PLA, ABS, and PETG are some of the most popular filament choices among 3D printing enthusiasts. But the question remains: Which one is the best? The PLA vs. ABS vs. PETG debate can be very confusing, especially for newcomers trying to decide which filament will suit their needs best.

The truth is that there’s no best-for-everything filament. Generalizing, PLA is the easiest to print, PETG provides a balance between strength and printability, and ABS is the most heat-resistant and durable of the three. Beyond these key differences, each filament has additional characteristics that set it apart from the others.

Selecting the right filament is crucial, as depending on intended use, using the wrong one can lead to issues like warping or delamination. For example, since it has poorer heat resistance than PETG, leaving a PLA print outside on a hot summer day can cause it to warp.

In this article, we’ll break down the strengths, weaknesses, and best use cases for each filament so you can determine which one suits your needs the most. Let’s dive in!

At A Glance

Material Properties

The mechanical properties of a 3D printing filament – such as strength, flexibility, and impact resistance – play a crucial role in its suitability for different applications. Let’s take a look!

Strength

When it comes to mechanical properties, each filament is pretty different from each other. Strength for filament is usually defined in terms of Young’s Modulus, Bending Modulus, Tensile Strength, and Impact Strength.

Young’s Modulus means how stiff the material is or how much it will flex before breaking. Bending Modulus measures a material’s stiffness when subjected to bending forces. It is similar to Young’s Modulus but specifically refers to how much a material resists deformation when bent rather than stretched or compressed. Tensile strength is its resistance to be pulled apart; such as if you were trying to tear apart a piece with pliers, for example. Impact strength dictates how well it holds up against sudden forces or shocks (e.g. if you hit it with a hammer).

The following information is from Overture’s Technical Data Sheets for PLA, ABS, and PETG.

*All properties are in X-Y directions.

PLA is the most rigid, with a higher Young’s Modulus and a decent tensile strength that makes it ideal for decorative models or functional parts where it won’t need to flex. However, since the impact strength is low, it’s quite brittle and hence not suitable any functional prints where it may face impacts. The best applications would be figurines, models, and low-stress functional parts such as mounts, brackets, or organizers for indoor use that don’t endure much stress or impact.

ABS is significantly less rigid than PLA, with a lower Young’s Modulus – so it has more flexibility before breaking. However, since the tensile strength is also lower than that of PLA, it’s more likely to deform under stress. The main advantage of ABS is that it elongates more before breaking point, so it can withstand more strain before failing, which makes it slightly better at handling impacts than PLA. Since ABS is less brittle, it’s more suitable for functional parts that need some flexibility, such as mechanical components.

When it comes to mechanical properties, PETG falls between PLA and ABS. It has a tensile strength close to PLA, which makes it strong and durable, but it also has a higher impact resistance than both of them – making it less brittle. Its moderate Young’s Modulus allows it to absorb shocks without breaking easily.

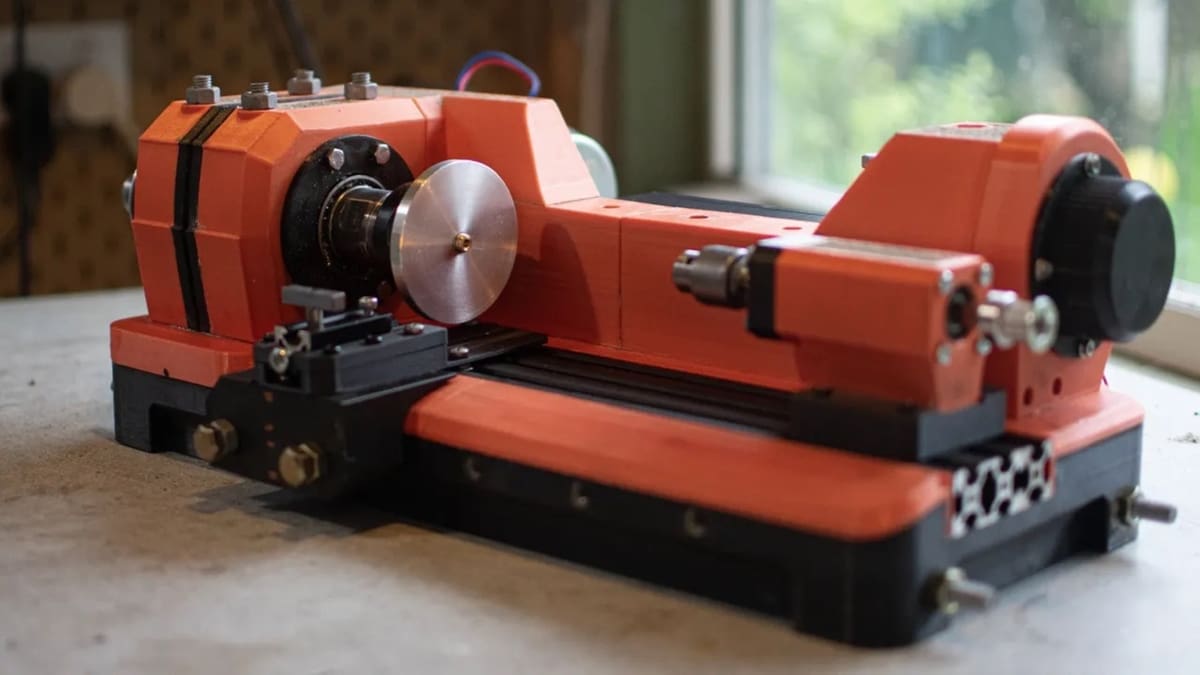

The balance of strength and flexibility makes PETG an excellent substitute to ABS for functional prints that need to be durable, impact resistant, and have some temperature resilience. As it’s also easier to print than ABS (discussed in more details later), PETG is often a popular choice among people for mechanical parts. Did you know Prusa also prints most parts of their printers using PETG?

Durability

For durability and longevity, it’s important to determine how well a filament withstands environmental factors such as UV (sunlight) exposure, moisture, and ambient temperature, and whether it matches a project’s requirements. For example, if the object you’re printing is purely decorative and will be kept indoors, then material choice might not matter as much; however, it may become a concern if you plan on installing the part outdoors.

PLA is the least durable of these three materials, since it has poorer UV resistance and lower heat resistance compared to ABS and PETG. Exposure to sunlight can cause PLA to degrade over time, becoming brittle and losing its structural strength. Additionally, PLA also has a glass transition temperature (lowest temperature at which the material can start warping or deforming) of 55-60 °C. So, if you leave your PLA mug holder in your car on a hot summer afternoon, chances are it will end up deforming.

ABS is more outdoor-friendly than PLA, especially in terms of temperature resistance and mechanical wear. With a glass transition temperature of ~105 °C, it can withstand much higher temperatures before deforming. So, it’s great for parts exposed to moderate heat. However, ABS still gets brittle over time when exposed to sunlight for extended periods, or it can fade in color.

If you want to use ABS prints outdoors, the best way to do it would be to paint it or apply some UV protection coating to make it last longer. Aside from the outdoors, it’s still a great material to use for functional parts that might get exposed to moderate heat, such as motor holders or automotive parts. This video from Teaching Tech discusses some interesting methods for coating prints.

PETG is the best choice for durability, whether it’s about weather resistance, UV protection, or water resistance. Its glass transition temperature is around 85 °C, which is between PLA and ABS. PETG will do okay in moderate heat, but may still soften under extreme weather conditions. Although – because of its ability to withstand sunlight for longer periods – it’s still objectively a better choice than ABS for most outdoor applications.

Hygroscopy

When it comes to how hygroscopic these materials are – how much moisture they absorb from their environment – it’s worth noting that, when exposed to moisture, PLA isn’t considered highly hygroscopic. But over extended periods, it may weaken, especially in humid environments. For these reasons, PLA shouldn’t be used for anything that would be outdoors (for example, a 3D printed flower vase by the window).

ABS isn’t particularly water-resistant either and can absorb moisture, which may degrade its structural integrity over time. And unlike PLA and ABS, PETG doesn’t absorb water easily, so it will be fine in humid or wet environment as well.

Still, proper storage is recommended for any of these filaments, and learning how to dry them before use can help avoid quite a few headaches.

Food Safety

When it comes to 3D printing objects for food use (like bowls), a common misconception is that if a filament is labeled as food-safe by the US Food and Drug Administration (FDA), then the final print must be safe too. That’s not always the case.

One of the biggest issues comes from additives. Even if the base material itself is food-safe (which is true for PLA, PETG, and ABS), manufacturers often incorporate dyes and additives to enhance the filament’s properties. These ingredients may not be tested or approved to be food safe, which means the safety is no longer guaranteed. Since most manufacturers don’t disclose their formulae as part of trade secret, it’s hard to know what exactly is in a particular spool.

Even if you do manage to get a completely food-safe filament, there’s still the issue of how fused deposition modeling (FDM) technology builds up the model layer by layer. The surface and wall will never be completely smooth – there will always be tiny crevices between the layers. These microscopic gaps can trap food particles, moisture, and bacteria. Washing by hand might not be enough to fully clean the surface, and using a dishwasher could cause the print to degrade or release chemicals over time.

For these reasons, even if PLA, PETG, and ABS are technically food safe in terms of the materials themselves, we shouldn’t assume they’re food-safe to print with solely based on that. If you want to know how to do it in the proper way (including the post-processing), check out this article. For example, apart from the materials, the printer itself must also adhere to standard hygiene practices. For example, brass nozzles must be avoided as they contain lead, and the printer itself should be very clean.

Recycling

As 3D printing is getting more and more popular, the environmental impact of different materials is becoming more important to consider – especially for print farms and small businesses that sell 3D printed products.

PLA is technically biodegradable under industrial composting conditions, but it doesn’t break down easily in home compost or landfills. That said, it’s derived from renewable sources, like corn starch, which makes the manufacturing process more eco-friendly than petroleum-based plastics. Still, failed prints and waste can’t be recycled by curbside trash pickup companies typically used by households. There are still noteworthy alternatives.

ABS isn’t biodegradable and is derived from fossil fuels, making it the least environmentally-friendly among these three filaments. However, since it’s found in many consumer products, recycling facilities are more likely to accept it. Do keep in mind that ABS releases volatile organic compounds (VOCs) in the form of fumes while printing, which also add to its environmental footprint.

PETG is partially recyclable and shares similarities with PET (used in water bottles), so most curbside programs should accept it. While it’s not biodegradable, it emits fewer VOCs than ABS during printing.

Check out our guides on recycling services, best recycled filaments, and best sustainable filaments for deeper dives.

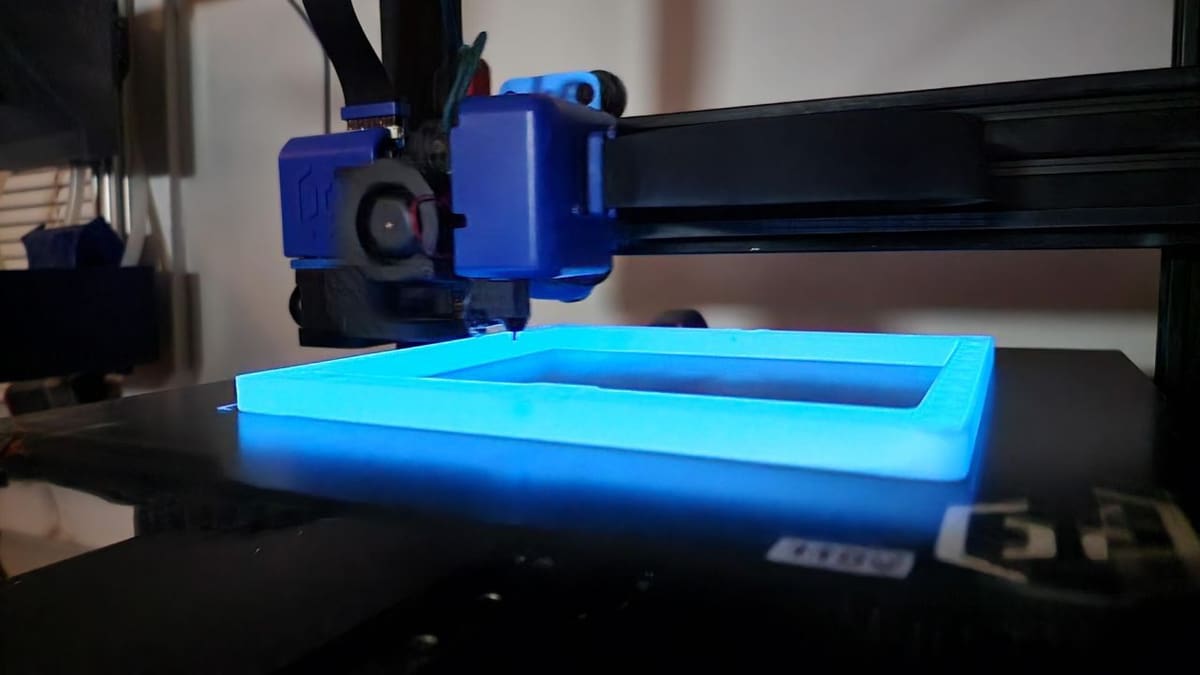

Printing

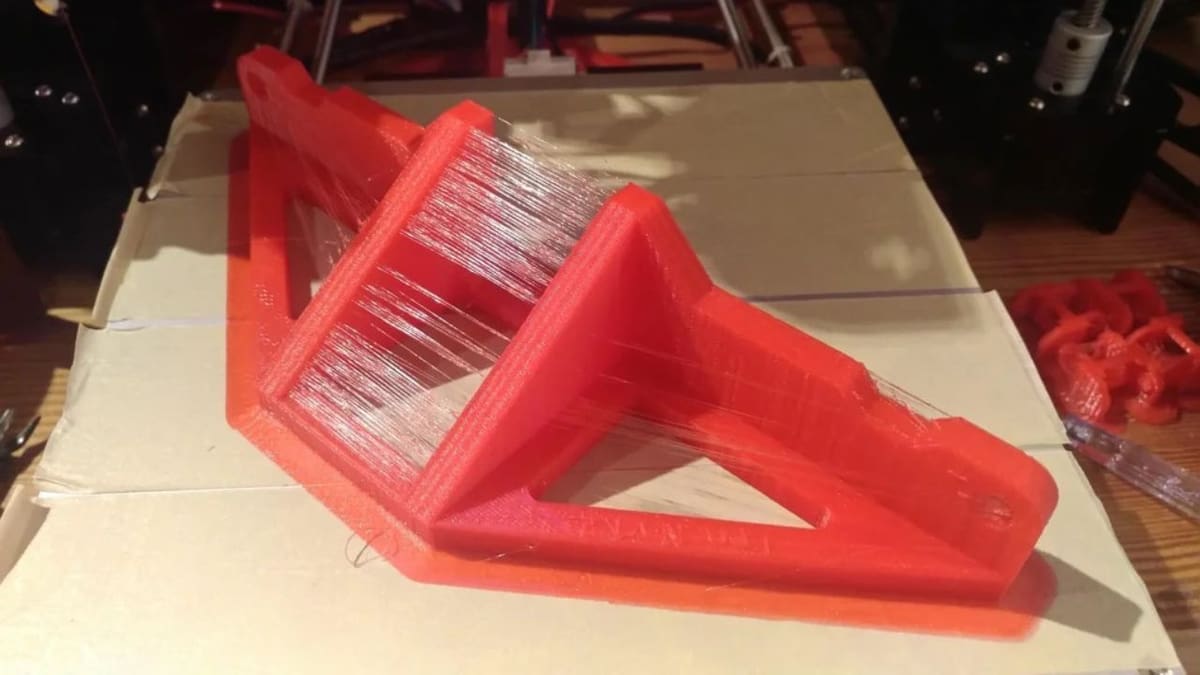

Next, we’ll go over general guidelines and printing tips for PLA, ABS, and PETG. Since the specific settings may vary from printer to printer and filament to filament, make sure to tweak the values to find out what works the best for you! And keep in mind that if you’re dealing with composites – e.g. wood PLA, carbon fiber PETG – the settings will more than likely differ from those for the base materials alone.

PLA

PLA prints the best at nozzle temperatures between 190-220 °C and a bed temperature of 50-60 °C. For best results, the fan should be at 100%. It adheres well to PEI sheets or glass, although a glue stick can be used if needed. Warping is rare, but a heated bed improves first layer adhesion.

An enclosure isn’t needed. If your printer is enclosed, keep the door or lid open, as a too hot ambient temperature might deform the print or result in a clogged extruder.

Some common issues are stringing, blobs, or rough surfaces, which can happen due to too high nozzle temperature or too little cooling. Or, if you’re facing poor layer adhesion, a too low nozzle temperature can be behind it. Adjust the temperature in small increments until it’s perfect.

ABS

ABS prints best at a hot end temperature of 220-250 °C, with a bed temperature of 90-110 °C. Cooling should be kept minimal or turned off to prevent warping and layer separation. Since ABS doesn’t stick as easily as PLA to the bed, using ABS slurry, Kapton tape, or a glue stick will help. A heated bed is essential to keep the first layer from lifting.

An enclosure is required to maintain a stable temperature throughout the print and to prevent warping. For best results, it’s a good idea to heat soak the chamber by keeping the heated bed on for a while before starting the print.

Common issues include warping and cracking, which often happen due to too much cooling. Keeping the enclosure closed and turning off cooling can help minimize these problems. Another thing to keep in mind is that ABS emits strong VOC fumes, so proper ventilation or an air filter is necessary.

Lastly, if you pull ABS print out of the printer as soon as it’s done printing, it can warp or shatter due to the temperature change (your room will probably be colder than the enclosure). Wait for a few minutes after the print is done so that the model has had some time to cool down slowly.

PETG

PETG prints well at nozzle temperatures between 220-250 °C, with a bed temperature of 70-90 °C. Unlike ABS, some cooling is beneficial – around 30-50% fan speed helps balance adhesion and reduce stringing. It sticks well to PEI sheets, but it can bond too strongly and damage the build plate, so applying a thin layer of glue as a release agent is recommended. Painter’s tape or a textured PEI build plate can also be used for better adhesion and easier removal.

An enclosure isn’t required for PETG, although maintaining a stable ambient temperature helps improve print quality.

Common issues include stringing and oozing, as PETG tends to create fine wisps between parts. Adjusting retraction settings and slightly lowering the print temperature can help. If excessive stringing occurs, the filament might have absorbed moisture, in which case it should be dried before printing.

Post-Processing

For post-processing, you can sand and paint PLA, but in order to get that really smooth texture, you’ll need to use a primer. It can be heat-smoothed with a heated or hot air gun, but keep in mind that too much heat can deform the model.

For post-processing, ABS can be vapor smoothed with acetone to create a glossy surface. It’s also easier to sand and glue than PLA or PETG.

For post-processing, PETG is difficult to smooth chemically, but it can be wet sanded for a polished finish. It can also be painted.

Examples

Let’s take a look at some reliable options for PLA, ABS, and PETG, shall we?

PLA

Polymaker’s PLA is known for its consistency and wide range of vibrant colors, which makes it a reliable option for most users. It’s available in larger rolls of 3 kg and 5 kg, which is convenient for high-volume printing. This filament is beginner-friendly, as default PLA slicer profiles generally work well with it without requiring additional tuning.

Overture has a more budget-friendly option that still delivers consistent results. It comes in several specialty variants, including silk and glow-in-the-dark filaments. A major advantage is that it typically requires no tuning, working well with standard slicer settings right out of the box. Although the filament itself is great, some have faced challenges.

Elegoo offers one of the most affordable options while maintaining good print quality. It’s available in a wide range of colors, including a clear variant, making it versatile for different projects. It’s generally pretty reliable with consistent results, and requires minimal tuning.

ABS

Sunlu has an easy-to-print ABS that comes in a variety of colors. Most are sold in 900-gram spools rather than the standard 1 kg, but larger 3- and 5-kg spools are also available. It’s also more affordable compared to Polymaker’s ABS.

Polymaker’s ABS provides consistent results with a wide range of color choices. It’s available in multiple spool sizes, including 1 kg, 3 kg, and 5 kg, which is useful for those who print large models or in bulk. The brand is known for its reliability and predictable performance.

Hatchbox’s ABS is a popular choice among users and is positively reviewed for its quality. It comes in a variety of colors, including transparent and glow-in-the-dark options, which makes it a great choice for both functional and aesthetic prints.

PETG

Overture’s PETG is a budget-friendly option that offers quality comparable to its PLA variant. Availabile in a wide range of colors, it’s generally consistent and works well with stock slicer profiles, making it a hassle-free choice for most users.

Sunlu offers PETG in many colors, and it includes the more specialized options, such as glow-in-the-dark and carbon fiber-infused variants. This makes it suitable for both standard prints and more advanced applications that require unique properties. Users are generally satisfied with it as well.

Elegoo’s Rapid PETG is designed for higher-speed printing, as it flows more easily than standard PETG. It comes in a variety of colors and maintains mostly consistent quality, though some report that slight tuning may be necessary to achieve optimal results.

License: The text of "PLA vs ABS vs PETG: The Main Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.