Introduction

3D printing has been around for decades but has experienced a surge of popularity in recent years. The beauty of 3D printing is that it’s a simple technology that can be applied to all sorts of fields. It’s lowered the barrier for anyone to design and create and opened up opportunities to streamline processes already in place.

Without further ado, here are five big applications for 3D printing in 2019.

Education

More and more schools are incorporating 3D printing into their curriculum as tools to better prepare kids for the future. Makerspaces, equipped with printers, CNC machines, and other tools, have become common. Also, 3D printers can be found in public libraries already. Most universities have at least one (if not several) 3D printers for students to use for classes or their own projects.

Not only do 3D printers allow students to create in completely new ways, but there’s also a lot of potential for educational models. From frog dissection kits to creating tessellations, free models are available on STL file repositories that can be used to educate.

Prototyping & Manufacturing

3D printing was originally developed as a faster alternative of prototyping – so it’s no surprise it is still a useful application in 2018! A big advantage of using 3D printing is its versatility and flexibility, which makes it perfect for small-scale manufacturing and prototyping.

An injection-molded prototype might cost hundreds of thousands and take weeks to make a single mold. That’s not good if you’re trying to iterate and improve on each design. Invest in a 3D printer, however, and your prototype can be sitting on your desk in hours, at a fraction of the cost.

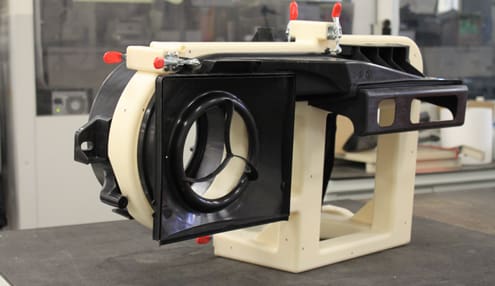

This also makes 3D printing perfect for situations where your product may not be mass-produced. Traditional manufacturing is only effective at large volumes, but a 3D printer allows companies to produce on a case-by-case basis. For example, MAHLE, an automotive parts supplier, used 3D printing to produce a custom fixture for their assembly line.

Medicine

In recent years, there’s been a lot of 3D printing applications to the world of medicine, from bioprinting and surgery preparation to prosthetics. This field is still under a lot of research, so it’ll be exciting to see where it goes in the future!

3D printed prosthetics are a helpful application of 3D printing’s versatility. It’s notoriously difficult and expensive to produce prosthetics that fit its patient, but open-source centric companies like eNABLE work against that.

Measured prosthetics can be modeled, and 3D printed at a dramatically lower price. Children who previously had to wait to get prosthetics they wouldn’t grow out of can now afford to 3D print a new one every few months. Those from third-world countries where prosthetics may not even be an option can take advantage of 3D printed ones.

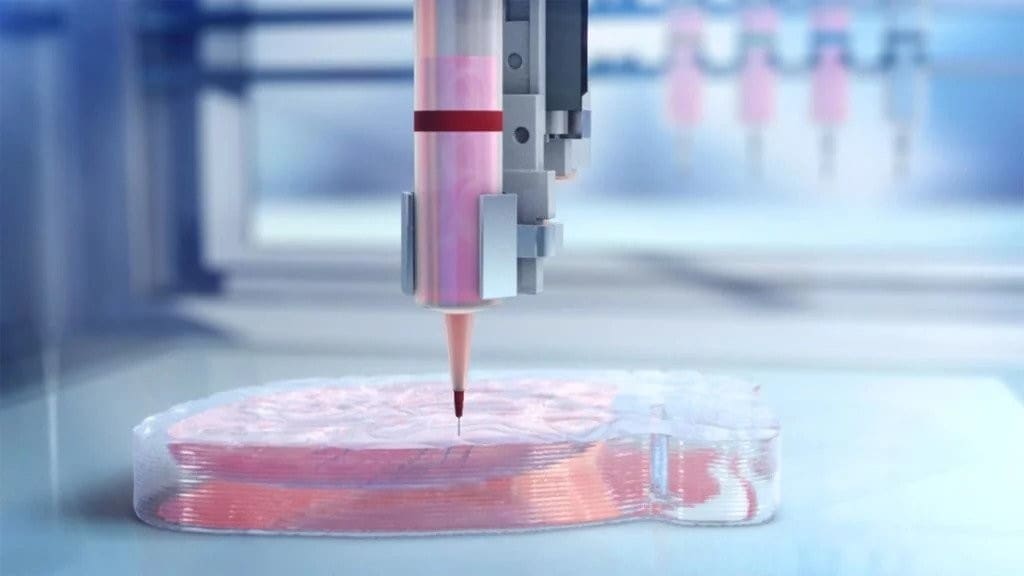

An application that’s a little farther in the future is bioprinting, or 3D printing cells and tissue. The dream is that one day, we’ll be able to 3D print bones and organs for patients who need them, rather than waiting for donors. For now, we’re still working on bioprinting human tissue.

Construction

Another exciting application of 3D printing is in construction. Concrete 3D printing has been in development for years as a fast and cheaper way to build buildings. Large-scale 3D printers specially designed to print in concrete can pour foundations and build walls onsite. They can also be used to print modular concrete sections that are later assembled onsite.

For example, this 3D printed concrete bridge in Shanghai, China was printed in 450 hours at two-thirds of the usual cost. It was also installed with detectors that relay information about stress and strain so the city can monitor its status in real-time.

That’s not all, though. Researchers are also investigating how 3D printing could be useful in colonizing Mars. If humanity ever wants to build a colony on Mars, it would be impractical to send up construction materials from Earth. Instead, we could turn Mars rock into 3D printable material, and send up 3D printing robots to construct habitats before humans arrive.

Jewelry

One unexpected application of 3D printing is in the fashion industry. 3D printed jewelry has become a popular niche for those searching for a unique look.

With the introduction of 3D printers, jewelry-makers can experiment with designs not possible using traditional jewelry-making methods. In addition, 3D printers make it cheaper to produce individual, unique pieces of jewelry or customize pieces for customers.

Jewelry is especially popular on 3D printing sites such as Shapeways or i.materialise, where you can order jewelry in PLA, gold, or even platinum. From rings to necklaces to earrings, check out some of these gorgeous pieces here.