Take a Spin

Although CNC (computer numerical control) may conjure images of machinery grinding and slicing their way through tough materials, these machines had humble beginnings. In fact, the mechanics can be traced as far back as ancient Egypt.

A Bit of History

For millennia, lathes have been used to turn logs or huge stone blocks into ornate columns for buildings or smaller items such as crockery and simple tools. Since then, their complexity has continued to develop until the Industrial Revolution, roughly 3,000 years later, when the first milling machines, or mills, emerged.

These subtractive manufacturing processes have been used throughout history for woodworking, metalworking, and toolmaking. Due to the increased availability of materials and outsourced mass production, mills and lathes are cheaper than ever before. This is especially true for lathes, where turning has become a popular hobby. With a lathe, makers can produce items such as bowls, cups, and other cookware, as well as pen barrels and unique art pieces.

Enter Computers

While we now know that manual machining has existed for millennia, using computers to numerically control mills and lathes (CNC) is a relatively recent innovation. For the majority of machines, G-code is written either by an engineering-focused CAM program or the operator of said machine. More often the former is the case, as it enables a more efficient workflow.

Multitasking machinery (MTM) combines the benefits of both mills and lathes into one aptly named multitasking machine. While you can do a lot with these MTMs, mass production of complex objects may be superseded by complex metal 3D printers in the future.

Mills

Let’s take a closer look at how each of these machines works.

Mills, or milling machines, began as rotating mechanisms to ground away material, rather than cutting or shaving, as is done with modern milling. This action of grinding, like grinding wheat into flour, was referred to as milling.

Types of Mills

- Vertical: The cutting tool (spindle) lies vertically within the machine. They are also referred to as Bridgeport mills, after the company that popularized them.

- Horizontal: The spindle lies horizontally within the machine.

- CNC: These mills are numerically controlled by G-code. The NC (numerical control) of CNC refers to the now rare practice of machine operators writing the G-code program themselves.

- Turret: A vertical mill where the cutter remains stationary as the workpiece is moved along the X and Y axes into the cutter.

- Bed: A vertical mill where the cutter moves into the workpiece along the Y-axis and the workpiece is moved into the cutter along the X-axis.

- Gang: A horizontal mill that has two or more cutter bits mounted to its spindle, enabling the cutting of specific complex profiles without the need for two or more separate runs.

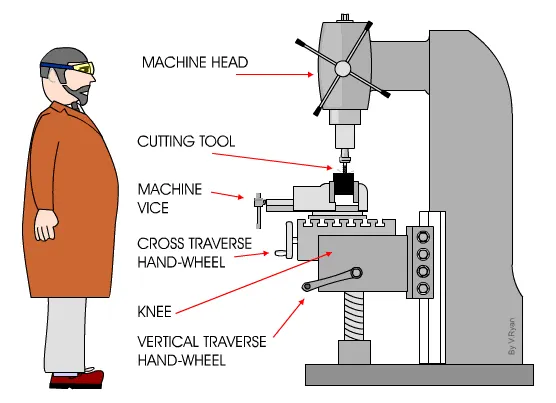

Mechanics

A workpiece (or two) is bolted onto a bed that moves, in most cases, along the X and Y axes. This movement cuts the workpiece with the spinning bit and results in the removal of material. The cutting bit can also be adjusted to a specific angle in order to cut chamfers and bevels or angled gouges.

Operation

A mill is much like a lathe in that manual operation is achieved by turning hand-wheels, which move the bed and workpiece along each of the axes. Again, CNC operation is mostly devoid of human interaction, as CNC machines lack the hand-wheels required for manual use.

There’s a fantastic video resource by NYC CNC explaining and showing the operation of a manual and CNC mill.

Lathes

Lathes come in a wide variety of shapes and sizes but are chiefly designed to do the same thing: turn a workpiece. This turning results in a length of circular-profiled material such as a pool or snooker cue.

Types of Lathes

- Engine: This lathe got its name from the past innovation of powering the machine with a steam engine. The name has stuck and is often used to refer to most motor-driven large-format lathes (if the word “lathe” alone isn’t specific enough).

- CNC: A lathe, much like a mill, can be designed to operate based on a program written in G-code. CNC lathes often replace several different specialist lathes, as they’re highly adaptable and cover many operations that just one type of lathe would struggle with.

- Bench: This is a tabletop lathe designed for use in smaller workshops or for hobbyists. Due to its small size, it’s often able to work at greater levels of precision than a larger lathe.

- Precision: Specifically designed to finish turning jobs completed by less precise lathes, it often replaces a precision grinder if the application isn’t right.

- Vertical: A huge machine designed to turn pieces too heavy to mount horizontally on a conventional lathe.

- Screw-cutting: This lathe is designed primarily to mass-produce screw threads in lengths of metal. While most modern lathes have a screw-cutting function, compared to a dedicated screw-cutting lathe, it isn’t as precise nor does it provide as many options.

Mechanics

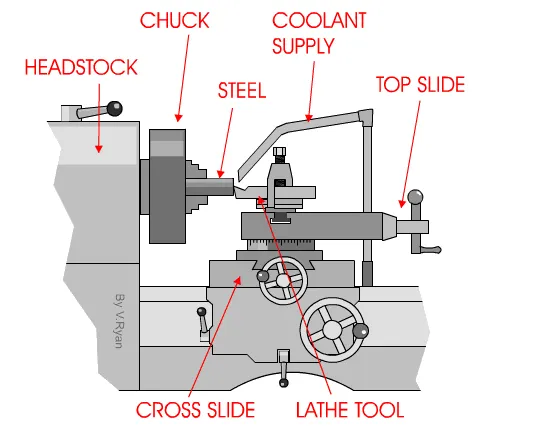

A workpiece is held tightly in a chuck, which is turned by an onboard motor, and cut into by a (single-point) cutting tool. The tool is able to make the cuts because the workpiece is held firmly against its rotation.

Operation

In the case of a manually-operated lathe, three hand-wheels are turned to accurately position the cutting tool in each axial plane to work the material to the exact depth and position required. A tool post grips the cutting tool and can hold several pre-mounted tools, removing the time it takes to swap out tools when machining a more complex piece.

CNC lathes work in the same way, without the need for human interaction once the G-code program is started. Additionally, they often have many more tools pre-mounted in the tool post, easily switching between them as the program demands.

If you’d like to see lathes action, sculptor Kevin Caron gives a video guided tour of his old metalworking lathe.

Distinctions

Mills and lathes do have some similarities, but let’s take a deeper look at their differences.

Cutting Method

- Mills require the workpiece to be moved into a slowly-rotating multipoint cutter by moving the bed that the workpiece is bolted onto.

- Lathes have the workpiece spun (turned) and it’s shaped by a single-point cutter moving into it.

End Product Shape

- Mills can create many different shapes of objects by moving the workpiece itself and angling the cutter.

- Lathes turn the workpiece and typically result in the object having a circular profile at some point, if not across the entire length.

Uses

- Mills are designed to shape blocks of metal or plastic into complex patterned geometry and excel with accurate hole drilling at varying angles and tapers.

- Lathes are ideal when making large threaded components and dimensionally-accurate bolts or studs as well as parts with varying or offset circular profiles, such as crankshafts.

Materials Worked

- Mills usually begin machining a flat block of hard material, or a rough casting (like the crankcase of an engine, for example), and refine or add details before being sent further down the production line.

- Lathes usually begin their work with bar stock – circular-profiled lengths of solid metal, wood, or plastic that are cut into to achieve the desired results.

Applications

Now that we know all about how these machines work, let’s see where they’re most often used.

Mills

- Drill: As a mill is essentially a glorified pillar drill, it may come as no surprise that they, too, can put holes in metal just as effectively as your standard workshop drill can.

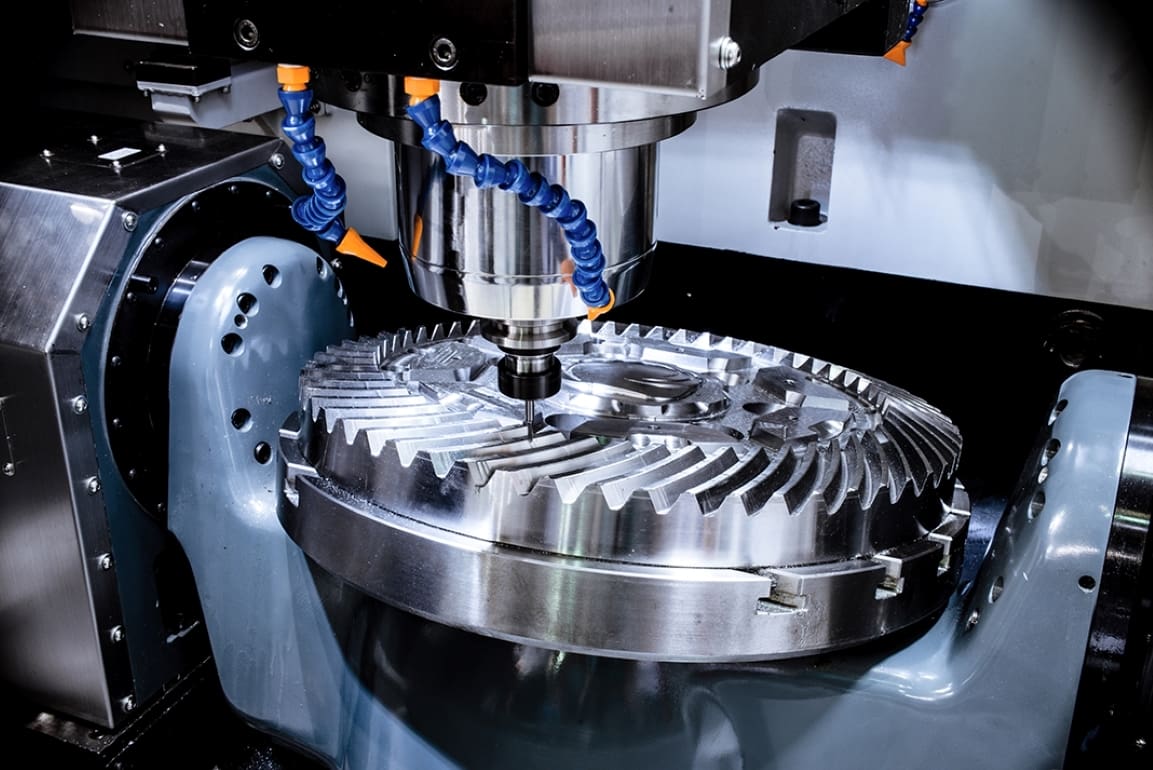

- Cut gear or cog profiles: One of the original uses of mills was to machine gears for clock mechanisms. It remains to this day one of the most widely applied uses of milling machines.

- Cut slots: You heard it here first! Mills can gouge lines in blocks of metal with amazing precision.

- Bore: Mills rule the roost when it comes to boring holes in material, which is notedly different than drilling.

- Plane: Running a cutter over material repeatedly produces the same outcome as a planer and is often used to machine perfectly flat surfaces instead of grinding.

- Manufacture PCB (printed circuit board): A more modern use of a mill is to cut a PCB. It’s often used by makers or prototypers to create bespoke circuit boards that won’t or might not go into mass production.

Lathes

- Thread cutting: Unlike a pair of scissors, lathes can be set up to thread cut as well as just cut thread. One of the primary uses of a lathe, in fact, is the precision machining of large threads.

- Crankshaft turning: Specialized lathes can be built to machine crankshafts, supporting the billet in differing offset positions in order to achieve the characteristics of such an object.

- Furniture making: Many items of furniture require parts to be turned on a lathe, such as chair or table legs, bed knobs, or curtain rail finials.

- Toolmaking: Lots of tools are variations of long, thin, round bits of metal. Lathes make toolmaking processes easier and are especially useful at creating knurled surfaces on things like center punches and dipsticks.

Lead image source: Protocast

License: The text of "Mill vs Lathe: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.