From spare parts to custom-designed jewelry and kitchen gadgets to motorcycle accessories, there’s (almost) nothing you can’t have 3D printed. Whether it’s one item or hundreds of parts that you plan to use in your business, 3D printing is the most accessible form of manufacturing that requires (almost) no knowledge of the process or the technology.

That said, there’s a huge variety of materials and a booming market of service providers to choose from, and, let’s be honest, some are more expensive than others. With a little bit of know-how, which we deliver below, you’ll be able to pick the right provider at the right price.

The cost of 3D printing services varies widely depending on several factors, including material, the complexity of your part design, the size of your part, how many you need, and the type of 3D printing technology used, which you may or may not be able to select.

General Estimate of 3D Printing Costs:

- Basic small prints: $10 – $100

- Medium-sized, more detailed prints: $100 – $500

- Large or highly detailed prints: $500 – $5,000+

To put 3D print service pricing to the test we, requested quotes from a wide range of companies. We ordered parts in various plastics and metals to be shipped to us in Chicago. As you’ll see from the charts below, prices vary widely, and we recommend you conduct the same research, with at least a few of the major providers, to understand your options. Fortunately, many services provide free instant quotes.

How Much Do Plastic Parts Cost to 3D Print?

If you’re considering having a part 3D printed then it is either a one-of-a-kind part, a replacement part, or a small batch of parts. In all three of these scenarios, you’re turning to 3D printing because it will either be faster or cheaper or both compared to other manufacturing processes or buying the part from a supplier. Each of these scenarios requires slightly different considerations.

Ordering One Unique Part or Prototype

3D printing is often referred to as “rapid prototyping” because, to this day, more people use it to make prototypes of products than they do to make end-use products, although that’s changing. This technology is ideal for prototypes because it takes no artistic skill to mold or sculpt the prototype, it’s simply printed directly from the digital file.

Although we cover a lot of detail in our guide “3D Printing Prototypes – How to Get Started,” what you need to know is that you can order a basic prototype from a 3D printing service, a fully functional one, or a full-color version. Each will be a different price.

Basic 3D prints are typically made with a plastic called PLA, which is almost always the least expensive material, and printed on a filament-based machine often called an FDM 3D printer. A more functional prototype that can stand in for the final product in actual testing could be made from a material such as carbon-fiber-infused nylon and printed on an industrial 3D printer, typically a selective laser sintering (SLS) machine also called powder bed fusion. Full-color product prototypes and anatomical models are typically 3D printed using a technology and machine called PolyJet.

Price of One Simple Prototype in Various Materials

To give you a sense of what a simple, relatively small part might cost in various materials, we selected this (below) popular yarn bowl with a 165-mm diameter (6.5 inches) created by a designer on Printables called Cecca_7. First, we’ll look at the price in a very basic PLA material, then go up from there to an ultra-durable carbon-fiber nylon. All of the prices below are from the 3D printing service Craftcloud, which generally has the lowest prices of the major service providers.

Price of One Functional Model from Various Services

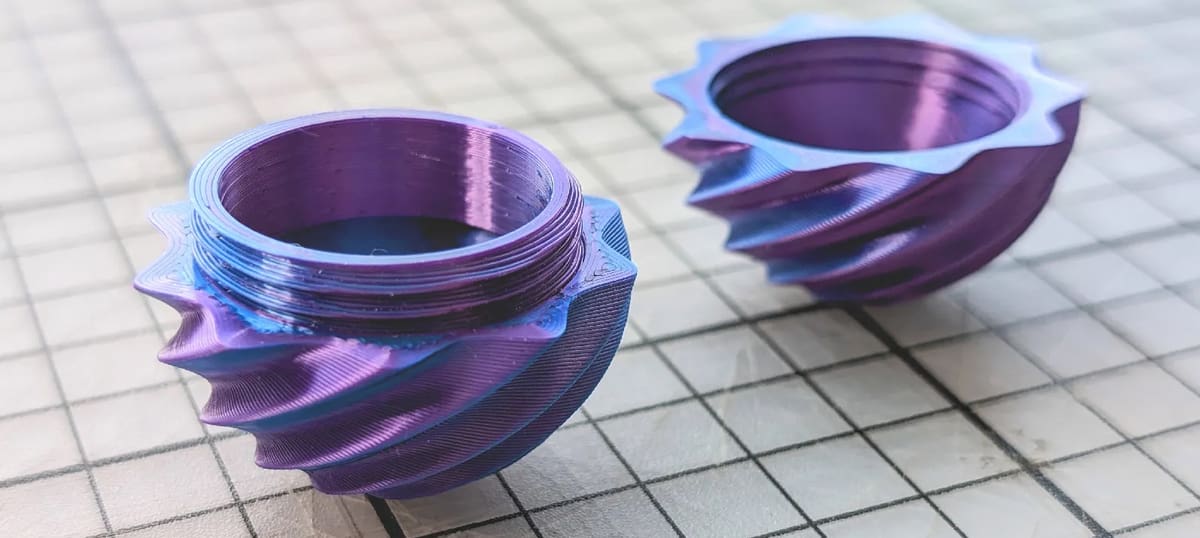

Multi Jet Fusion is the name of a 3D printing process developed by the company HP that’s sought after for durable, end-use parts. MJF offers very fine resolution and high details, so we wanted to put it to the test on a functional part (which requires the strength and durability of nylon with MJF) that is also visually appealing.

For this, we wanted to investigate a 3D printing a part with a complex geometry that includes threaded parts that must align perfectly, so tight tolerances were essential.

The idea behind this spiral sphere container project (STL file available on Printables by IKA Meister) is to test MJF nylon 11 for a functional prototype. Here we found that one prototype was affordable enough to repeatedly order as your design develops.

We also wanted to explore nylon PA 11 because it is derived from renewable resources, specifically castor oil. It is more eco-friendly and sustainable than nylon 12, which is made from petroleum. Unfortunately, Protolabs and Skybridge do not offer PA 11 in MJF.

How Much Do Metal Parts Cost to 3D Print?

You can have your part or parts 3D printed in a wide range of metals ranging from stainless steel to titanium, and you’ll also have a choice of technologies.

Metals are more expensive than plastics so before you order a part in metal, even if it’s a replacement for a part in metal, consider if it really has to be metal. Often, a composite material, like glass-fiber or carbon-fiber nylon will do just fine.

To compare various 3D printing services in metal, we created three printing project orders:

- 3D Printing 500 Aluminum Brackets

- 3D Printing 50 Stainless Steel 316L Hand Levers

- 3D Printing 1 Titanium Drill Bit

3D Printing 500 Aluminum Brackets

This sample project represents a scenario any manufacturing company could find itself in when the normal part supply chain is disrupted.

Imagine a company that routinely receives thousands of these aluminum brackets a year, which are used as a component in its final product. Because of a factory fire, a spike in the price of aluminum or transport, or a change in global trade tariffs, the overseas supplier cannot deliver. 3D printing is used to bridge the gap until you expect your full order of injection molded or cast parts.

Note that this particular model file, as with all of our four project model files, are relatively standard and, in real life, could be sourced elsewhere. However, we’re using them as representative of more unique parts that our fictional company wasn’t able to source elsewhere.

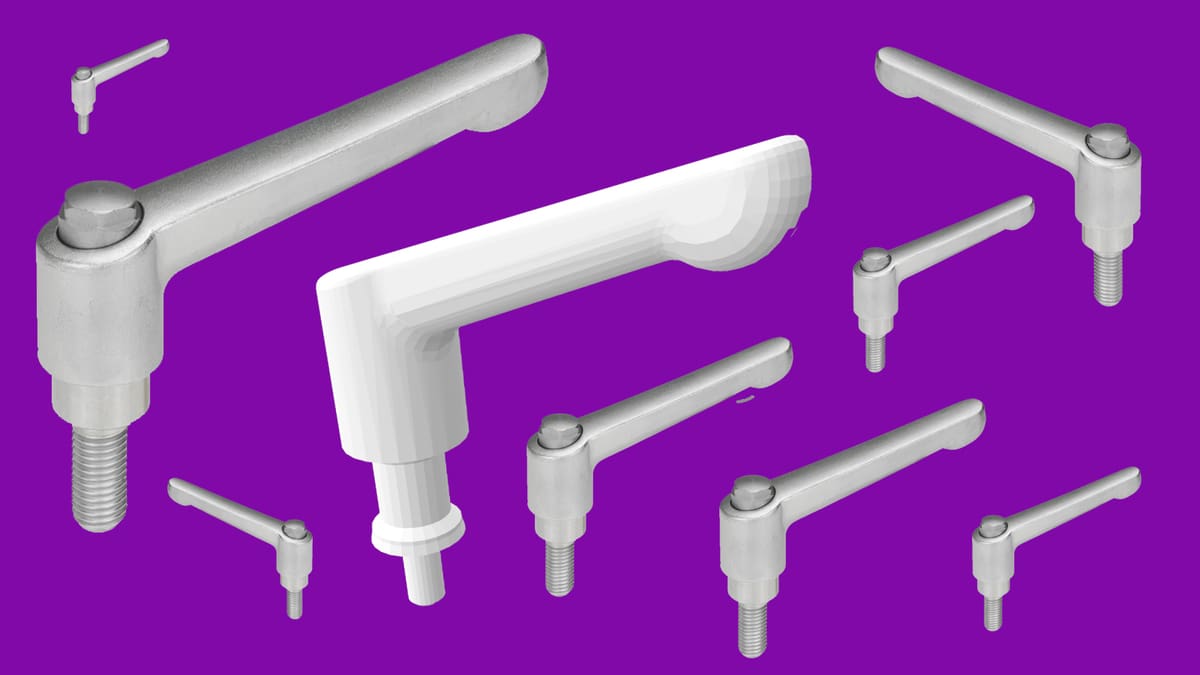

3D Printing 50 Stainless Steel 316L Hand Levers

This project represents when a company needs a small volume of specific parts unique to their product, but machining or injection molding just 50 is cost-prohibitive. The mold itself to injection mold these handles would likely be thousands of dollars and the cost of the steel to machine them would, likewise, be very high.

Typically, a company might change the design of their product to incorporate a “standard” or off-the-shelf part. This would reduce the uniqueness of the final product, reduce the innovation it delivers, and possibly affect its function and appeal in the marketplace.

Metal 3D printing enables companies to not sacrifice their design for what is more easily manufacturable.

3D Printing 1 Titanium Drill Bit

In this sample project, we wanted to test the availability and price of titanium. Titanium drill bits are extremely hard and maintain their cutting edge for a long time, making them more durable than standard steel bits. This metal also has excellent resistance to corrosion and is often used in marine or chemical processing applications, where exposure to corrosive substances could degrade other materials.

Although this standard drill bit design we used in this project is likely available from suppliers, we used it as a stand-in for a unique titanium part that a company may need only one of. Rather than a drill bit, you could imagine this project representing one unique aerospace part or one medical instrument in titanium.

Comparing 3D Printing Services

When shopping for a 3D printing service, you’ll notice that many have instant quote features online. These are great to get a rough estimate for your pinter job. But an even better and faster way to get multiple price quotes it to use a 3D printing service marketplace, like Craftcloud, All3DP’s 3D printing marketplace. Here, you upload your digital file once, select your materials, and receive quotes from several 3D printing companies and you select the one that best meets your needs. Plus, unlike some other marketplaces, you’re given the name of the manufacturer.

Craftcloud gives you real-time prices from providers who can print your design in the material of your choice and deliver it straight to you. There are more than 100 material options, not to mention numerous finishes and colors. Besides the wide array of choices, there’s no minimum order price, IP-protected ordering, and a customer care team. And for business customers, Craftcloud offers customized payment options to adapt to everyone’s needs.

10 Tips for Avoiding Overpaying on 3D Printing Services

When ordering a part from a 3D printing service, there are several strategies to reduce costs without compromising the quality of the final product.

1. Optimize Your Design for 3D Printing

If your part was designed to be 3D printed, great. But if it’s the same digital file you use for injection molding or CNC machining, there are ways to optimize that design to reduce the amount of material necessary. For example, ensure that your design is hollow where possible, using, instead strong internal lattice structures to maintain strength while saving material. Likewise, if your design involves multiple parts, often you can combine them into a single part in 3D printing.

2. Choose the Right Material

If your part is intended to be a visual model, you won’t need it in nylon, a less expensive PLA will do. Similarly, consider if your part really needs to be be metal. Perhaps a composite nylon will be just as strong.

3. Select the Appropriate Printing Technology

Opt for a 3D printing technology that is cost-effective for your design. For example, FDM is typically less expensive than SLS or SLA, especially for larger parts, but when you start to increase your volume to 10s or 100s of parts, SLS can end up being cheaper than FDM.

4. Reduce Part Size

If your prototype doesn’t have to be lifesize, scale down the size of the part. Smaller parts use less material and require less print time, directly lowering costs.

5. Opt for Low-Resolution

Selecting a lower resolution (layer height) or draft mode is best when fine details are not crucial. Lower-resolution prints are faster and require less material, reducing costs.

6. Order a Draft Print Before Your Final Print

If the part you need is in metal or a more expensive polymer using a more expensive technology, like MJF or LPBF, order a low-quality draft part in an expensive plastic first. This way, you can do a quick check for size and fit before investing more in the final 3D printing order.

7. Minimize Supports and Post-Processing

Design parts that require minimal support structures during printing, which reduces material use and post-processing time since those parts typically have to be manually removed by the service. Or request that the part be sent with the supports so you can remove them yourself to save on this labor cost.

8. Consider Lead Time

If time allows, choose a longer lead time for your order. Many services charge extra for rush orders, so selecting a standard or extended delivery option can save money.

9. Shop Around

Compare prices from different 3D printing services. Prices can vary significantly based on the service, material, and technology used. Some services might offer better rates for specific types of jobs or materials.

10. Reach Out to Customer Service

Instant quotes and online ordering are great, but if you’re not 100% sure of your selected material or technology, go with a company that has robust customer service ready to answer questions about your specific order.

License: The text of "The Real Cost of 3D Printing Services?" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.