A Sci-Fi Writer's Dream

Many of us will be familiar with the Star Trek scene where Captain Picard steps up to the food synthesizer and says, “Tea, Earl Grey, hot,” and the drink miraculously appears. When you mention 3D printing to the uninitiated, this is sometimes what they expect.

The reality is that 3D printing is a lot more down to earth and certainly easier to understand than matter scrambling.

In this article, we’ll look at how this approach to manufacturing has become a mainstay among hobbyists and engineers alike.

Manufacturing Through Subtraction and Addition

Most people are familiar with the concept of subtractive manufacturing, if not so much the name. Subtractive manufacturing is the process of sculpting or machining a desired object from a core piece of stone, metal, wood, or any other carvable material by removing the unwanted material. The inverse of this is additive manufacturing.

Additive manufacturing is defined as depositing a formative material in layers onto a build surface for the purpose of creating a 3D object. The material can be paper, plastic, resin or even metals and concrete. Instead of removing unwanted material to leave the desired model behind, additive manufacturing begins on an empty canvas, building a creation one layer at a time.

Additive manufacturing is nothing new. Born in the early 1980s, many of its pioneers are still around to tell the story today. We present a snapshot of these men and the birth of this technology in The History of 3D Printing.

If you are interested in having something 3D printed, but you don’t know which technology to use, take a look at Craftcloud – 3D Printing & Price Comparison Service by All3DP. We provide real-time prices from a wide variety of professional services, including Shapeways, i.Materialise, and Sculpteo.

A Manufacturing Era Grown in Layers

The additive manufacturing process owes its existence to the computer. A typical 3D model begins its life as a CAD drawing. From there, slicing software converts it into thin, flat profiles to be expressed in the desired medium.

Each profile layer is a thin slice of the model, tracing its XY dimensions while bonding the print medium into a solid form through some type of reactive process. These layers are manufactured one atop the other, ultimately forming the Z dimension of the end object.

A Developing Industry

Additive manufacturing represents a quantum leap in prototype modeling. It allows concepts to be digitally defined, expressed as layers as thin as a fraction of a millimeter and subsequently deposited to create the finished product. As the concept has matured and its acceptance spread, additive manufacturing has grown into a viable manufacturing process.

Since its birth, the additive manufacturing concept has exploded. Industry produces end-use goods, hobbyists are developing new craft ideas and doctors, dentists, and other medical professionals are now printing custom prosthetics while their patients wait.

Technologies in Abundance

New approaches to additive manufacturing appear regularly. Ten of the most popular methods are capsulized in our article All 10 Types of 3D Printing Technology in 2019.

However, as with any endeavor, there are contenders and superstars. In the sections that follow, you will become better acquainted with three of those superstars.

Fused Deposition Modeling (FDM)

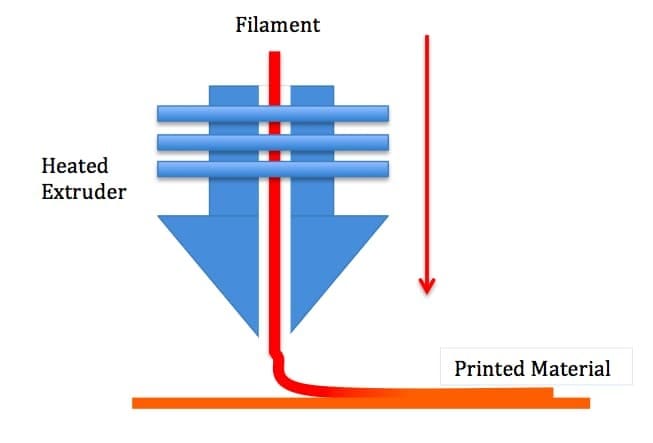

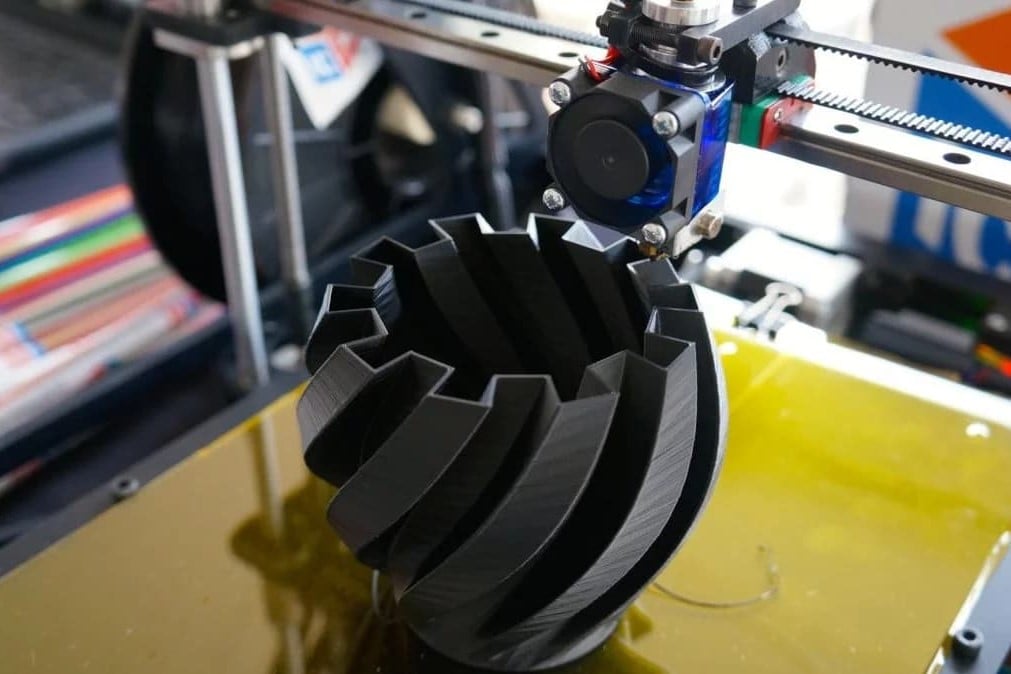

Fused deposition modeling (FDM), is the technology that most people think of when the conversation turns to 3D printing. In FDM, the printing medium is a thermoplastic. It’s delivered in the form of filament, much like fishing line on a reel.

The filament is forced into a heated nozzle, where it becomes a semi-liquid paste. That paste is then extruded onto a printing surface as the nozzle follows a computer-guided path. As the plastic paste extrudes, it hardens almost immediately, leaving behind a foundation for the next layer.

Once a layer is complete, either the surface or the nozzle will re-position a fraction of a millimeter away and the process will begin again, fusing a new layer atop the previous one. This layering process then repeats, ultimately resulting in the desired 3D model.

Pros and Cons

One of the primary factors that makes FDM modeling so attractive is its price. FDM machines start at under $200, giving them the lowest entry cost of all the additive manufacturing technologies.

The low cost of FDM is directly related to the fact that the formative technology is a simple heated nozzle. The cost of a hot end for the average 3D printer is less expensive than a new soldering gun.

FDM devices are also relatively easy to use and produce decent parts fast, whether for aesthetic or functional purposes.

FDM manufacturing does have its challenges:

- Low precision: Compared to SLA and SLS, FDM is the least precise additive manufacturing technology.

- Necessary supports: Growing a part from the ground up sometimes requires support structures that are not part of the final model. This represents additional time and material going into the finished product. Plus, those support structures must be removed, a challenge with delicate models.

- Limited materials: Because FDM requires material that melts and cools, the technology is restricted to thermoplastics.

- Moderate strength: Though generally stronger than SLA prints, FDM prints demonstrate decent strength, at best. This is because of the materials used and the interior structure, which cannot be wholly solid.

- Environmental sensitivity: Most FDM machines are open to the air. In such cases, something as subtle as a breeze or a change in room temperature can potentially hurt a print.

Stereolithography (SLA)

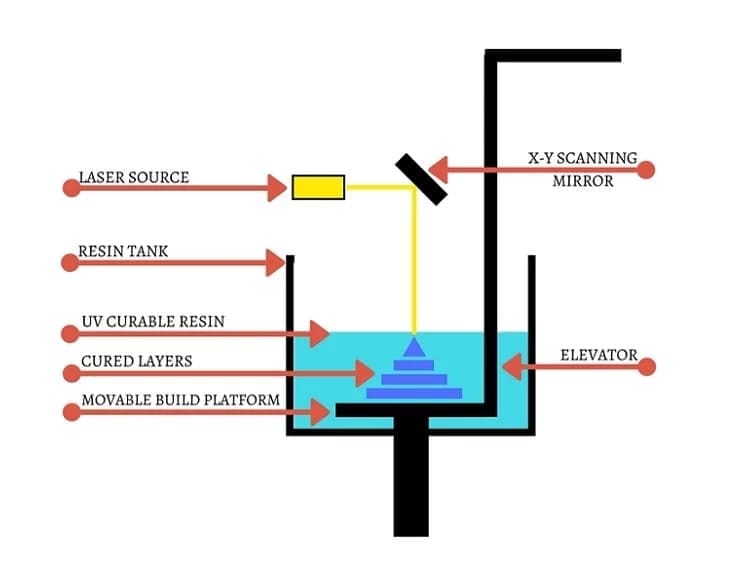

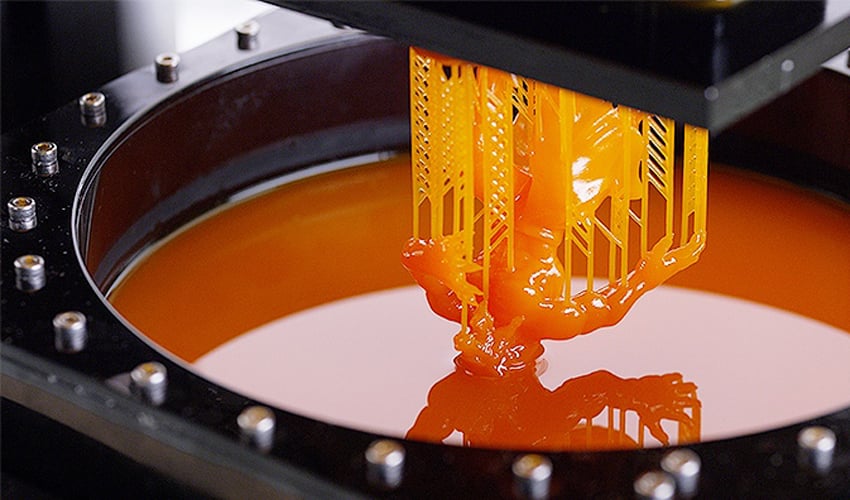

Stereolithography (SLA) is a 3D printing process based on a process called vat photopolymerization. It works by exposing a tank of photosensitive liquid medium to a laser, which acts as a UV light source. The beam is redirected through computer-controlled mirrors, exposing and hardening the resin in an X-Y representation of the model, building one layer at a time. As a layer completes, the surface lowers into the vat and the next layer begins.

SLA manufactured products can be produced as described above or in an inverted manner, where the light shines from below and the build platform is raised out of the resin tank.

A similar 3D printing technology is digital light processing (DLP), which uses a projector screen instead of a laser.

Pros and Cons

Being built around laser technology does have drawbacks. SLA printers are generally not cheap. And the process is much more involved that heating and depositing fusible modeling media. But the almost total absence of heat from the process means that thermodynamic expansion is not part of the equation. Almost no size compensation is required.

Because the laser light source can be focused very tightly, SLA printed parts have a much higher resolution than most other forms of 3D manufacturing. Tiny, delicate parts are routinely created using the SLA process. Also, the hardening process is not completed in one pass of the laser so the subsequent layer bonds into the previous one, not over them. Finished models usually exhibit no layer lines.

Selective Laser Sintering (SLS)

Another laser-based additive manufacturing technology is selective laser sintering (SLS). This technology, however, creates a model from dry media instead of liquid.

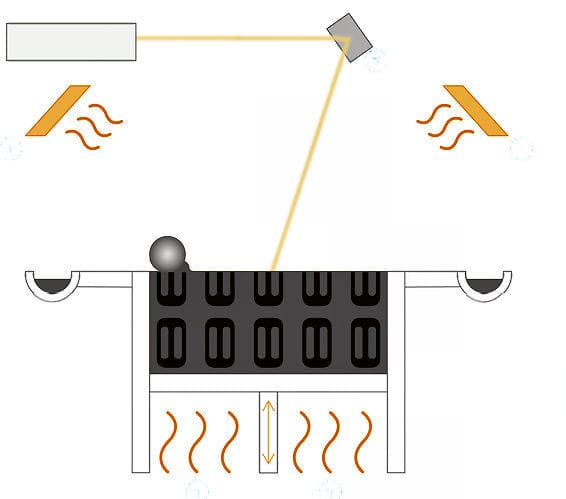

With SLS, the media, generally plastic or nylon, is placed inside a forming chamber, again containing a movable surface. The media is a particle with a texture somewhere between granulated sugar and flour. The chamber temperature is then raised to just below the melting point for the selected media.

A mirror-directed laser beam draws a profile of the desired model into the warm media. The energy pushes the media’s surface temperature just above its melting point, causing the particles to fuse together or sinter.

The surface then drops a fraction of a millimeter and a wiper sweeps a fresh, level layer of media across the work field. The process repeats again and again, creating a model in much the same manner as most 3D printing processes.

Variations of SLS include direct metal laser sintering (DMLS) or selective laser melting (SLM), which apply a similar technique to metals.

Pros and Cons

A distinct advantage of SLS printing over FDM and SLA is that it can produce parts with much higher strengths. Additionally, the SLS process requires no supports, as the level of the unsintered media rises with that of the sintered product, acting as support material for the model being manufactured. This means complex structures are generally much easier to produce with SLS.

Once sintering is complete, most SLS models require only a gentle post-process media blast, similar to sandblasting, to sweep away any remaining unsintered particles.

SLS is not without its downsides. The main drawback is accessibility. Because the technology requires a high power laser, SLS machines are both expensive and unsafe to operate in anything less than a workshop type of space.

Furthermore, as the process involves particles that are only surface liquefied, finished projects tend to exhibit rough, grainy surfaces. This can be mitigated through the post-print blast cleaning process, but SLS alone will never produce a smooth, shiny surface.

That being said, the technology is a popular choice for rapid industrial manufacturing. As CO2 laser packages continue to drop in price, it is only a matter of time before SLS printing becomes a popular hobby option.

A Surge in Popularity

Over the past few years, additive manufacturing has exploded in popularity, both with industry and hobbyists alike. The manufacturing reasons are obvious. For hobbyists, this choice is driven by a handful of factors, most leading back to price:

- Creative freedom: AM is the creative person’s dream. With respect to ease of production, painting, sculpting, carving all pale in comparison to 3D modeling.

- Computer control: For AM, a personal computer and the knowledge to operate it is a requirement. But with computers now as ubiquitous as televisions, most are easily able to sit down and immediately get to work.

- Accessible software: 3D CAD software, an expensive requirement in the past, is now available at little or no cost. There is, in fact, no longer the need to own the software at all. Websites like Tinkercad host a design environment that’s free to all users, along with the training to use it.

- Small-scale computers: The past ten years have seen the rise of single-board computers. Devices like the Arduino or the Raspberry Pi are now the engines driving 3D machines. A typical dedicated single-board CAM computer like this runs about $20.

- Small-scale electronics: The XYZ axis drive systems for most 3D printers are stepper motors. Because of the low torque required to drive a print head or position a mirror, a typical stepper motor for a desktop 3D printer will run about $15. The required stepper driver which powers the motor, another $10. Add a frame, maybe an enclosure and a power supply and you have a manufacturing device for less than the cost of a new cellphone.

The Future

Additive manufacturing is now accepted as a legitimate production process. Printing with reinforcement agents such as Kevlar or carbon fiber is commonplace. Small buildings are being printed through the robotic positioning of nozzles extruding layer upon layer of concrete.

As patents expire and technologies fall into the public domain, prices continue to drop. And as we move forward, new technologies will continue to emerge. It’s an exciting field to be a part of. And who knows. Maybe twenty years from now we’ll be able to step into the kitchen every morning and say, “Coffee, Colombian, touch of foam.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.