In the world of hobbyist fused deposition modeling (FDM) 3D printing, polylactic acid or PLA has become a popular go-to filament for many beginner and veteran makers. This popularity stems from PLA being easy to print, inexpensive, and widely available in different colors and combinations with other materials.

PLA has several material properties that make it easy to print. These include a low melting temperature, good bed and layer adhesion, and a nearly non-existent (almost non-toxic) odor. Despite these qualities, parts printed in PLA exhibit several drawbacks, including brittleness and poor temperature resistance because of the material’s low melting temperature. These downfalls cause PLA-printed objects to be less than optimal for use under stress, whether from temperature, physical load, or both.

Manufacturers have sought to find a way to negate these weak spots in PLA while keeping all of its positive qualities. One of the results of their endeavors is what is commonly known as PLA+. Getting to the crux of the matter, PLA+ is essentially a category that includes each filament company’s upgraded PLA. Different companies will call it PLA Plus, Pro, Extra, or Premium, but it all just means an upgraded or enhanced version of their standard PLA. For the purposes of this article, we will refer to it as PLA+.

To make PLA+, companies add certain additives and modifiers during the manufacturing process’ synthesis phase to enhance the material’s mechanical and material properties. This article will present the material properties that PLA+ tends to improve upon conventional PLA, the best settings and printing tips for both materials, as well as some of our favorite brands of both PLA and PLA+, so that you can make an informed choice if you’re not sure which type will be better suited for your prints.

At a Glance

The information above and below is based on data sheets from eSun (PLA, PLA+), UltiMaker (PLA, Tough PLA), and Polymaker (PolyTerra PLA, PolyMax PLA). More specific settings will be dependent on the particular brand and material.

Material Properties

Depending on the brand, PLA+ doesn’t always show significant improvements over conventional PLA. The following comparison of material properties is a generalized contrast across a variety of brands based on data sheets from different companies (as mentioned for the previous comparison table) and user reviews. This section only describes what PLA+ tends to improve (or not) upon PLA, and these improvements vary across brands.

With that in mind, here are the main material properties of PLA and PLA+ compared.

Strength

In terms of strength, PLA is in the medium range of the spectrum of FDM 3D printable plastics. While hardly the weakest material, its strength is still significantly less than that offered by other materials like PETG or ABS. PLA is also very brittle, so it tends to fracture under stress rather than deform, making it less suitable for applications requiring flexibility.

On the other hand, PLA+ is generally more flexible than PLA, so it tends to flex when put under load before breaking. PLA+ usually exhibits higher tensile strength (the maximum stress a material can withstand while being stretched before breaking) and less brittleness, making it more resistant to cracking or breaking under pressure. PLA+ is also more impact-resistant (the ability of a material to absorb a sudden, intense force without breaking) than PLA.

Durability

While PLA offers decent strength, it falls short in terms of long-term durability. PLA is prone to wear, particularly when exposed to mechanical stress, heat, or outdoor conditions. In contrast, PLA+ shows greater durability due to the additives incorporated into its formula. It’s more resistant to impact and wear, allowing it to perform better in demanding environments. However, even though PLA+ is more durable than standard PLA, it still doesn’t match the robustness of materials like ABS or PETG for applications requiring toughness.

Hygroscopy

Both PLA and PLA+ are hygroscopic, meaning that they tend to absorb moisture from the air. This is a concern for both materials as moisture absorption can degrade their mechanical properties and make printing more difficult. Over time, moisture can lead to reduced strength and a more brittle material. PLA+ generally doesn’t offer better resistance to this problem, even with the additives it contains. Hence why it’s useful to keep a dry box for either material.

Food Safety

PLA is considered food safe in its pure form, as it’s derived from renewable resources like corn starch. However, the safety of PLA for food-related applications becomes questionable after printing, as the printed layers create microscopic gaps that harbor bacteria. Moreover, any additives, dyes, or colorants in the filament could pose additional risks. And there are additional aspects that relate to food-safe 3D printing that are worth keeping in mind.

PLA+, which incorporates additives to improve its mechanical properties, is generally not considered food-safe unless explicitly stated by the manufacturer. Therefore, PLA+ is less reliable for use in food-related applications compared to standard PLA.

Recycling

In terms of sustainability, PLA is biodegradable and can theoretically be recycled. However, it requires specific industrial composting conditions to decompose efficiently, and it doesn’t break down easily in regular landfill conditions or home composting setups. Under the ASTM International Resin Identifier Codes, PLA is classified as Type 7, or “Other”, which isn’t typically processed by municipal programs.

PLA+ introduces further complications in recycling because of the additives used to enhance its properties. These can interfere with the composting process and make PLA+ more difficult to recycle than pure PLA. As a result, while both materials are marketed as environmentally friendly, they aren’t easily recyclable by typical means.

Arguably the current best method to recycle PLA and PLA+ is by turning the failed prints, waste, and unused models back into usable filament through re-extrusion. In a nutshell, this process usually involves first cleaning the PLA waste to remove contaminants. The cleaned PLA is then shredded into small pieces using a plastic shredder. Afterwards, the material is dried to remove any moisture. Then, the shredded PLA is fed into a filament extruder, where it’s heated and melted into a continuous strand of filament. This newly extruded filament is then cooled, spooled, and ready to be printed again.

Printing

Different materials require different print settings, so calibrating your printer to new filaments is essential for good results. This section provides tips and recommendations for achieving quality prints with both PLA and PLA+ filaments.

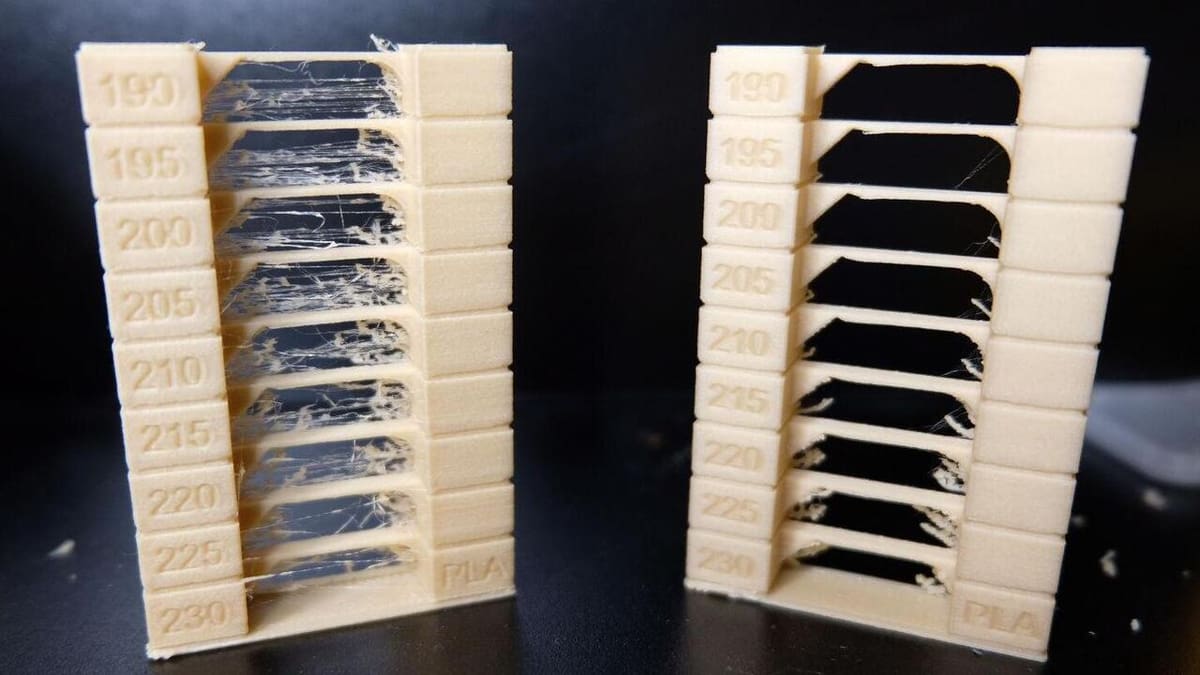

Nozzle Temperature

Depending on the brand, PLA should be printed at temperatures ranging 180-220 °C. Because of the additives that improve the heat resistance of PLA+, it has a higher melting point, so a temperature range of 200–250 °C is typically required.

As with all materials, if your nozzle temperature is too high, your print will be deformed with uneven layer lines and the overhangs will be droopy, and you might encounter stringing. Conversely, too low of a print temperature will result in poor bed and layer adhesion, under-extrusion, and potential clogging.

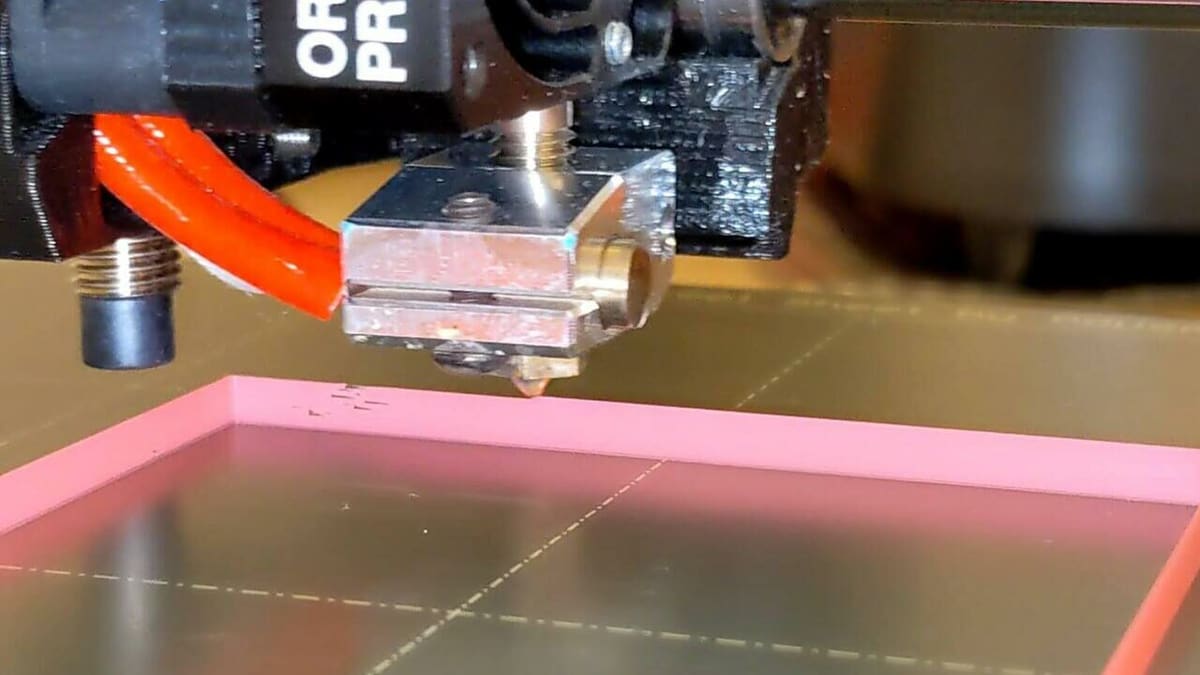

Bed Temperature

Neither PLA nor PLA+ require a heated bed to adhere properly. Even so, a print bed heated to 55-70 °C will improve adhesion. A big indicator that a bed is too hot is elephant foot. On the other hand, signs that the bed temperature should be increased are if the print warps or detaches from the bed mid-print.

Part Cooling

As with temperature settings, cooling recommendations are the same for both PLA and PLA+. When printing with these materials, the first layer shouldn’t be cooled as allowing it to naturally cool will promote bed adhesion. Turning the fan on after finishing the first or second layer will prevent the print from becoming distorted as the nozzle passes over previous layers. This is because PLA and PLA+ stay soft after being printed due to their low glass transition temperature.

Print Speed

As with the other settings, print speed is dependent upon both the printer and filament. The proper print speed for PLA and PLA+ is best found through trial and error, beginning with a slower print speed of about 15-20 mm/s. If the speed is less than this, the print may become deformed due to the nozzle sitting on previous layers for extended periods of time. If the speed is too fast, ringing, under-extrusion, and poor layer adhesion may all appear.

Enclosure

PLA is suited for printing without an enclosure in open-air environments due to its low printing temperature and minimal warping during cooling. However, print quality and layer adhesion may benefit from a stable environment, especially in drafty or cold spaces.

PLA+ typically has better layer adhesion than PLA and doesn’t require an enclosure either. Like PLA, it can be printed in open air, though some of its additives may make it more resilient to variations in ambient temperature. Enclosures are less critical for both materials compared to high-temperature filaments like ABS.

Post-Processing

Both PLA and PLA+ are relatively easy to post-process. Support material for both PLA and PLA+ can be removed without much effort and any roughness from the support material can be simply sanded off. If present, stringing can be removed from both materials by softening the strings with a hairdryer and brushing them off by hand.

Both materials can be sanded, painted, and glued with ease. Although they can’t be smoothed with acetone like ABS, PLA and many PLA+ prints respond well to smoothing techniques.

Storage

As mentioned before, both PLA and PLA+ are hygroscopic. This means they should be stored in a cool, dry environment to maintain their printability and mechanical properties. Exposure to moisture can degrade the filament, leading to issues such as poor layer adhesion or brittle prints. Long-term exposure to moisture can negatively impact both PLA and PLA+ and proper storage is essential to ensuring optimal print quality for both materials. You might want to consider drying either material before printing if you’re not sure the storage conditions were optimal.

Examples

PLA and PLA+ filaments are available from many different manufacturers in many different forms, making it difficult to choose which one(s) is best for your project. The following section consists of some of our favorites.

Prusament PLA

Prusament is the filament brand from Prusa Research. Prusament PLA is a great choice for those seeking high-quality PLA that delivers consistent print results. Many reviews mention ease of printing, and we have confirmed this in our own. However, these great characteristics come at a cost, as it is the priciest filament option on this list at around $30 per kilogram.

Polymaker PLA

Polymaker is an exclusive manufacturer of 3D printing materials and they have an excellent PLA. Many online reviews praise its consistent great results, good overhangs and bridges, and minimal stringing. In addition to their standard PLAs, they offer an eco-friendly option where the filament is spooled on cardboard and Polymaker plants a tree for every purchase. In addition to these fantastic qualities, the filament is relatively inexpensive, priced at around $20-$25 for a 1-kg spool.

PrintedSolid Jessie Premium PLA

Another popular PLA filament among makers is PrintedSolid Jessie’s Premium PLA. While its name might make you think it should be considered PLA+, we couldn’t find any information on its composition that would make it so. That said, this filament is competitively priced and boasts a dimensional tolerance of ±0.02 mm. What sets this PLA apart are its transition rolls: 1-kg spools sold at approximately $10 each. These spools have the same specifications as the regular ones but consist of a mix of random colors, which result from color changes on the production line.

eSUN PLA+

Chinese company eSUN is one of the few brands specializing in PLA+. This means that they have a greater collective number of PLA+ options than standard PLA. They specifically state that their PLA+ is an enhanced version of conventional PLA. eSUN PLA+ is also FDA food-safety-approved and 100% biodegradable. This filament comes in a wide variety of colors at a very reasonable price: around $20 per 1-kg spool.

ColorFabb PLA/PHA

ColorFabb is a 3D printing filament company based in the Netherlands. ColorFabb offers a special PLA+ and although the company doesn’t specifically call this filament PLA+, this material falls under the definition of PLA+ as it has an additive (PHA or Polyhydroxyalkanoate) that improves the qualities of the final print. This filament boasts an impressive dimensional accuracy of ±0.1 mm. One of its notable features is the “Color on Demand” option, allowing customers to request a custom filament based on the RAL color scheme.

Micro Center Inland PLA+

Micro Center doesn’t exclusively produce PLA+ as their main filament, unlike the two above-mentioned brands. However, this PLA+ is still chosen due to its excellent reviews. Micro Center claims that their filament is “10x tougher than other PLA filaments on the market, and is less brittle than standard PLA.” This PLA+ is also one of the most affordable options compared to others across the board, coming in at around $19 a spool.

License: The text of "PLA vs PLA+/Plus Filament: The Main Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.