When it comes to 3D printing materials, polyethylene terephthalate glycol-modified (PETG) and polylactic acid (PLA) stand out as favorites and are arguably the biggest contenders in the battle between the filaments.

The main reason these two are so popular is because they both have extremely well-balanced relations between great material properties and ease of printing. In addition to this, both filament types are chosen due to their affordability, availability, and ease of printing.

Although these materials are similar in several ways, the focus of this article is to help you choose between the two for various applications, and to do that, we’ll compare their similarities and differences.

In the following sections, we will discuss the differences in material properties and print settings between PETG and PLA, and offer some examples from different brands that stand out. By the end of the piece, you’ll hopefully have a clear idea of which option to turn to depending on your intended use.

At a Glance

The above and following descriptions are based on information from data sheets (as specified below) from different brands, in addition to a few other sources. As such, the comparisons aren’t representative of all brands but are otherwise generally accurate.

Reference data sheets used include Prusament’s PETG and PLA, Polymaker’s PETG and PLA, and eSun’s PETG and PLA.

Material Properties

Material properties are compared assuming all test prints were printed with similar parameters (i.e. layer height, wall thickness, infill density). Otherwise, depending on the brand and print settings, an otherwise stronger material may be discounted as weaker (e.g. if it’s printed with 5% infill while a weaker material is printed with 100% infill).

The above out of the way, here are how PETG and PLA generally stack up against each other.

Strength

PETG is generally recommended and chosen for its strength. However, under slowly increasing stress applied until failure (tensile tests), PETG isn’t always stronger than PLA. The tensile strength difference varies greatly among brands, but both materials are usually in the mid to higher end of the spectrum compared to other filaments.

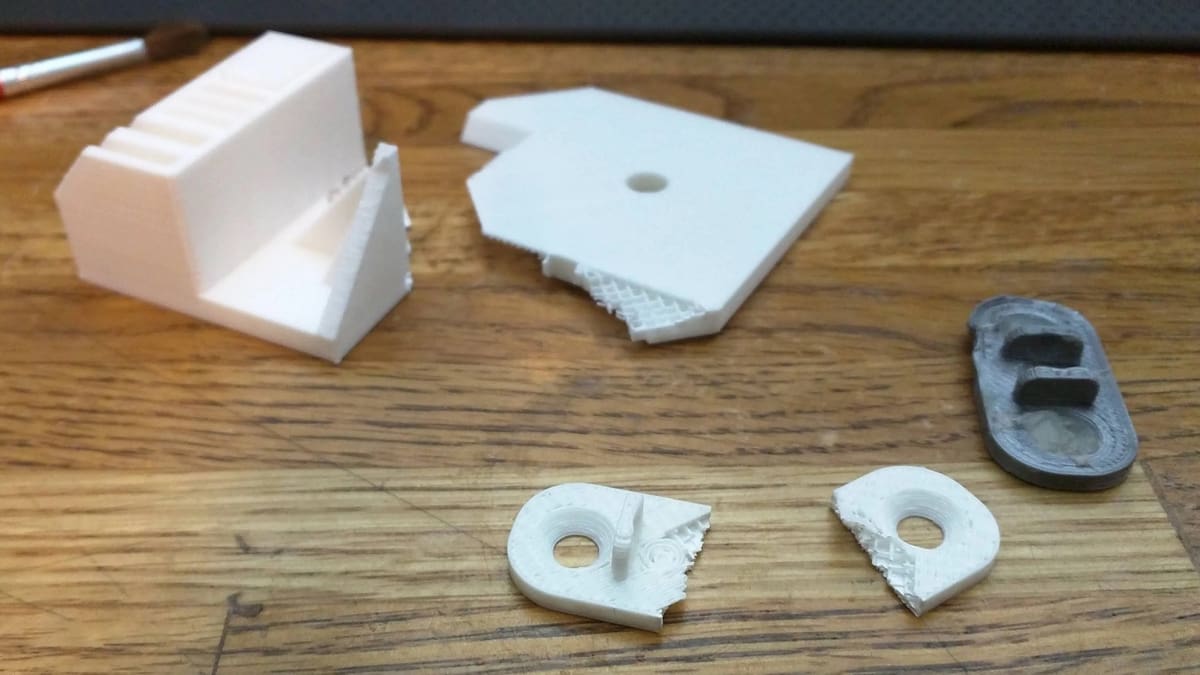

Although there isn’t much difference in pure tensile strength, the strength difference can be found in other aspects of these materials. For example, in the way that the materials fail. PLA is brittle, meaning it has an abrupt failure point, with little warning or flex before failing. In contrast, PETG tends to flex some before failure, giving it a bit more leeway in certain situations.

The other main strength dissimilarity is impact resistance. In this area, PETG takes the lead, performing nearly twice as well as PLA in impact tests (tests measuring a material’s toughness and energy absorption by applying a sudden force or shock). Regardless of the type of stress, both materials tend to break along the layer lines with little difference in layer adhesion.

Durability

While tensile and impact strength for indoor use is one thing, resistance to the elements and durability are important factors to consider when choosing a material that will be used in other conditions. This is because the strength of a material can change when under extreme temperatures.

Because of its low glass transition temperature, PLA has very low heat resistance and will easily soften and deform in a hot car. On the other hand, PETG is much more heat resistant and is a very practical material if you need to print something that can withstand the heat of hot summer days.

UV radiation plays a negligible part in weakening these materials when compared to heat. And on the opposite end of the spectrum, both materials will become brittle in the cold (-20 °C).

Hygroscopy

As with other filaments, PETG and PLA are both hygroscopic – very susceptible to absorbing moisture from the air. There is little-to-no difference in hygroscopy between them, and both will benefit from being stored in a dry box to maintain ease of printing and their mechanical properties.

Food Safety

PETG is a modified version of PET, the most common plastic found in food packaging. The main difference between PETG and PET lies in the ‘G’, which signifies the glycol modification that lowers PETG’s melting point and makes it easier to 3D print. This glycol modification is generally recognized as safe, so PETG is a good choice for printing your lunch box.

As for PLA, this material is also food safe in its pure form. PLA is usually derived from the starches of corn and sugarcane, and there are dedicated options for this intended use.

Although considered food safe, there are additional aspects to keep in mind beyond the filament for this type of projects. From the printer’s extruder and bed to post-processing techniques, as well as bacteria appearing in gaps, hazards of both of these materials increase during and after printing. Caution is warranted.

Recycling

While PETG is chemically similar to PET, which is recycled almost nationwide and has only one difference in composition, it is precisely because of this difference that most municipal recycling programs reject PETG. The glycol modification of PETG that helps with ease of printing affects the thermal stability of recycled PET.

As with PETG, so with PLA. While PLA is biodegradable and theoretically recyclable, it requires specific industrial composting conditions to decompose efficiently. It doesn’t break down easily in regular landfill conditions or at home composting setups.

Both PETG and PLA are classified as Type 7 (Other) under the ASTM International Resin Identifier Codes, meaning that you usually cannot recycle them through municipal recycling programs. Recycling facilities will sometimes incinerate entire batches of plastics contaminated with PETG or PLA.

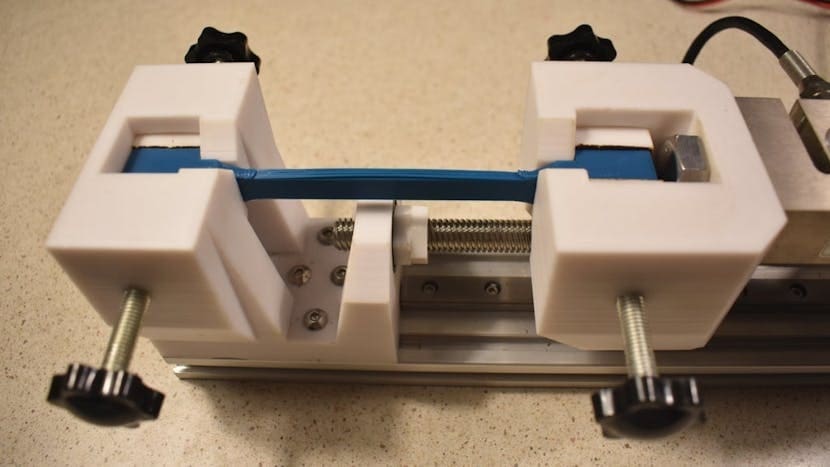

At the moment, the best way to recycle used filament is through filament re-extrusion. The process of re-extrusion generally includes shredding and drying the old filament and evenly pushing the plastic through a large, hot nozzle. Re-extrusion machines can be purchased or fabricated – if you’re an advanced DIYer.

Printing

Printing with a new material requires new print settings, and calibrating your printer to different filaments is crucial to achieving good results. As always, trial and error within the manufacturers’ recommended settings is key to getting the best out of your specific setup.

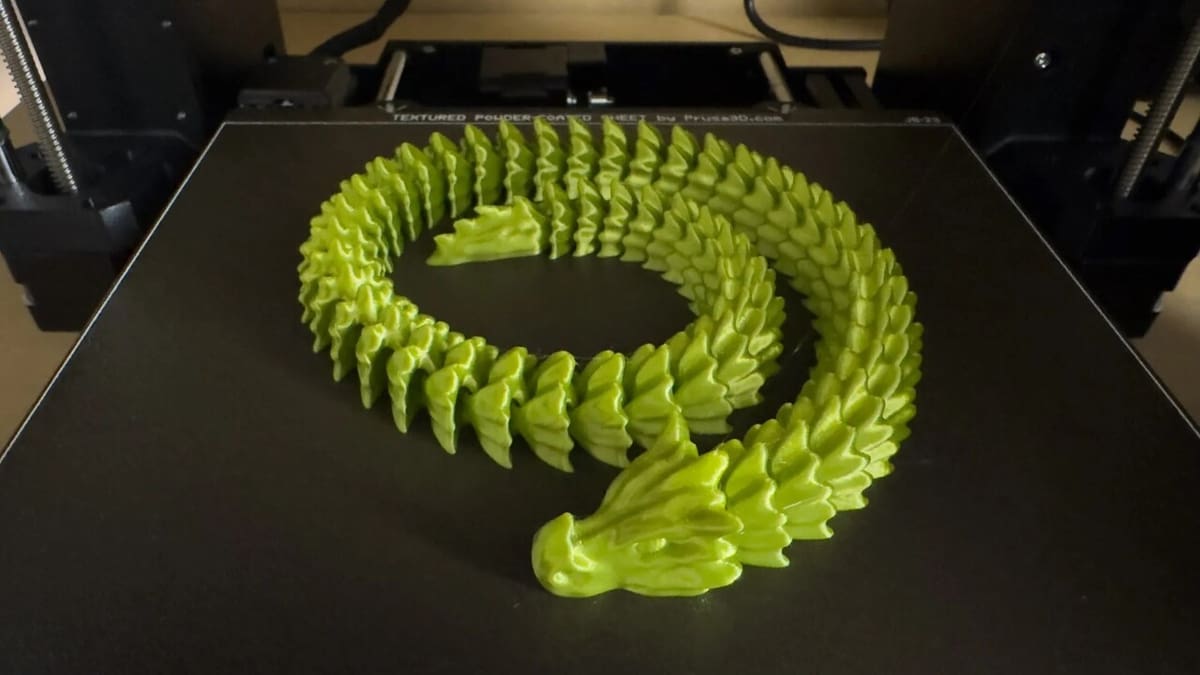

Next, we’ll compare tips and recommendations for achieving quality prints with PETG and PLA filaments. Note that these printing tips only apply to PETG and PLA in their base forms, as most composites – like carbon fiber or glow-in-the-dark – often require different settings.

Nozzle Temperature

When printing PETG, the nozzle should be heated to around 220-260 °C. PLA should be printed at a comparatively low 180-220 °C. PETG tends to string more than PLA, so in addition to the temperature settings, retraction must also be balanced accordingly.

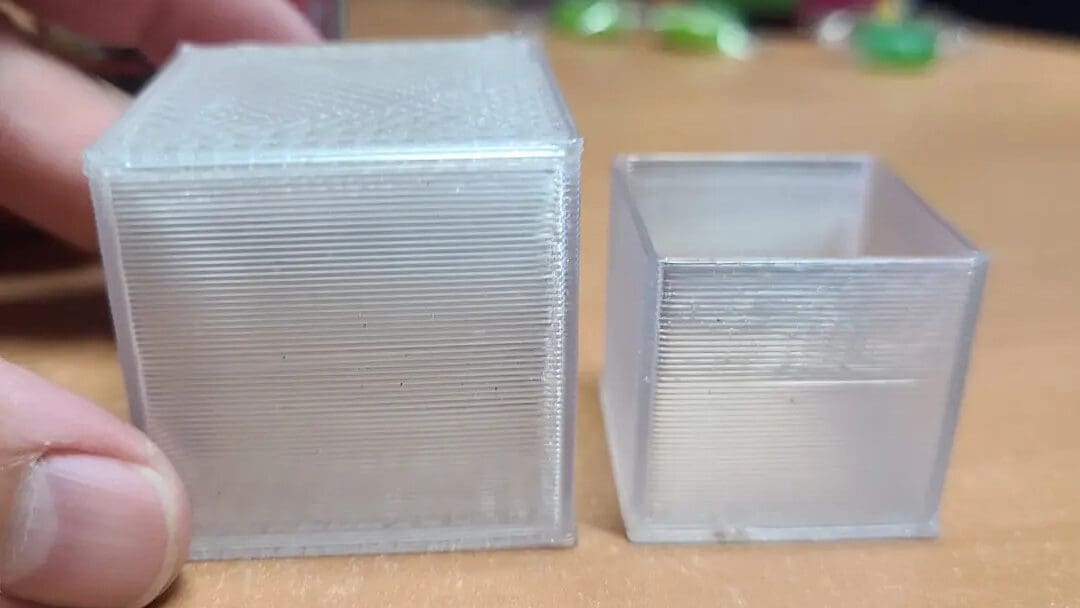

As with other materials, opting for very high temperatures will lead to stringing, uneven layer lines, and droopy overhangs. On the other hand, low temperatures can result in poor bed and layer adhesion, under-extrusion, and even clogging. So, finding the right values for the specific material might take a bit of tweaking, but will help avoid headaches down the line.

Bed Temperature

Neither PETG nor PLA require heated beds to adhere properly, although it will help with adhesion for both, with PETG benefiting the most.

A bed set too hot will increase the chance of elephant’s foot, while signs that you should increase the temperature are warping or print detachment mid-print. It’s recommended to heat the bed to 50-80 °C for PETG and 0-70 °C PLA.

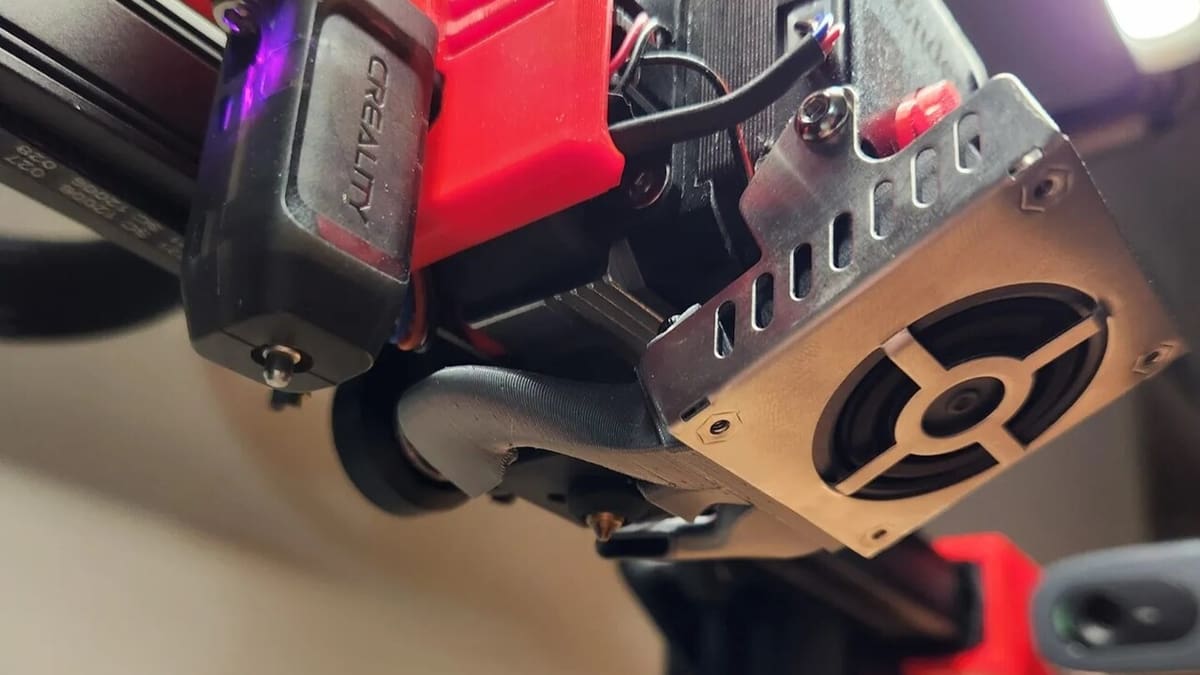

Part Cooling

When printed with part cooling fans turned up, PETG often suffers from delamination due to the layers being unable to fully bond. With PLA, it’s completely different: The glass transition temperature is lower and the cooling fan should be turned up to prevent the nozzle from distorting uncooled layers as it passes over them.

Part cooling fans should generally be set to 20-50% for PETG and 100% for PLA. Both materials benefit from no cooling for the first layer or two for increased bed adhesion.

Print Speed

The print speed for both materials depends not only on the printer used, but also on the filament. However, PLA can usually be printed faster than PETG because it has better layer and bed adhesion. To find the optimum print speed for each material, start with lower speeds of 15-20 mm/s before increasing it by 5 mm/s bumps. Dial the speed back when you start noticing uneven results.

Enclosure

Neither material requires an enclosure and can be printed in the open air, as long as the environment is stable, without drafts or sudden temperature changes.

Post-Processing

After printing, there are different steps and techniques that can be carried out to improve the model’s look.

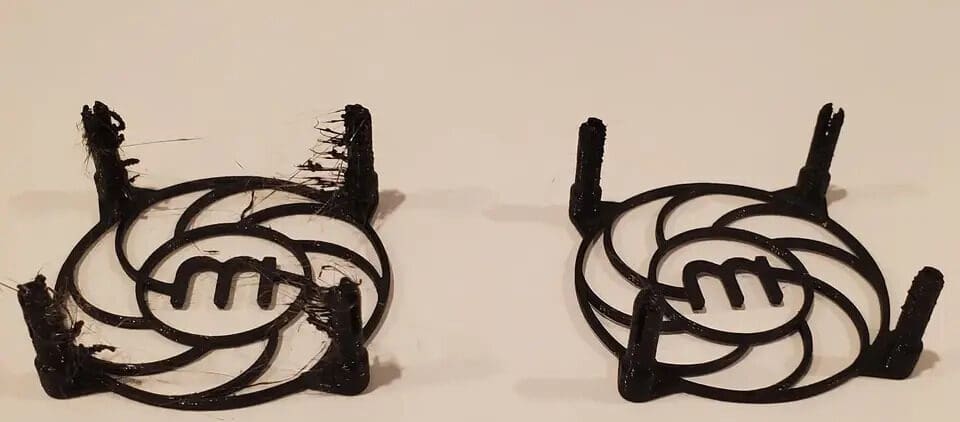

Whether the same or a different material, supports for PETG and PLA can be easily removed as long as you have calibrated the support settings. Any roughness can be fixed with filing or sanding.

Both materials can be easily sanded and can be painted. Although not dissolvable in acetone like ABS, PETG and PLA respond well to other smoothing agents.

Storage

As mentioned, because they tend to absorb moisture, PETG and PLA benefit from being stored in a dry box. If a dry box is unavailable, be sure to keep them in the driest room in your house, preferably under 40% relative humidity.

Examples

Next, we’ll take a look at three PETG and three PLA filament brands. These filaments were chosen while considering the price, popularity (quality and quantity of user reviews), and availability.

Overture PETG

Overture is a popular manufacturer of several types of filaments, and their PETG is a great choice if you’re looking for a decent filament without breaking the bank (~$20 per 1-kg spool). They offer around 20 different color options and boast a ±0.02 mm dimensional accuracy. A favorite is the starry blue color; some report that it prints better than other colors.

Hatchbox PETG

If you’re looking for a solid PETG that delivers consistent prints at a decent price (~$25), you should consider Hatchbox. They offer almost 20 different color options with a dimensional accuracy of ±0.03 mm. This PETG apparently has extremely high layer adhesion, as a maker reports that they bent a pair of pliers while removing supports from a print. If you plan to use this filament, be sure to increase your Z-tolerance on supports.

Prusament PETG

Prusament by Prusa is well known for its top-of-the-line filament materials. Their PETG line is certainly no exception. They offer a standard PETG for ~$30 and a UL-certified self-extinguishing variant for ~$55. As with all materials offered by the brand, you will get individualized parameters and stats on every spool, as well as great customer service.

Prusament PLA

Prusament PLA is a great choice for those seeking high-quality PLA that delivers consistent print results. Many reviews mention ease of printing, and we have confirmed this on our own. However, these great characteristics come at a cost, as it is the priciest PLA filament option on this list at around $30 per kilogram.

Polymaker PLA

Polymaker is an exclusive manufacturer of 3D printing materials and they have an excellent PLA. Many online reviews praise its consistent great results, good overhangs and bridges, and minimal stringing. In addition to their standard PLAs, they offer an eco-friendly option where the filament is spooled on cardboard and Polymaker plants a tree for every purchase. In addition to these fantastic qualities, the filament is relatively inexpensive, priced at around $20-$25 for a 1-kg spool.

PrintedSolid Jessie Premium PLA

Another popular PLA filament among makers is PrintedSolid Jessie’s Premium PLA. While its name might make you think it should be considered PLA+, we couldn’t find any information on its composition that would make it so. That said, this filament is competitively priced and boasts a dimensional tolerance of ±0.02 mm. What sets this PLA apart are its transition rolls: 1-kg spools sold at approximately $10 each. These spools have the same specifications as the regular ones but consist of a mix of random colors, which result from color changes on the production line.

License: The text of "PETG vs PLA Filament: Properties, Printing & Examples" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.