Nowadays, polylactic acid (PLA) is arguably the most common material used for hobbyist fused deposition modeling (FDM) 3D printing. It’s loved by users for its ease of printing, wide range of types, and availability, making it a wonderful choice for decorative prints or non-functional prototyping.

However, PLA isn’t recommended for functional prototypes or end-use parts due to its poorer mechanical properties, such as its brittleness (low flexural and notched impact strength) and poorer temperature resistance. This is where materials like polyethylene terephthalate glycol (PETG) and acrylonitrile butadiene styrene (ABS) come in.

PETG is adapted from polyethylene terephthalate (PET), where glycol is added at the molecular level to improve strength and durability – which also aids in 3D printing. There are many things you can 3D print with PETG. ABS is one of the most widely used plastics worldwide, being used in anything from toys to automotive parts. It’s also one of the earliest materials used for FDM printing.

But how do they fare against each other? Read on to find out!

At a Glance

*Note: HDT stated is estimated, in general, as per ISO75 @1.8 MPa testing standards and can differ depending on manufacturer. Parts will creep significantly under loads at these temperatures or over longer periods of time. It’s not recommended to operate parts under loads at such temperatures for prolonged periods.

Material Properties

Let’s first take a look at the material properties of both PETG and ABS. We’ll examine their strength, durability, temperature resistance, post-processability, hydroscopic, and recyclability.

Strength

The “strength” of materials is arguably one of the most important factors to compare. While the term is quite broad, we’ll focus on PETG’s and ABS’ ultimate tensile strength and impact strength.

Ultimate Tensile Strength

Ultimate tensile strength (UTS) is the maximum stress that a material can withstand while being stretched or pulled before breaking. It’s measured using a tensile testing machine, which applies a pulling load to a test specimen until it breaks.

According to material datasheets (i.e., from Polymaker and 3DXTech), PETG has a higher ultimate tensile strength than ABS for the same load specimen printed using the same settings. That said, one should also consider that PETG has a ~20% higher density (~1.24 g/cm3) than ABS (~1.04 g/cm3). This makes their UTS-to-weight ratio very similar.

Importantly, when printed at a low chamber temperature, ABS will have lower layer adhesion, which decreases the strength of a part, especially when loading across the layers. However, this won’t be an issue for printers with high chamber temperatures, as ABS parts can be printed with excellent layer adhesion in them. We’ll take a closer look at this under “Printing” further below.

Impact Strength

Impact strength, also known as impact resistance, is the ability of a material to withstand shock loading – that is, the ability of a material to absorb a sudden or intense force or shock without breaking. Common test methods include the Izod impact test and the Charpy notched impact test, which strikes a notched specimen using a pendulum and measures energy absorbed during breakage.

According to material datasheets (i.e. the aforementioned from Polymaker and 3DXTech), ABS has a much higher impact strength than PETG. This is unsurprising, as ABS is known for its very high impact strength when compared to almost all other economical plastics. ABS is also more rigid than PETG (albeit more flexible than PLA), hence its being widely used as a general plastic that’s quite rigid yet with very high impact resistance.

That said, PETG’s impact strength still outperforms PLA’s.

For a deeper dive, My Tech Fun’s detailed comparison includes further tests and materials, as they compare PLA, PETG, ABS, ASA, and PC.

Durability

Describing a material, durability is the ability to last a long time without significant deterioration, when subjected to the designed operational conditions. A durable material or product helps decrease environmental and economical waste by avoiding repair and continuous replacement of parts. When it comes to PETG’s and ABS’ durability, different aspects can be considered.

UV Resistance

In terms of UV resistance, PETG fares better than ABS, so it would be a better choice for prints that are meant to be exposed to UV light. However, PETG will still degrade with prolonged exposure.

For long-term outdoor use, acrylonitrile styrene acrylate (ASA), a slight derivative to ABS, can yield much better UV and weather resistance compared to both ABS and PETG. It also maintains the excellent mechanical properties and temperature resistance as ABS, although it’s more expensive than both PETG and ABS.

Chemical Resistance

In terms of chemical resistance, PETG is more resistant than ABS from a variety of acids and alcohols (and at different concentrations). Prusa Research developed a summary table, where different filaments were tested under laboratory conditions.

Temperature Resistance

Temperature resistance is undoubtedly important in a variety of applications.

Here, ABS has an edge over PETG. While PETG’s glass transition temperature is around 80 °C, ABS can go until about 105 °C.

It should be noted that glass transition temperature is not the temperature you can safely operate the material at, especially under loads. Rather, it’s the temperature at which an amorphous polymer changes from a hard or glassy state to a soft or leathery state (or vice versa).

The ISO75 testing standard simply shows the temperature where the material deflects by 0.25 mm instantly (hence “heat deflection temperature“) under small loads of 0.45 MPa and 1.8 MPa. At temperatures near the HDT, mechanical properties of the parts are drastically reduced and make it unfit for mechanical use. Safe operating temperatures are operating temperatures with minimal material creep, much lower than the glass transition and heat deflection temperatures.

For example, noticeable creep can be observed over prolonged periods above 70 °C with ABS parts in higher temperature enclosed printers. PETG should not be operated at prolonged periods above 50 °C.

Hygroscopy

Both PETG and ABS filaments are rather hygroscopic, easily absorbing moisture from the air.

This moisture deteriorates the material itself and causes excessive stringing, bubbling, and poor layer adhesion during the printing process. This results in poor print quality and lowered part strength.

Hence, it’s important to store the filaments in non-humid environments and to dry them at appropriate temperatures (about 55 °C for PETG and 75 °C for ABS) prior to printing.

Food Safety

Both pure PETG and pure ABS are non-toxic and food-grade materials. They are widely used and approved in applications involving food processing and applications. However, products in these applications are typically injection molded using pure virgin pellets.

PETG and ABS filaments contain many additives that drastically improve printing characteristics and performance (for example, not requiring very high chamber and nozzle temperatures to print). Most of the time, these additives make the filament not food grade. That said, some manufacturers do offer food grade compliant filaments. Despite there being more PETG options, there are also a few ABS ones on the market.

Nonetheless, parts of your printer that come into contact with your filament are likely not food safe. For example, the extruder gears and nozzles may not be made out of a food grade steel and might have come into contact with non-food safe filaments or lubricants. Furthermore, parts printed through material extrusion have small voids between layers, which encourages the growth of bacteria. To prevent this, post-processing steps are necessary.

Thus, whether the material itself is food safe or compliant or not isn’t enough. FDM printed PETG and ABS are most likely not food safe, and it’s not recommended to use them in such applications unless you consider all the other aspects involved.

Recycling

Recycling-wise, both PETG and ABS are recyclable. However, they both fall under resin identification code #7 (“Other’), which means neither is recyclable in normal collections. As PETG requires much higher temperatures and processing in the recycling process than PET (the material mostly used for plastic bottles), it doesn’t fall under the identification code #1 (PET).

Lastly, whether these filaments can be recycled or not depends on the recycling company. Most of the time, polymers in the #7 category are unprofitable or impractical to recycle, hence their being disposed of instead. That said, there are services to recycle 3D prints, including for both PETG and ABS materials.

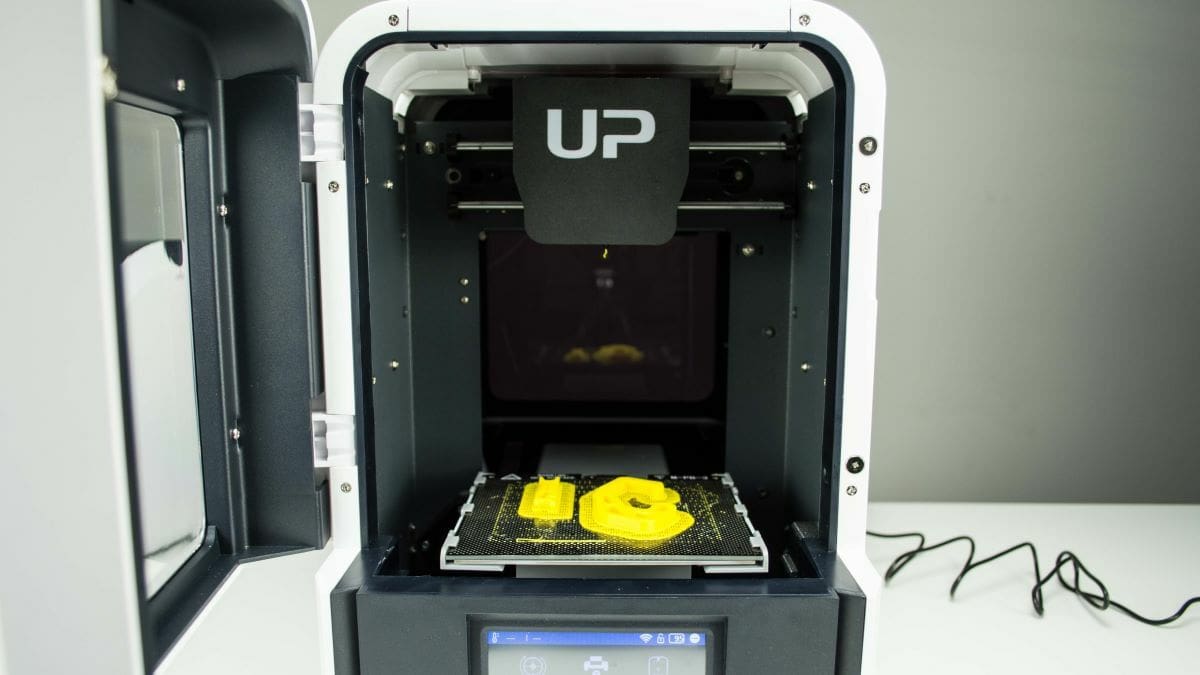

Printing

As you can assume by now, the two materials – being so different – need different printing settings for best results.

Temperatures

Temperatures are an important factor to consider when printing both materials, especially for ABS. Let’s find out more!

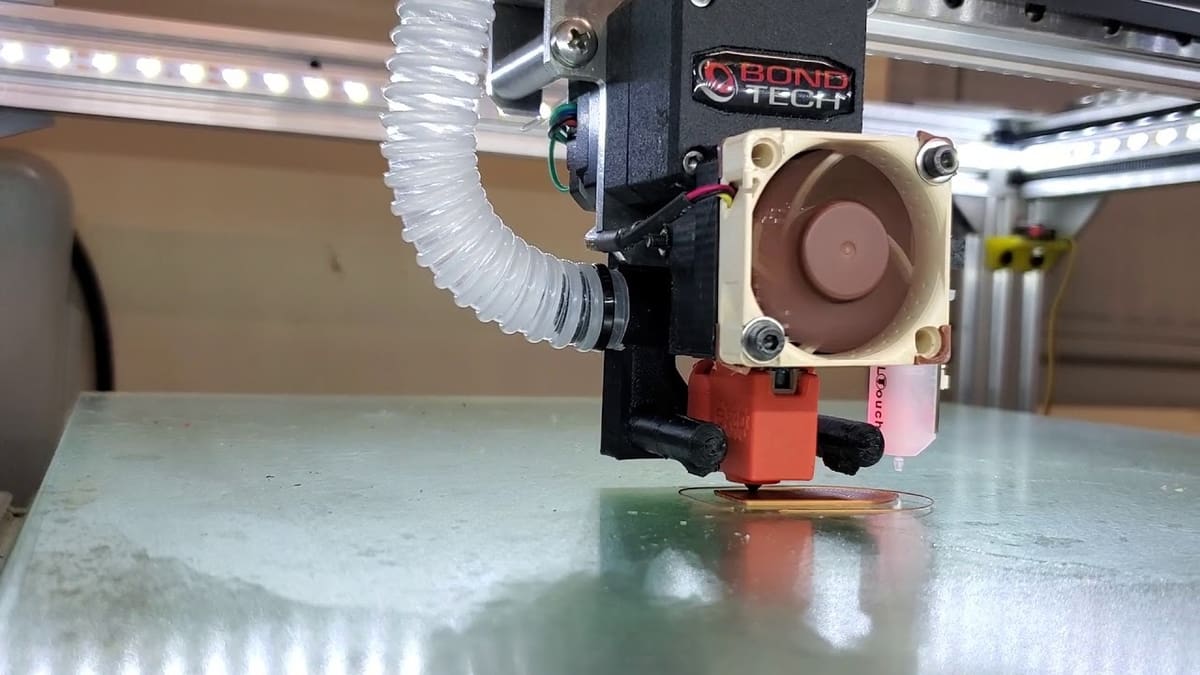

Hot End

ABS requires a slightly higher temperature to extrude than PETG, but it’s recommended to print both materials with an all-metal hot end. ABS typically prints at 230-270 °C, while PETG prints at 220-260 °C.

Similar to most filaments, it’s a good idea to lean towards the higher end of this range for better maximum volumetric flow rates and layer adhesion. However, be cautious of exceeding this range significantly, as an overly high temperature may lead to excessive stringing, heat creep, or poor overhangs. As always, remember to refer to the manufacturer’s recommendations!

Heated Bed

A higher temperature heated bed is crucial for printing ABS parts. It not only allows for good first layer adhesion (to reduce warping) but also helps in warming up a passively heated enclosure (which we will discuss next). This value mostly lies in the ballpark of 90-120 °C, but experienced users lean towards 110 °C to prolong the life of magnets for popular magnetic build plates.

PETG’s bed temperature lies typically around 60-80 °C, which suffices for good first layer adhesion. Remember that these values are a range, and the exact temperature depends on your exact filament and setup.

Enclosure

Although an enclosure isn’t necessary for PETG parts, it’s crucial for strong and defect-free ABS parts.

ABS is infamous for its tendency to warp and delaminate across its layers due to thermal contraction. An enclosure keeps the print enveloped at a warm temperature, resulting in a smaller thermal gradient (to prevent parts from cooling down too quickly), hence alleviating warping and delamination issues. It also reduces temperature fluctuations and drafts, which are detrimental to the printing performance and strength of ABS parts.

A high temperature enclosure or actively heated chamber is best for strong ABS parts – a high ambient temperature also allow layers to bond better and relieves internal stresses, resulting in a significantly stronger part. Thus, it’s recommended to have chamber temperatures exceeding 65 °C for strong ABS prints. Even higher temperatures (80-90 °C) are beneficial for strength, but they also demand more cooling.

PETG is much easier to print than ABS and sticks to the bed well. In fact, PETG may stick too well to smooth PEI sheets or glass if the bed temperature is set too high – causing part of the bed to rip off to the print! To combat this, some users choose to use glue stick as a removal agent to prevent overly strong adhesion with the bed.

In any case, for PETG, an enclosure or heated build chamber are not required. That said, for extra strong parts, you could consider an enclosure. Be careful not to go too high on the chamber temperatures, though; PETG’s glass transition temperature is significantly lower than ABS, and you don’t want heat creep!

Cooling

Cooling is important in FDM printing to prevent print defects. For PETG, cooling settings should be like the ones for other filaments that don’t require heated chambers, like PLA. Set the cooling just enough for good bridging and overhang performance but not high enough to reduce strength of parts.

For ABS, cooling depends on the chamber temperature it’s printed at. On the one hand, it can improve overhang and bridging performance. On the other, cooling ABS too quickly (or excessively) can result in poor layer adhesion, with increased warping and delamination. This won’t be a problem for high chamber temperatures – hence, the higher the chamber temperature, the more cooling you should use.

If your enclosure is a relatively low temperature, passively heated one, beware of using too much cooling, as this will reduce part strength significantly.

Post-Processing

ABS has more post-processing options than PETG. It especially shines (pun intended) in its ability to be vapor smoothed by acetone, creating parts with a very smooth, glossy surface finish and without any visible layer lines. PETG is more difficult to dissolve with solvents, and only specialty chemicals can be used to smooth it.

Also, ABS parts can be relatively easily modified or joined using an effective solvent, such as acetone (or ABS glue or cement derivatives). For large parts or modeling, this is especially helpful.

That said, both PETG and ABS can be easily post-processed by sanding, drilling, or tapping for your mechanical components.

Examples

There are many brands of PETG and ABS filaments. The following are some of our top picks.

Sunlu PETG

Sunlu is known throughout the community for its high quality filaments, yet highly affordable pricing. Its PETG – in nine color variants – retains an excellent dimensional tolerance of 1.75 mm ±0.02 while being at a very low price point (~$20/kg). Users report that it prints just as well, or better than, other options and that it offers great print quality and durability, making this option a solid option for everyday use.

Hatchbox PETG

Hatchbox is a popular filament brand, and so is their PETG filament. There’s a enormous variety of over 30 colors to choose from, though it’s a bit more expensive at ~$25 per kg. However, if you like having lots of interesting colors to choose from and you trust the many, very positive reviews at Amazon, Hatchbox is surely the way to go.

Polymaker PolyMax PETG

Similar to other materials in the PolyMax range, Polymaker’s PolyMax PETG promises increased ductility and impact resistance while remaining as easy to print as regular PETG. Although only available in two colors (black and white) and coming in at a high price point of ~$30 per 750-g spool, it can be well worth it, given the improved material properties.

Sunlu ABS

Sunlu’s ABS has a dimensional tolerance of 1.75 mm ±0.02, which competes with premium options such as Prusament’s but at a lower price point: You can find this filament under ~$15 per kg. In addition to the accessible price tag, it has good printing performance and strength, making it a great pick for a budget filament.

Polymaker PolyLite ABS

Among their PolyLite series, Polymaker’s PolyLite ABS is advertised to have been made with a specialty bulk-polymerized ABS resin to promise lower-odor printing, and users seem to agree with it! PolyLite ABS is ~$22 per kg, similar to other filaments in the PolyLite range.

3DXTech ABS

3DXTech is a well-known manufacturer of highly technical and specialized filaments like polyether ether ketone (PEEK), Ultem (PEI), polycarbonate (PC), and various exotic blends. That said, they also offer basic ABS and its fiber-filled blend. Although they are pricier (at ~$36/kg), you can be assured with a highly experienced specialized manufacturer, good quality, and strong customer support.

License: The text of "PETG vs ABS: Filaments Compared Short & Sweet" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.