eSun is a protagonist in the 3D printing material scene, producing both a variety of filaments and resins. The company was founded in 2002, initially focusing on developing PLA and PCL, and it wasn’t until 2007 that it entered the filament market with a wide range of materials. Eight years later, it began its journey in the resin market.

Now eSun sells its materials to nearly 70 countries, featuring 15 types of resins with different properties and use cases. These resins are used in medical fields, art, product design, and much more.

The vast majority of eSun resins are meant to be cured at a wavelength between 395 and 405 nm, and are compatible with LCD (MSLA) printers. These are the most common machines among hobbyists and makers. To make the 3D printing experience easy, eSun includes recommended settings for some of the resins and a few popular resin-based 3D printers. Even if these don’t meet your exact model, they’re a good starting point to create a resin profile in your slicer.

In this article, we’ll dive into eSun resins and their properties. Before starting, keep in mind that not all resins are available for purchase to retail customers. Some types of resins need to be bought in bulk or exclusively via eSun, and the pricing may not be listed. We’ve noted this where relevant. And last but not least, resellers might also offer more (or fewer) colors than eSun themselves, so browsing might be needed to find a particular hue.

And now, a few considerations before we jump into the list…

Before Printing

There are some important steps that you should pay attention to, to obtain great results when 3D printing with resin. eSun has shared some tips on how to use and store its materials properly.

First of all, since resins are cured by UV light, you should keep the bottle far from sunlight to avoid premature solidifying. If you pour resin into the tank with solid bits, you risk ruining your machine. In fact, if you start printing, the plate of the machine will lower all the way down and push these pieces into the FEP film, and you’ll have to replace it.

To avoid altering the resin’s properties, you should store it in a dry environment; plus, keeping it in a room that is cooler than 30 °C will help you preserve the material for longer. On the other hand, when printing you should make sure that the resin isn’t too cold, otherwise it won’t cure properly. The temperature should range between 20 and 30 °C, but don’t worry if that’s not the case – many machines now come with built-in resin heaters.

Before pouring the liquid into the vat, make sure to shake it well so that the pigments mix well with the resin. For this reason, eSun also suggests not leaving the resin in the vat for a long period, as well as mixing new resin with leftovers in the vat.

To avoid issues while printing and with the final model, make sure that it’s the right type of material for your printer. As we mentioned, different types of machines require different types of resins. Since most of the eSun resin formulations were designed to be cured with a wavelength between 395 and 405 nm, you’ll need a compatible machine to obtain the best results. The main types of resin printers (as accessible to hobbyists) are stereolithography (SLA), liquid crystal display (LCD), and digital light processing (DLP) machines. Some printers work best with proprietary materials, or the ones that are, for example, high resolution, show the best results with the corresponding resin.

When it comes to eSun, their resins are meant to be used with LCD printers, which are the most common machines among consumers, but many of them can also be used on DLP machines since they feature a similar curing wavelength of 405 nm.

With all this out of the way, let’s take a look at what resins eSun has to offer.

General

Let’s start with the most common type of resin: Standard. This material is perfect to begin your journey in resin printing, as every machine should come with a premade profile that works with it. It’s meant to be fast to cure, with a general exposure time that shouldn’t exceed 5 seconds per layer.

eSun includes a table for the suggested print parameters for some of the most common machines out there. It is a great base point to start with, and from there you can fine-tune your profile. You can find it on the Standard S200 page, under the “Download” tab.

Standard

The Standard resin is a great starting point. It features a handful of colors that you can choose from, in case you’re looking for variety. In terms of strength, it’s pretty rigid, offering a 78-82D Shore hardness. Thanks to this, it’s perfect for functional prototypes too.

- Viscosity: 170-200 mPa/s

- Density: 1.08-1.13 g/cm³

- Colors: Beige, black, white, transparent, gray

- Sizes: 0.5 kg, 1 kg

- Price per kg: ~$30

Standard S200

The Standard S200 resin is similar to the Standard, but it’s offered in macaron colors. The properties are similar but the S200 is slightly more rigid, providing a Shore hardness of 83-86D. This also increases its impact strength from the 14-42 GPa range to the 25-55 GPa range.

- Viscosity: 182-252 mPa/s

- Density: 1.107-1.109 g/cm³

- Colors: 11 options, including light blue, mint green, and peach pink

- Sizes: 1 kg

- Price per kg: ~$23

Standard S300

The Standard S300 was designed to be a high-precision resin. This makes it perfect for printing miniatures and for dental models too, although we’ll talk about dental resins further below. The Standard S300 requires a low exposure time – as low as only two seconds on the Photon Mono X! You can find more about the suggested print settings in the Download section of the Standard S300 page.

Keep in mind that the Standard S300 is available only for bulk purchases.

- Viscosity: 200-500 mPa/s

- Density: 1.05-1 .20 g/cm3

- Colors: Black, dark gray, red, white, yellow

- Sizes: 0.5 kg, 1 kg

- Price per kg: Not specified

Performance

eSun offers a wide variety of high performance resins that you can find in their Engineering Resins section. These materials provide different properties that are suited for many applications; let’s dive deeper into them!

Hard-Tough Resin

eSun’s tough resin was designed for high toughness and impact resistance, so it’s perfect for functional pieces. In fact, eSun resin features similar properties to eSun ABS+. The tensile strength of tough resin ranges between 30 and 60 MPa, depending on the settings used, while ABS+ offers 40 MPa. Furthermore, the elongation at the break of resin overtakes the one of ABS+, varying between 35-52% versus the 30% of ABS+.

- Viscosity: 200-300 mPa/s

- Density: 1.08-1.12 g/cm3

- Colors: Black, white, blue, gray

- Sizes: 0.5 kg, 1 kg

- Price per kg: ~$53

eResin-ABS and A200 eResin-ABS Pro

As the names imply, these kinds of resins aim to replicate ABS’ high-strength and physical properties. The test results speak clearly: ABS-Like and eResin-ABS Pro resins can compete with ABS filament. The tensile strength of A200 eResin-ABS Pro is 68-83 MPa, with eResin-ABS only slightly lower at 42-62 MPa versus 40 MPa of eSun ABS+. This makes these resins perfect for mechanical applications. You can also drill holes without cracking eResin-ABS Pro prints!

Unfortunately for makers who only want to buy small quantities, eResin-ABS Pro is available only for bulk purchases. The details below are only for e-Resin-ABS.

- Viscosity: 200-350 mPa/s

- Density: 1.05-1.13 g/cm3

- Colors: Black, gray, white, beige

- Sizes: 0.5kg, 1kg

- Price per kg: ~$60

PA100 Nylon-Like Resin

Nylon-like resin is a high-strength resin designed by eSun specifically for engineering and manufacturing applications. Its tensile strength overtakes the brand’s nylon filament with a whopping 68 MPa versus 52.45 MPa. Its properties make this resin ideal for mechanical parts that need to be durable. Furthermore, it’s perfect for assemblies where your pieces need to move or rotate at high speed.

Since it was designed for functional pieces, it’s produced only in white, so it is not the most suited for aesthetic applications.

- Viscosity: 500 mPa/s

- Density: 1.05-1.15 g/cm3

- Colors: White

- Sizes: 0.5 kg

- Price per kg: ~$122 (0.5 kg for ~$66)

F300 eResin-Flex and E100 eResin-eLastic

As the names of these resins suggest, they’re meant to be flexible. In particular, F300 eResin-Flex features a Shore hardness that ranges between 60 and 90A, depending on the settings, while E100 eResin-eLastic provides a 70A Shore hardness. These values are reflected also by the elongation at break tests, with a noteworthy range of 100-350% elongation at break! With these properties, these resins are perfect for objects that need soft and elastic or are subject to bend.

F300 eResin-Flex is only available for bulk purchasing.

- Viscosity: 500-1400 mPa/s

- Density: 1.02-1.085 g/cm3

- Colors: Transparent yellow

- Sizes: 0.5 kg

- Price per kg: Not specified

HS100 High Speed Resin

As you might have guessed, HS100 High Speed Resin was formulated to be printed at high speed with half the average exposure time of Standard resin. This material is perfect for rapid prototyping and tall prints with an average time save of 72% compared to the standard option! eSun recommends this material for miniature printing – it’ll sure save on time if many models need to be printed.

On the downside for hobbyists who might not need that much high speed resin, this material is only available via bulk purchasing.

- Viscosity: 183 mPa/s

- Density: 1.14 g/cm3

- Colors: Gray

- Sizes: 0.5 kg, 1 kg

- Price per kg: Not specified

S1003 Standard Resin

Despite its name, the S1003 Standard Resin isn’t standard. In fact, it’s a high-toughness resin that’s meant to be less brittle than Standard resin. It offers a great IZOD impact strength that ranges between 29 and 50 J/m. It’s designed for SLA machines, with a curing wavelength of 355 nm. This makes it suitable for the vast majority of SLA 3D printers on the market.

Given its specifics, it’s not surprising that it’s only available for purchase in bulk or via agency.

- Viscosity: 250-410 mPa/s

- Density: 1.08-1.16 g/cm3

- Colors: White

- Sizes: 5 kg

- Price per kg: Not specified

Water-Washable

As the name implies, this resin is washable with water. The vast majority of resins require isopropyl alcohol to be washed properly before curing. Because IPA is expensive and can be difficult to purchase, many people prefer using water-washable materials.

eSun offers two water-washable resins at time of writing.

Water-Washable

This resin is similar to Standard resin but, as we have explained above, it can be washed with water. This material isn’t meant to be used for functional parts, but rather for aesthetic ones, such as jewelry or figurines. Because of this, it’s produced in many different colors that you can choose from. It also features less odor and great fluidity thanks to its low viscosity.

- Viscosity: 110-180 mPa/s

- Density: 1.10-1.14 g/cm3

- Colors: 13 options, including transparent green, peach puff, and transparent red

- Sizes: 0.5 kg

- Price per kg: ~$60 (0.5 kg for ~$28)

PW100 PLA Water-Washable Resin

PW100 PLA Water-Washable Resin is produced with eSun PLA polyol, making it a bio-based material. It’s compatible with both color and monochromatic screen printers and, like the standard water-washable resin, it’s meant to be used for aesthetic components rather than functional parts.

eSun has given some suggestions for post-processing this kind of resin. In particular, they recommend washing it with water for a maximum of one minute and drying it before curing. If you don’t follow these steps, water may damage your print – especially models with many details.

- Viscosity: 160-360 mPa/s

- Density: 1.08-1.20 g/cm3

- Colors: Brown, black, gray, white, red

- Sizes: 0.5 kg, 1 kg

- Price per kg: ~$80

Specialty

The list of eSun resins is not yet complete! Next, we’ll delve deeper into materials that don’t belong to previous categories but which offer useful properties of different kinds. These may have unique characteristics that make them suitable for specific applications, and it’s important to explore their features to understand the full range of options available.

If you haven’t found the right material for your project between the previous items, you’ll surely discover it there!

eResin-PLA and eResin-PLA Pro

PLA-Like resins are plant-based resins that are synthesized from corn, like PLA plastic. This makes them safer to use and less irritant in case of contact with skin. Despite this, it’s always better to wear gloves when handling resins.

These materials provide great rigidity and a 75-82D Shore hardness, so they’re suitable for functional applications. You can use them for aesthetic prints too, thanks to the wide range of available colors.

eResin-PLA also cures relatively fast, with an exposure time between 4 and 8 seconds, as suggested by eSun for the Elegoo Mars Pro. But PLA Pro-Like really shines with a single-layer exposure time that can be as little as 1.8 seconds on a monochrome printer! This makes the achievable print speed as high as 60 mm/s! In fact, one of the peculiarities of this resin is that it has been developed to be the best resin for machines that use black and white screens. Furthermore, it was designed to feature mechanical properties similar to PLA+. The goal has been successfully achieved with test results similar to the plastic ones and with an impressive elongation at break that is more than twice eSun PLA+’s!

- Viscosity: 100-400 mPa/s

- Density: 1.05-1.10 g/cm3

- Colors: 11 eResin-PLA options, including red, clear, and grass green; 7 eResin-PLA Pro variations, including beige, orange, and sky blue

- Sizes: 0.5 kg, 1 kg

- Price per kg: ~$30 (eResin-PLA); ~$37 (eResin-PLA Pro)

PM200 PMMA Like Resin

The main characteristic of the PM200 PMMA Like Resin is transparency. It’s similar to clear resin but after grinding, polishing, and oil spraying it becomes even clearer. This makes it perfect for applications where transparency is key, since it resembles a glass or acrylic appearance. Additionally, it’s formulated to avoid yellowing. If you cure it for too long, though, it can become yellow, but you can keep it away from UV light to restore the original transparency.

Unfortunately, this resin can’t withstand high temperatures.

- Viscosity: 200-600 mPa/s

- Density: 1.05-1.15 g/cm3

- Colors: Clear

- Sizes: 0.5 kg, 1 kg

- Price per kg: ~$300

MA100 Matte Resin

Named after its appearance, the MA100 Matte Resin is a matte resin that resembles a clay finish. This specialized resin was designed for high-detail 3D prints, making it an ideal choice for intricate models and figurines that need precision. The low viscosity of this resin ensures that it is easy to work with and allows for smooth printing, resulting in a high-quality finish. Furthermore, with a curing wavelength of 405 nm, this material is compatible with a wide range of both LCD and DLP 3D printing machines.

This special material is only available for bulk purchasing or via agency.

- Viscosity: Not specified

- Density: Not specified

- Colors: Gray clay, red clay, white clay

- Sizes: 0.5 kg, 1 kg

- Price per kg: Not specified

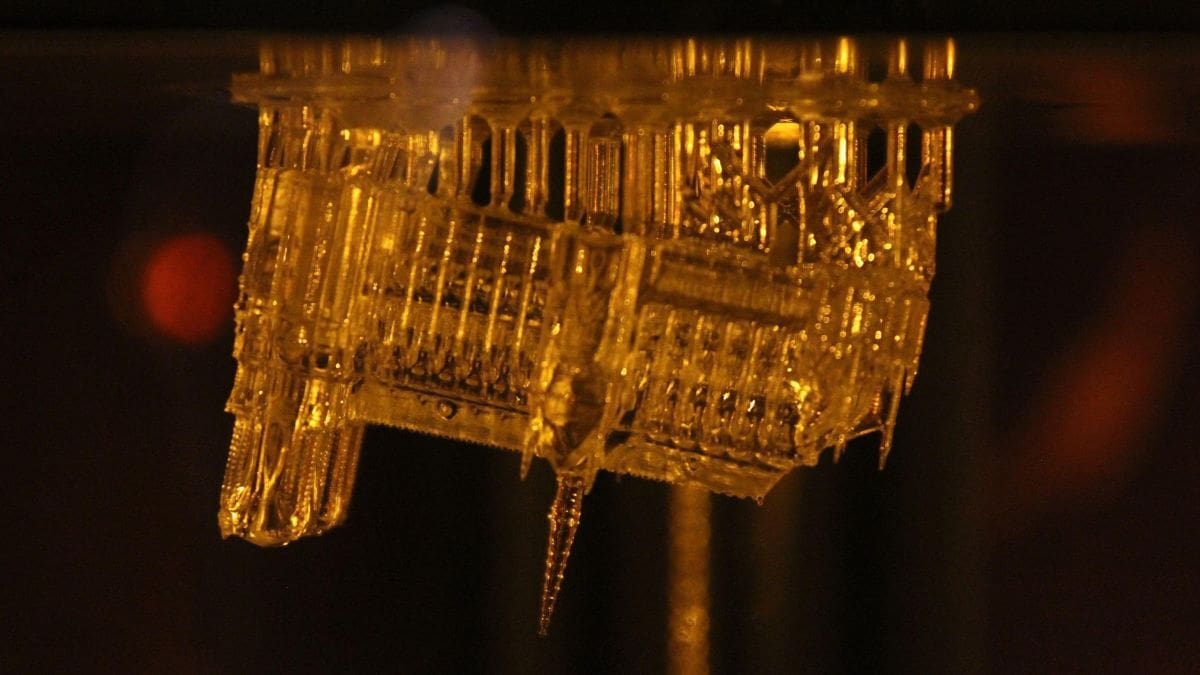

Precision Model Resin

This resin was formulated for high molding precision and resolution. The surface finish of the parts printed with this material is smooth, ensuring that the model details are clearly defined and visible. These characteristics make the Precision Model Resin particularly suitable for jewelry production, figurine printing, and educational models.

- Viscosity: 170-270 mPa/s

- Density: 1.13-1.16 g/cm3

- Colors: Orange-red

- Size: 0.5 kg

- Price per kg: ~$120 (0.5 kg for ~$60)

JC100 Castable Resin For Jewelry

Although we’ve mentioned several resins that are a good fit for jewelry manufacturing, none of them was specifically designed for this purpose. That said, the JC100 Castable Resin For Jewelry was developed precisely for this – specifically for casting. It leaves minimal ash and residues after burning and it ensures high details and precision that are essential for jewelry. It can be used for gold, silver, and copper models.

It’s worth noting that, given it’s more professional applications, it’s only available for purchase in bulk or via agency.

- Viscosity: 100-150 mPa/s

- Density: 1.05-1.12 g/cm3

- Colors: Green

- Size: 1 kg

- Price per kg: Not specified

Dental Resins

Dentistry is an industry where 3D printing has been and continues gaining space. According to a report released by the market research firm MR, the global dental 3D printing market is worth about $1 billion and it is expected to reach about $3.4 billion by the end of 2025!

eSun is part of this revolution in dentistry, offering eight different resins for this field with numerous applications. OM100 Ortho Model Resin is suitable for high-temperature resistant dental models. WO100 Water-Washable Ortho Model Resin is, as its name anticipates, water washable, while DM100 Dental Restoration Model Resin was developed for high-precision dental models. For very specific uses, you can find resins for gingival models, custom trays, implant guides, dental casts, and temporary crowns and bridges.

As can be imagined, all these materials are available only via bulk or agency.

- Viscosity: Not specified

- Density: Not specified

- Colors: Depends on specific type, but gray and pink recur

- Sizes: 0.5 kg, 1 kg

- Price per kg: Not specified

Accessories

In addition to resins, eSun offers also some accessories for resin printing, in particular for the post-processing phase. After the 3D printer has finished the part, the model needs to be washed and cured before it can be considered finished. The washing process eliminates any excessive resin that might have remained on the model and that can ruin its detail in the curing process. Once the piece has been washed and dried, you can cure it with UV light to complete the solidifying process.

eSun offers two machines for this last phase of the resin printing workflow. In particular, its listing provides a consumer machine and a professional one. Let’s take a look at them!

eCure Lite

This curing machine was designed for consumers and can be used to complete your projects, regardless of the type of 3D printer you use. The eCure Lite is made up of three main components: a UV lamp, a rotating table, and a foldable enclosure. The lamp features four 405-nm lamp beads to ensure uniform curing.

You can either hold the lamp to cure a specific area or you can unfold the enclosure and place the lamp on it. At the base, the rotating table helps ensure that all the areas of the print can be evenly cured. Once you’ve finished, you can fold back the enclosure and store it, making this machine a perfect solution for those who lack space.

- Price: ~$37

eCure Pro

The eCure Pro was designed for professional use and is available only via agency for purchase. This light box features no less than 16 multi-angle lamp beads! This guarantees a smooth and uniform curing. Each lamp has a power of 3 watts to speed up the process and the lamps should last a good 20,000 hours.

You can set a desired curing time with a minimum value as low as a single second. The maximum curing cycle is 10 minutes, which should be plenty for the vast majority of projects, even bigger ones. In fact, this light box measures 300 x 300 x 250 mm, providing plenty of space for curing prints – even multiple parts at once. With the rotating platform, you won’t have any problem obtaining a uniform curing.

- Price: Not specified

License: The text of "eSun Resin Buyer’s Guide – An Unexpected Variety" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.