Open-source principles have been instrumental in the development of 3D printing technology, especially Fused Deposition Modeling (FDM). For years, 3D printing enthusiasts have banded together to discuss their experiences and share ideas. The innovations growing out of the community have made 3D printing more accessible, affordable, and capable.

In the context of 3D printing, open source is understood as the public release of CAD design files, custom firmware source code (if any), firmware configuration samples, and a bill of materials. This information allows users to repair, modify, and upgrade their machines in accordance to their needs, without relying on the manufacturer.

As FDM technology improves, consumer 3D printer manufacturers are making more affordable and higher performing machines. This is also accompanied by an increasing trend toward closed-source ecosystems.

Despite this trend, open-source ideals are still thriving within the 3D printing community. In this article, we highlight three open-source machines that we highly recommend as well as a couple of honorable mentions.

At a Glance

Voron 2.4 R2

We’ll start off with one of the most well-known high-performance DIY printers, the Voron 2.4. The R2 is the latest revision, and with over 7,500 serialized builds at the time of writing, it’s also one of the most popular Voron printers.

This legendary printer popularized the CoreXY motion system, which allows for high-speed and high-precision toolhead positioning. Whereas conventional CoreXY systems have a gantry that’s fixed to the frame and a bed that moves down the Z-axis using leadscrews, the Voron 2.4 uses a “flying gantry” system: The gantry moves up along the Z-axis, and the bed is fixed at the bottom. Four separate belts are used to raise the gantry along the Z-axis, which allows for true quad-gantry leveling and fast Z movements like Z hops.

A main feature of the Voron 2.4 is its ability to print more advanced functional materials such as ABS and ASA. This is due to the fact that it’s fully-enclosed with a passively-heated chamber. The temperature within the chamber can reach upwards of 60°C.

Like many other high performance DIY printers, there are MGN linear rails on all axes, and the frame is built out of 2020 extrusions. Standard configurations include 250 x 250 x 250 mm, 300 x 300 x 300 mm, and 350 x 350 x 350 mm build sizes.

All of the information needed to build your very own Voron 2.4 is available on their GitHub page and website. While you can build one from scratch, it’s also possible to buy the printed parts or full kits to save you some time.

Annex Engineering K3

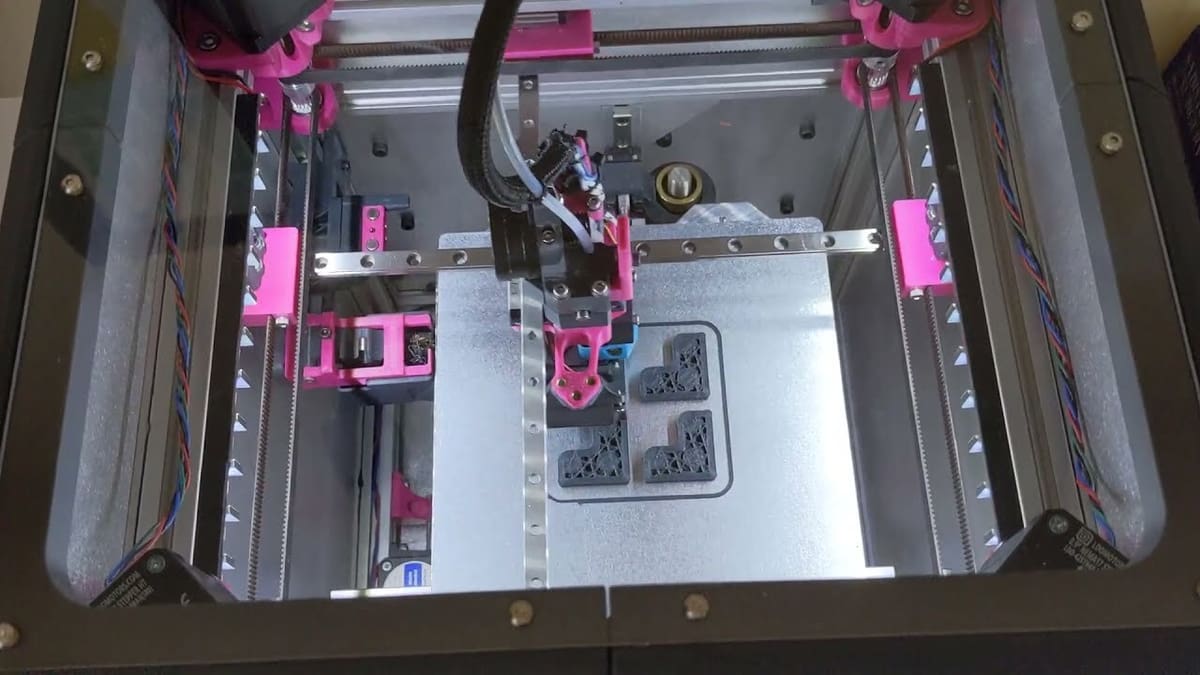

Though not as well-known as Voron designs, the performance of Annex Engineering’s K3 certainly doesn’t fall short. This feature-rich 3D printer is designed to fulfill your functional prototyping needs.

Rather than CoreXY kinematics, the K3 uses a crossed gantry motion system driven by four stepper motors – which allows for shorter and more rigid belt paths. This translates into stability and speeds that exceed those of other high-performance CoreXY printers. Check out Keyan Mobli’s YouTube video to see it in action.

The K3 is also fully enclosed, passively-heated, and able to reach relatively high chamber temperatures. The 180 x 180 x 180 mm build volume is relatively modest – this isn’t a design oversight, however. This volume is the perfect for small plates of functional prototypes and allows for faster chamber heat up, which is helpful when printing engineering materials.

The frame is built using 2020 aluminium extrusions, and the printer has linear rails on all axes. The print bed is driven along the Z-axis by three independent leadscrews or three independent belt drives, allowing for true 3-point bed leveling.

All of the information you need to build the K3 is available on GitHub. A kit as well as relevant components and accessories can be purchased from Fabreeko and Annex Engineering’s online store, among other retailers.

Positron v3.2

We’re saving the best for last. The Positron v3.2 is an extremely innovative printer. It was designed with a highly ambitious goal: to fit a fully-capable, high-quality FDM printer into a portable spool-box. With a folded size of 200 x 200 x 70 mm, the printer boasts a generous build volume of 180 x 180 x 165 mm, similar to a Prusa Mini and the Annex K3.

Don’t be fooled by its small size, though. This capable printer can achieve travels of 300 mm/s and accelerations of 10,000 mm/s2. Further, it can accurately print the same materials as an unenclosed full-sized printer. All axes run on linear rails and tiny belts on the X- and Y-axes, which makes the whole motion system compact, accurate, and stable. It’s also quick and easy to set up from a folded to functioning state.

What makes this printer even more unique is that it prints upside down. Prints adhere to a cantilevered heated build plate and stay on till it cools down. It also features a custom hot end with a 90° bend – in order to save space – and has a Bowden extruder.

Unsurprisingly, its high portability combined with good print accuracy has gained the Positron widespread attention. The documentation for this fully open-source project can be found on the project’s GitHub pages (v3 and v3.2) as well as the website. Kits are also available from various retailers.

Other Machines

With so many impressive open-source projects out there, it was hard to narrow down to just three printers. It would have been criminal to leave out mentions of the following two fully open-source gems.

Rat Rig V-Core 4

This highly capable CoreXY printer offers larger configurations up to 500 x 500 x 500 mm. The V-Core 4 is a significant evolution of the previous version, bringing innovations such as IDEX capability with two independent toolheads and an all-wheel-drive (AWD) option for a single toolhead. Users can choose RatOS – Rat Rig’s firmware modified from Klipper – to allow for greater ease of installation and configuration for their printers. Of course, you could also opt for native Klipper firmware. Find everything you need to build the V-Core 4 at Rat Rig’s website.

LH-Stinger

The LH-Stinger is a one-of-a-kind, no-compromise bed slinger designed simply to push its motion system to the extreme. It’s capable of achieving accelerations and input shaper values even higher than those of common CoreXY printers. You’ll find overkill features such as an AWD 48V-powered Y-axis, configurable AWD X-axis, a lightweight carbon fiber print bed with a thin polyamide heater, among others. Check out the project’s GitHub page for CAD files, firmware, a bill of materials, and other documentation.

License: The text of "These DIY 3D Printers Are Keeping Open Source Alive" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.