Quick Introduction to CNC -- I Came, I Sawed, I Conquered

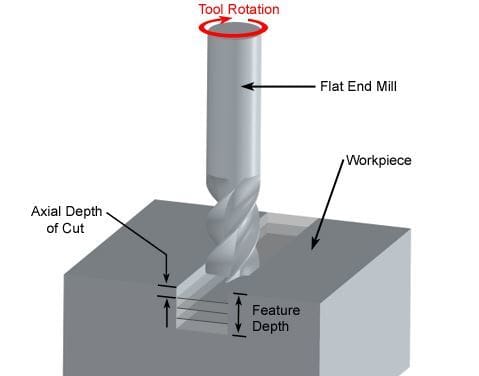

CNC is the “subtractive 3D printer”. Just imagine three-axes of motion, software, and a spindle with a cutter in the place of an extruder, and you have a CNC router. CNC stands for computer numerical control, a term that goes back to when a computer was the size of a refrigerator. CNC’s range from desktop hobby machines to four-foot furniture-making machines and metal working behemoths.

CNC starts with a block or plate of clamped material. Then, using a g-code motion recipe (like a 3D printer), CNC moves the cutter in paths to cut pockets, outlines, and through-holes as well as face off surfaces.

CNC offers these advantages over 3D printing:

- works with wood, plastic, aluminum, and steel (with an industrial kit)

- can be extremely accurate and deliver very smooth surfaces

- large work envelope — a 24-inch square is typical but it can go up to 4′ x 8′

- much faster than 3D printing

CNC has these downsides:

- parts are solid under the surface (no analog to infill in CNC)

- color choice is very limited

- the starting material is the bounding box of the final part… and a lot of it gets turned into chips

- the machines can be expensive

- the cutting process is NOISY!

But the next question is, assuming you have a machine and earplugs, what kind of material should you feed into it? Let’s take a tour of the basic CNC material choices for the hobbyist maker.

Short Tour of the Hobbyist CNC Maker's Go-To Materials

First stop: baltic birch plywood. This is a great prototyping material for many CNC projects. It’s low-cost, high-quality, and paintable. Just be careful you don’t need any of the following:

- waterproof

- clear

- impact resistant

- slippery, bearing-like surface

- abrasion resistant

Next up is polycarbonate. If your part can be clear and doesn’t need to serve as a bearing or slippery surface, PC is often the way to go. If you need more strength or rigidity, consider an assembly, and remember that polycarbonate can be cold-bent on a bending brake, an excellent way to add structure and rigidity after machining.

Now we come to a fork in the road:

- For more strength, hardness, or temperature resistance, move to aluminum.

- For thicker parts, with a slippery surface, impact strength and abrasion resistance, try UHMW.

Last stop on our short tour is acetal, for when you need a precise, slippery material available in black or white.

Getting confused between the different plastic options? Check out this chart comparing plastic properties.

For more detail, we take a more in-depth look at the five recommended materials for CNC.

CNC Material #1: Baltic Birch Plywood

Baltic birch plywood is great for CNC: It’s consistent, void-free, stable cabinet-grade plywood. It also has an attractive exposed edge. For more, see all about Baltic birch plywood.

- available thickness of 1/10″ to 1″

- about $3 for a 1/4″-thick, 12″ x 12″ piece

- about $6 for a 3/4″-thick, 12″ x 12″ piece

- easy to cut

- easy to join

- ready to finish with paint or stain

CNC Material #2: Polycarbonate

Polycarbonate, also known as Lexan or Makrolon, is a strong, impact-resistant engineering-grade plastic that mates very well with CNC. Thicker material does get very pricey. If you can work with 1/4″ clear sheet, this is a versatile material that is a pleasure to cut.

- available in thickness of 1/10″ to 3/4″

- about $15 for a 1/4″-thick, 12″ x 12″ piece

- about $200 for a 3/4″-thick, 12″ x 12″ piece

- easy to cut

- high impact strength

- cold bendable

- generally available only as clear or tinted

CNC Material #3: Aluminum

Aluminum is what they used to make airplanes of (until carbon fiber came along). Aluminum has an excellent strength-to-weight ratio, and is much stiffer than plastic. Working with aluminum has its challenges but opens the door to strong, high-tech parts coming right off your CNC machine.

- available in thickness of 1/32″ to multiple inches

- about $35 for a 1/4″-thick, 12″ x 12″ piece

- about $122 for a 3/4″-thick, 12″ x 12″ piece

- can be challenging to cut — requires lubrication and or cooling

- about 4x stronger and 30x stiffer than polycarbonate

- the basic engineering material — strong, light, and non-corroding

- post-CNC: choose 5052-H32 for bending and 6061-T6 for welding

- can be hard coated for abrasion resistance

CNC Material #4: UHMW

Ultra-high-molecular-weight polyethylene (UHMW) is like a poor man’s Teflon. Apart from having the same ultra-low coefficient of friction, UHMW is TOUGH. UHMW has a good bit of flex, so it isn’t a precision material. But if you need a bulky, slick, indestructible part with no moisture absorption, this is a good material to try.

- available in thicknesses of 1/8″ to 5″

- about $12 for a 1/4″-thick, 12″ x 12″ piece

- about $26 for a 3/4″-thick, 12″ x 12″ piece

- easy to cut

- slippery

- excellent abrasion, wear, and impact resistances

- generally available only in black or white

- better as virgin material (avoid reprocessed)

CNC Material #5: Acetal

Alternatively known as POM or Delrin, acetal is a terrific engineering-grade material with very similar properties to nylon. It absorbs no water and cuts like butter.

- available in thicknesses of 1/32″ to 4″

- about $22 for a 1/4″-thick, 12″ x 12″ piece

- about $58 for a 3/4″-thick, 12″ x 12″ piece

- very easy and accurate to cut

- precise

- low friction

- low water absorption

- generally available only in black or white

Other Options

The following are some other popular options for CNC milling:

- MDF is a cost-effective wood-like composite, but can create nasty dust.

- Nylon is a bit more expensive than acetal, absorbs water, and can swell. It is, however, an excellent bearing material.

- Acrylic (plexiglas), when compared to polycarbonate, is clearer and more scratch resistant. But with a much lower impact strength, it can be difficult to cut. Note that it cannot be cold bent.

- G-10/FR4 is the stuff that circuit boards are made of. It’s an epoxy-grade industrial laminate and phenolic with high strength and low moisture absorption. A glass-filled material, it’s both stiffer and stronger than polycarbonate.