The first thing people think of when it comes to laser cutting is often a big, industrial project, like cutting through a thick piece of wood or a crystal clear sheet of acrylic.

In reality, lasers are extremely versatile and work just as well with delicate materials, too. In fact, they’re often a superior cutting option for lightweight materials, as they can cut and engrave without making any contact with the material.

One perhaps surprising material that works well with lasers is paper. It needs very little power to cut, so the process is quick. In this article, we’ll discuss laser cutting paper and its various applications. We’ll also introduce you to the two main types of lasers used for cutting paper (CO2 and diode), as well as some popular alternatives for paper cutting without lasers.

Why Laser Cutting?

So, we’ve established that lasers and paper are a great match. But what are the best ways to use a laser with paper? The most common scenarios for cutting paper are decorative items like wedding invitations, dioramas, shadow boxes, and paper decorations like bunting.

With lasers being very accurate and well suited to repeatable patterns, batches of identical creations can be created easily. Wedding invitations are a great example. Compared to traditional invitations, they look great, save money, and offer the potential for more personalization with a custom pattern.

As paper only needs low power to be cut, you can use all manner of machines for the work. This ranges from small diode lasers to industrial CO2 lasers, and everything in between.

Next, we’ll look at the differences between the types of lasers as well as some important things to keep in mind when you’re working with laser cutters.

Diode Lasers

Diode lasers are generally on the lower end of the price spectrum when it comes to purchasing one for yourself. Most people only consider them useful for engraving surfaces, as cutting can take a lot of time due to the necessity of repeating the same shape multiple times (known as passes). This is due to the much lower power generated by a diode laser when compared to CO2 lasers.

Luckily, paper doesn’t need much power to cut, so a diode laser is perfectly up to the task. If your primary material for cutting will be paper, you can save a lot of money by opting for this kind of laser.

The main things to focus on when setting up a laser for cutting paper are the more “mechanical” parts. Having a solid base and a good cutting table will make cutting paper much easier.

Another consideration is that diode lasers can be mounted onto other CNC equipment to replace the original toolhead. This might be a 3D printer or a small desktop CNC router, such as the popular 3018 routers. There are even kits to convert printers – the Ender 3, for example – to accept a diode laser head instead of the hot end. If you’re comfortable with some light modification work to your existing equipment, this can prove a cheap and effective way to add paper engraving to your toolbox.

Each diode laser will require slightly different power and speed settings, as will each different type of paper. As a ballpark figure, Endurance Lasers suggests a speed of 5-8 mm/s and a power output of 5.6 W as a good starting point for testing your project.

CO2 Lasers

If you’re looking to produce bigger volumes of laser-cut paper or to make a living from your machine, the primary factor to consider will be time efficiency. This is where CO2 lasers come into their own.

Generally, CO2 lasers have more power than diode lasers, and can therefore be run at a much faster speed. Normally, the limiting factor is the drive system itself and whether it can handle the changes of direction. This is evident in the testing we did with a K40 CO2 laser in comparison to the Mantech Lasertech 4060.

With the K40, we were able to get to speeds of around 35 mm/s before the drive hardware (belts and motors) were unable to accurately change direction to follow a design. This was at a power of roughly 3 mA. In comparison, the Lasertech handled speeds of 125 mm/s using 10% of its maximum 80-W power.

A similar level of detail was achieved by both machines. However, for paper cutting, we found it easier to use the honeycomb bed included with the Lasertech, as there was less chance of the paper moving.

The huge increase of speed over diode lasers was evident in our testing, but the efficiency comes at a cost. CO2 lasers are much more expensive and can’t easily be added to an existing desktop machine, so they’re perhaps less convenient for the average maker.

Safety

Safety is paramount when using laser cutters, whether you’re cutting paper or any other material. To protect your eyes from potentially harmful laser radiation, always wear the appropriate safety glasses designed for the specific laser wavelength. Avoid operating laser cutters in open or public spaces to prevent accidental exposure to the laser beam.

Laser cutters produce intense heat, as they essentially burn through the material. This heat poses a fire hazard, so never leave the machine unattended during operation. Always have fire prevention measures in place, such as a fire extinguisher, and be ready to respond swiftly in case of any issues.

Additionally, laser cutting generates smoke, fumes, and airborne particles that can be hazardous when inhaled. Ensure adequate ventilation in your workspace to remove these byproducts. Installing an exhaust system or using a fume extractor can help mitigate the risks.

By following these precautions and any other instructions provided by your machine manufacturer, you can safely enjoy the benefits of laser cutting paper while minimizing potential risks.

Tips

When using laser cutters for paper, a few tips can enhance your cutting experience.

- Ensure the design is viable: First, ensure your CAD file is well-prepared. Avoid overlapping lines and ensure that all lines are joined together to prevent cutting errors.

- Adjust corner power settings: Many controllers allow adjustments to the laser power configuration. Pay attention to corner power settings, as high corner power can overburn paper corners. As paper is a delicate material, lower the corner power relative to the general power.

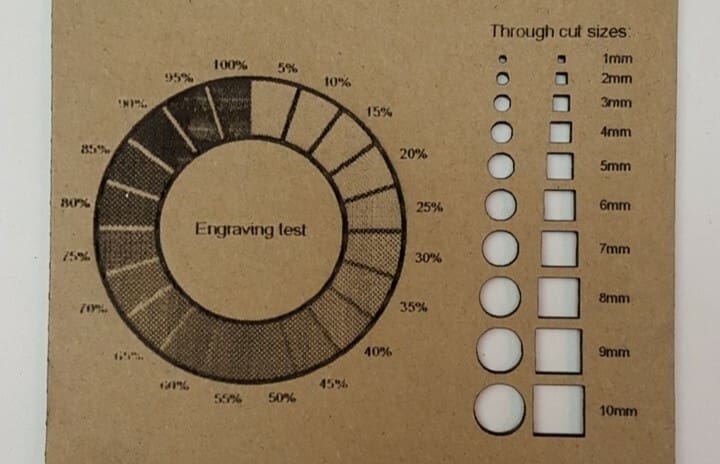

- Test materials and settings: It’s good practice to conduct material testing, especially with new materials. Cut small samples and experiment with different speed and power combinations to find the best settings. Alternatively, you can cut a material test card. Either way, testing will help to optimize the cut quality and prevent waste.

Online Services

If you need some paper to be laser cut but don’t have access to a machine, the final option is to outsource your paper cutting. Using a laser-cutting service can also be a way to see the outcome before you invest in your own setup.

Services vary from store to store, but the general premise remains the same. A company will take your design (normally in a vectorized format), cut it using the technology and materials of your choosing, then deliver it to you.

PaperShapers and Laser Cutting Shapes are two examples of services that will laser cut paper. Each offers quotations and support, and you can view photos of previous commissions as both inspiration and quality assurance!

In the long term, relying on an online service can be an expensive way to go, but part of the cost is the professional experience and machinery that will be used for your project.

Alternatives

If laser cutting seems like more work than you want to handle and services cost more than you want to spend, die cutting machines are a great alternative for paper enthusiasts. Ideal for those primarily working with paper, vinyl, or transfers, these machines can be quite compact and user-friendly. With prices starting around $180, they’re budget-friendly too.

Two popular brands in this category are Cricut and Silhouette. Both offer machines with a range of features and capabilities that suit various cutting needs. They’re also known for their precision in cutting paper and other materials, making them an excellent choice for projects like scrapbooking, cardmaking, and vinyl decal production.

License: The text of "Laser Cut Paper: A Guide to Laser Cutting Paper" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.