Laser beams were properly created in 1960 when the physicist Theodore Maiman used a synthetic ruby crystal to make the first working prototype capable of producing a straight laser beam. But it was not until 1963 when the electrical engineer Kumar Patel invented the gas laser cutting technology using CO2, making the laser cutting process cheaper and more efficient.

Patel’s efforts allowed the mining industry to give lasers a practical application in 1965: Cutting and drilling in diamond mines. Later on, in 1967, thanks to Peter Houldcroft, who developed the first gas-assisted laser cutting nozzle, it was possible to cut a 1-mm-thick steel sheet.

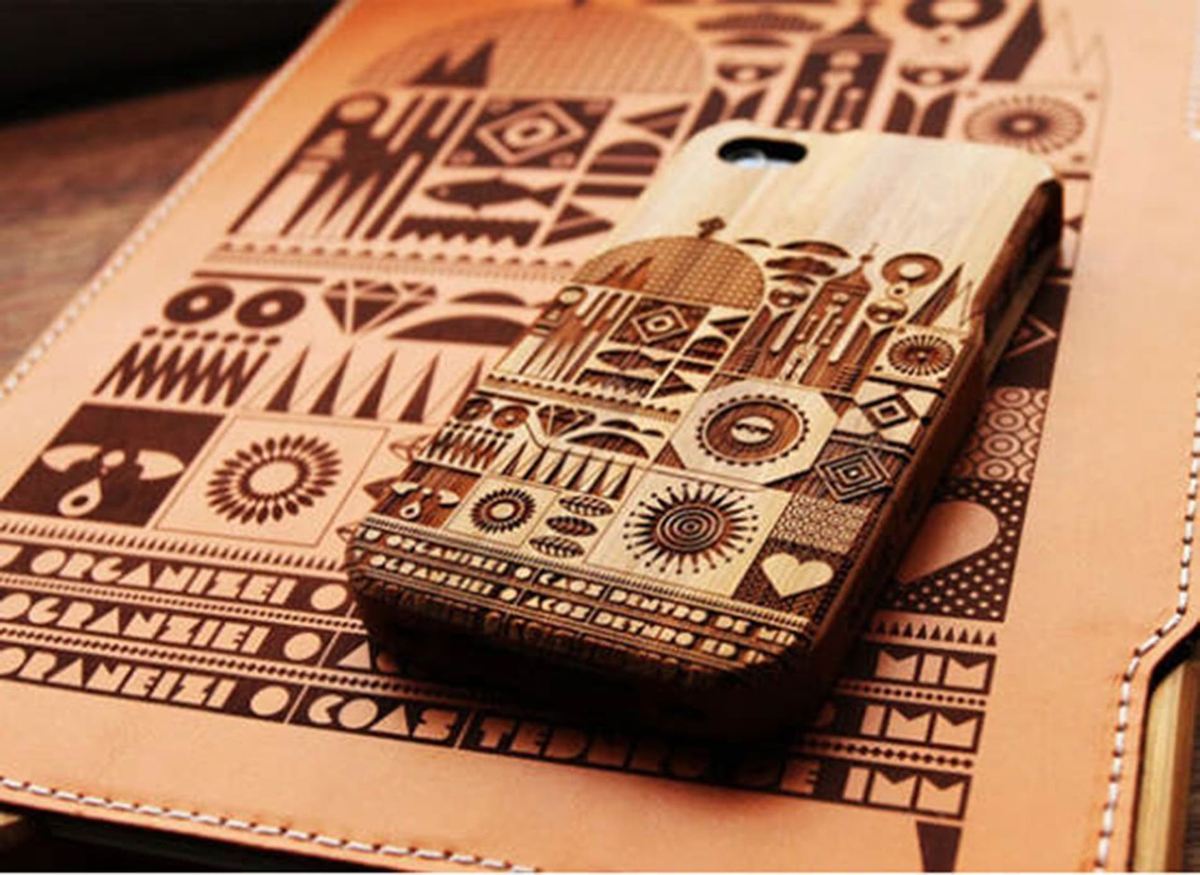

Today, CO2 laser cutters are a common tool used to cut and engrave materials like cardboard, plywood, MDF or acrylic, to name a few. Let’s take a closer look at the technology!

Laser Cutting vs. Engraving

Laser cutting and engraving are both subtractive manufacturing methods; the process starts with a solid object and the laser beam removes material to form a final image. There’s a distinction, however, between laser cutting and laser engraving.

Laser cutting is a high precision process in which a laser beam hits the surface of a material and heats it up until it melts or vaporizes completely to leave a clean cut.

Laser engraving is a very similar process to laser cutting, but the laser beam’s intensity is decreased in order to leave only a mark on the material’s surface rather than cut it all the way through.

How Does It Work?

CO2 lasers are the most common these days, among both makers and professionals, so we will explain how this specific type of laser works. The word “laser” is an acronym for “light amplification by stimulated emission of radiation”. This means the laser is an intense light amplified through mirrors and lenses to produce enough power to cut any material. It’s an easy process to understand if we analyze it in the following way:

- The beam is produced by a laser resonator, which is an airtight glass tube with two mirrors facing each other, this tube is full of CO2 and other gases like helium, nitrogen, and hydrogen. The mix of these gases is activated by an electric discharge or diodes that emit energy in the form of light, which is reflected back and forth by the mirrors.

- Once the beam is generated, it travels through the machine, bouncing in different directions with the help of other mirrors positioned strategically to reach the laser cutter head.

- Finally, when the beam reaches the laser cutting head, it travels through a curved lens that magnifies the power of the laser and focuses it onto a single point. Laser cutting or engraving can be achieved by adjusting some parameters like the beam intensity and speed.

Pros & Cons

There are other technologies like CNC milling that can achieve similar results to a laser cutter/engraver, but here we list what we consider the advantages of laser cutting over other techniques.

- The high precision it offers allows for engraving more detailed images and having cleaner cuts.

- The production speed is higher.

- A wide range of materials are cuttable without damaging them.

- It’s a more affordable option compared to CNC machines.

- It’s compatible with any vector software like AutoCAD (DWG) or Adobe Illustrator (AI).

- It doesn’t generate waste like sawdust.

- It’s very safe to use with the right equipment.

And because not everything can be good, here are what we considered disadvantages:

- Thicker materials are more difficult to cut or require very low speeds.

- Higher density materials like glass can’t be cut.

- It burns the edges of any material you want to cut.

- Some materials, like plastic, can produce toxic emissions.

- Production speed aren’t always consistent, depending on the material thickness and density.

- Some laser cutters consume a lot of energy, increasing the production cost.

Conclusion

Laser cutting (and engraving) is a fascinating technology, having more than proven its utility. Best of all, it’s accessible to everyone these days, either through commercial services or desktop machines.

However, as can be seen, the process isn’t yet perfect, with some issues needing to be solved before it can be considered superior to other similar technologies like CNC routers. More powerful and precise machines are developed every year with better cutting capacities, so we expect many ofthese disadvantages will be mitigated in the future.

Feature image source: ddprinting.net

License: The text of "Laser Cutting – Advantages & Disadvantages" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.