When it comes to cutting glass, there are a variety of ways to make it happen. Despite the existence of simpler methods, such as using a glass cutter or a bottle clamp, when it comes to precision, laser cutting is the method of choice. Cutting glass using conventional methods works, but complex shapes often can’t reliably be cut without significant time, effort, and wasted material.

In contrast, laser cutting glass can be done as easily as cutting plastic. That said, the types of devices capable of cutting glass are fewer and cost significantly more, limiting consumer-level access.

Nevertheless, we’ll go through what you’ll need to cut glass using a laser as well as some other considerations, including safety concerns and how to get the cleanest cut.

Defining "Glass"

Glass comes in many different forms, so much so that there’s an entire museum dedicated to showcasing it. However, 90% of glass is soda-lime glass, which is made using either the float glass method or glassblowing. The float method makes extremely transparent and flat glass by “floating” molten material on a bed of liquid metal (usually tin). Other types of glass include the following:

- Stained glass (glass with color additives)

- Lead or borosilicate glass

- Aluminosilicate glass (colloquially known as transparent aluminum)

- 96% silica glass

- Fused silica glass

In addition to these types of glass, safety glass undergoes a special heating and cooling process such that, when it breaks, it does so into tiny pieces to reduce danger. Because of this treatment, this type of glass cannot be cut at home.

Best for Cutting

For cutting glass, soda-lime float glass is the easiest and most straightforward to cut. While the other types of glass can be cut, they usually require extremely expensive professional tools and special preparation. This is mainly due to the fact that other types of glass typically have higher melting temperatures and are designed to be more resistant to heat and impact.

With that in mind, let’s delve right into what is needed so that you can get to building your next glass project.

Questions to Consider

For consumer-level projects, soda-lime float glass is most commonly used, as it’s one of the easier types of glass to cut using a laser. In this context, one should consider the following questions, as they’ll influence the type of laser and power you’ll need to do the cutting:

- How thick is the glass? In terms of thickness, the thicker a material is, glass or not, the harder it will be to cut. There may need to be multiple passes or even a focus adjustment of the laser after a cut in order to get the laser to cut entirely through a thick material.

- How accurate and precise of a cut do you want? Multiple passes tend to make the cut dimension inaccurate, so fewer are usually better, if possible. In terms of a single cutting pass, the precision and accuracy will depend on the laser used, and this information is obtainable from the manufacturer.

- Can you afford to potentially break the glass? Finally, particularly with pieces that require multiple passes to cut, there’s a chance that the thermal expansion from heating and cooling the glass will cause it to crack or break, so you should consider how important the particular piece of glass you’re using is before you cut it.

Types of Cutting & Lasers

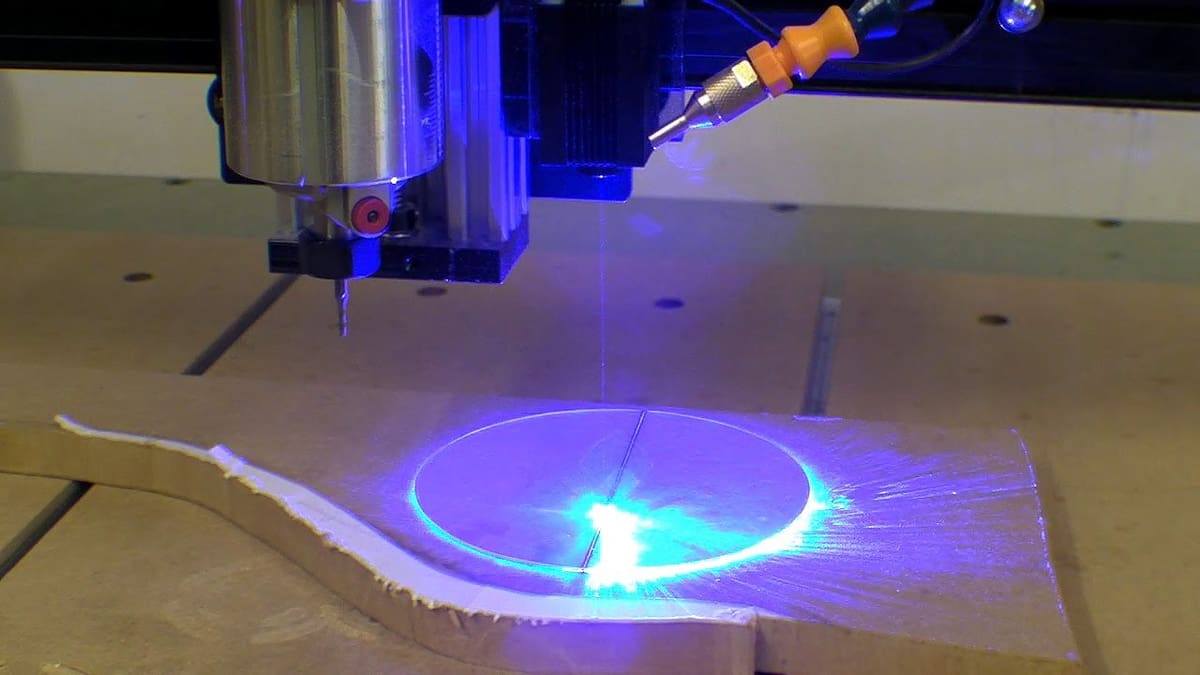

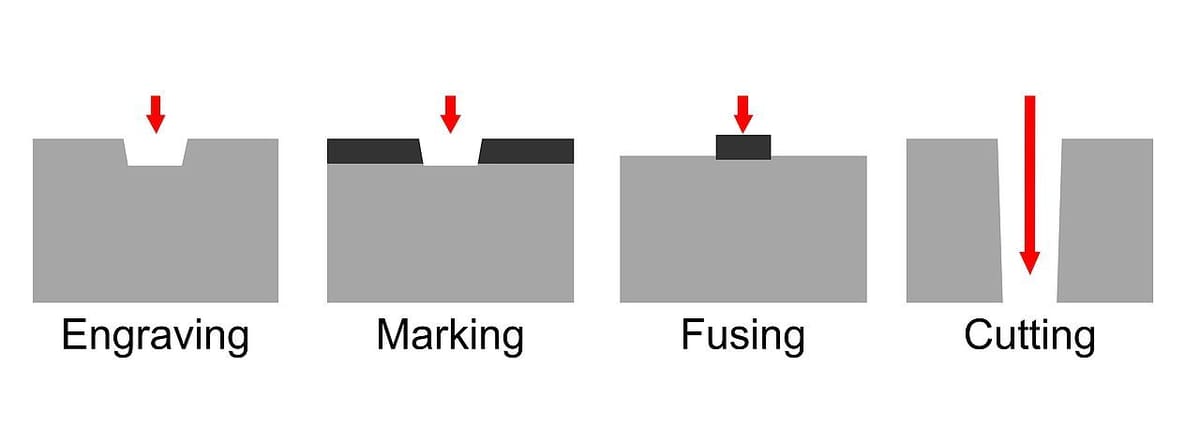

In general, glass can be cut by applying a high-energy laser to melt it. Two other methods of cutting glass include engraving and etching.

- Laser cutting works best with thin glass (when using specialized cooling processes). Stained glass can be cut at high wattage (400 W).

- Laser engraving generally removes from 0.02 to 0.125 inches from a material’s surface, but this is typically less with glass due to its high melting temperature.

- Laser etching only removes around 0.001 inches of material.

The goal with laser engraving and laser etching is essentially to create a scoreline in order to break the glass the same way you would with a traditional glass scoring tool, but with more precision. Of course, laser engraving works better for this purpose. It gives a deeper score, but either method could work depending on your application and the thickness and type of glass.

Lasers Suitable for Cutting

In the world of laser cutting, two types of lasers are in common use.

- Continuous-wave laser: This type of laser continuously delivers energy during the cut. Cutting occurs because the glass is heated to the point of vaporization.

- Pulsed laser: This type of laser compresses the energy for cutting into a very short period of time. Compression allows high energy densities and temperatures to be achieved, which can lead to better cuts overall, with less deformation.

Between the two, pulsed lasers tend to be more expensive, due to the exotic materials and electronics that allow them to pulse.

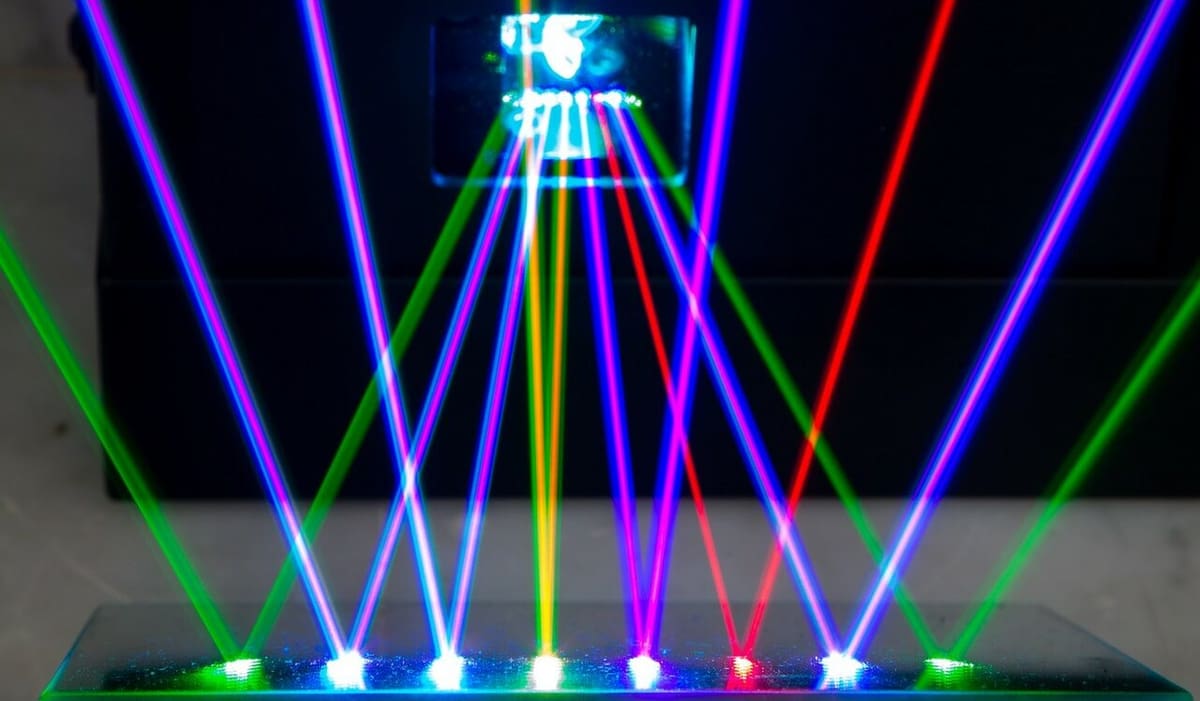

Wavelengths Suitable for Cutting

A Bit of Background

Generally speaking, it’s not possible to cut glass with a laser of a wavelength in the visible spectrum. This makes sense given that glass is typically clear, meaning very little laser energy within the visible spectrum would be absorbed.

Colored glass, such as stained glass, does have inherent pigment in it that’s capable of absorbing energy (light and heat). This makes it more susceptible to being marked with a visible laser of an appropriate wavelength (a color that will be absorbed by the colored glass).

There is an exception where visible light is able to cut or score glass. If a laser’s light intensity is so high that it’s capable of ionizing the air, this highly-focused beam can cause glass to crack by superheating the air around it. This mimics the appearance and some of the effects of marked glass.

Selecting a Wavelength

In general, the most common wavelength for cutting glass is 10,600 nm, or infrared light from a CO2 laser. At this wavelength, the Si-O bond in most forms of glass absorbs around 80% of the light, thus giving that wavelength a strong ability to cut the glass.

Another commonly-used wavelength, effective for similar reasons, is 355 nm, over in the UV zone.

You might wonder why someone would use a UV cutting method as compared to an infrared cutting method. The answer is that the smaller UV wavelength allows for a smaller cutting area, which in turn leads to less cracking and thermal effects on the glass. Typically, UV lasers are used for industrial cutting processes for products such as phone screens and microelectronics, whereas CO2 lasers are typically used for consumer- and design-level glass cutting.

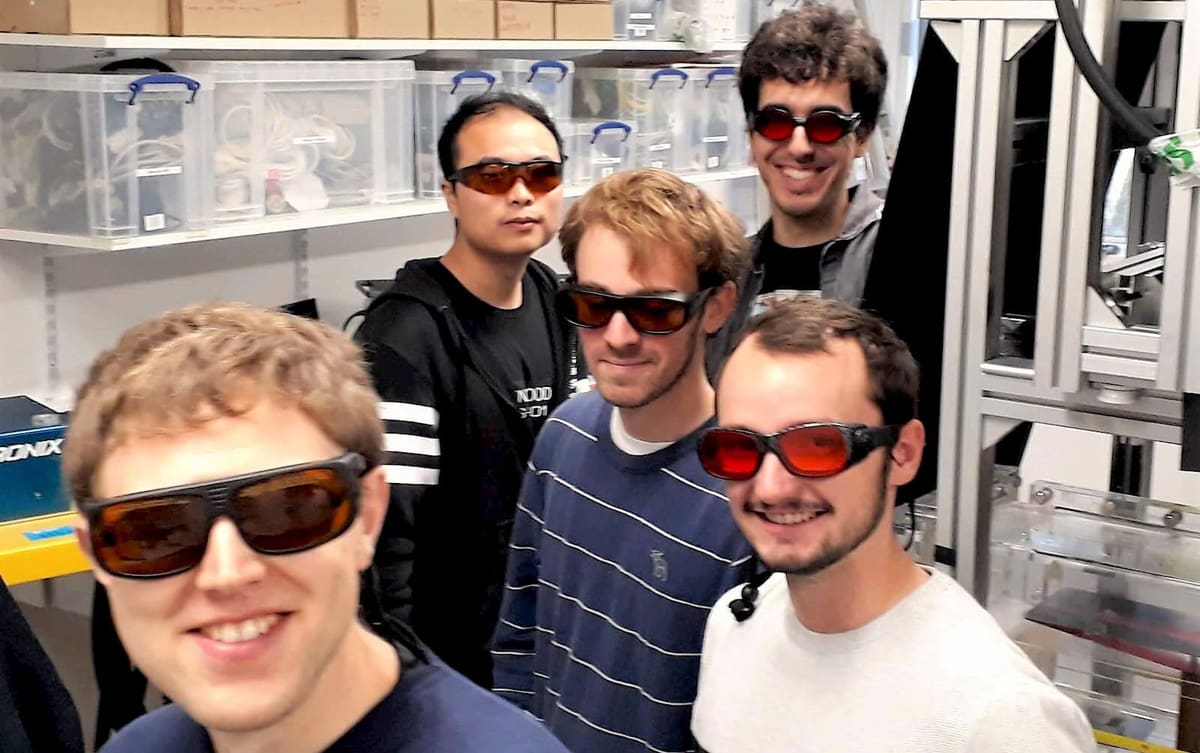

Laser & Glass Safety

When it comes to lasers (and glass cutting), there are a few simple but important rules:

- Wear eye protection that blocks the laser wavelength you’re using. You should check the optical density (OD) of the safety glasses and make sure that it protects you against the specific wavelength of the laser you’re working with. Keep in mind that CO2 and UV lasers have different wavelengths and that there may be differences based on the specific machine used.

- Don’t ever look directly into the laser beam.

- Don’t put your extremities anywhere near the path of the laser beam or on the level of the laser.

- Provide adequate ventilation for the laser.

- Use appropriate gloves when handling glass to avoid cutting yourself.

It should be noted that CO2 lasers use transparent plastic covers so that you can watch the item as it’s being etched. This is generally safe, as long as the plastic used absorbs CO2 light similarly to glass and is thick enough. (An example is acrylic.) That said, you should still wear the goggles, as a stray laser beam can burn through acrylic quickly; a secondary layer of protection is always advised.

Getting Started

To cut glass with a laser, you’ll need to follow a few steps, similar to what you would do to create a 3D printed object:

- Find a piece of glass you’d like to cut, and ensure that it fits inside your laser machine.

- In order to use most laser cutters, you’ll need to create a DXF file. This process will vary depending on the software you use, however, the general process will be the same. Got a 3D model? You can convert from STL to DXF.

- Put on all personal protective equipment (goggles and gloves).

- Place the glass on the laser platform and turn on the ventilation system (usually a fan within the laser machine).

- Load the file and laser-cut, etch, or engrave the glass.

- Once the glass has been cut, the edges may be extremely sharp, so you may need to sand them down until they are dull enough to be handled.

Tips

The laser may not cut all the way through the glass on the first pass. If that happens, either increase the number of passes or use running pliers to get the glass to crack apart cleanly.

Using cold water or oil can help, but it can also cause the part to break in unwanted areas. Test with a scrap piece of glass first.

Laser Cutting Machines

The sad truth is that it’s very difficult to find a consumer-level laser cutter that can cut through glass. The 30-W to 50-W machines that dominate the consumer market simply aren’t powerful enough. As an alternative, makers might want to consider plexiglass, which is well within the range of consumer-level machines’ capabilities.

On the positive side, these machines can often etch and engrave glass. For example, machines such as OMTech 40 W or the GlowForge series market this capability. For more consumer-level options, check out The Best Laser Cutters – Buyer's Guide.

Industrial-Grade Laser Cutting

Actual glass laser cutting is much more the purview of industrial-grade laser cutters. As consumer-level machines are already in the four-figure price range, you can only imagine how much an industrial laser cutter costs.

But to give you an idea of the type of laser that actually cuts glass, we present Coherent’s HyperRapid NXT laser. It’s the top of the line in both price and functionality. Its SmartCleave technology reportedly allows for glass and ceramic materials to be cut by a very high power peak laser pulse, which rapidly pulses (up to 4 million pulses per second) to cut the material.

The advantage of this system is that it can produce UV, visible, and IR light to allow for optimum cutting and engraving. In addition, the extremely short pulse duration of this laser prevents thermal effects from causing stress cracks and fractures in the glass while cutting.

License: The text of "How to Use a Laser to Cut Glass" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.