Defining Resolution

Resolution is one of the crucial factors to consider when evaluating the print quality of 3D printers, especially when determining whether a machine is a high-resolution 3D printer. But manufacturers use different methods to define resolution; layer height is one commonly cited standard.

However, the resolution is more than the layer height that most people are accustomed to. In fact, layer height is a poor representation of resolution because it only factors in the Z resolution and ignores the XY plane.

The reality is that the planar dimensions (X and Y) and the Z dimension must work together to give the print its volume.

XY Resolution

The XY resolution (horizontal resolution or minimum feature size) is the smallest movement (on the horizontal plane) made by the print head within a given layer. Therefore, the lower the value, the higher the resolution, which means high detail in the print.

It’s possible you will see a value given for the X/Y resolution on a printer’s specification sheets, but given the complex nature involved in measuring this, it is not always accurate.

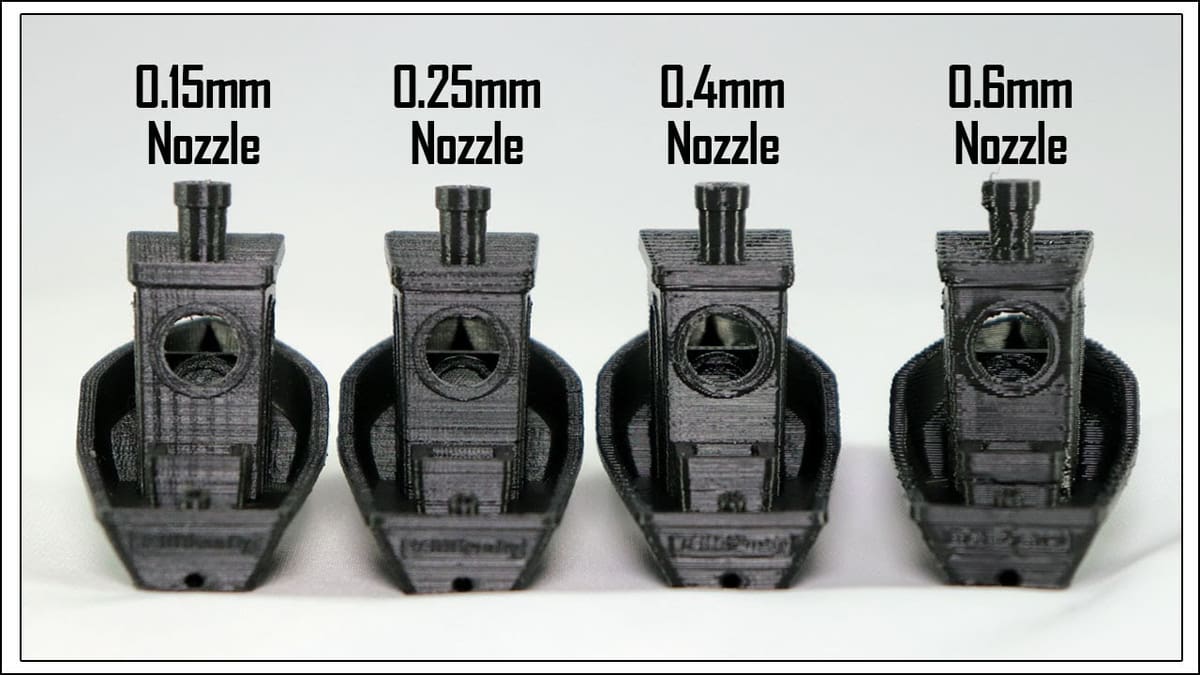

For day to day judgment of the XY resolution is a function of the nozzle diameter. Therefore, the smaller the nozzle, the higher the resolution.

Z Resolution

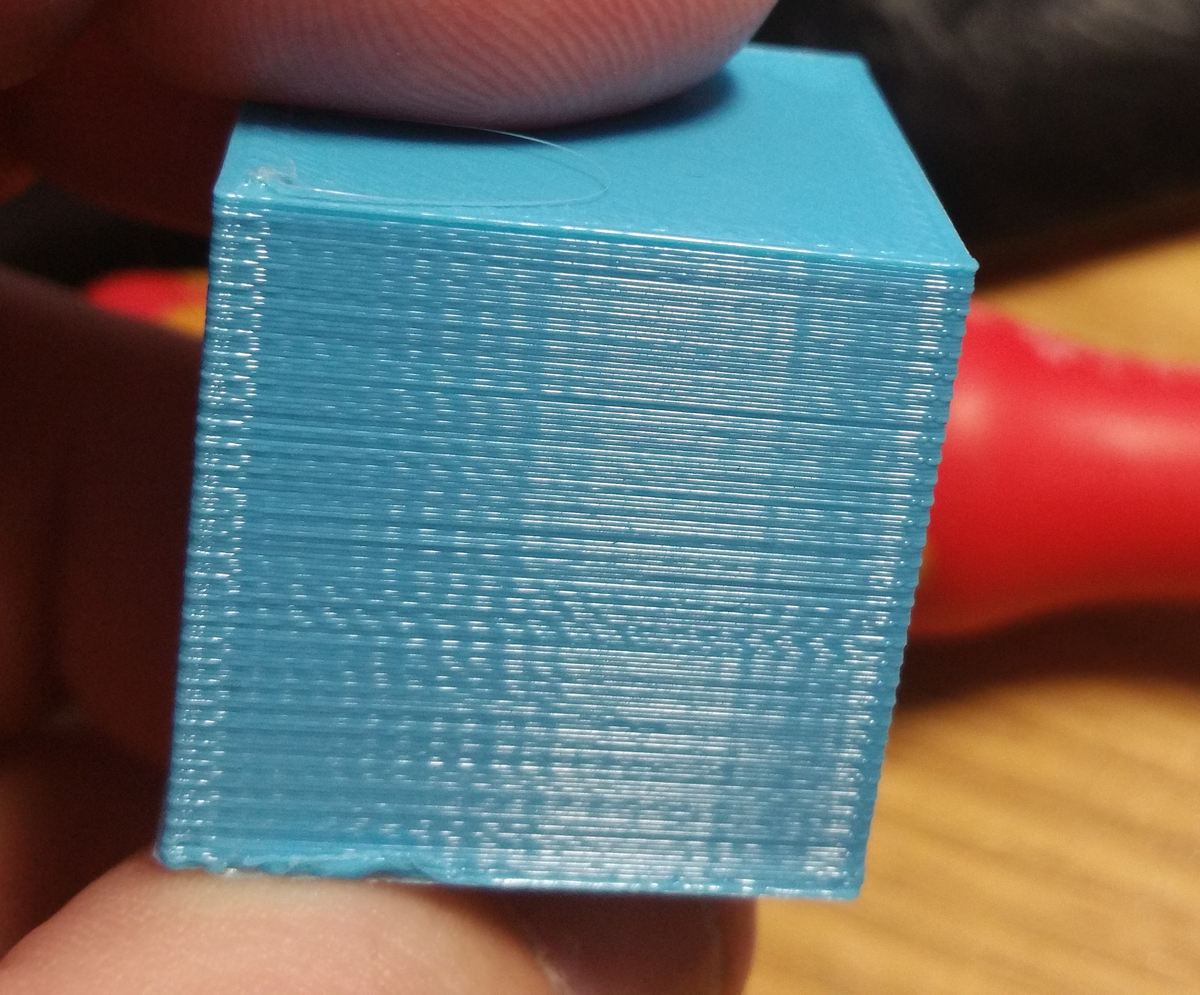

On the other hand, the Z resolution (vertical resolution) is the minimal thickness of a layer; sometimes called layer height or layer thickness. The smaller the layer height, the higher the resolution, which means the printed surface will be smoother and more detailed.

The downside of a smaller layer height is that the printing process will take longer because of the need for more layers. In addition, thinner layers do not always guarantee better prints. If anything, they increase the possibility of errors (like mismatched ridges on the surface). Formlabs recommends erring on the side of thicker layers unless it is necessary to use thin layers.

Most consumer FDM printers claim standard printing heights of between 0.1 – 0.3 mm although the Ultimaker 2, which is considered a high-resolution desktop 3D printer, boasts of a 0.02mm layer height.

It is also important to mention that the nozzle size affects the maximum layer height. When printing layers, you need your filament to be squished a bit for it to stick to the previous layer. Therefore, you cannot print a layer that is thicker than the size of your nozzle. The generally accepted rule of thumb is that your maximum layer height should not exceed 80% of your nozzle diameter.

For example, if your nozzle diameter is 0.4mm, you should not attempt to print layers that are thicker than 0.32 mm. If you try to go beyond 0.32 mm, the plastic won’t be squished, and the layer adhesion will be poor.

The use of thinner layers is most noticeable in the surface finish of prints with diagonal or curved surfaces, leading many users to generalize that they are the sole determinant of resolution. The Z resolution is mostly associated with a printer’s resolution because prints are created layer-by-layer, and since this value describes the thickness of each layer, it is easier to define and shows up more often on spec sheets.

SLA vs. FDM

Stereolithography (SLA) 3D printers, like the Form 2, are a resin-curing alternative to their Fused Deposition Modeling (FDM) cousins, which melt plastic and extrude it in successive layers to build an object.

SLA printers cure liquid resin using a precise laser to form layers, and this enables them to produce high-quality prints. The light is directed across a tray of liquid resin, causing a thin layer to solidify before repositioning to form the next layer. SLA printing resolution is dependent on the optical spot size of the projector or the laser. The Form 2, for example, has a spot size of 140 microns (0.14mm), while its discontinued predecessor, the Form 1+, has 155 microns. This is a different league even for a top FDM printer like the Ultimaker 2, which has a nozzle size of 0.4 mm (or 400 microns).

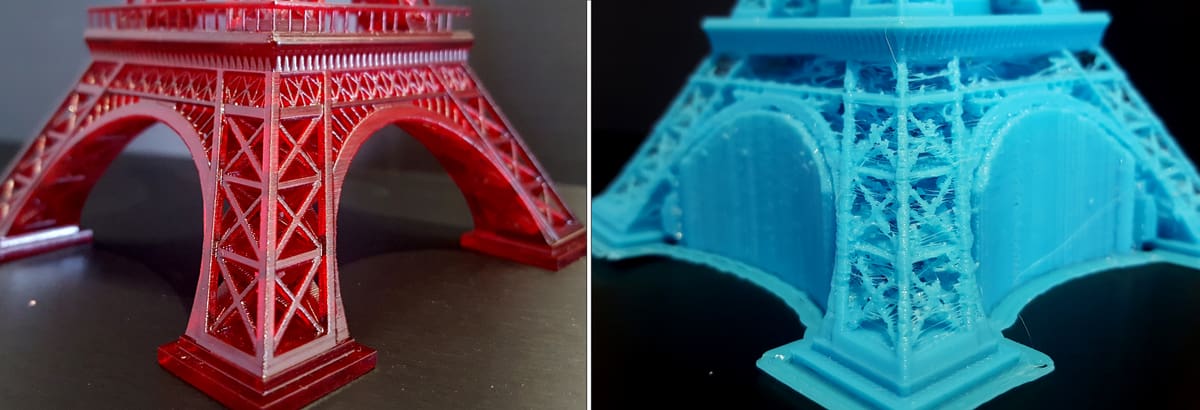

Unlike FDM machines, SLA printers produce more detailed prints because they have a much higher XY resolution and can achieve much smaller layer heights. The Form 2, which can produce layers as thin as 0.025mm, can be considered a high-resolution 3D printer because it performs well in both the layer height and XY resolution.

SLA printers can achieve a professional print quality that FDM printers can’t match, and they are the gold standard for resolution in 3D printing, according to Additive Manufacturing. A standard SLA machine will normally outdo the print quality of what one might consider a high-quality FDM 3D printer. Most of the desktop plastic extrusion printers lack the resolution and finish that can be considered end use. This is mainly because FDM printers are limited by melted plastic flow dynamics.

Industrial 3D Printers (FDM and SLA)

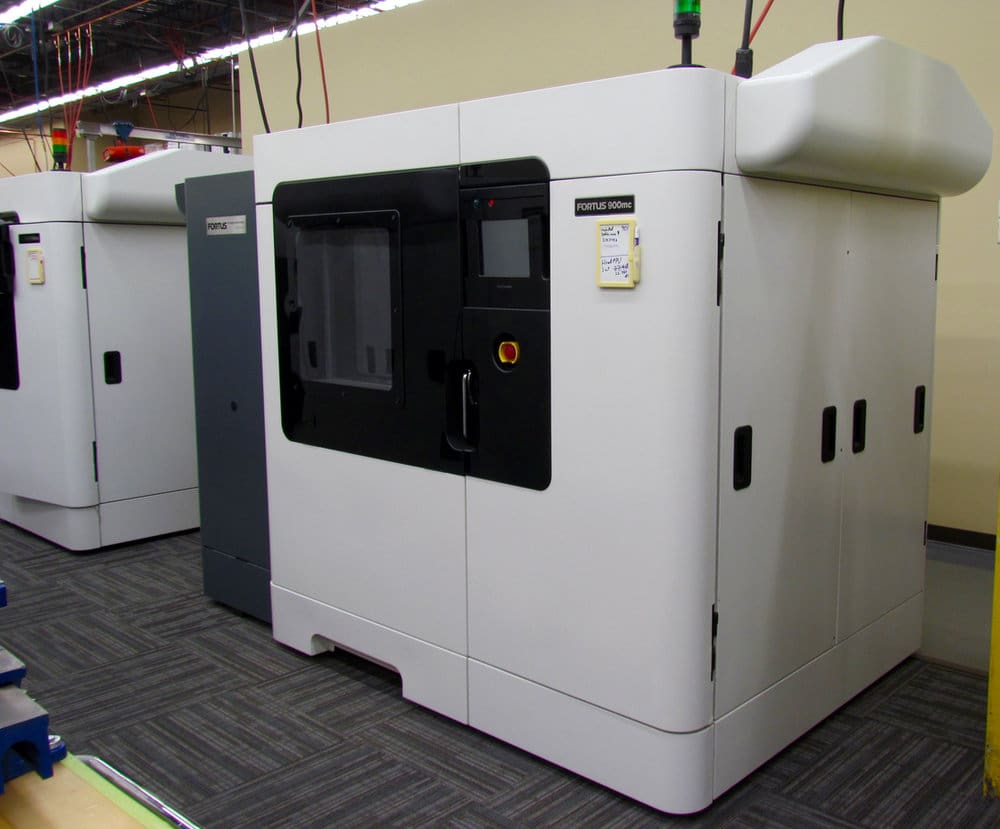

The FDM technology is also used in high-end industrial 3D printers. These high-resolution 3D printers, like their low-cost desktop counterparts, create prints by extruding molten plastic through a nozzle but have a much higher capability.

Industrial FDM 3D printers produce prints of a higher quality compared to desktop FDMs. This is mostly because the parameters of an industrial printer are carefully controlled during the printing process. Industrial printers typically have a heated chamber to counter the effects of quick cooling and tend to run calibration algorithms before every print. A good number of these printers support dual extrusion, making it easier for them to print complex geometry with the utilization of support materials.

Even industrial SLA printers will produce more accurate parts than the desktop ones. Industrial SLA printers are manufactured using high-cost components, and they print in a highly controlled environment — just like industrial FDM printers. While a desktop SLA printer can achieve a tolerance of between 150-300 microns, an industrial machine can go up to a tolerance in the region of 30 microns.

Desktop printers come nowhere close to their industrial counterparts.