Acrylic, known also as PMMA, Plexiglas, Acrylite, and Lucite (among many other brand names), is a versatile plastic that is, for many, the go-to choice for laser cutting. Acrylic is so useful as a laser cutting material that even 3D printers like the Tronxy X1 and Anet A8 V1 are partially built from laser-cut acrylic.

With the right techniques and tools, any maker can harness the power of this versatile material at home.

In this article, we’ll go over the basics of laser cutters and acrylic, a few considerations when it comes to designing and preparing files to be laser cut, different operations that can be carried out, and, in addition to a few aspects to consider about laser cutting at home, some services that’ll take care of the work for you.

But let’s start with lasers!

Laser Cutters & Acrylic

Generally, a laser cutter is a two-dimensional cutting machine that removes material through photoablation, or by vaporizing a thin path (either partially or entirely) through the material in order to engrave or cut the stock medium.

In the case of acrylic, this typically includes sheets of either extruded or cell-cast sheets of various thicknesses, although the maximum thickness of cuttable acrylic depends largely on the laser cutter itself. For example, the Trotec Speedy 400 laser, a commercial, 300-W laser cutter, can cut up to 12-mm acrylic, whereas the Glowforge laser cutter claims to be able to cut up to 6.25-mm acrylic in a single pass.

Within these thickness parameters, makers have the option to choose various colors and styles of acrylic that will add artistic or functional flair to a project. Unlike wood, another popular material that can only be colored on the outside and can’t be transparent, acrylic is available in hundreds of different transparency, color, and additive combinations. Some acrylics are patterned, while others involve glitter.

Acrylic has a myriad of uses for home makers or business owners, and can be used as a transparent side to a project with impressive geometries, such as a diorama, a Raspberry Pi case, or even as parts to a homemade 3D printer. Just make sure to account for ESD safety in design.

Preparing a File

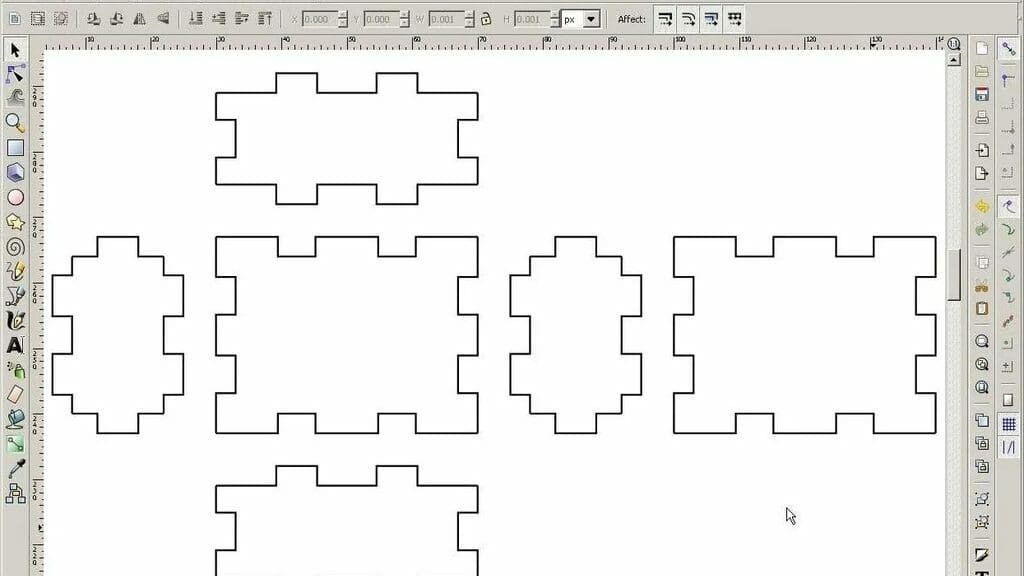

Laser cutters use vector files, such as SVG or DXF files, (depending on the preparation software), to create machine-readable instructions. Different software can be used to make these files, such as:

There are plenty of online tutorials for creating files that can be laser cut, but certain aspects of acrylic must be taken into account when designing such files. For one thing, it’s important that parts requiring any sort of structural integrity be devoid of sharp corners. This issue is often easily solved by rounding corners in the vector modeling software.

Additionally, it’s important to take into account the kerf of the laser cutter on the acrylic, which is the thickness of the line of removed material. While this is different depending on each laser, the number tends to be pretty small for acrylic, so when designing parts that slot into each other, make sure to account for between 0.1 and 0.4 mm of kerf, and to be wary of the kerf of the machine. Typically, to adjust for kerf using software, makers offset edges outwards by half of the kerf value.

The file design will also be influenced by whether you want to cut, engrave, or raster engrave the acrylic.

Different Operations

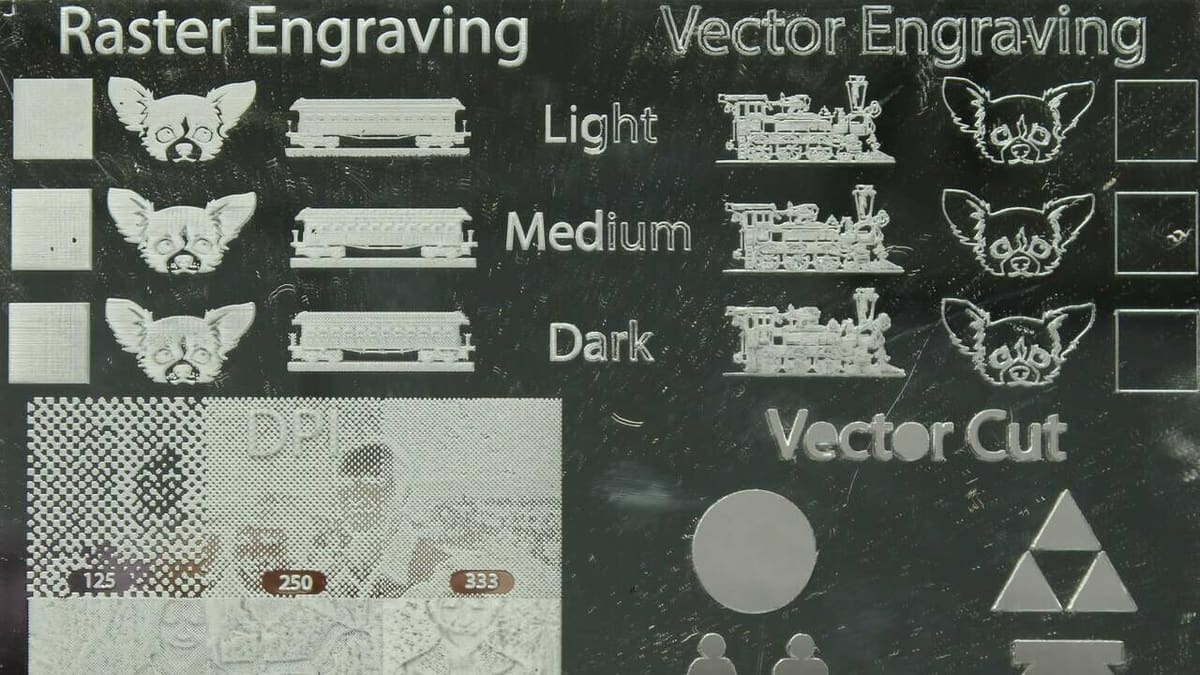

Laser cutting involves three different operations: cutting, engraving, and raster engraving. On acrylic, this might look different than on, for example, wood. Here’s what the three laser operations do to acrylic:

- Cut: Just as with all other materials, the cutting operation on acrylic will penetrate completely through the material and leave a smooth edge through the length of the cut line. The surface of this cut will be about as smooth as the surface of the acrylic itself, unless special cutting operations make it otherwise.

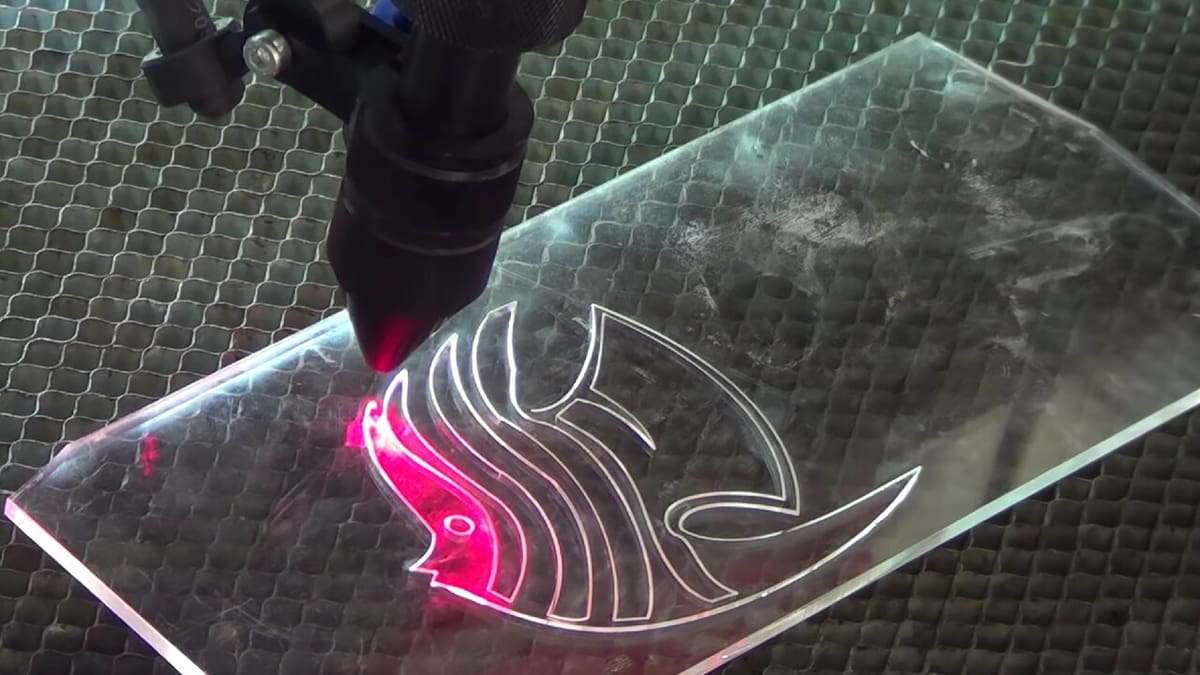

- Engrave: An engraving, or vector engraving operation, is a cut that doesn’t penetrate entirely through the material. In the case of acrylic, this partial cut will diffuse light and appear lighter than the rest of the acrylic. With transparent acrylic, the vector cut will look “frosted” and be easily visible.

- Raster: A raster engraving operation refers to the laser traveling back and forth, partially removing the material according to a particular ratio given by the grayscale of the image being reproduced on the acrylic. For example, an image of a dark gray mountain over a light gray sky would laser the locations of the acrylic with the dark gray mountain with greater intensity than the light gray sky. While raster engraving takes longer than cutting due to the multiple passes required, when working with photos, for example, it will lead to better results.

Home Setup

Often, laser cutters are large, professional-grade machines that take up a good portion of a living room’s floorspace. Recently, though, along with the boom of affordable desktop 3D printers, desktop laser cutting solutions capable of cutting substantial acrylic thicknesses have become available to makers.

Laser cutters such as the Glowforge and xTool, as well as others available for home makers, have proven to be capable of working on many acrylic projects, often producing impressive results.

It’s important to note that not all home cutting setups are suitable for cutting acrylic; options such as Cricut should only be used for lighter materials like vinyl. When considering a laser cutter or engraver, check the manufacturer’s website to find out what materials can be cut and whether acrylic is included on the list.

It’s worth noting that material compatibility isn’t the only concern if you want a home laser cutting setup. Acrylic releases methyl methacrylate fumes when laser cut, which is a flammable irritant that shouldn’t be inhaled. Due to this, fume extractors are necessary. Additionally, fire safety measures such as on-hand fire extinguishers, functional smoke detectors, and an area cleared of flammable debris are necessary to prevent accidents caused by acrylic laser cutting.

Services

Just because it’s hard to laser cut at home doesn’t mean you can’t have laser-cut products. There are many companies that provide acrylic laser cutting services. In the following sections, we look at some recommendable websites.

Fab Lab

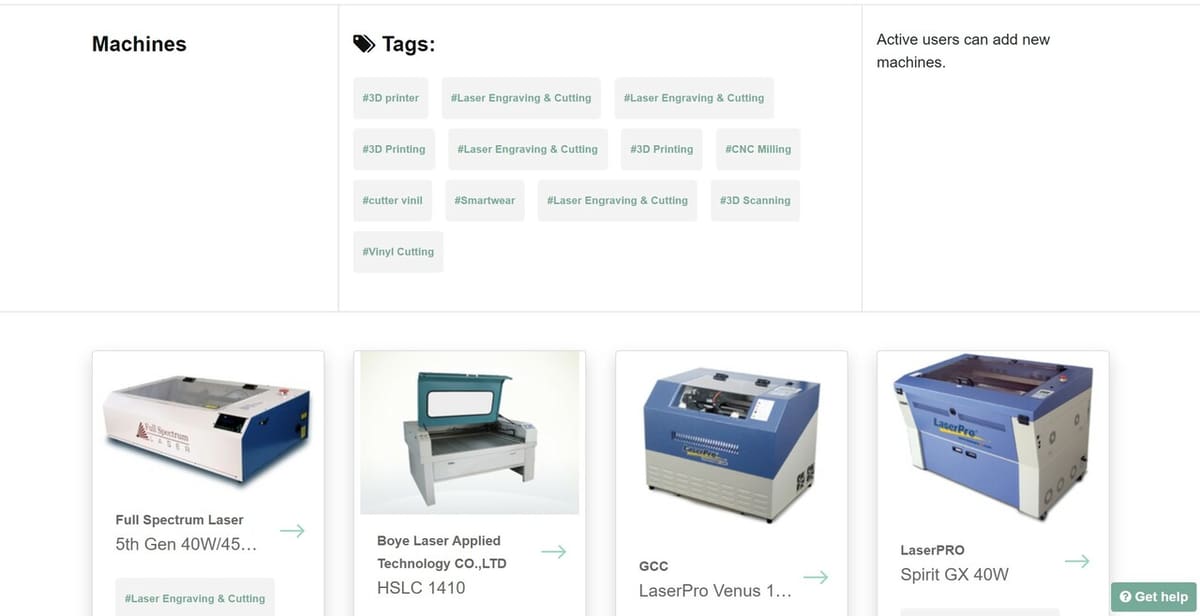

Fab Labs are a collection of makerspaces across the world that are available for use by the public. Maintained and organized by the Fab Lab Project, which aims to connect makers with digital manufacturing equipment pertaining to their needs, Fab Labs are spread across the world. It’s possible to search for Fab Labs with specific machines, too, to avoid the conundrum of showing up to a Fab Lab without the proper laser cutter for the job.

Each Fab Lab is different, so make sure to plan according to the rules of the one that you ultimately choose to visit. Additionally, you’ll probably have to take a quick training course on the machine, as well as bring your own acrylic to cut. Fab Labs are bastions of digital creativity, and often draw much interest and excitement when they come to a community – find out if there’s one near you!

NYC Laser Cut

NYC Laser Cut is a studio focused on CNC milling, laser cutting, and engraving. They started as an architecture design and fabrication service but are now renowned for both digital and conventional technologies. They can also help prepare the design you need!

Materials

- Acrylic up to 1/4″ (6 mm): opaque, translucent, transparent, and mirrored

- Wood up to 1/4″ (6 mm): birch plywood, basswood, wood veneer, and more

- Paper/board: cardstock, museum board, chipboard, and cardboard

If you need thicker materials, they also have CNC milling machines!

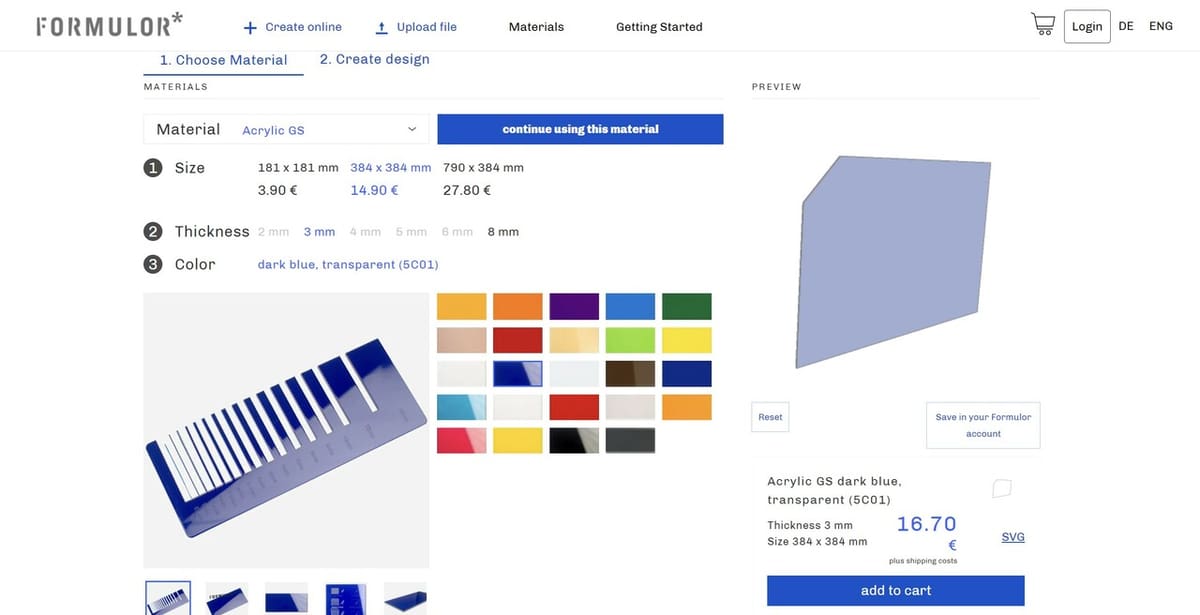

Formulor*

Formulor* GmbH, based in Baden-Baden, Germany, is an acrylic-focused laser cutting service that allows you to order finished laser-cut acrylic parts straight to your door using their online material selection and pattern design guide.

With file uploading available for SVG and DXF, as well as instant quoting, it can be a quick and easy solution for getting a laser-cut acrylic part with minimal hassle.

Materials

- Acrylic up to 8 mm: frosted, matte opaque, pastel, fluorescent, two-color, and mirror; available in many colors

- Plastic: polypropylene, PETG, Mylar, and stamp rubber

- Paper/board: Finnboard, cardboard, and photo mounting board, in addition to corrugated cardboard

- Wood: MDF and plywood

- Extras: felt, leather, and cork

The Laser Co

The Laser Co in Australia specializes in laser cutting and engraving. Like NYC Laser Cut, they can help design new ideas and offer local and sustainable materials.

Materials

- Acrylic up to 6 mm: matte, colored, clear, opal, and frosted

- Wood up to 6 mm: poplar plywood, bamboo plywood, and premium beech plywood

- Cork up to 3 mm

- MDF up to 4 mm: cardstock oak veneer or walnut veneer

- Polypropylene up to 0.6 mm

- Screenboard up to 2.5 mm

- Corrugated card up to 7 mm

Online Laser Cutting

Also based in Australia, Online Laser Cutting provides a professional and high-quality service for all types of designs, materials, and sizes. The company has years of experience in laser cutters, so you can trust their expertise.

Materials

- Acrylic: colored, two-tone plastic, transparent, glitter, matte, glow-in-the-dark, and frosted

- Wood: plywood, bamboo, solid wood, MDF, and veneered MDF

- Rubber stamps: eco rubber, assemble yourself, finished stamps, and A4 sheets

- Stencils up to 0.3 mm: reusable, tear-proof, mylar, and polyester

- Board: boxboard and mattboard

- Extras: double-sided and adhesive backing

License: The text of "Acrylic Laser Cutting/Engraving: How to Get the Job Done" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.