The transformative landscape of manufacturing continues to move toward on-demand production, enabled by technological advancements such as 3D printing, which offers a more responsive and personalized framework.

The traditional and advanced fabrication techniques have complemented one another in a series of applications, stages of production, and processing paradigms, such that businesses are increasingly adopting both into their workflow. This improves production efficiency, costs, and rapid adaptation to the dynamic market.

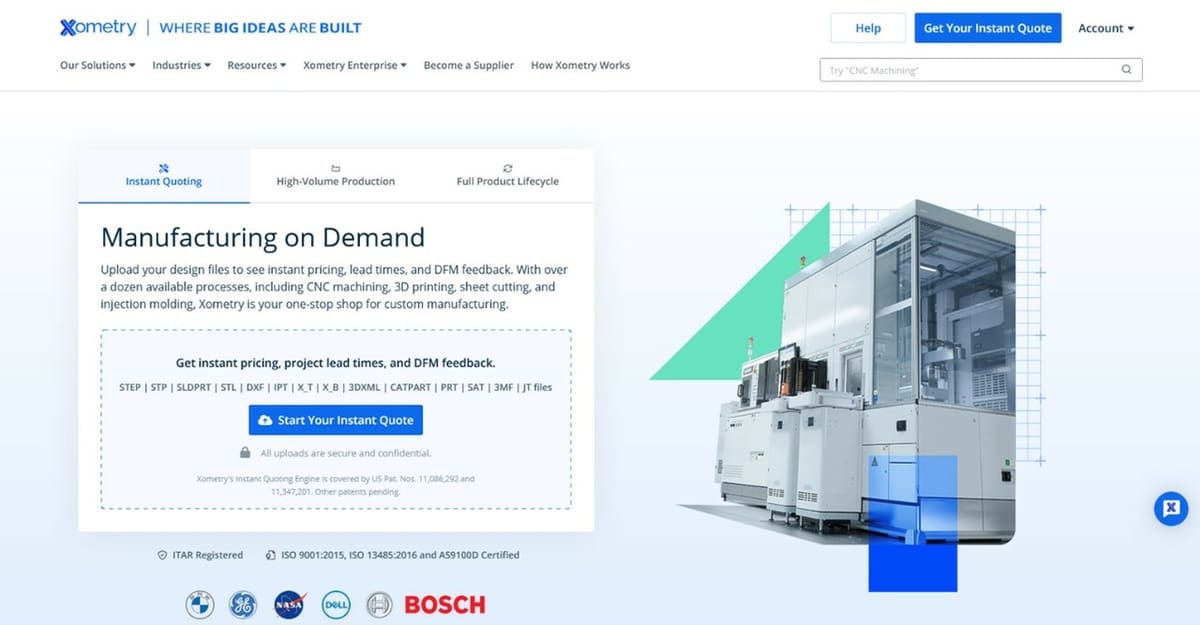

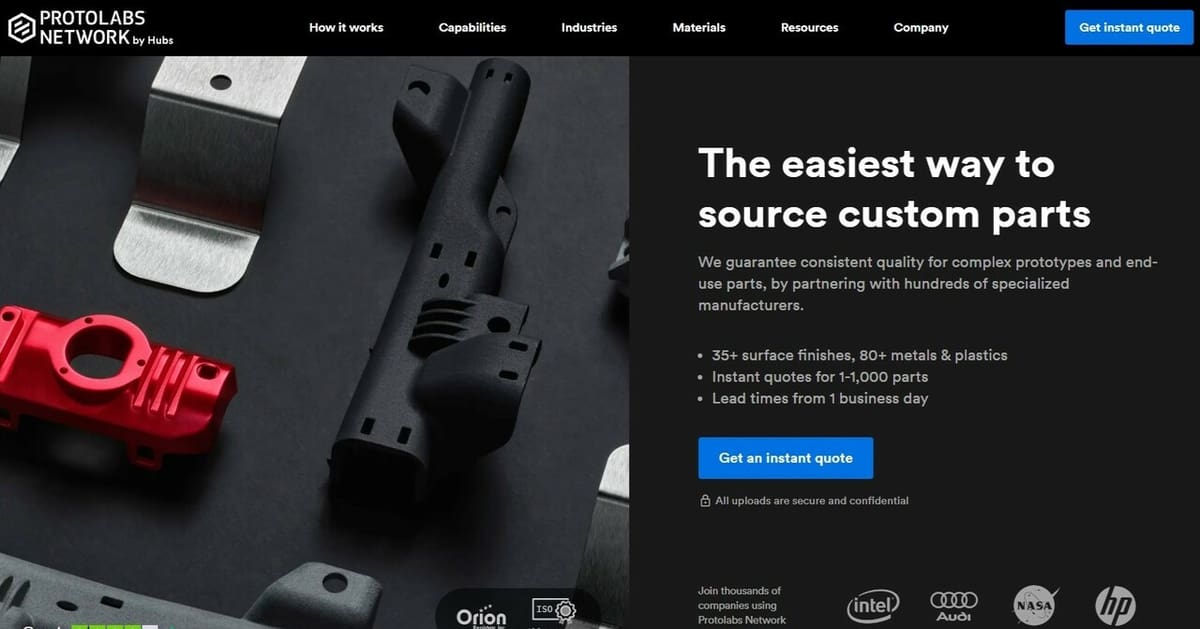

Within this dynamic market, Protolabs Network (Hubs) and Xometry have risen to prominence in 3D printing and other forms of rapid prototyping and end-use products, leveraging advanced manufacturing technologies to provide on-demand solutions with global reach.

Protolabs Network (Hubs) specializes in on-demand production with rapid prototyping capabilities. In a somewhat similar manner, Xometry operates by connecting businesses and other interested parties with a vast network of partners that offer a broad spectrum of manufacturing technologies, such as 3D printing, CNC machining, and injection molding.

This article aims to showcase the capabilities and business models of each platform, highlighting their similarities and differences. We hope readers will have a more comprehensive view of how these two giants are shaping the future of on-demand manufacturing.

Background

Both Protolabs Network (Hubs) and Xometry have, in a nutshell, a similar business model, but there are still aspects worth looking into for both in terms of the background and network of partners.

Business Model

Protolabs recently acquired Hubs, which has been rebranded as Protolabs Network. Before this acquisition, Hubs was also known as 3DHubs. This move marked a shift to a decentralized network model, expanding beyond 3D printing to include traditional manufacturing services such as CNC machining and injection molding.

That said, the business model for both Protolabs Network and Xometry is similar: The two companies assume a marketplace role, connecting businesses and consumers with a network of hundreds of vetted manufacturing partners (MPs) worldwide. These partners offer a wide range of processes, which will be discussed further below.

The networks provide speed and flexibility in order fulfillment, allowing both Protolabs Network and Xometry to earn a commission for each purchase order completed through their platforms.

Taking matters a step further, Protolabs Network goes beyond physical production by providing additional digital service tools such as design optimization, a material library, and supply chain management. Its platform, powered by AI, offers valuable data to potential customers, providing more insightful recommendations for their projects. Furthermore, Protolabs Network streamlines its digital manufacturing services by partnering with leading software developers and providers and relevant industry agents.

As for Xometry, its platform technology can be licensed to other manufacturers and organizations, where their AI-powered platform provides fast and accurate quotes. Recently, Xometry announced a partnership with Google Cloud to help accelerate newly developed auto-quote models within their AI-powered Instant Quoting Engine. Additionally, Xometry acquired the company Thomas, a leader in product sourcing, supplier selection, and digital marketing solutions, back in 2021.

Network of Partners

Protolabs Network (Hubs)

Based on location and required expertise, Protolabs Network’s global network of manufacturing partners (MPs) provides users with the flexibility to adaptively select what best suits their specific requirements. It boasts more than 250 highly vetted supply partners spread globally, and it acts as the digital platform for the already impressive Protolabs company.

MPs can be integrated into every part of the life cycle of a product, from innovation and prototyping to production and end-of-life product support. The platform can cater to orders made at specific locations or time zones. Their MPs are also capable of handling small-volume prototypes to high-volume manufacturing (HVM) and strict quality control measures.

Protolabs Network can offer same-day orders with expedited purchases, depending on part size and volume. Generally, they provide quick quotes for fast turnaround times at different prices from various partners, leveraging the best value for different budgets. From quoting to delivery, communications with selected partners are ensured through their platform while managing the entire project through their system. For certain technologies, Protolabs offers in-house manufacturing capabilities with faster production turnaround.

Xometry

Xometry has been a player in the field of manufacturing marketplace for a while now, reporting 10,000+ global manufacturing suppliers. Thus, they claim to be the largest network of its kind with an estimated 30 million available machine hours. Equally diverse, Xometry’s network guides users through a partner selection process based on required specifications.

Across the globe, their partners offer a wide range of manufacturing capabilities and benefits, especially those related to standard adherence (ISO, NADCAP, etc.). Similarly to Protolabs Network, users have access to diverse capabilities of technology and materials. The platform allows price comparison for the best value and provides quality assurance services. Orders ranging from small-batch prototypes to larger production runs can all be handled efficiently. Also, it allows for quick turnaround times with streamlined quoting from accessible partners around the globe at different locations and time zones.

Xometry also has in-house manufacturing services for some featured technologies. However, their goal is to expand their network to strategic locations to cater to a wider range of potential customers and handle larger production volumes. To make their process more streamlined, they have invested in integrating reputable software packages into their platform and vice versa. This includes Xometry CAD add-ins in software packages including SolidWorks, Autodesk’s Fusion, and Onshape. These offer users seamless instant quoting, design-for-manufacturing (DFM) feedback, and quick toggling between process, material, and quantity to generate quotes in real time and within the CAD workspace. This has made the network much more accessible and communication between buyers and sellers more reliable, reducing potential repeats and improving quality standards.

Similarities & Differences

Essentially, both Protolabs Network (Hubs) and Xometry are key players in the on-demand manufacturing market. However, they do have some differences in adapting their respective business models.

The key similarity between the two is their dedication to expanding their network by connecting businesses and buyers with diverse manufacturing solutions offered by qualified sellers. Protolabs Network adopts a more decentralized model, focusing on rapid prototyping. Xometry’s model represents a comprehensive marketplace as a one-stop shop for numerous services.

Both Protolabs Network and Xometry manage their models through an online platform, offering a streamlined quoting process. They earn commissions on completed orders through this platform and offer quality control measures for customers seeking fast-turnaround production, whether it’s for prototypes, low-volume, or bulk manufacturing. In recent years, Xometry has been growing its revenue heavily from B2B services with a focus on engineering and product development.

Both offer a similar range of technologies with some variations, as will be discussed later.

Arguably the most prominent difference between the two is the size of their partner network, with Xometry having a much wider global reach. On the other hand, before acquiring Hubs, Protolabs had its own in-house facilities, allowing a one-stop-shop model for some projects.

Overall, both platforms serve the same market, with Protolabs Network relying more on a curated network with certain quality standards, and Xometry depending on a larger network with competitive pricing.

Platform Interface

Protolabs Network (Hubs) and Xometry have user-friendly online platforms that manage the ordering process from idea to finished product in a seamless and streamlined manner. Next, we will highlight some of the unique features of each platform.

Protolabs Network (Hubs)

Protolabs Network, operating under the Hubs brand, provides large, clear buttons to help customers through every step, from uploading CAD files to placing orders. The “Get an instant quote” button can be found on the homepage and leads immediately to options on the choice of technology and to upload the CAD file of interest. The supported file types depend on the technology, and the CAD files can be easily dragged and dropped into the upload area, where the platform automatically recognizes the file format and checks if everything’s in order.

After the file is successfully uploaded, a quote is automatically generated with a page containing a few important elements. These include shipping, lead times, and quality documentation options. For the latter, different options may appear depending on the chosen technology, such as Conflict Minerals Declaration, REACH Compliance Declaration, Certificate of Conformance, and Material Certificates for All Materials. For other quality documentation or certificates, Protolabs Network gives you the option to connect with their account manager to provide the best option moving forward. This is important as some technologies chosen would not show quality documentation options such as for 3D printing.

On the quote page, customers can view the current part, specs, quantity, and price under “Parts & Specifications”. At any time, users can change these parameters while utilizing Protolabs Network’s design for manufacturing (DFM) analysis. The DFM prompt checks and issues possible warnings or errors regarding intricate details, mesh integrity, thin walls, and hard-to-remove materials. Otherwise, users can change file measuring units, materials, processes, color, and more. The available parameters depend on the process and material chosen.

Xometry

Xometry’s platform takes the form of a well-organized toolbox. The main page offers three tabs to start a project: Instant Quoting, High-Volume Production, and Full Product Life Cycle. The latter two are more oriented toward B2B models, where one can securely upload production files or talk to Xometry’s team for dedicated program management, multi-year program agreements, and in-house production. The platform remembers past projects for customers to revisit and provide additional certification if need be. Xometry accepts a wide range of file formats, with the uploaded design then being analyzed and ideal materials and technologies suggested based on its specifications.

After the part is uploaded, a quote number is generated within a personalized dashboard with a number of important items including “Lead Time Options” and “Add Certificate”. It should be mentioned that Xometry offers a number of certificates, making it easier for customers to certify their products without having to reach out to an account manager or sales representative for different quality inquiries. Some of the featured certifications for which Xometry is registered are International Traffic in Arms Regulations (ITAR), Defense Federal Acquisition Regulation Supplement (DFARS) Compliant material certification, and Standard Material Certification.

In the quote, customers can find their list of uploaded parts, where one can see the current settings for measurements, process, technology, material, finish, and quantity. It should be mentioned that DFM feedback is automatically generated when uploading the file, showing checks such as confined hollow, floating parts, large parts requiring a manual quote, and part volume checks. Additional options are generated depending on the chosen technology, such as infill for 3D printing, and color. The infill option is qualitative with no numeric values but can be found in the manufacturing standard page along with other parameters. The same goes for available finishes, where one may have to manually write a desired finish from the gallery.

It’s worth mentioning that Xometry has different site extensions for different continents and regions, should one want to order a part from a particular area. The site versions where customers can order from include the US, UK, Europe, Turkey, and Asia.

Processes

Both Protolabs Network and Xometry connect customers with partners for on-demand manufacturing needs. However, their roster of processes can differ somewhat for specific needs and preferences.

Protolabs Network (Hubs)

Protolabs Network, operating under the Hubs brand, assumes a legacy role for its diverse manufacturing capabilities since it was known as 3DHubs. Its platform caters to meet the needs of businesses and consumers alike with various services and processes.

3D Printing

Protolabs Network’s suite of 3D printing technologies includes fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and Multi Jet Fusion (MJF). It also includes an industrial scale for FDM and SLA technologies. The most notable service missing from this list is metal 3D printing. However, this and additional technologies are offered by Protolabs.

CNC Machining

Protolabs Network extends beyond additive manufacturing (3D printing), integrating CNC machining into its arsenal. The platform has invested quite a lot in an in-house production CNC plant, where the platform can accept orders for 3- and 5-axis machining and CNC turning.

Injection Molding

Buyers can make use of their impressive suite of injection molding technologies which includes plastic injection molding, die casting, insert molding, overmolding, and liquid silicone rubber molding.

Sheet Metal Fabrication

This technology is ideal for creating metal enclosures, brackets, and other needs made available by their network of manufacturing partners. Customers can make use of their laser cutting and bending equipment.

Xometry

Xometry’s comprehensive suite of services covers a broad spectrum of technologies and processes. As an on-demand manufacturing giant, users can rest assured that they have access to a breadth of manufacturing tools for a diverse array of applications, from prototypes to end-use products.

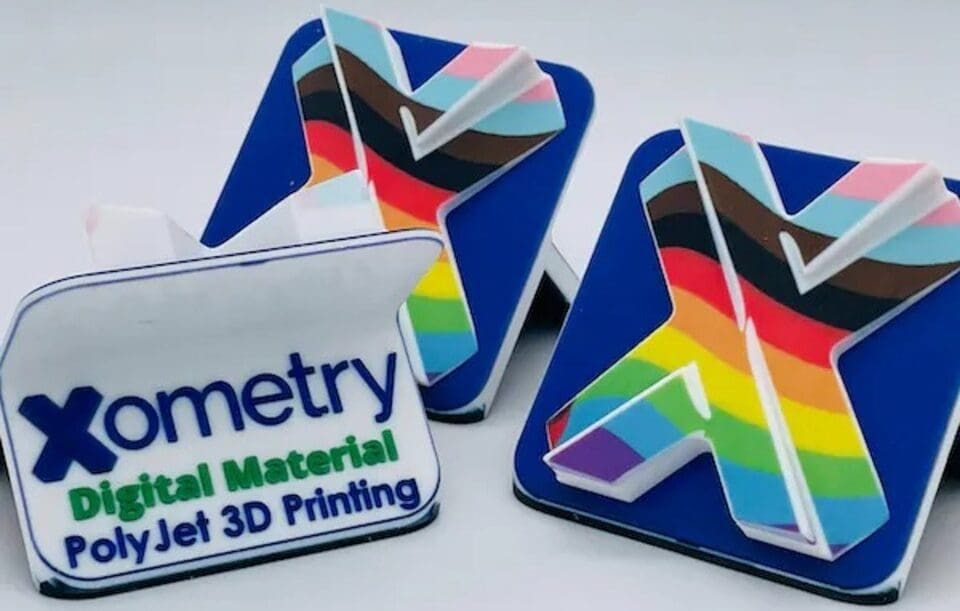

3D Printing

Similar to Protolabs Network, Xometry provides access to FDM, SLA, SLS, and MJF technologies. However, they expand their additive manufacturing tools to include metal 3D printing technologies that include metal binder jetting and direct metal laser sintering (DMLS). The latter’s other synonyms include selective laser melting (SLM), laser metal fusion (LMF), direct laser melting (DLM), and direct metal printing (DMP). Additionally, their roster includes PolyJet 3D printing for high-definition color models, Nexa3D’s Lubricant Sublayer Photo-curing (LSPc), and Carbon’s Digital Light Synthesis (DLS) for ultra-fast, high-performing prototypes.

CNC Machining

Xometry provides custom CNC machining services, including machining, turning, milling, and routing.

Injection Molding

Similar to Protolabs Network, Xometry’s injection molding services are suitable for a wide range of industries with different-class molds. Their solutions come in the form of insert molding, die casting, overmolding, metal injection molding, and medical injection molding.

Sheet & Tube Fabrication

This subtractive/formative process is designed for high precision and durable sheet metal parts. The platform provides fast and cost-efficient solutions for end-use applications like chassis, enclosures, and brackets. Their services include sheet cutting, laser cutting, waterjet cutting, plasma cutting, tube bending, and laser tube cutting.

Others

Xometry’s platform shows a wider range of additional processes customers may be interested in due to their broader network reach. These include urethane and silicone casting, metal extrusion, metal stamping, plastic extrusion, die-cutting, electrical discharge machining (EDM), micro-molding, and micro-drilling. These technologies are included in actual part production or as post-processing solutions to achieve desired aesthetics, surface finish, and performance.

Materials & Finishes

When it comes to on-demand manufacturing, the right material and finish selection play an integral part in deciding the right manufacturer for your project needs. Protolabs Network and Xometry both have a diverse range of options, but there are some subtle differences as presented here.

Protolabs Network (Hubs)

For varied needs and industries, a diverse selection of materials is available for customers engaged in different manufacturing processes. The platform also offers a wide range of material finishing selections that can be broken down for each technology.

3D Printing

For plastics, PLA, ABS, Nylon, and resin, among others, are all excellent options for small to industrial-scale production. As mentioned, metal 3D printing is available through Protolabs, with aluminum, titanium, Inconel, and more options offered. The platform also offers composites for special products, including glass-filled nylon and carbon-fiber-reinforced nylon for exceptional strength and stiffness. As for finishes, vapor smoothing is a popular one for plastic 3D printed parts.

CNC Machining

A wide selection of CNC plastics is available for suitable one-off prototypes and end-use custom parts. These include Nylon, ABS, PEEK, PTFE (Teflon), and PMMA (Acrylic), to name a few. The metal CNC suite, which is highly sought after, consists of aluminum, stainless steel, brass, and more.

CNC machining has the largest options for surface finishes of all the technologies provided by Protolabs Network. Some of the finishes listed include as-machined, polishing, bead blasting, anodizing type II and III, and electroless nickel plating. The platform also outlines its Cosmetic Acceptability Criteria to ensure complete transparency of its finishing process.

Injection Molding

The choice of injectable plastics includes ABS, polypropylene, polyamide 6, PMMA, PEEK, and more. The platform doesn’t provide pop-up options for finishes exclusive to injection molding, and users must provide clear instructions if they wish to request a specific surface finish.

Sheet Metal Fabrication

The technology mainly deals with metals. Thus, the available suite of different alloys provides the most common and highly demanded materials, including aluminum, copper, and stainless steel. As for available finishes, they are the same as those listed in CNC machining, with the exception of smooth machining, fine machining, polishing, and electroless nickel plating.

Xometry

To accommodate diverse manufacturing processes, Xometry has provided a broad spectrum of materials and finishes applicable to any of their featured processes. This is enhanced by their impressive network reach, allowing for a choice in high performance, aesthetics, textures, and colors.

3D Printing

Similar to Protolabs Network, Xometry has a wide selection of 3D printing plastics that includes nylon, ABS, ASA, Ultem, and other photopolymers (resins). As mentioned before, Xometry allows metal 3D printing directly on their platform. The featured materials are aluminum, stainless steel, Inconel, titanium, and more alloys. Their partnership with ExOne and their binder jet metal printing has expanded their gallery to include stainless steel infiltrated with bronze, single alloy stainless steel, and tungsten-bronze metal composites.

Xometry also boasts a wide range of material finishes. Three of the most common ones are vapor smoothing, color dying, and nickel plating. Others include sanding, polishing, and clear finishing. For metal parts, Xometry offers CNC machining, polishing, and sandblasting.

CNC Machining

For CNC machining materials, the platform provides plastics and composites as options for material selection. Some of the readily available materials are ABS, Garolite (fiberglass composite), PTFE (Teflon), and Ultem. As for metals, CNC materials represent a wide array of options for high-end applications, including aluminum, copper, bronze, stainless steel, titanium, and zinc alloys. Each alloy provides different numbering options and grades, averaging 4-5 different alloys per material.

Their CNC finishes include bead blast, anodized type II and III, electropolishing, electroless nickel plating, silver, gold, and zinc plating, and more. Customers can request custom orders on finishes.

Injection Molding

Xometry provides an impressive material stock for plastics and elastomers. The stock consists of ASA, polyethylene, liquid crystal polymer, PEEK, liquid silicone rubber, and much more. They also include blends of high-performing polymers for optimum, user-defined specs. For die casting, polyurethane options of textures, colors, and shore indices are available. For metal parts, the library includes stainless steel, tungsten heavy alloy, and WC-Co cemented carbide with different specified alloy numbers for each material.

The finishing options start with the Society of Plastics Industry (SPI) finishes from Grade 3 diamond or high polish to 320 stone low polish for plastic injection molding. Mold texturing, inserts, and laser engraving are also within the offered finishing stock. As for metal injection molding, electropolishing, chemical treatments, anodizing type II and III, and annealing are all available for users to choose from as their finishing option.

Sheet & Tube Fabrication

As mentioned earlier, sheet and tube fabrication deals mainly with metals. However, Xometry includes foam, wood, rubber, and composites in their suite. The library is expanded to include, among others, ABS, PVC, PTFE, and Garolite. As for metals, they have a similar selection provided by the CNC metal library, including Inconel.

The finishes available for sheet and tube fabrication are standard with de-tabbing and deburring. Additionally, parts can be left as-cut, bead-blasted, anodized, chem-filmed, metal-plated, and powder-coated, to name a few.

Pricing & Lead Time

Pricing and lead times on both Protolabs Network and Xometry depend on a number of variables such as design, order volume, materials, finishes, and the chosen process. The complexities and details of the part play a significant part in the equation, as more complex components require specialized processes that can impact both price and delivery times.

Both costs and lead times are directly influenced when it comes to overall manufacturing technology. Ordering large quantities has an economy of scale property, especially with technologies mostly associated with high-volume manufacturing (HVM) such as injection molding. However, this can logically increase lead times, with material choice also having a direct influence on pricing. In addition to this, the type of finishing chosen can further extend lead times and costs.

Overall, the vast network established in Xometry provides a more competitive pricing model with lower base costs on certain specs, often providing multiple lead time options, where accessing close partners helps in reducing shipping costs and faster delivery.

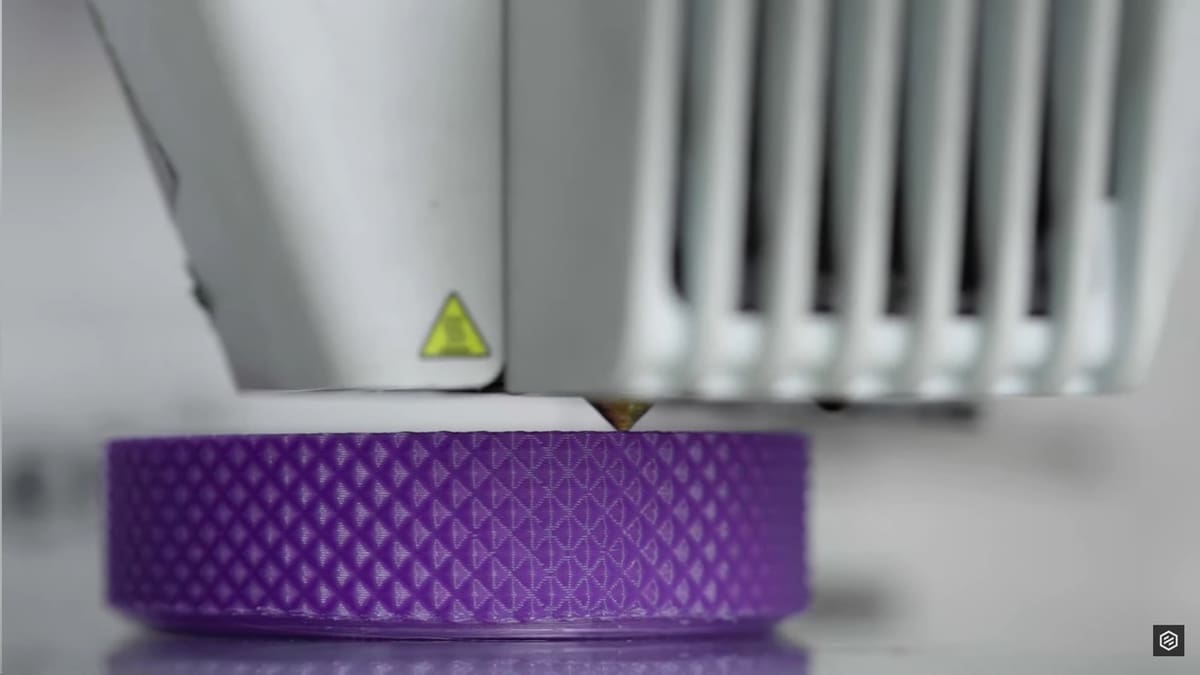

For example, the pictured 3DBenchy was quoted for $19.83 with Xometry when opting for FDM with ABS and a full infill. The same specs were chosen for Protolabs Network, where the quote was set as $22.51, with a delivery time of 3-5 days for both.

For both platforms, minimum order or volume depends highly on the manufacturing process. 3D printing can offer a single part for customers, whereas for injection molding, Protolabs Network requires a minimum of 500 units and Xometry requires 50. Additionally, both offer batch discounts and provide room for negotiations with dedicated account managers. An expedited production process can be made through clear communications with an assigned point of contact for each quote.

Customer Support

Protolabs Network and Xometry offer robust customer support through online help centers, support channels, and direct communications with their staff from multiple departments, whether technical or administrative. Their quick response system helps address queries and other issues within and beyond their quick quoting sites.

Both sites offer extensive resources. Protolabs Network’s help center provides detailed information, guides, case studies, videos, and FAQs for common issues and platform materials, and Xometry’s knowledge hub covers various aspects of the production process, along with technical guides, articles, tools, standards, and certifications, and plenty more.

If customers need to reach the support team, Protolabs Network offers phone, email, or scheduled live chats with partners, Xometry’s support channels include email, phone, and live chat, with the possibility of addressing doubts or issues related to the platform, specific requests, quality controls, and receiving guidance through the selection of processes, materials, and lead times.

Xometry’s support can scale with customer needs, from basic self-serve decisions to assigned communication channels for special projects and high-volume orders. Their platform is powered by AI to allow instant recommendations for common steps of the process through their intuitive online knowledge base. Additionally, they provide a huge library of case studies, blogs, supplier shop tips, procurement, and reshoring topics.

You can find plenty of support and guidance from both platforms, no matter which one you choose for your project.

License: The text of "Protolabs Network (Hubs) vs Xometry: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.