Since the introduction of 3D printers that claim to achieve 600 mm/s of speed and 20,000 mm/s² of acceleration, like Creality’s K1, K1 Max, and K1C, filament manufacturers have been trying to keep up with the demand for high-speed materials. In the last few years, many brands have introduced high-speed filaments to the market to unlock the full potential of these machines.

In particular, polylactic acid (PLA) is the most common material used in fused deposition modeling (FDM) 3D printing, given that it’s the easiest to find and print. Furthermore, PLA offers one of the highest flow rates among 3D printing materials. That said, sometimes the faster, the better, so here comes high-speed PLA, a filament designed to provide higher speeds while still producing high-quality parts.

We’ve delved into the speedy topic by testing five popular options to see how they perform and what our experience was like. We’ve considered different characteristics of the resulting prints, such as surface finish, cooling speed, layer adhesion, and much more. While tensile and impact strength and layer adhesion come into play as well when analyzing the quality of prints, in this instance, they weren’t considered.

Keep in mind that this isn’t a comparison piece of how the different brands stack up against each other, but rather a general assessment of how they perform individually and what our experience was like printing them.

For an in-depth study regarding high-speed PLA, make sure to also check out our dedicated article. But first things first, let’s take a closer look at what is meant with “high-speed PLA”.

What Is High-Speed PLA?

So, what exactly is high-speed PLA? As mentioned, it’s a special kind of PLA that’s meant to be printed at high speed.

When it comes to hardware, generally speaking, the original Ender 3 and other models could reach great quality at 60 mm/s, while Bambu Lab was introduced to the market printing at 100-150 mm/s. Newer 3D printers claim speeds of up to 500-600 mm/s, and we’ll consider high-speed printing starting at 300 mm/s for the purpose of this article.

To properly extrude the filament at this speed, companies have modified the formulation of classic PLA with additives that make the material melts faster. This allows printing of the filament more quickly without needing to increase the nozzle temperature much or at all.

In fact, while you can print pretty much every material at a high speed, the quality of the resulting part is important. High-speed materials are formulated to let you print high-quality pieces faster. Depending on the brand, different additives might be used. Because of this, there are some variations between high-speed PLAs from manufacturers. When choosing which filament to buy, make sure to check the maximum speed recommended by the company because it varies from brand to brand.

Now that we generally know what we’re talking about, let’s see how five high-speed PLAs performed when being put to three tests. We’ll take a look at the settings used for each of them, together with their strengths and weaknesses.

Test Setup

Before getting into the thick of the action, let’s take a look at the setup used for this test.

Hardware

As mentioned, many 3D printers that claim good quality, high-speed performance have been released over the last few years. Bambu Lab has led the way for this with accessible machines like the P1P and P1s, and many other 3D printer manufacturers have followed suit. The wide variety of high-speed models include Prusa’s MK4S, Anycubic’s Kobra 3, and Elegoo’s Neptune 4.

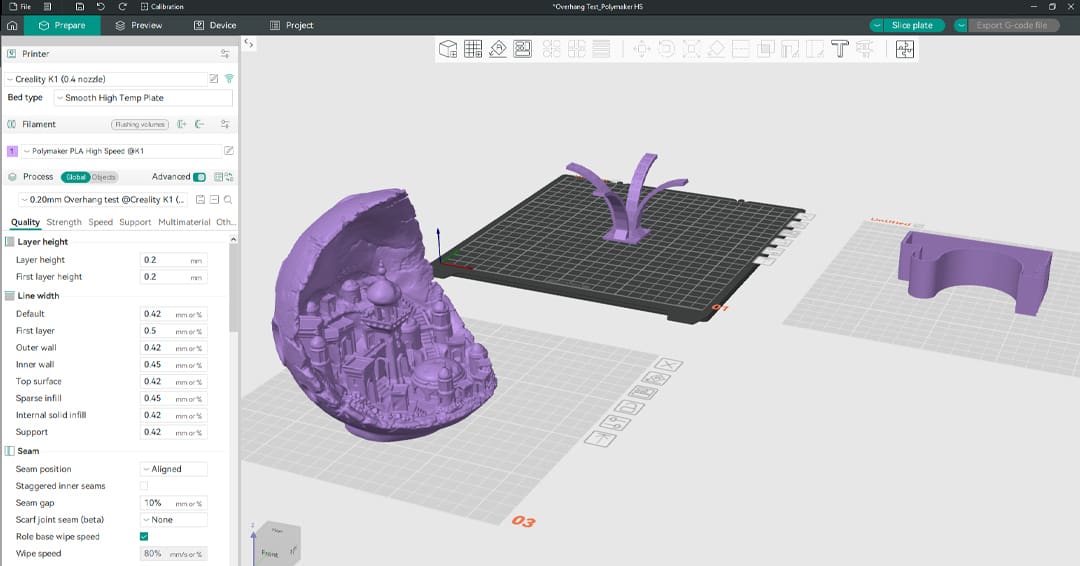

For this test, I selected a Creality K1 with the stock extruder and hot end, with a 0.4-mm nozzle.

Filament Selection

With the increasing popularity of high-speed printers, the demand for high-speed filament has also grown, which is why many companies now offer this kind of material.

For this test, I’ve chosen five high-speed PLAs based on brand reputation, technical specs (i.e. claims that they can be consistently printed with such settings, all marketed as “high-speed”), and community reception (i.e. these filaments have been positively received and rated by makers).

In particular, I’m looking at Sunlu, Eryone, Polymaker, Elegoo, and Flashforge. While Sunlu, Eryone, and Polymaker are popular filament manufacturers, Elegoo and Flashforge are mainly focused on 3D printers. That said, they’ve also grown in the filament market with their constantly expanding offerings. For a clearer distinction of the brands, I used different colors. Blue was used for Sunlu, magenta for Eryone, gray for Polymaker, orange for Elegoo, and clear for Flashforge.

For Eryone and Elegoo, because there was wider availability of the PLA+ version (instead of PLA), I went for the former.

I also opted to keep things as out-of-the-box as possible. Wherever a material was particularly hygroscopic, I noted it, as this would impact the print quality.

Next, let’s take a look at the test models opted for.

Test Models

To test these filaments, I chose to perform three tests to give an overview of how these materials perform.

Overhangs

First is the overhang test by tomi3d. This model is really useful to see how cooling is affected by the high-flow nature of these materials. A better overhang performance allows for the use of fewer supports, saving time and material. Knowing this value is fundamental for a well-tweaked slicing profile, and it can prevent a lot of headaches.

Surface Finish

As you might have noticed in some prints, certain areas of the model might present a glossy finish, while other parts of the same piece have a matte appearance. This is not a random phenomenon: The more a filament is melted, the glossier the finish it leaves. If you want to use it to your own advantage, you can see which speed to use with this surface finish test by ordnerino.

In addition to the aesthetic aspect, the test also has sections that include 45° overhangs, indented text, digits, and shapes, and sharp turns and curves for each temperature. While the original test is designed to start at a speed of 20 mm/s, given that these are high-speed PLAs, I bumped this to begin at 120 mm/s, with a 20 mm/s increment, and the final segment printed at 300 mm/s.

Moon City 2.0

Finally, I chose a file that’s not a classic test print but which can help identify a variety of issues. Kijai’s popular Moon City 2.0 generally allows makers to evaluate many aspects, like stringing, small detail resolution, layer adhesion, and more. As a bonus, you can print the ornament version for your Christmas tree or the earring version for some stylish jewelry.

Printer Profiles

The slicer of choice was Orca Slicer, with a custom profile for each filament based on the manufacturers’ recommendations. Every material presents different temperature suggestions, usually with a range of 30 °C between minimum and maximum values.

The amount of plastic that melts in a second is usually called “flow rate”, and it’s a key factor when printing at high speeds. A higher temperature melts more filament (compared to a mid-range value). For this reason, if you want to push these materials to their limits, you need to increase the temperature.

To get a good grasp of what quality and experience to expect with these filaments, I printed the selected tests twice. The first time, I used the middle ground of the range suggested by the manufacturer, while the second time, I opted for the highest temperature value recommended. I’ll specify if a tweak was necessary in the appropriate section.

The shared aspect for all prints was the speed, as they all have similar claims: The test for all the filaments was performed at 300 mm/s, except for the surface finish test because of its specific variations.

Without further ado, let’s see how the filaments performed.

Sunlu

Let’s start with Sunlu.

If you’re into 3D printing, you probably know this brand. Founded in 2013, Sunlu offers an extensive catalog of over 40 products, including high-speed PLA. Sunlu formulated this material to be printed with a speed of up to 600 mm/s! Since the filament melts at a lower temperature compared to regular PLA, Sunlu also adds that you can print with a speed between 50 and 150 mm/s while setting the nozzle as low as 190 °C, saving energy.

As a bonus, Sunlu’s filament arrived in a detachable spool that you can reuse by purchasing refills instead of a whole new spool, decreasing plastic waste.

First Test: Overhangs

Sunlu’s high-speed PLA was one of the best performers for this test while looking at the overhangs. The filament almost reached 60° before failing for both the 230 °C and 260 °C tests. This means that you could use 52/54° as a safe value for overhangs on your printing profile, saving material and time on models that have overhangs steeper than the common 45°. That said, there were some defects on the underside of the overhangs starting at 50°, so this might be a safer value for sharper results.

On the other hand, an evident problem was the stringing. On both the prints, there was quite a lot of stringing between the different arcs. This generally indicates that the filament has absorbed moisture and needs to be dried before printing.

Second Test: Surface Finish

This test was really interesting. Sunlu didn’t present a difference in finish throughout the speed range when printed at 230 °C: It remained shiny along the entire height of the print for every feature of the model. When the nozzle temperature was set to 260 °C, the result was a much more matte and rough surface.

Some stringing was also noted inside the part. In particular, the part printed at a lower temperature presented stringing in the zig-zag area and inside the print at sharp angles. The test printed at 260 °C didn’t return an ideal result: The stringing was present on every feature of the print, starting from the sharp angles up to the curves, the text, the zig-zag, the overhangs, and the seam.

Third Test: Moon City 2.0

This third print confirmed the observations of the previous tests.

Sunlu’s high-speed PLA worked well on overhangs, as observed from the bottom of the moon and its tip. This was also reflected in the bridges: The sag was almost absent and the small bridges came out perfect at the lower temperature. The fan had difficulty keeping up with the hotter print: The small bridges remained clean while the longer bridges and overhangs presented artifacts.

The details printed great, as seen from the well-defined tips of the buildings, also at 260 °C. The most obvious problem was the surface finish. As observed previously, the appearance of the test printed at a higher temperature was rough and matte. Additionally, I noticed an inconsistency in color: Some areas printed darker than others.

From my experience, 260 °C was too hot for this filament and I’d stick to a lower temperature, even when printing at high speed. This could be due to the base material being PLA and it not being meant to be printed this hot, although this is only a guess. In any case, a nozzle temperature between 230 and 240 °C is more than enough.

Whether this applies to other colors remains to be seen. A test for another day?

Eryone

Eryone is another filament manufacturer that offers a massive catalog of products, ranging from a multitude of different PLAs up to more engineering-grade materials, as such ABS and ASA.

Their high-speed PLA+ was formulated to reach a maximum speed of 400 mm/s and the key claim of this material is that it allows to print models with intricate details even at high speeds.

As we’ll see in a moment, this statement is well founded. It was really easy to work with this filament since no tweaking was needed during our test use. It had great bed adhesion and it didn’t absorb moisture quickly, which was reflected in the overall quality of the prints.

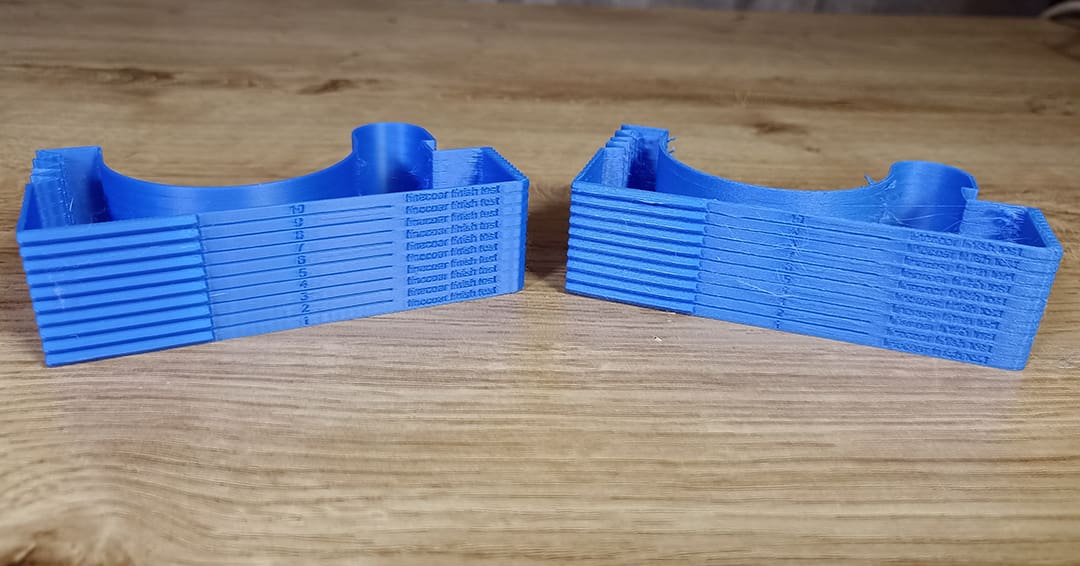

First Test: Overhangs

Eryone excelled in this test, reaching almost 60 °C overhangs for both the 210 °C and 230 °C print. That’s because the filament cooled really quickly and the bed adhesion was great. While a bit of caution might be warranted for Sunlu given the underside defects, given that Eryone didn’t show these, 52/54° would be an appropriate overhang setting for your printing profile.

As can be seen in the image, Eryone presented minimal stringing, which could make it a great choice for models that need many retractions.

Second Test: Surface Finish

Eryone performed really well in this test, presenting a glossy finish for the entire model for both temperatures.

By observing the back part of the model (which features curves), one could appreciate the smooth finish. Furthermore, the numbers could be clearly read on both prints and the stringing was almost absent, except for the zig-zag segment that presented some fine strings.

The seam of the model showed that this filament printed better when pushed to higher speeds. In fact, some small blobs formed at the bottom, where the speed was lower and the filament was maybe melting too quickly for it.

Third Test: Moon City 2.0

Eryone’s Moon City showed very similar results at both temperatures tested. The overhangs and bridges came out great and the small details cooled fast enough. The major difference came down to stringing, which was slightly more present on the higher temperature part, but still minimal all things considered.

To obtain the best results, I increased the fan speed when working with the higher temperature. This led to super clean overhangs.

Overall, the price-quality ratio of this filament is really spot on and I had a great experience printing with it.

Polymaker

Founded a year before Sunlu, Polymaker has now over a decade’s experience in filament manufacturing. And this brand couldn’t miss a high-speed material, so here comes PolySonic PLA.

The official maximum speed to use with this filament is 300 mm/s, although Polymaker has shared the results of some tests conducted, specifying that it can reach up to 363 mm/s when printed at 0.2-mm layer height.

This filament was prone to absorb moisture, so drying it is fundamental to obtain the best possible results.

When it comes to the software side of things, Polymaker streamlined the slicer setup. If you own an AnkerMake M5, a Bambu Lab X1 Carbon, a Creality K1, or a Raise3D Pro 3, you can find premade printing profiles that Polymaker provides on their website.

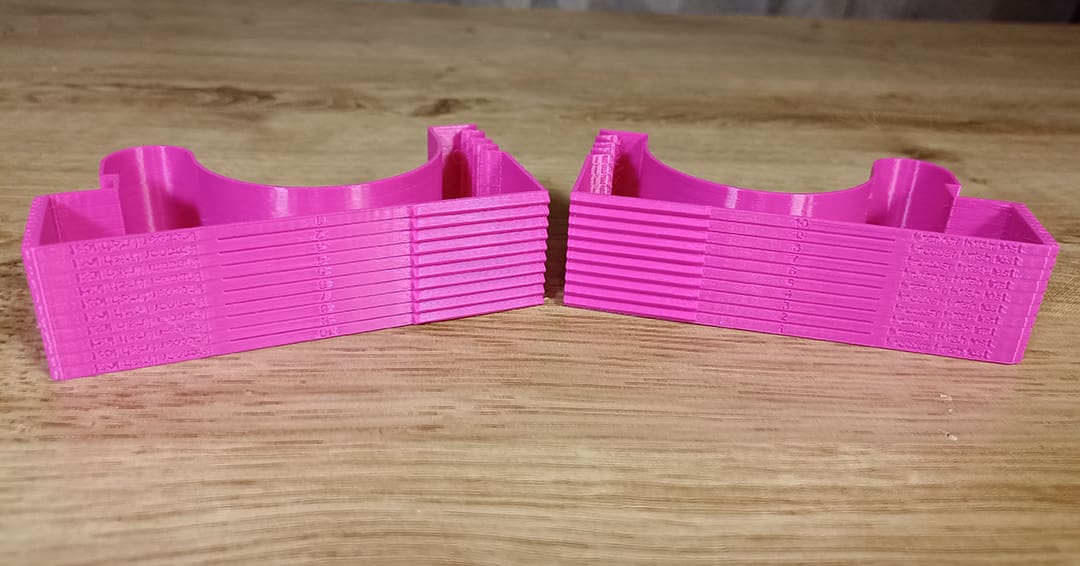

First Test: Overhangs

Unfortunately, Polymaker didn’t shine in this test. The first side failed at just 50° at 220 °C, and slightly under it at 230 °C. There were even some artifacts on the underside of the overhang at around 45°. This makes 42-45° the safe range for this filament, whose values match the usual settings of a premade profile for PLA printing. This means that you’ll need the same amount of supports as regular PLA, so you won’t save material.

Although I’ll dive deeper into it in a moment, in the image above you can already see the difference in the appearance between the two prints, with the hottest one being glossier than the other.

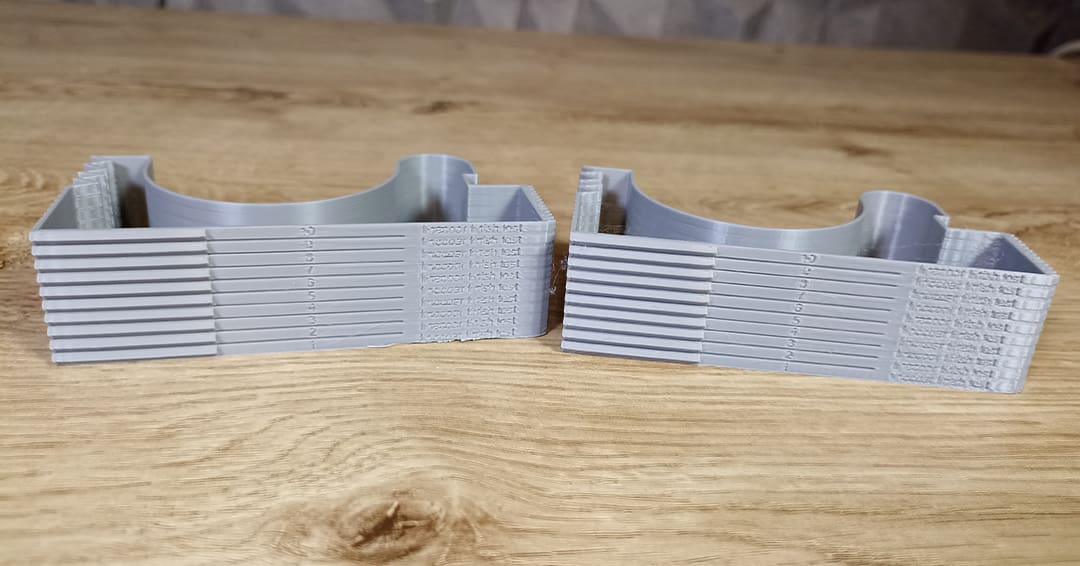

Second Test: Surface Finish

This test clearly showed how important temperature was for the surface finish. When printed at 220 °C, the part presented a more matte appearance, while with a hotter nozzle temperature, the surface finish was visibly glossier.

When printing the first test at the lower temperature, the filament had a little problem sticking to the build plate in the area of the text. For the second print, we slowed down the first layer speed by 10 mm/s and this improved bed adhesion.

Overall, the parts came out smooth, as could be seen from the backside. The numbers were recognizable and the small overhangs completed fine. The major problem was the stringing between the small and big zig-zags, which was also present inside the model between the point where the printhead jumped from one area to the other.

Third Test: Moon City 2.0

As expected after the first test, the Polymaker Moon City prints suffered on the overhangs for both temperatures. Even when increasing the fan speed, the bottom remained rough. For the same reason, bridges were less clean and presented some artifacts.

On the brighter side, the stringing with this more organic model was far less than the one that I saw on the last two models. That could be due to the reduced amount of direction changes, so, depending on what you aim to print, it shouldn’t be a big problem on a daily basis.

Summing up, Polysonic PLA can keep up with the flow requested to print at high speeds, but it doesn’t shine on overhang areas. For this reason, it might be best suited for models that don’t require supports.

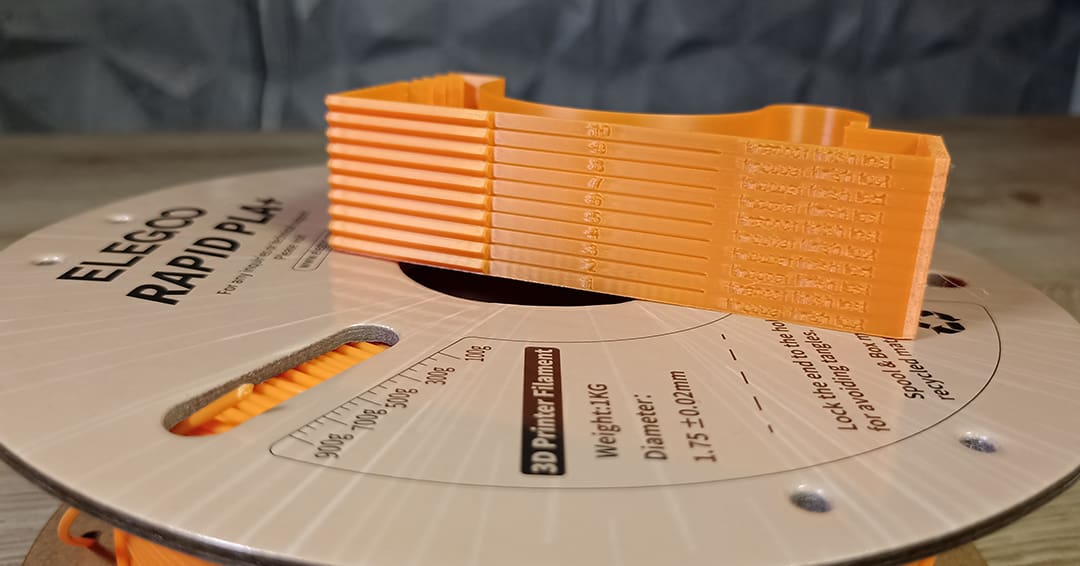

Elegoo

You probably wouldn’t expect a brand known mostly as a printer manufacturer on a filament article. In fact, Elegoo doesn’t produce only 3D printers – such as the Neptune 4 – but filaments and resins as well. The high-speed line of Elegoo materials is called “Rapid” and it features not only PLA+, but also PETG!

Elegoo claims that this material can be printed with a speed of up to 600 mm/s while maintaining a glossy and smooth surface, and the PLA is one of the highest rated high-speed materials at Amazon – for good reason. Spoiler alert for my findings below: No matter at what temperature, I saw almost no stringing on any of the parts.

Plus, it’s a really cheap filament with an excellent price-quality ratio.

First Test: Overhangs

Elegoo performed really well in this first round, reaching approximately a 55° overhang at 215 °C and failing just a little below that when printing at 230 °C, with minimal or negligible artifacts on the underside. This was a great result that could allow makers to tweak the print profile with a maximum overhang of 50/52°, saving time and material when printing models with overhangs of this type.

What this filament can really brag about is how it avoided stringing. Even printing at 230 °C, the issue was almost completely absent, which makes it a great choice for models that need a lot of retractions.

Second Test: Surface Finish

The results with Elegoo filament were interesting. When printing at the middle temperature of the suggested range, the print was glossy almost for the entire model – but on the curves, it presented a semi-transparent shade. The slower the speed, the bigger the area with these lighter stripes. On the other hand, when printing at 230 °C, these artifacts completely disappeared. To have an even surface finish, I’d recommend setting the nozzle temperature to the higher half of the range.

As with the previous model, Elegoo filament offered very little stringing with just a tiny bit present between the big zig-zags. Consequently, as mentioned above, this would be a great filament for models with little details that need many retractions and direction changes.

On the other hand, you might need to pay attention to bed adhesion. When trying to print this model, the model wouldn’t stick to the plate until I reduced the first layer speed by 10 mm/s.

Third Test: Moon City 2.0

This brand performed great on small bridges with only minor defects on the longer ones. That said, the difference between the tests printed at different temperatures was quite visible: The bridges printed at the higher temperature weren’t as clean as the ones printed at 215 °C. Additionally, although the filament performed really well in the first test, I needed to increase the fan speed to obtain the best overhangs at 230 °C.

These prints confirmed that Elegoo would be more than suitable for models that need many retractions, for example for small details. In fact, there was no stringing at all on this print, even between the small columns of the balcony of the tower.

Considering everything, Elegoo is a worthwhile filament that doesn’t need much tweaking. The great overhang performance, low presence of stringing, and cheap price make this a solid choice for high-speed printing.

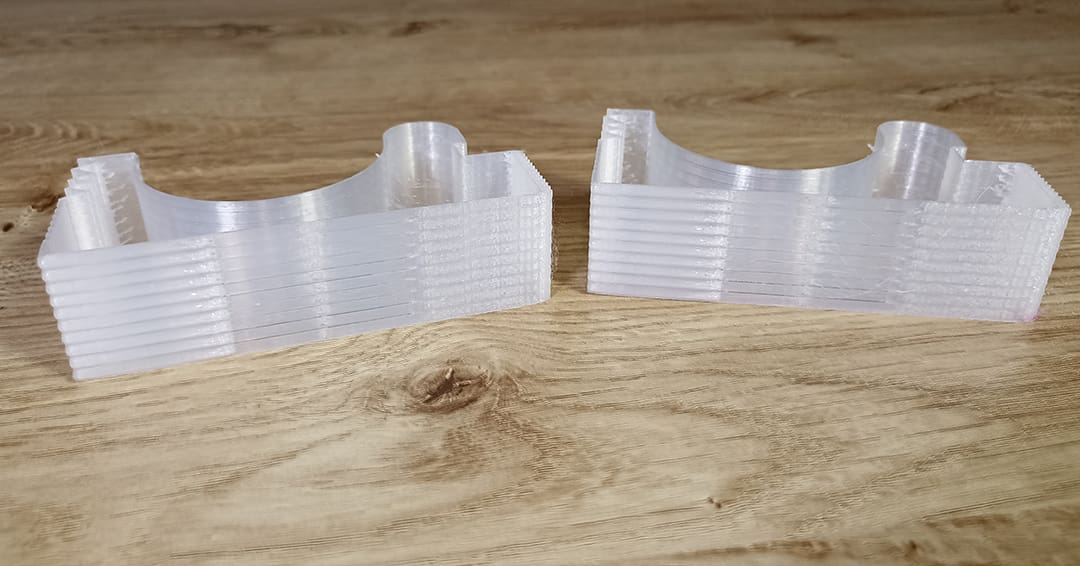

Flashforge

Like Elegoo, Flashforge is a company that specializes in 3D printers but that produces 3D printing materials as well. It offers a wide variety of colors that you can choose from for your high-speed PLA, making it ideal for aesthetic applications.

Flashforge claims that its high-speed PLA melts twice as fast as its regular PLA (see Melt Flow Rate under Mechanical Properties), allowing it to reach up to 350 mm/s. Additionally, the company states that this material is food-contact compliant. If you want to dive deeper into this topic, make sure to check out our article about food-safe filaments.

First Test: Overhangs

This filament reached approximately a 55° overhang when printing at 230 °C. Conversely, it failed at just 50° when setting the nozzle to 240 °C. For both tests, artifacts were noted on the underside of the overhangs in the 50-55° range. This means that supports would be needed for overhangs that exceed approximately 45°.

Unfortunately, the weakness of this material was evident when it came to retractions. This filament created a lot of stringing at both the higher and the lower temperatures used, which could be explained by its highly hygroscopic nature. It absorbed a lot of moisture, so it would be best to dry this material before using it. Flashforge suggests drying it at 50 °C for five hours before using it.

Second Test: Surface Finish

With Flashforge, I could really see a difference in the finish of the different features when printing at lower temperatures. While on the straight segment and the curves the appearance was transparent, on the zig-zag areas and sharp angles the finish became opaque.

As for the higher end of the temperature range, at 240 °C the finish was transparent pretty consistently throughout the model. This would indicate that the filament can’t melt quickly enough at 230 °C (for an even extrusion) to be printed at 300 mm/s, so if you want to go fast, you need to set the nozzle temperature higher.

Unfortunately, this print confirmed that Flashforge high-speed PLA tends to create quite a lot of stringing. Not only was there stringing between the big and small zig-zags, but also in the middle of the model, where the printhead needed to change direction. Additionally, on the seam, some blobs formed during the change from a layer to the next one.

Third Test: Moon City 2.0

With this print, we could clearly see the change in the finish of this filament based on speed and features. Although it was more present on the lower temperature print, we could notice it on the 240 °C test too.

For the most part, the Moon City came out opaque, but in many areas I could observe a change in appearance to a more transparent finish. This effect might be connected to the transparent nature of the color chosen, so it might be absent on solid hues.

As one might have assumed from the first test, bridges were also imperfect on the first print. The 240 °C print featured cleaner overhangs and bridges thanks to the increase in the fan speed.

Stringing was present, especially in the small detail areas. For instance, I could observe it between the columns. So, although the settings could be tweaked some more to cool the details faster, drying the spool to avoid post-processing would be best.

From my experience, this filament needs tweaking to deliver great-quality parts. The abundant stringing and the poor overhang performance made this spool a little challenging to work with.

License: The text of "High-Speed PLA Shoot-Out" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.