The Guinness World Record holder for the largest solid 3D printed object is a boat that’s 25 feet long and took 72 hours to print. Although you may not need an object quite this big, there are companies that can deliver your 3D printed large objects right to your door.

If your own 3D printer isn’t up to the task of making a life-size mannequin, a coffee table, a room divider, or store signage, a growing number of 3D print-to-order companies can help. Some of the most popular on-demand service providers have large-format 3D printers, but another option is the large-scale 3D printer makers themselves, such as BigRep or JuggerBot 3D.

Although there are many options for large-scale 3D printing services, location is important since you want to avoid large-scale shipping charges. Below, we cover options across the US and Europe, with an up-and-coming company in the Middle East. We also detail if these companies provide ancillary services such as painting. You’ll also find the biggest print size these companies offer and in which technologies since that affects the price, the level of fine detail, and the material options.

Some of the popular large-format 3D printing services can produce parts in sizes just over 500 mm, but here, we’re focusing on companies that specialize in large-scale 3D printing, which starts around 1,000 mm in at least one axis.

What is Large-Format 3D Printing?

There’s no specific measurement for “large-format” 3D printing technology, but the goal is a single, typically not assembled, 3D print of an object larger than your average 3D printer volume, say more than 500 mm wide or tall. However, assembly is commonplace with very large 3D printed objects, such as the life-size T-Rex at the Japanese Dinosaur Museum, which was printed in 50 parts.

The benefit of large-format 3D printing is that it vastly reduces the number of parts to assemble. The more parts, the more labor and potential weak spots in the assembly.

Large 3D prints are achieved with very large 3D printers using fused deposition modeling (FDM), resin 3D printing also called SLA, or robotic arm 3D printers that extrude polymer material from a nozzle. Each technology has different size limits, speed, and detail levels. Due to the variety of available technologies, it’s important to carefully consider your part and application before ordering.

* Massivit Gel polymers are materials used in the Massivit line of large-format 3D printers.

Craftcloud

Craftcloud is more than just a 3D printing service. It helps you compare prices and technologies from various manufacturers to find the one that fulfills your needs at a price you’re comfortable with.

Craftcloud partners with more than 150 printing service providers all across the globe. Comparing them is easy — all you need to do is upload your CAD model, pick the material and finish you need, and browse through the list to find a quote that works for you. Craftcloud generates quotes instantaneously in real time and doesn’t include any hidden fees. You’ll also see who will print your part exactly. Each provider has customer reviews, and Craftcloud takes responsibility for everything to ensure your satisfaction.

The maximum size of the prints, alongside available technologies, depends on the supplier. Once you upload your digital file you can browse the possibilities. The service works for both one-off prints, like prototypes, and small batches of fully functional industrial-grade parts.

Craftcloud also has an extensive library of material and support documentation to help you choose the right service provider.

- Large-format technologies: FDM, SLA

- Maximum build volume: 1,800 x 1,000 x 1,000 mm (FDM), 1,380 x 680 x 480 mm (SLA)

- Detail level: Varies by supplier & technology

- Materials: PLA, ABS, PETG, PP, TPU, resins, +

- Turnaround: Varies by supplier

- Location: Local manufacturing in 36 countries, ships worldwide.

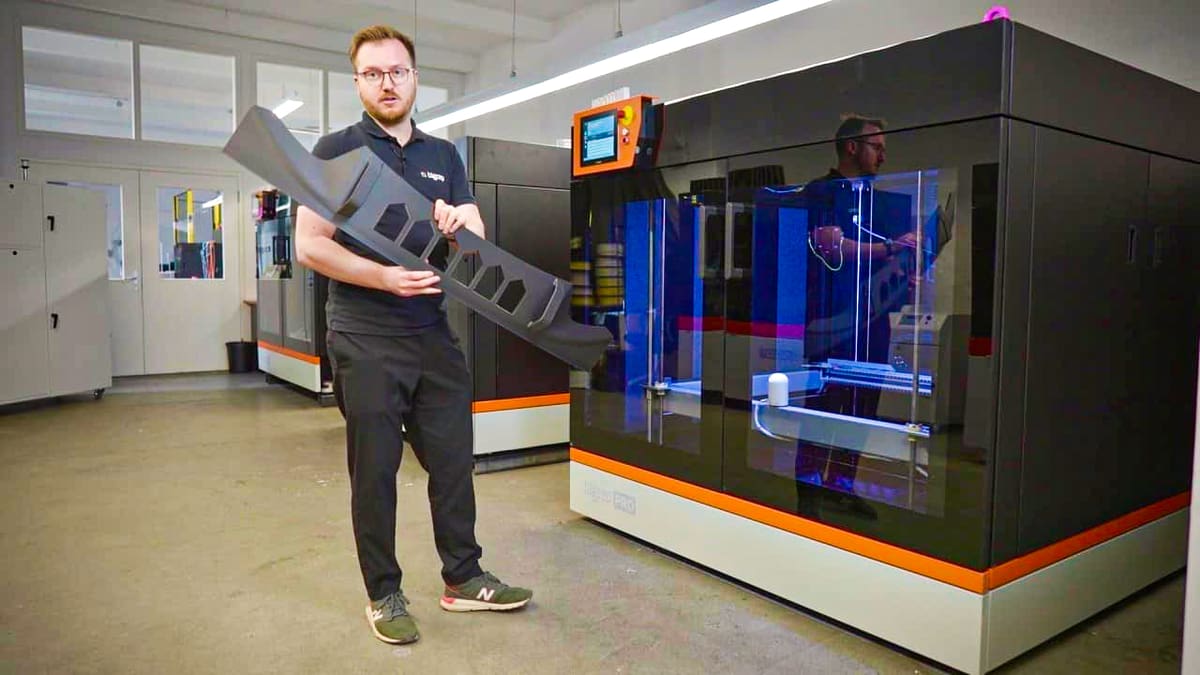

BigRep 3D PartLab

BigRep is a well-known maker of large-format 3D printers, which many services use. BigRep also offers its own 3D printing service through its Berlin facility and its manufacturing center in Wilmington, Mass. One advantage of going with a printer maker is that they know their machines inside and out and can better guide you on your options and limits. It’s also a great option if you already own a BigRep large-format 3D printer but need extra capacity when orders surge.

Ordering is easy with an online portal where you simply upload your part, get a price quote, and then receive the parts shipped to you. There’s a wide range of materials to choose from, including carbon-fiber-reinforced nylon, which is ideal for factory fixtures and automotive prototypes.

- Large-format technology: Fused Deposition Modeling (FDM)

- Maximum build volume: 1,000 x 1,000 x 1,000 mm

- Detail level: 300 microns

- Materials: PLA, PETG, ASA, nylon (PA6, PA12) carbon-fiber nylon, + third party materials

- Turnaround: From 5 business days

- Location: Germany, US

The Factory NYC

At The Factory NYC, they say you can come to them with a napkin sketch, a physical object to scan, or with fully engineered CAD file and they’ll bring your idea for a large-scale part to life. They company works with artists, engineers, and designers and specializes in displays for events.

With sectional fabrication, they can create individual objects at 5,700 mm and even larger. The company can deliver your large part in one piece or in pieces for assembly on-site.

The company uses a Massivit 3D printer, which use a type of material jetting technology with a resin gel to rapidly create large forms for industries ranging from automotive and mobility to marine and consumer products. Massivit 3D machines are a favorite among large-format service providers.

The Factory NYC’s online ordering form enables you to upload your idea and they’ll get back to you with guidance.

The company also offers CNC milling, carpentry, metalworking, and 3D modeling.

- Large-format technology: Material Jetting

- Maximum build volume: 1,447.8 x 1,117.6 x 1,778 mm

- Detail level: 500 microns

- Materials: Massivit Gel polymers

- Turnaround: From 5 business days and rush

- Location: New York

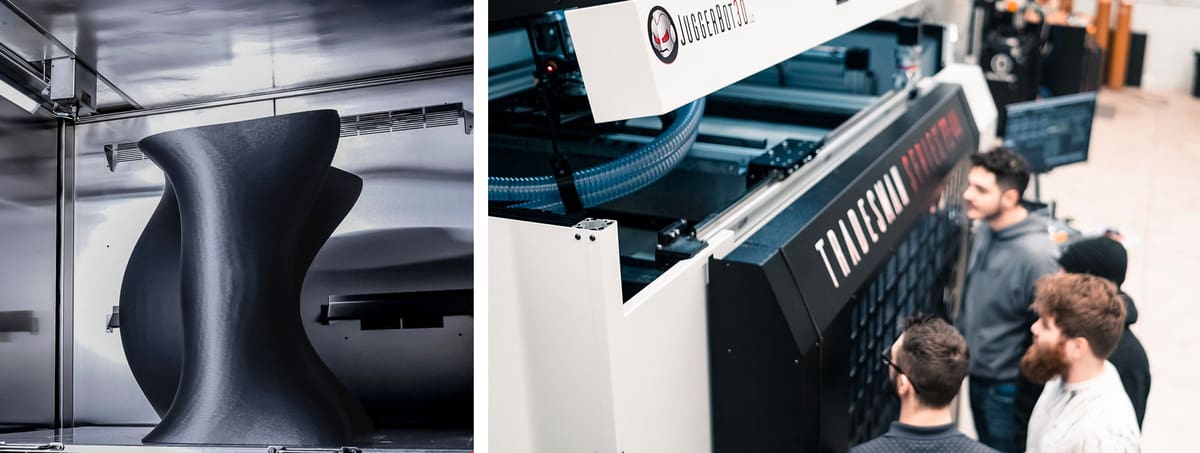

JuggerBot 3D

JuggerBot 3D is an Ohio-based large-scale 3D printer builder that also offers a print service. The company uses its own Tradesman Series P3-44 3D printers, which, naturally, they are experts with.

The Tradesman printers can build parts as big as 914 x 914 x 609 mm with filament, or 914 x 1,219.2 x 1,219.2 mm with JuggerBot 3D’s pellet extrusion technology. Material in pellet form is typically less expensive than filament and can dramatically cut the cost of your printed part.

Tolerances and detail will vary with nozzle size, part size and geometry, and material, but can be as close as +/- 0.13 mm, the company says. You can choose, corse, standard, or fine detail level, which is a great feature if you need a quick large prototype (corse) or a final product (fine). The wide material menu ranges from PLA to carbon-fiber reinforced nylon or PEEK.

- Large-format technology: FDM

- Maximum build volume: 914 x 1,219.2 x 1,219.2 mm

- Detail level: 500 microns

- Materials: ABS, ASA, PLA, TPC, PET, PETG, nylon 6/66, carbon-fiber nylon, PC, PEKK, PEEK, HIPS

- Turnaround: na

- Location: Ohio

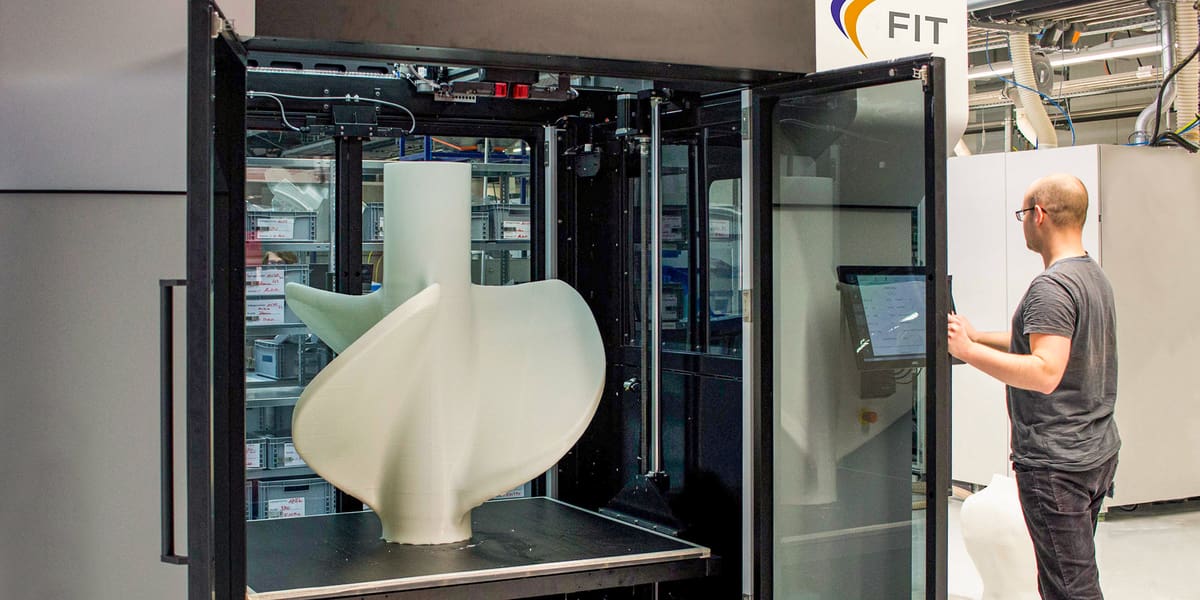

Fit AG

Fit AG of Germany is a European veteran in additive manufacturing. The company has provided on-demand 3D printing services for nearly 25 years, offering a respectable range of technologies. Although the service focuses primarily on Germany, Fit AG serves customers worldwide.

Fit AG’s large-format printing is unique with its use of Gel Dispensing Printing (GDP) technology. This proprietary printing method by Massivit 3D uses UV-curable resin gels to build large objects. The technology can create parts up to 1.8 meters in height. Although GDP can’t create accurate surface details, it does provide impressive print speeds. Fit AG says it can print at a rate of up to 2 kg/h. It’s also possible to improve the rough surfaces after printing with coatings, painting, and polishing. According to Fit AG, it’s particularly good for creating advertising objects, shop fittings, large props, and trade show stands.

Sadly, the service doesn’t have an option for instant quoting. In addition to 3D printing, Fit AG offers product design, part optimization, and reverse engineering services. They’re a good option for businesses located in Europe.

- Large-format technologies: Material Jetting

- Maximum build volume: 1,800 x 1,450 x 1,110 mm

- Detail level: 800 microns

- Materials: Massivit Gel polymers

- Turnaround: na

- Location: Germany

3D Next Level

3D Next Level is a Dutch manufacturing company specializing in large-scale 3D printing for both creative and industrial markets. Their services range from 3D design of your concept, through manufacturing, painting, engineering, and more, including 3D scanning.

The company has created 3D printed objects for billboards, marketing campaigns, trade shows, museums, and movie sets. The more industrial side of the company creates large-scale 3D printed prototypes, molds, and building facades.

Like a few other 3D printing studios on our list, 3D Next Level owns a Massivit large-scale 3D printer, which is their main production method. The also have a large resin printer from Photocentric.

- Large-format technology: Material Jetting, SLA

- Maximum build volume: 1,447.8 x 1,117.6 x 1,778 mm

- Detail level: 500 microns

- Materials: Massivit Gel polymers

- Turnaround: From 5 business days and rush

- Location: Netherlands

Caracol AM

Italy’s Caracol AM, with a new facility in Texas, is dedicated to large-scale 3D printing mostly using large-format robotic arm 3D printers it developed in-house. Recently, it began selling a robotic arm 3D printer called the Heron.

The company provides large-scale 3D printing solutions for any application, including a 3D printed sail boat.

The robotic system allows Caracol to print truly immense objects. The company cites the maximum width of a single print as four meters. However, Caracol also says it can stretch objects up to 10 meters wide by adding a rail or trolley system to move the arms.

The robot arms also give Caracol the ability to print at great speeds and to create geometrically complex parts. Each arm can move along six axes and print from any direction, making it possible to create overhangs and other challenging structures.

In addition to robotic arm 3D printers, Caracol offers large-format FDM printing using traditional 3D printers. The company also has CAD design services, material and waste recycling, consulting, and training services in its catalog. Due to the size and complexity of the parts Caracol creates, their on-demand printing service doesn’t offer instant quotes. Nonetheless, Caracol can create some of the largest 3D printed parts you’ll ever see.

- Large-format technologies: FDM

- Maximum build volume: 40,000 x 4,000 x 3,000 mm

- Detail level: N/A

- Materials: Various thermoplastics, including PEEK, PA, and PP

- Turnaround: N/A

- Location: Italy, Texas

REV3RD

Rev3rd (pronounced revered) is a Puglia, Italy-based company that launched back in 2020 makes large-scale 3D printers and offers a print service using their own machines.

The name comes from the Italian word for green, “verde,” referring to the company’s commitment to sustainable manufacturing combining by 3D printing with the use of recyclable materials.

The company has developed three pellet extruders that can be mounted on robotic arms or gantry machines depending on the size of the project. Their largest machine is the appropriately named RD-Huge with a printing capability of 2,500 x 2700 x 2,100 mm. All of their machines work with both recycled and recyclable polymers, standard or high performance thermoplastics, and they have recently put in for a patent for continuous fiber coextrusion.

To get a quote, simply contact them through their website with a message describing your project needs. They have a team of experts to help you both online and in person with 3D printing, laser cutting, and project and material testing.

- Large-format technologies: FDM

- Maximum build volume: 2,500 x 2,700 x 2,100 mm

- Detail level: 100 microns

- Materials: Polymers and thermoplastics

- Turnaround: na

- Location: Italy

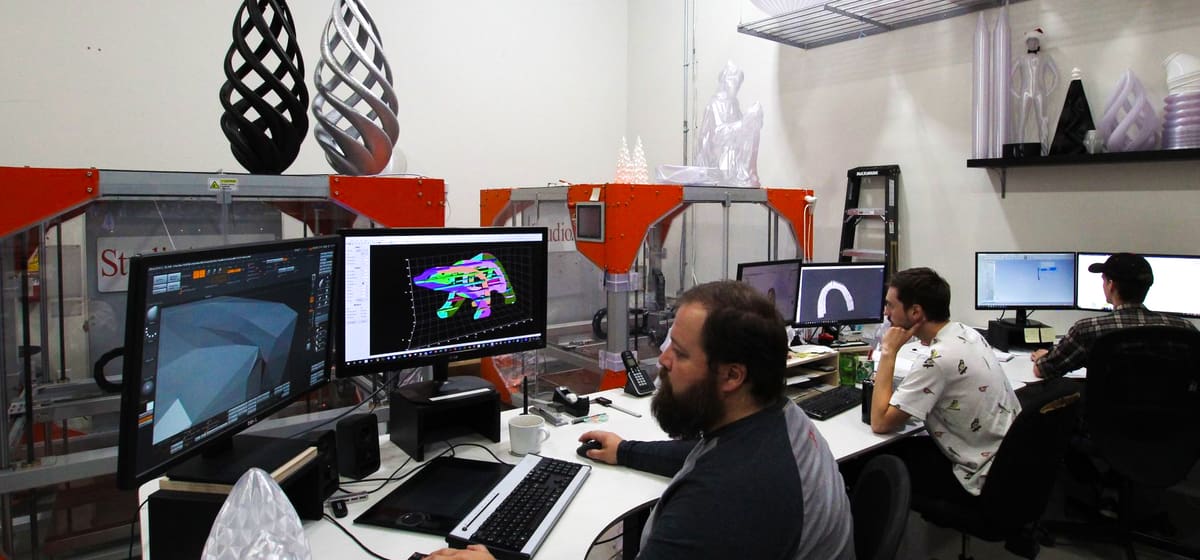

Studio Artefact

3D printing is both a production tool and a creative asset at Montreal-based Studio Artefact. The company has six BigRep 3D printers capable of parts up to a cubic meter each. For decades, the company has produced large-scale displays and turned to 3D printing to make the process faster and more innovative

There’s no quick-quote feature since this studio is more of a creative partner to your vision rather than a just a part-printing service. Studio Artefact has carved out a niche in North America as the premier maker of holiday decorations for shopping malls and also caters to the theme park industry.

Besides printing capabilities, the company also provides a wide ranges of design and engineering consulting to help you get your project off the ground, plus painting and assembly. In addition to 3D printing, Studio Artefact offers carpentry, welding, illumination, textiles, and more.

- Large-format technology: FDM

- Maximum build volume: 1,000 x 1,000 x 1,000 mm

- Detail level: 500 microns

- Materials: PLA, PETG, ASA, nylon (PA6, PA12) carbon-fiber nylon, +

- Turnaround: na

- Location: Montreal

Branch Technology

Branch Technology, headquartered in Tennessee, is a company you turn to for very large detailed architectural features, such as the moon-surface building skin, shown above. The company is not a construction 3D printing company, like those you’ll find in our guide to concrete 3D printing. Branch uses proprietary Cellular Fabrication (C-Fab) 3D printing technology that it says is capable of printing construction components up to 13 meters wide.

C-Fab is based on robotic arms tipped with 3D printing extruders, like other robotic arm 3D printers, but Branch uses fiber-reinforced filaments for structural strength they need. Branch Technology’s parts can serve either as standalone structures or as scaffolds for conventional construction materials.

Branch is able to create organically curved, complex architectural shapes that would be impossible or immensely expensive to achieve through traditional methods.

- Large-format technologies: FDM

- Maximum build volume: 13,716 x 3,048 x 355 mm

- Detail level: 100 mm minimum feature size

- Materials: Fiber-reinforced polymers

- Turnaround: N/A

- Location: US

Printing Portal UK

Although Printing Portal in the UK is a small company, it has a lot of experience with large. The company provides flexible solutions to customers who need digital file creation, design, 3D scanning or reverse engineering in order to bring their project to life.

Printing Portal works with customers in healthcare, automotive, aerospace, consumer goods, and art and design.

The company not only 3D prints with Bilder brand large-format 3D printers but is also a reseller of the machines.

- Large-format technologies: FDM

- Maximum build volume: 1,100 x 500 x 820 mm

- Detail level: 100 mm minimum feature size

- Materials: PLA, BASF Ultrafuse Pro 1

- Turnaround: N/A

- Location: UK

Namthaja

Namthaja in Saudi Arabia, houses the Middle East’s largest robotic 3D printers fleet, capable of printing up to 3.5 meters in height and 6 meters in width. The service uses Caracol robotic 3D printers.

Namthaja was founded in 2015 as the first factory specialized in 3D printing in Saudi Arabia. Its facility has an area of more than 750 m2 and boasts several 3D printing technologies.

Additional service include engineering and product development, plus the company can help you establish a digital inventory of your parts and products.

- Large-format technologies: Plastic and sand binder jetting

- Maximum build volume: 4,000 x 2,000 x 1,000 mm

- Detail level: from 300 dpi depending on technology and materials

- Materials: Large variety of thermoplastics and industrial sand

- Turnaround: From 2 business days

- Location: Saudi Arabia, shipping throughout the Middle East

Voxeljet

Specializing in large-scale casts and molds, Voxeljet is another 3D printer maker that also provides a print-on-demand service. It provides industry with large-scale metal casting molds for ship propellers and also delivers molds for investment casting of detailed sculptural art, such as the one used to fabricate the “The Embrace” statue in Boston.

Headquartered in Germany with facilities in the US, Voxeljet aims to make your additive manufacturing both as simple and flexible as possible. Send them your CAD data via email and define the quality and application purpose of your component. From the CAD file, Voxeljet will provide a quote, then verify and prepare your data and produce your part worldwide on request in a few working days. Their experts can also advise you on choosing the right process and material.

Additional services include part dyeing and surface blasting.

- Large-format technologies: Plastic and sand binder jetting

- Maximum build volume: 4,000 x 2,000 x 1,000 mm

- Detail level: from 300 dpi depending on technology and materials

- Materials: Large variety of thermoplastics and industrial sand

- Turnaround: From 2 business days

Lead image source: Caracol

License: The text of "3D Printing Services for Large Objects: Our 13 Picks" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.