A Conceptually Simple Technology

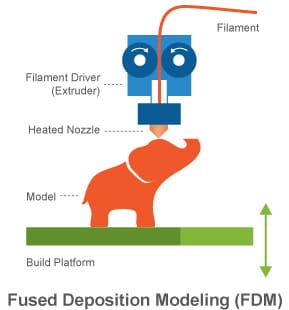

A fused filament fabrication (FFF) printer works in the following way.

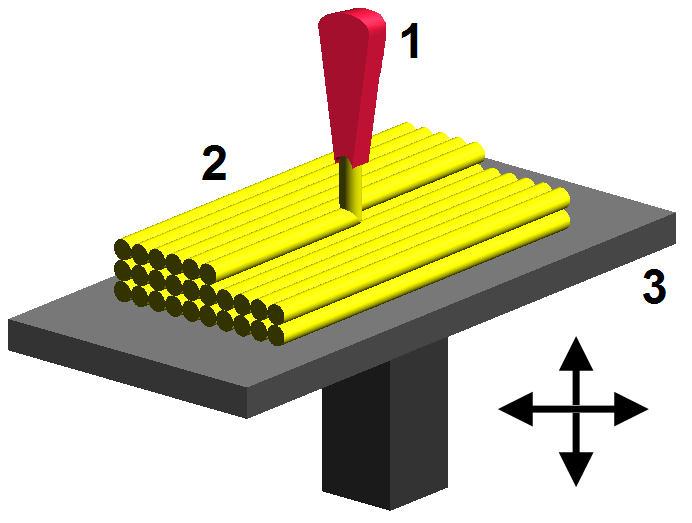

A heated nozzle (1) ejects molten plastic, depositing it in thin layers, one on top of another (2), onto a print bed (3), eventually forming the 3D printed part. In order to draw a particular pattern, the nozzle or the print bed (or both) move while plastic is being extruded. Prior to printing, slicing software determines how to break a 3D digital model into layers that the printer is able to print.

A variety of designs of FFF printers are available. Variations exist in the mechanisms used to move the print head as well as whether extruders use filament, pellets, or paste. For more information, refer to our article Fused Deposition Modeling (FDM) – 3D Printing Simply Explained.

Behind the Name

FFF 3D printing is a form of additive manufacturing where filament is fused together to fabricate a solid part.

Members of the RepRap project came up with the term as an alternative to the term fused deposition modeling (FDM) because Stratasys, owner of several patents on the process, had already registered the FDM trademark in 1991.

A History

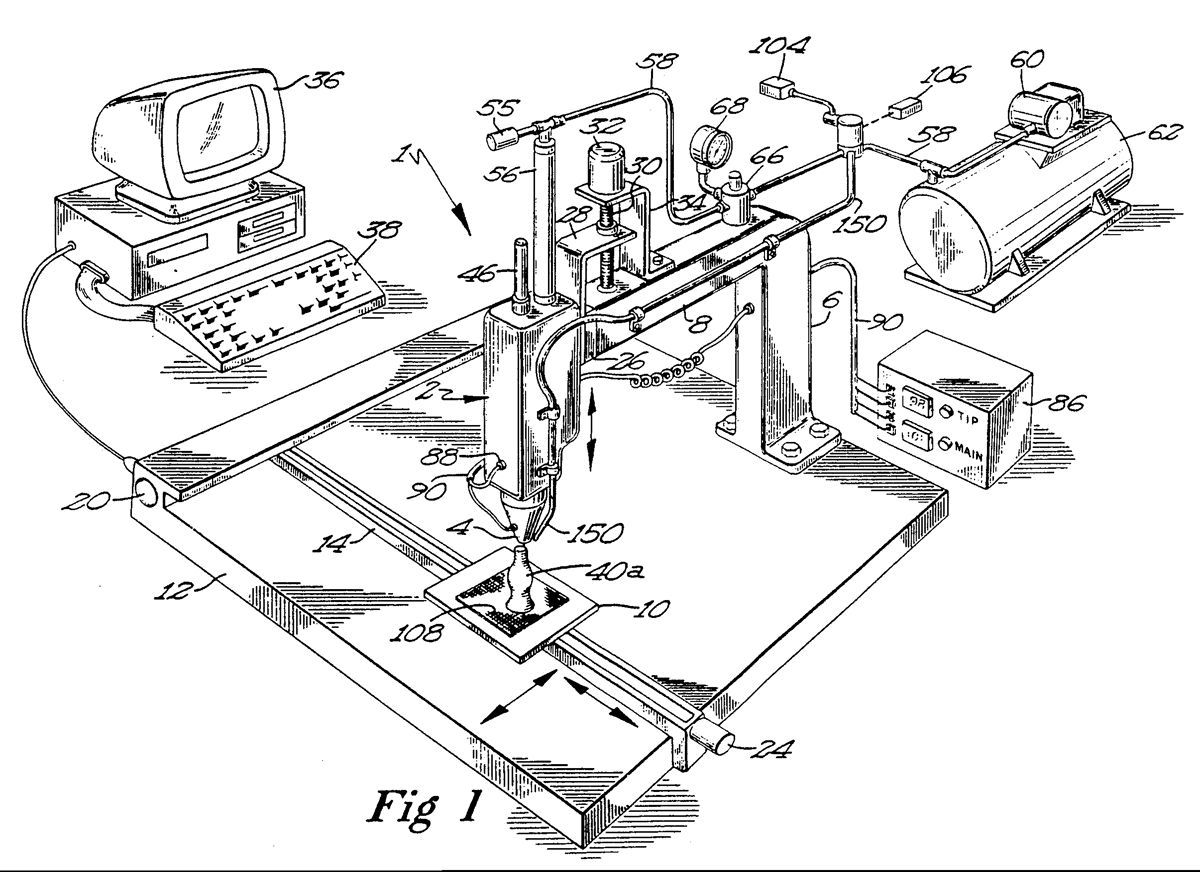

The FFF process was invented in the late 1980s and commercialized in the 1990s. S. Scott Crump was awarded U.S. Patent Number 5,121,329, entitled Apparatus and Method for Creating Three-Dimensional Objects. It was granted on June 9, 1992, and assigned to Stratasys, Inc.

Stratasys commercialized the technology with a series of 3D printers, including the FDM 300, FDM Maxum, and FDM Titan. Since the patent has now expired, other companies are now free to market products based on this technology, although Stratasys still maintains their trademark rights.

Benefits

Here are some of the benefits of FFF:

- Large selection of materials, including many common thermoplastics, wood and metal-infused thermoplastics, and even food (such as chocolate).

- Least expensive printer technology.

- Least expensive materials.

- Easy to switch materials.

- Possible to print using multiple different materials.

- Printers and materials offered by many manufacturers.

- Relatively easy to build your own printer.

- Fast printing.

The major disadvantages of FFF are the following:

- The detail of finished prints is limited by the size of the nozzle. Other technologies offer higher detail.

- The strength of finished parts is limited because each layer is joined to the layer below it.

Additional Information

For more information, check out the following articles: