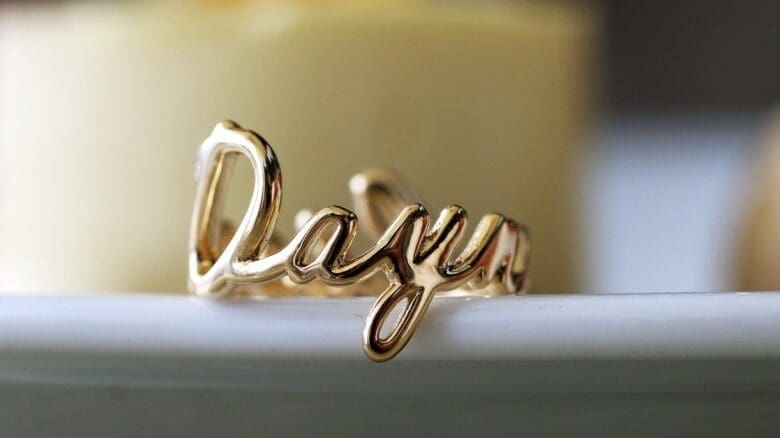

The wide availability of 3D printing services and the ease of use of computer-aided design software have transformed the jewelry industry. Today, virtually anyone can design, produce, and sell unique, quality jewelry online—or make it just for themselves.

There’s no denying why more jewelry designers are turning to 3D printing to craft jewelry: the design freedom, the low upfront investment, the speed, but even large jewelers are taking advantage of 3D printing for jewelry at production volumes because it’s faster and more economical than producing individual pieces in-house.

3D printing custom gold jewelry requires a digital design of your piece; from there, it can be as easy as uploading to a 3D printing service.

Let’s look at where to turn to get your jewelry 3D printed in gold (for silver check out: 3D Printing Silver: How to Get Silver 3D Printed) as well as the top places to sell it.

How is Gold Jewelry 3D Printed?

Practically all jewelry today starts with a digital design file created in software. There is a wide range of software programs to use and some are even unique to jewelry offering templates and workflows. Jewelry focused application, such as CrossGems, Stuller’s MatrixGold, and CounterSketch, plugin to larger computer aided design (CAD) programs like Rhino and are used by professional jewelers, while JewelCraft for Blender and Jewelry CAD Dream make jewelry design more accessible to beginners.

If your goal is to replicate an existing gold piece, you can use a 3D scanner to create a detailed digital file, then bring that into your design software.

Once you have your digital file, ordering it in gold is as easy as uploading it to a 3D printing service, like the ones we cover below. However, first, it’s important to understand the process the service will provide: wax casting, directly 3D printing, or plating.

Wax Casting Gold Jewelry

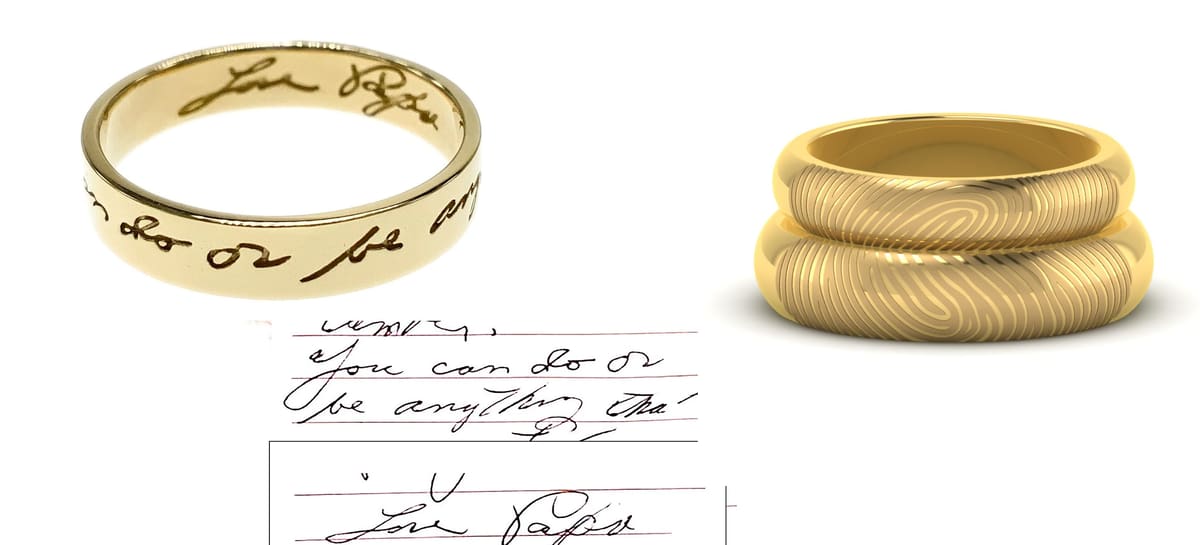

At most 3D printing services, your ring, for example, will not be “directly” 3D printed in gold. The service provider will 3D print your digital fine in a very high-resolution wax material or a “castable” resin like the models above in purple. The model is then dipped in a casting material, like a plaster or ceramic. This is then heated to melt out the wax, leaving a hollow mold into which molten gold is poured.

This is exactly the same “lost wax casting” method used by jewelers for centuries. Jewelers have long hand-carved wax, but today, it is more often 3D printed.

Directly 3D Printing Gold

Directly 3D printing gold is not as common as wax casting, but is possible with industrial 3D printers.

Gold in powder form is loaded into the vat of the 3D printer and then a laser fuses the metal powder together layer by layer to make a fully metal part. This process is called metal laser powder bed fusion (LPBF).

Another 3D printing technology that can produce solid gold parts is called binder jetting. In this method, an inkjet head distributes fine droplets of a binding solution onto a very thin layer of gold powder in the shape of one layer of the jewelry. More powder and binding agent is added until the entire part is finished. Once complete, the part is sintered in a furnace to remove the binding agent and produce a solid gold part.

These pieces are then finished with polishing.

Directly 3D printing jewelry is not yet a common option at 3D printing services for entrepreneurs because of cost factors. Today, only large commercial jewelry manufacturers are turning to direct 3D printing because it’s more economical to produce batches of high-end custom orders. If you’re looking to print in low volumes or on-demand, your only option at a 3D printing service is lost-wax casting.

Despite the advantage of being able to directly 3D print gold, LPBF and binder jet machines are expensive, starting at around $300,000, and not all can accommodate gold. Plus, you’ll need an investment in gold powder to fill the powder bed for each print run.

More custom jewelry companies, however, are adopting 3D printing because it accelerates custom jewelry production. In one print run, you can print a dozen rings or more, where each one is different. It’s a direct digital model-to-printer process, eliminating the time-consuming steps of printing the model in wax and making the mold before pouring the metal.

Another benefit is the ability to quickly produce jewelry samples without molds. There is also the design complexity of parts only possible with 3D printers, and the ability to print only on demand, which eliminates stock and enables jewelry companies to react quickly to the latest jewelry trends.

Industrial 3D Printers with Gold as a Certified Material

- Sissma Mysint – 100 (LPBF)

- Desktop Metal Production System P-1 (binder jetting)

- EOS M100 (LPBF)

- GE Additive Concept Laser Mlab R (LPBF)

Gold Plating Over 3D Printed Plastic or Metal

If the price of solid gold jewelry doesn’t appeal to your target customer, you can 3D print your collection in stainless steel or even a lightweight plastic, then have it electroplated in gold. Few 3D printing services offer electroplating, but there are many electroplating services where you can send your 3D printed parts. The process would go from your digital file to a 3D printing service, where you’d receive your jewelry in metal or plastic, then you’d send these parts to a plating company locally.

Craftcloud is one of the only few remaining options for electroplating your 3D prints in precious metal. Craftcloud offers plating in 18k Gold, 14k Gold, 14k Rose Gold, 18k Rose Gold, and 9k Gold.

Gold 3D Printing Services

Using a service is much cheaper (and safer) than setting up an investment casting workshop in your garage. It also brings the high-quality results only possible with industrial machines right to your doorstep.

In fact, most of the small jewelry entrepreneurs you’ll find online or at marketplaces like Etsy or eBay custom-design jewelry, then use a service like the ones below to produce the pieces on demand.

We’ve selected the top gold 3D printing services below and scoured their offering for the key decision-making metrics you’ll need, such as the type of gold and the technology to choose from.

To give you a sense of cost for 3D printed gold jewelry, we uploaded the same basic ring design to each provider and ordered it in 14k gold.

Where to Sell Your Custom Jewelry Collection

With software, 3D printing services, and the internet, anyone can fulfill their dreams of becoming a jewelry designer.

Although there’s nothing at the moment that combines a marketplace with a 3D printing service, small jewelry businesses can launch their own websites to house their collections or use a marketplace like Etsy, take orders, and have pieces produced at 3D service providers.

Craft and jewelry marketplaces, such as Etsy, are a growing stage where you can get your designs in front of shoppers. In fact there’s an entire section on Etsy for custom and personalized jewelry.

Another potential outlet is social media platforms, such as TikTok, Instagram, and Facebook. One custom 3D printed jewelry maker, Cloud Factory, creates unique jewelry pieces for social media influencers to sell to their followers, which also brings the company traffic to their own shop.

You May Also Like:

License: The text of "Turn Digital Designs into Gold: How to 3D Print & Sell Your Own Jewelry" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.