal Silk, available in copper, silver, and gold.

- eSilk Magic, Mystic, Rainbow: Just like eSun’s eSilk PLA, these filaments have a silky finish but with interesting color play, too. The Magic and Mystic variants contain two or three colors, respectively, in the same spool of filament! This gives a color-changing effect to printed parts as you view them from different angles. The eye-catching Rainbow variant has all colors in the same line!

- Metal: This metal-looking filament is not infused with metal particles, but it’s described to have a “metallic luster” texture, providing prints with the appearance and feel of real metal.

- Luminous, Luminous Rainbow, eStars: These filaments make up eSun’s glow-in-the-dark PLA range. Luminous comes in blue or green, as well as a Rainbow color option. eStars is black in the light but glows starry green when in the dark.

- Wood: For aesthetic designs, consider this composite filament. It contains a mixture of wood particles and PLA to produce prints with a wood-like texture.

- eTwinkling: eTwinkling features fine glitter powder as an additive to give your prints some sparkle.

- Marble: This marbly-looking filament offers the appearance and texture of real marble, allowing you to create stunning and realistic prints that are perfect for architectural models and decorative objects.

- Matte: PLA Matte, also available as a spool-less refill, provides a smooth and non-glossy finish to printed objects, while also hiding layer lines.

- Gloss: If, on the other hand, you’re looking for an extra glossy finish, there are eight color options of Gloss PLA to choose from. Unfortunately, this filament seems to be difficult to find.

- ePLA Lite: This user-friendly filament offers similar properties to PLA but with reduced density, making ePLA Lite ideal for creating lightweight models and objects with minimal warping.

- ePLA-HS: Also called “-HF” (high flow), this HS (high speed) PLA is a high-performance filament with improved melt flow, allowing for faster and smoother prints.

- ePLA-ST: ST (super tough) PLA is designed for durability and impact resistance. It provides exceptional toughness and strength, making it suitable for functional prototypes, mechanical parts, and rugged applications.

- ePLA-LW: As a lightweight filament (LW) that offers reduced density while maintaining good strength, it’s perfect for applications where weight reduction is crucial, such as drone components or lightweight prototypes.

- ePLA-GF: This PLA is reinforced with 16% GF (glass fiber), offering enhanced strength and stiffness. It’s primarily available for purchase through certain retailers.

With these specialized ePLA materials, users have access to a diverse range of options to meet specific printing needs, whether for improved flow, toughness, strength, or lightweight properties.

PETG

PETG (polyethylene terephthalate glycol-modified) is another popular material for 3D printing. It’s a type of thermoplastic co-polyester that combines the strength and durability of ABS with the ease of use and clarity of PLA.

The biggest strength of eSun’s PETG is its excellent layer adhesion, which, combined with its great impact resistance, good flexibility, and low shrinkage, make it a highly reliable filament suitable for functional parts. PETG also has good chemical resistance and can withstand moderate temperatures.

You can use PETG as a versatile material for a wide range of applications, including toys, electronic products, and even food containers. Reddit users are fans of eSun’s PETG, but noted that some tweaking of retraction and print speed may be necessary.

- Colors: 16, including both solid and transparent options

- Recommended settings: Hot end 225-250 °C, heated bed 70-90 °C

- Sizes: 1.75 mm

- Price: ~$22 for PETG

Variations

- Refilament: Refill rolls for reusable spools that are the same material as regular PETG rolls.

ABS & ASA

ABS (acrylonitrile butadiene styrene) is another widely used material in 3D printing known for its durability. It’s commonly used in various industries, including automotive, aerospace, and consumer goods. Prints using ABS have excellent structural integrity, making them suitable for functional prototypes, end-use parts, and complex geometries.

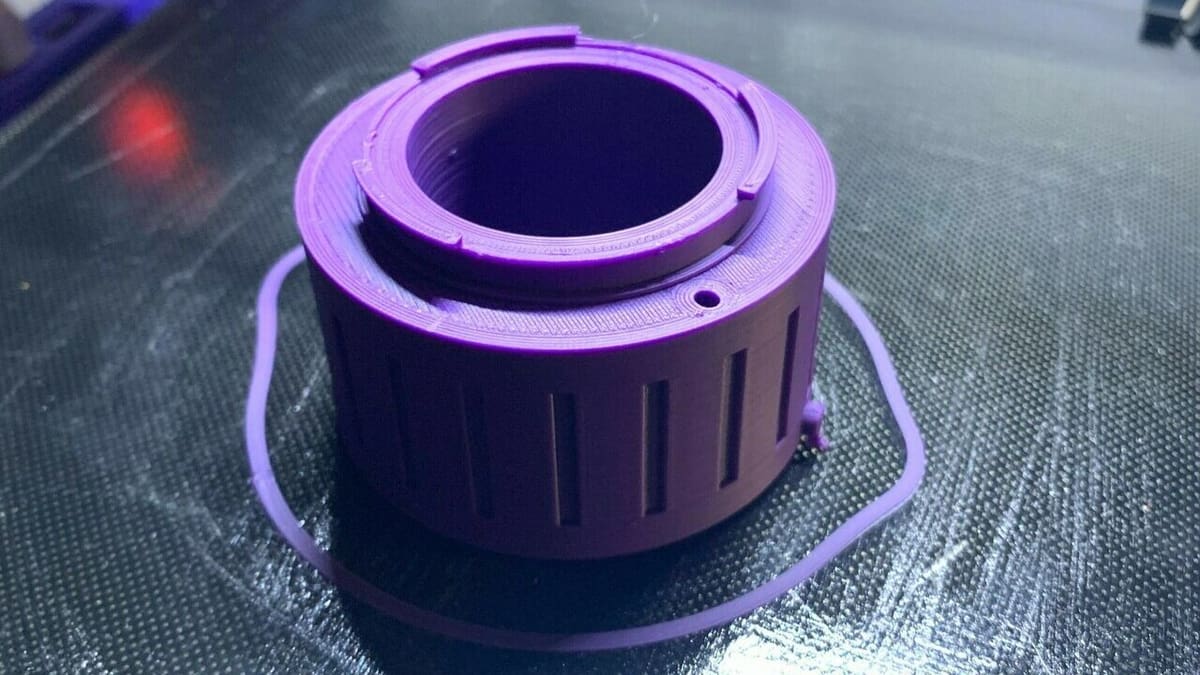

eSun’s ABS+, an improved formulation of regular ABS, is perfect for creating durable and stable parts. According to the company, their ABS is also heat- and scratch-resistant. While users do find that ABS+ is indeed easier to print than ABS, an enclosure is still needed for the best results.

ABS holds up well with many post-processing methods like sanding, painting, and acetone smoothing. However, it’s worth noting that ABS can emit potentially harmful fumes during the printing process, so proper ventilation is recommended when working with this material.

- Colors: 11 covering the basic range

- Recommended settings: Hot end 230-270 °C, heated bed 80-110 °C

- Sizes: 1.75 mm; 1 kg

- Price: ~$23 for ABS+, $22-$40 for variants

Variations

- ABS: The original ABS formulation seems to still be available in black, white, and gray.

- eABS Max: This maxed-out filament has further improved mechanical properties compared to ABS+, specifically for tougher, more demanding applications. It’s also flame retardant.

- eASA: ASA is very similar to ABS, however, it’s more resistant to weather and aging, making it perfect for outdoor applications. When printing this material, use the same print settings as ABS.

- Odorless: One of the biggest challenges of printing ABS is its odor. This formulation reduces the unpleasant smell, although it’s only available for purchase by contacting eSun directly.

TPU & TPE

TPU (thermoplastic polyurethane) is the most popular flexible material for 3D printing. TPU is an elastic polymer with excellent mechanical properties, making it ideal for creating objects that require both strength and flexibility. It’s known for its high abrasion resistance, durability, and impact absorption.

eSUN’s eTPU-95A is great for applications where you need a hard rubber. With a Shore hardness of 95A, it’s about as hard as the wheel on a shopping cart. There are other options for softer filaments, too.

Thermoplastic elastomer (TPE), a broader material category in which TPU falls, is very similar to TPU but has a wider range of properties.

TPU can be printed without too much difficulty due to its low melting point and good layer adhesion. However, some printers, like ones with Bowden extruders, have difficulty handling such an elastic material, especially with retraction settings.

- Colors: 12 colors, including rainbow and several transparent options

- Recommended settings: Hot end 220-250 °C, optional heated bed 45-60 °C

- Sizes: 1.75 mm; 1 kg

- Price: ~$35 for TPU, $35-$45 for variants

Variations

- eLastic (TPE-83A): eLastic is a flexible filament designed for exceptional stretchability and elasticity. This makes it suitable for producing parts such as rubber-like prototypes and wearable devices.

- eFlex (TPU-87A): Similar to eLastic, eFlex is also a highly flexible thermoplastic elastomer filament. Being TPU based, it’s a bit more rubber-like and durable.

- eTPU Antibacteria: This specialty filament possesses similar properties as regular TPU-95A but with the added benefit of inhibiting bacterial and fungal growth. This makes it ideal for applications such as medical equipment and food-handling products.

- TPU Color Change: Another modification of the TPU-95A, this time purely aesthetic. This magic material currently only comes in a bright red that changes colors to a yellow-orange at temperatures above 28°C!

Nylon

Polyamide (PA), also known as nylon, is one of the all-rounders of filaments: It’s durable, flexible, and heat resistant. Its main flaw, however, is that it’s difficult to print; you usually need an enclosure. On top of that, nylon filament absorbs water very easily; therefore, keeping it in a dry environment is a must.

eSun’s ePA doesn’t come with any surprises. As YouTuber Mom Will Be Proud discusses, nylon is more difficult to print than ABS. It loves to warp, and eSun’s, especially, has difficulty printing sharp corners. The best choice is to use a brim around the part to hold down any sharp edges.

Nylon filament can be used to create functional prototypes, intricate designs, and end-use parts, all with very high tolerances. It also provides good chemical resistance, allowing it to withstand exposure to oils, solvents, and various chemicals. Moreover, nylon’s low friction coefficient and self-lubricating properties make it ideal for contact parts and assemblies.

- Colors: Natural

- Recommended settings: Hot end 250-290 °C, heated bed 70-90 °C

- Sizes: 1.75 mm; 1 kg

- Price: ~$36 for ePA, $30-$90 for variants

Variations

- ePA-CF: This tough filament combines the benefits of nylon and reinforces it with 25% carbon fiber (CF), resulting in a lightweight yet rigid material suitable for functional parts and prototypes.

- ePA HT-CF: Designed for high-temperature (HT) applications, this nylon filament has 15% carbon fiber making it capable of withstanding elevated temperatures while maintaining its structural integrity.

- ePA-12, ePA12-CF: This nylon-12 variant is available in black or white, as well as with 15% carbon fibers, and is the most rigid and fatigue resistant of the PA filament offerings. eSun claims it also has fewer issues with moisture absorption compared to regular nylon filament.

- ePA-GF: eSun took ePA and replaced 25% of its weight with glass fibers to create this filament. These fibers give the material incredible rigidity and toughness, allowing it to even replace metal parts. It seems like this filament is only available for purchase by contacting eSun directly.

Dissolvable Materials

Unlike traditional support structures that need to be manually removed or cut away, soluble supports can simply be removed through dissolution in water or solvent, leaving behind a clean and intricate print.

These materials are particularly useful for complex designs with overhangs, cavities, or intricate geometries, where removing conventional supports can be time-consuming and challenging. Taking advantage of this unique property requires a multi-material printer, as it allows you to print both regular materials and dissolvable support material in the same layer.

eSun’s PVA is one the most popular dissolvable support material as it dissolves easily in water. With excellent adhesion to various other materials, it enables the creation of complex and detailed models. Its water solubility allows for easy removal, leaving clean prints behind.

- Colors: Natural

- Recommended settings: Hot end 190-220 °C, optional heated bed 45-60 °C

- Sizes: 1.75 mm; 0.5 kg

- Price: ~$50 for PVA and ~$25 for HIPS

Variations

- PVA+: PVA+ offers improved properties compared to regular PLA, although ordering can only be done directly through eSun.

- HIPS: Another popular dissolvable support material option, HIPS adheres well to various build surfaces and also has good dimensional stability. The material can easily be dissolved in limonene.

Engineering Materials

When filaments like PLA, ABS, PETG, or nylon aren’t strong enough, you should consider trying an engineering filament. These materials are designed to perform well in certain conditions, such as high temperatures, chemical exposure, or frequent impact, to name a few. Just be sure you have a printer that can handle them!

ePC

PC, better known as polycarbonate, is perfect for structural parts. Combined with its fire-resistance properties, it’s quite a versatile material and requires high temperatures to print well.

Interestingly, eSUN’s ePC filament has a lower printing temperature (235 to 260 °C) than other brands that offer PC. MatterHackers, for example, found that the best results were achieved at a minimum of 290 °C.

- Colors: Black, clear

- Recommended settings: Hot end 240-270 °C, heated bed 80-120 °C

- Sizes: 1.75 mm; 0.5 kg

- Price: ~$32

ePEEK

ePEEK is an engineering material specifically designed to withstand high temperatures and chemical exposure. It can handle temperatures up to about 200 °C. Obviously, you can’t print ePEEK with just a regular old 3D printer. You’ll need one specifically designed to print PEEK.

- Colors: Tan

- Recommended settings: Hot end 400-450 °C, heated bed 430 °C

- Sizes: 1.75 mm; 0.25 kg

- Price: ~$190

Specialty

These filaments won’t be your daily go-to filament (unless you print with a 3D pen), but they have their own niche.

eClean

eClean is a specialized cleaning filament designed to effectively clean and unclog 3D printer nozzles. It’s made from a proprietary formula that helps remove residual material buildup and contaminants from the extruder. This maintenance tool helps ensure the longevity and optimal performance of your 3D printer by preventing clogs and blockages.

- Colors: Natural

- Recommended settings: Hot end 160-300 °C

- Sizes: 1.75 mm; 0.1 kg

- Price: ~$14

eMate

eMate filament is a low-temperature PCL formulated to work with 3D pens. Its printing temperature is only 70 °C and printed parts can even be reshaped or recycled by immersion in 60 °C water.

- Colors: 26 colors, although availability is limited for some options

- Recommended settings: Hot end 70-100 °C

- Sizes: 1.75 mm; 0.1 kg

- Price: ~$15

e4D-1

This is quite a special filament with heat-induced shape memory properties. Once printed, you can deform your print only to bring it back to its original form by printing it in warm water! Unfortunately, it only comes in one color option. We hope this neat filament becomes more widely available soon.

- Colors: Natural

- Recommended settings: Hot end 200-230 °C, heated bed 45-60 °C

- Sizes: 1.75 mm; 0.5 kg

- Price: Contact eSun

Accessories

Adding to their filament lines, eSun makes accessories to bring the best out of those filaments.

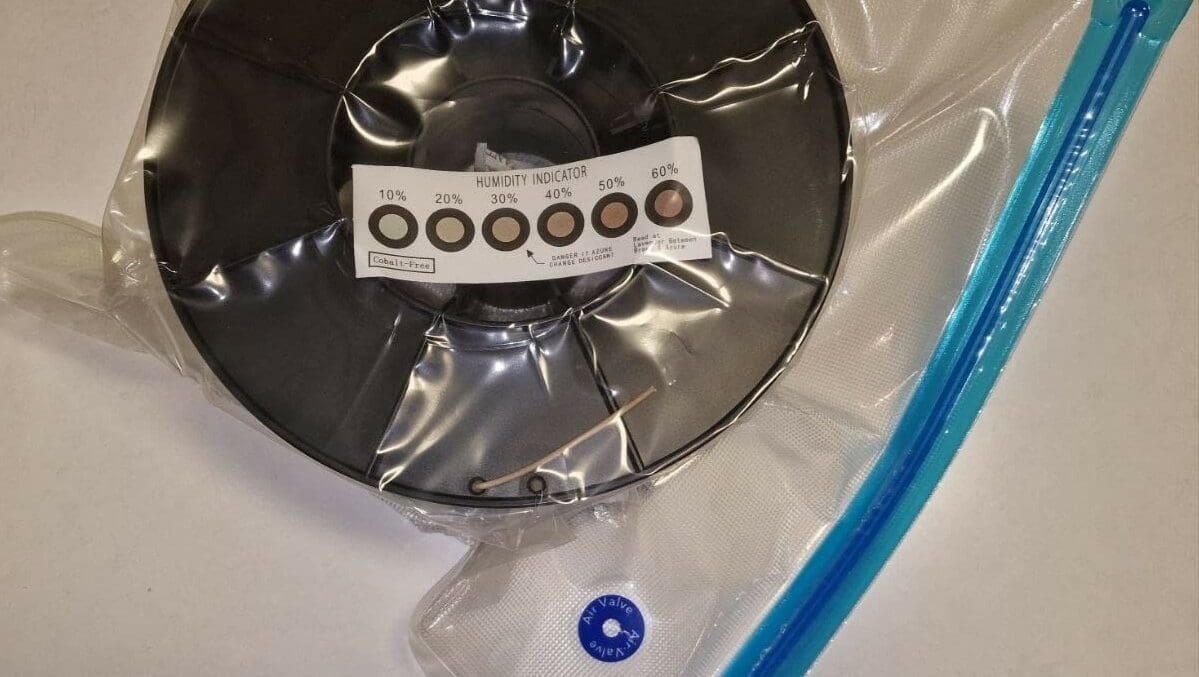

The biggest problem for 3D printing materials is that they absorb moisture, which leads to imperfect prints as the water vaporizes during printing, giving the filament a cratered look. These accessories are made to prevent and minimize this problem.

- eBox: The eBox is a filament storage solution that keeps your filament dry and tangle-free. The box can preheat your filament to dry it, something that is very important for materials such as nylon.

- eVacuum: The eVacuum kit is another storage solution that helps ensure your filament stays dry and doesn’t lose its mechanical properties. The kit comes with plastic bags that go around your spool, and then the included pump sucks all of the air out of the bag, ensuring your filaments can be stored unharmed. You can opt for a hand or electric-powered vacuum pump.

License: The text of "eSun Filament Buyer’s Guide" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.