When it comes to 3D printed texture, some people love it, and some people hate it. Nevertheless, there are many reasons that you may want to finish a print and give it a smoother surface. Maybe it’s a display piece, or perhaps you need to reduce friction between moving parts.

As the most common FDM 3D printing material, it’s worth knowing how to post-process PLA. Sadly, the nature of the material means acetone smoothing isn’t an option, but there are other ways to achieve a smooth and shiny finish.

In this article, we’ll take you through different ways of smoothing out and finishing your PLA prints. We’ll start with the basics, like trimming and sanding, before moving on to different ways to coat or even melt the surface of a part for a smooth finish.

If all of that sounds like more effort than you can put in at the moment, try Craftcloud. With a wide range of available finishes, you can get parts professionally printed in PLA and finished to your specifications.

Before Printing: Slicer Settings

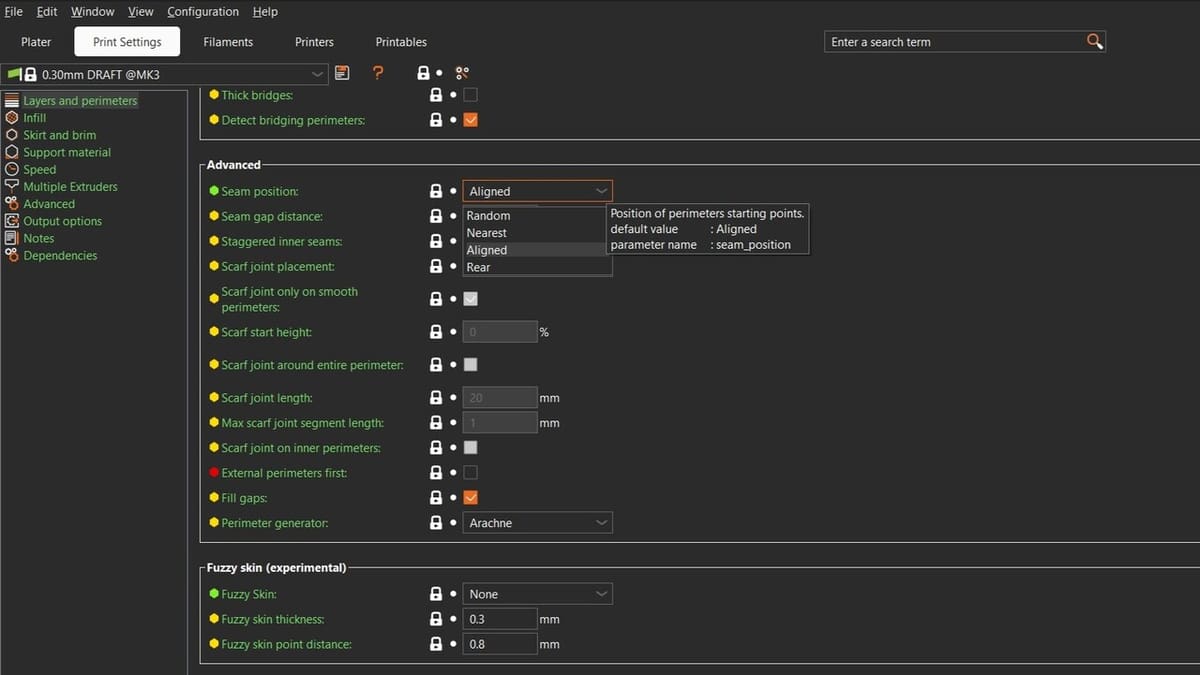

While smoothing takes place after the part’s printed, makers can take advantage of several features and tools in the slicer beforehand to try to minimize the post-processing.

- Z seam: Every layer has to start and stop extruding at some point, which creates a small “zit” or “seam”. Slicers like UltiMaker Cura or PrusaSlicer have settings that allow makers to place this “Z seam” on the inside of sharp corners, for example, which reduces surface roughness.

- Ironing: Many FDM slicers also have options to “iron” the top layers of 3D prints, where the hot extruder retraces the top layer to smooth the material.

- Vase mode: For certain geometries (notably vases), slicers can enable “vase mode“, which 3D prints the object with one singular wall in a clean spiral. This facilitates a clean transition between layers, eliminating the Z seam because there are no stops and starts in layer shifts.

- Orientation: Fewer supports mean fewer problems when removing them, and gradual overhangs mean decreased chances of poor bridging. Changing the orientation of the part so that it has no supports or overhangs over 15 degrees can ensure a 3D print that comes off smooth. If your 3D printer is a dual-extruder, dissolving supports can help decrease or eliminate these problems altogether.

In addition to these slicer features, it’s important to have dialed-in retraction settings for the specific material in use. This is because inadequate retraction settings can lead to stringing, which takes a lot of effort to remove. Stringing can also be reduced by drying the filament before 3D printing, which is especially important for hygroscopic materials like PETG or TPU. Lastly, smaller layer heights will lead to better defined 3D prints – at the expense of a longer 3D printing time.

Having gone over the “before”, let’s go over the “after” ways of smoothing PLA 3D prints.

Removing Excess Material

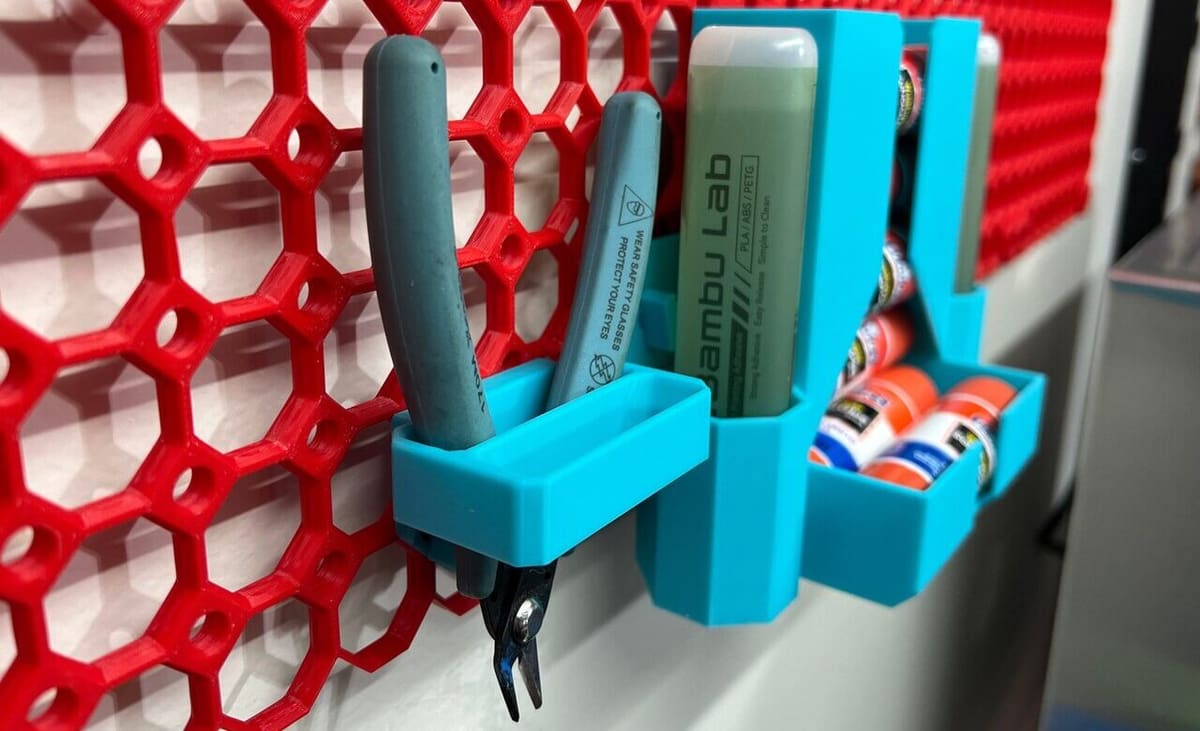

To remove supports, brims, rafts, or stringing artefacts, flush cutters are the best tool to use. Used with caution, they can effectively remove filament from flat surfaces, leaving very little – if any – material.

For places where the flush cutters can’t effectively remove material (for example, because they can’t fit into tight corners), a utility knife can be used. It’s important to follow safety measures to minimize the chances of injury:

- Never use a utility knife with someone else within two meters of your work area.

- Always point and move the knife away from you (including away from your other hand, which might be holding onto the 3D print). If this isn’t possible, use a vice clamp to secure the part to a table before continuing.

- Make sure that the knife blade is sharp and has no visible defects.

- Don’t force the knife to the extent that it might slip or break; if you find yourself forcefully shaking while trying to use a utility knife, the cut should be made using a different method.

Rotary Multitool

Rotary multitools like Dremels are another great option for finishing 3D prints. You use these tools similar to how you would use a knife, but because of the many different bits available, they allow you to easily finish the inside edges and other difficult-to-reach places on a part.

There are two things to keep in mind when using a rotary multitool. First, they are speed tools, not torque tools. So, rather than applying more pressure when you aren’t seeing the desired results, increase the rotary speed. This will not only save you a lot of work, but it will also increase the lifespan of your tool.

Second, because you’re using a power tool on plastic, don’t hover over one spot for too long or apply too much pressure. The movement of the tool creates heat, so doing this is a surefire way to melt the plastic on the spot where you’re working and create divots and holes in the print.

Some rotary tools also come with sanding attachments, but they can be too intense for smoothing PLA. We’ll look at effective sanding techniques next.

Sanding

Sanding is one of the more accessible methods of smoothing out prints. As you might have figured out from your own experimentation, there are many different ways of sanding 3D prints.

If you have a print with large surface areas, consider using a sanding block. They take the strain off your hands and create even wear on the sandpaper and your print.

If you have a print with lots of detail, your best bet is to use nail files. There are many different sizes and types of nail files, and the right choice will depend on what you’re sanding, but the cheap cardboard files will often work perfectly well.

Of course, you can also use loose sheets of sandpaper, which may be preferable in some situations. To get the best results from your sanding efforts, move the sandpaper in circular motions across the print against the grain of the layer lines.

You’ll also want to step up your sandpaper grits. Depending on the result you’re looking for, you could start as low as 400 grit sandpaper and work your way up to 4,000 grit.

On a final note, you’ve probably heard of wet sanding. High-grit wet sandpaper can be used as the final sanding stage because it doesn’t remove a lot of material and will leave a polished finish. The technique for using wet sandpaper is mostly the same as regular sandpaper, you just have to wet it every now and then.

Surface Melting

As you probably know, PLA is not particularly heat resistant, which makes it unsuitable for outdoor applications. However, you can still harness the impact of heat on the plastic to finish your prints.

The most commonly used tool for this purpose is a heat gun, set to its lowest heat setting. The best, most consistent results are attained by placing the print on a turntable and spinning it slowly to evenly distribute the heat. This also helps prevent over-melting any specific areas for an overall better result.

And while it might seem like a hairdryer would be a good alternative to a heat gun, a hair dryer isn’t designed to be hot enough to melt plastic. Many models won’t be able to reach temperatures that are suitable for a gentle surface melt.

Surface Coating

Another way to achieve a smooth surface on a print is by adding an additional coat of material, whether sprayed, painted, or dipped. This can fill any defects in the surface texture, including layer lines, and leave a shiny, even finish. Two common examples for PLA are using a paint primer or an epoxy coating.

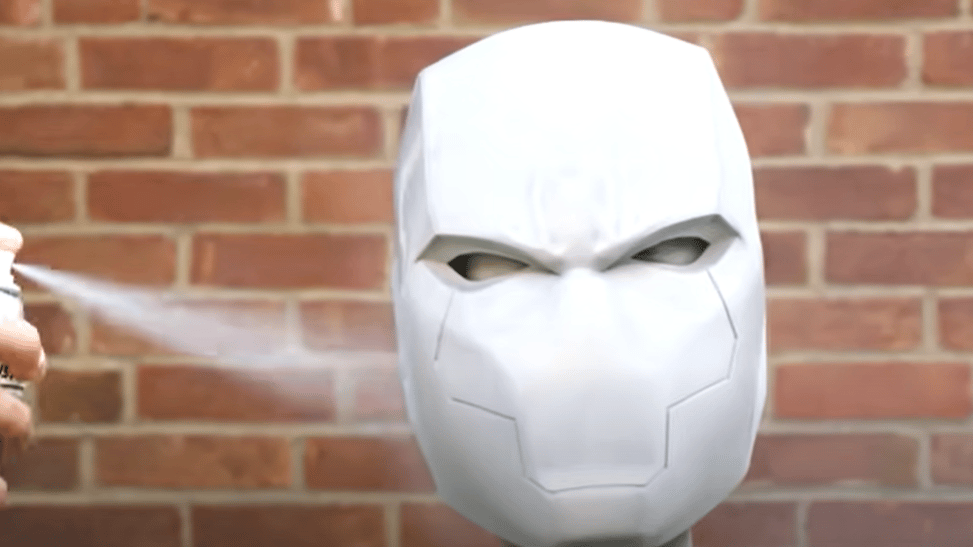

Primer

Using primer on a print more or less goes hand in hand with sanding. The idea behind using a primer to finish your print is that the primer will fill in the layer lines to create a smooth surface. You then let the primer dry and subsequently sand the top layer down. Sanding the primer is generally a lot easier than sanding down the actual PLA because the primer is much softer.

Using primer usually results in a print that looks nicer than a print that has simply been sanded. You should, however, remember that this method is more time-consuming since you’ll have to wait for each layer of primer to dry. Additionally, it’s best to follow up a primed print with paint, as primer alone won’t stand the test of time if left uncovered.

Epoxy

Epoxy is a resin coating that works in much the same way as a primer. However, it’s a little more challenging to work with as you need to mix it before applying it to your print. That said, one thing epoxy is significantly better at than primer is filling larger holes or print artifacts left behind by the printing process.

Finishing your print with epoxy consists of mixing up a batch of epoxy resin. You can then apply it liberally to all surfaces of your print with a paintbrush. Just make sure that your coats are even, so you’re not left with different thicknesses on the finished print.

XTC-3D is a well-known option that sticks to and self-levels within the layer lines of 3D prints. MatterHackers advertises it as capable of smoothing a 3D print to a matte finish with one coat of resin, and smoothing it to a glossy finish in a second coat. Each coat adds 0.4 mm of thickness to the wall of the 3D print, so make sure to account for this when designing multi-part assemblies.

Chemical Smoothing

Finally, we come to chemicals. As we mentioned previously, PLA can’t be smoothed with acetone in the way that ABS can, but there are a few other chemicals out there that could have a similar effect, although results have been mixed.

Dichloromethane (also known as methylene chloride) is a solvent for PLA that can dissolve away those pesky layer lines. As HazelChem demonstrates, a quick dip into this solvent can give great results, just be sure not to leave it for too long, or else you risk losing detail or completely ruining your part. It’s also important to use the utmost caution when working with dichloromethane, including only opening solvent containers in well-ventilated spaces, wearing goggles, and working with PVA gloves (dichloromethane can eat through typical nitrile gloves).

If you’d prefer not to bother with harsh solvents, Polymaker Polysmooth is composed of PVB, a material very similar to PLA that can be chemically smoothed. However, it requires the use of the Polymaker Polysher. This is a box that disperses isopropyl alcohol, which interacts with the filament to smooth the top layers.

Purchasing everything required is a bit of an investment, but if you need a large number of smooth prints, it might be worth taking the plunge and setting yourself up with this system.

License: The text of "PLA Smoothing: How to Smooth 3D Prints" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.