POM, short for polyoxymethylene, is an engineering plastic seen in the likes of zippers, rollers, bushings, and gears. Aside from having a spectacularly low coefficient of friction, it features high strength, along with temperature, chemical, and abrasion resistance. This makes it excellent for applications that involve physical contact and sliding. You may have also heard the material referred to as Delrin or acetal, which we’ll explain in a bit.

You’ll often see POM machined or injection molded, but less often 3D printed. This is because, while the material offers fantastic properties, it poses quite a challenge to print. The purpose of this guide is to explain what exactly POM is, its features, applications, as well as the ins and outs of its use. By the end, you’ll be well-equipped to understand when and how to print with this challenging material, should the need arise or should you get your hands on some filament.

Alternatively, if you don’t own a 3D printer, or don’t want to print POM yourself, you can always use Craftcloud. You’ll save time and get the best price, all while having someone else deal with the challenges of printing with POM.

Multiple Names

To better understand this plastic, we’ll start by exploring its multiple names.

Polyoxymethylene, a synthetic polymer of carbon, hydrogen, and oxygen, is also referred to as acetal, polyacetal, or polyformaldehyde due to inconsistencies between different manufacturers, but it’s all the same material. Of the names, POM, the abbreviation of the official chemical nomenclature, is the most common term, but certain trade names still linger. An example is Delrin, a product of DuPont that’s often used synonymously with POM.

Two Variations

Dupont’s Delrin is actually one of two types of POM, in this case, a homopolymer. This means that the long polymer chains that make up this material are comprised only of the exact same monomer unit, oxymethylene, repeated over and over. With a highly regular and uniform structure, Delrin is highly crystalline, contributing to the rigid and tough mechanical properties of POM homopolymers.

The other type of POM is a copolymer: Instead of the polymer chain structure consisting of only oxymethylene units, other monomer units are incorporated into the same chain. This is not the same as blending in additives or plasticizers into a homopolymer as these do not become part of the polymer chain.

Even small amounts of another monomer can disrupt the crystallization of the polymer, resulting in significantly different physical properties. Reduced crystallinity generally decreases a material’s strength to the benefit of some flexibility and easier thermal processing. A common comonomer is ethylene oxide, which makes POM less susceptible to degradation, more chemically resistant, and fare better in the long term, especially when kept at elevated temperatures for prolonged periods.

Turning now to 3D printing, filament manufacturers don’t usually advertise whether they’re selling homopolymers or copolymers. While both 3D print somewhat similarly, understanding the differences can be important in certain use cases. If you’re curious about which type of POM a filament manufacturer is using, you’ll likely be able to find an answer by checking out the material safety data sheet (these are available for any purchasable filament). For us, we’ll continue referring to POM in a general sense; just recognize that not all POM is the same.

Pros & Cons

As we’ve briefly mentioned, POM is an excellent engineering plastic that boasts many impressive mechanical properties, but getting great results isn’t easy. Let’s break it down.

Pros

- Low coefficient of friction

- High stiffness

- Chemical resistance

- Heat resistance

- Abrasion resistance

- Dimensional stability

- Low moisture absorption

POM is essentially a high-performing engineering plastic with a unique mix of properties. For starters, it has high mechanical strength and excellent rigidity. POM is also known to provide superb dimensional and geometric stability and is very easy to work with in terms of machinability. It also offers a particularly good fatigue and wear resistance.

On top of that, POM is highly resistant to chemicals and heat, with low moisture absorption and a low coefficient of friction. Although not known for its aesthetics, in its natural form it is an opaque white color with a distinct shiny surface.

With this particular combination of properties, POM can be a fitting replacement for metallic parts for a number of different purposes. At the same time, the benefits of the material make it more challenging to 3D print.

These properties make POM excellent for mechanically-demanding applications, but they do come at a cost.

Cons

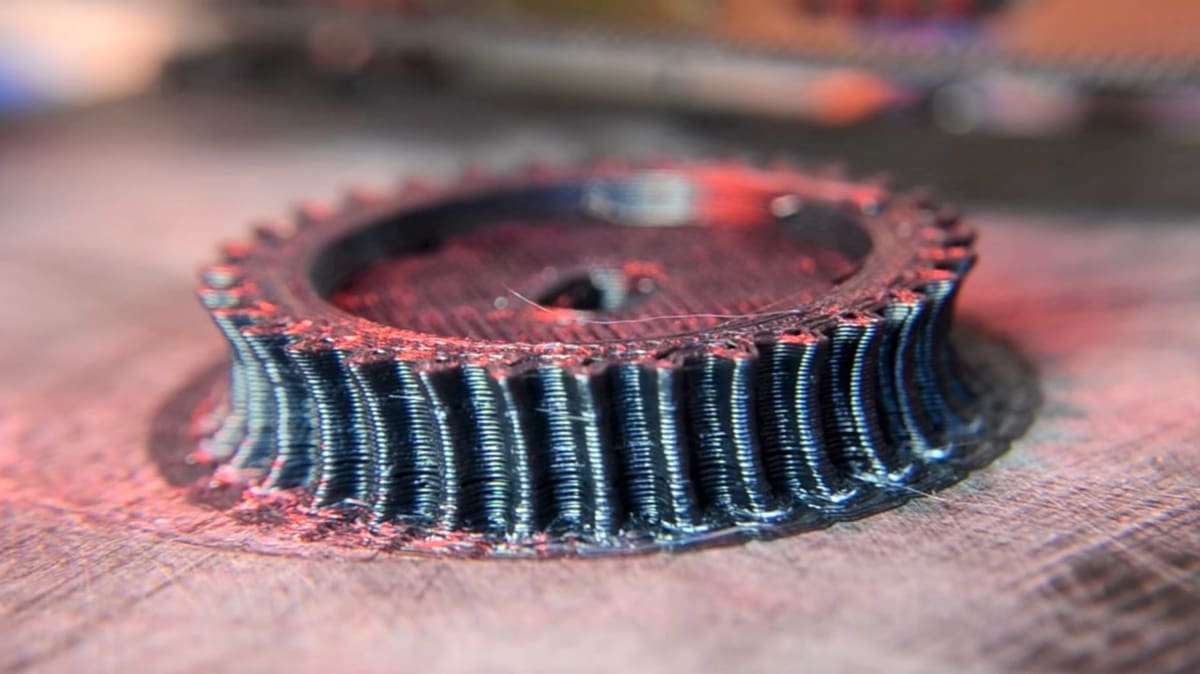

- Poor 3D printer bed adhesion

- Risk of layer delamination

- Releases toxic fumes at high temperatures

- Limited processing temperature range

- Degradation in UV light

- Poor resistance to strong acids and bases, as well as oxidizing agents

- Difficult to glue

- Fewer purchasing options for 3D printing due to low popularity

The same properties that make POM so attractive also make it notoriously difficult to handle.

Especially with POM’s relative rarity in the 3D printing scene, it hasn’t been especially well-tuned for the printing process. Compared to other difficult-to-print materials that have been made more approachable, such as polycarbonate and nylon, POM has remained a challenge.

Printing with a raft won’t guarantee that warping won’t be an issue, and if a part breaks or you need to glue together different prints, the usual suspects won’t necessarily cut it.

Not to worry! We’ll arm you with methods of tackling these issues for successful printing. Now that you have a bird’s eye view of what POM is good at and not so good at, let’s explore when and where you should be using this material.

How It Stacks Up

Being such a well-rounded material, it may seem like POM is perfect for almost any application. This well-roundedness, however, comes with a big asterisk regarding its printing difficulty. As such, deciding when to use POM is a matter of balancing its properties and printability relative to other 3D printing materials.

Choosing the correct type of 3D printing filament for a particular project is always tricky. PLA, PETG, and ABS are among the most common FDM 3D printing materials, so one might wonder how POM compares.

- PLA is arguably the easiest-to-print filament and doesn’t produce any harmful fumes during printing. However, PLA’s main setback is thermal resistance, making it inadequate for functional parts intended for outdoor use.

- PETG is a step up from PLA in terms of properties, being more flexible and durable. PETG is also easier to 3D print than ABS with the plus of not producing harmful fumes. And while it can be suitable to produce some moving functional parts, it’s not entirely on the same level as POM in terms of rigidity.

- ABS is slightly more durable than PETG but emits fumes and can be tricky to print. Compared to POM, ABS is easier to print, perhaps because ABS isn’t as rigid. POM is known for its excellent machinability, which is handy for post-processing and something that ABS is not. POM also has a lower coefficient of friction than ABS.

But that’s not all…

Applications

A material you’ll often see POM compared to is nylon, or polyamide (PA). Like POM, PA is often used in bearings, gears, rollers, and the like, due to its high abrasion resistance and low coefficient of friction. It is, like POM, also chemically resistant. The major difference here is that PA has been used more widely in 3D printing, so manufacturers have tuned the material to be much more printable. In addition, more options and blends exist on the market providing better versatility.

In light of this, it suddenly becomes more difficult to recommend POM. The tradeoff of printability seems rather high, especially next to PA.

When Should You Use POM?

As it turns out, POM has one key property that PA lacks: low moisture absorption. In fact, PA is notorious for degrading from moisture in the air, making proper material storage a must. In addition to that, your PA prints will also absorb moisture, and their properties will change over time. This makes POM a far superior choice in wet and high-humidity environments where this kind of degradation is simply unacceptable.

The bottom line is, unless you have a specific reason in mind, we only recommend using POM when moisture makes PA a poor choice. If you’ve decided that POM is for you, read on to see how to 3D print it.

The properties of a material have a strong influence on its final applications. Engineers love high-stiffness materials for high-load and high-impact parts, but POM’s other functional properties make it suitable for a wide range of mechanical applications, too.

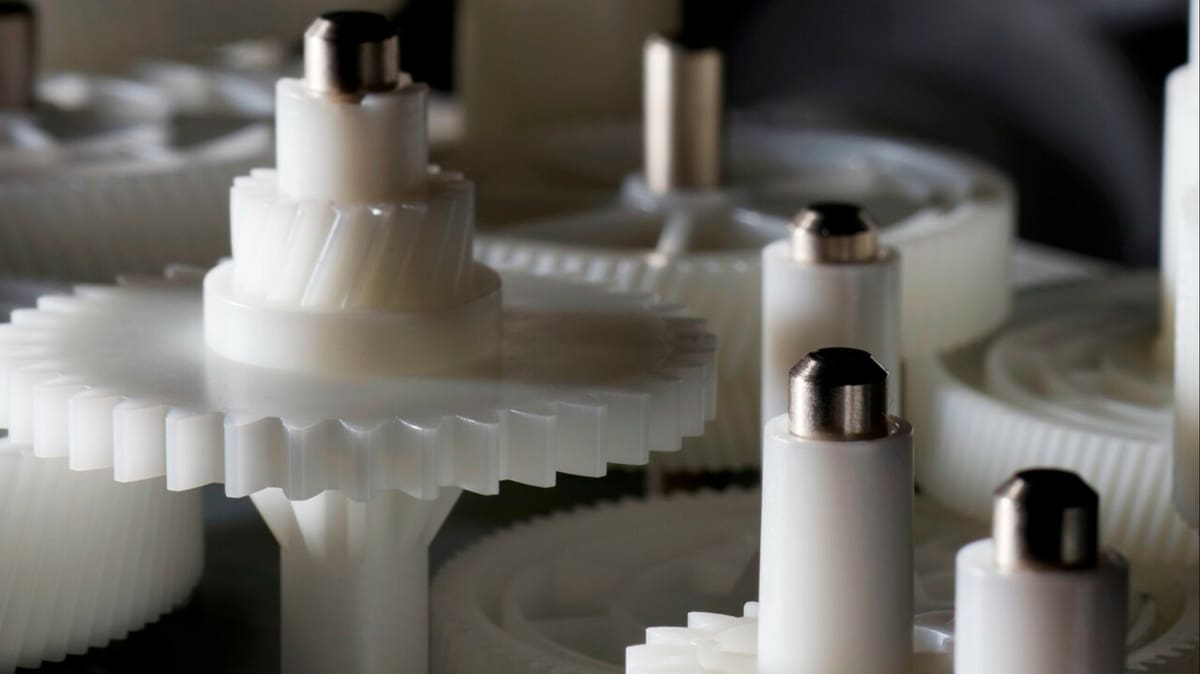

Gears & Bearings

Apart from high loads and pressure, mechanical components, such as gears and bearings, are also subject to wear due to the cyclic loads they have to endure. As POM is highly resistant to wear, it’s an ideal material choice for such parts.

Another aspect that’s important for making gears is the material’s coefficient of friction. Think of it as a measure to express how “slippery” the material is.

For example, rubber is a very grippy material, and that grip gives rubber a high coefficient of friction (imagine trying to zip up a zipper made of the same material as tires). On the other hand, rubbing two pieces of POM together is nearly effortless, so it has a low friction coefficient. This makes it ideal for rotating and moving parts that should easily glide against surfaces.

High Temperature & Chemicals

POM’s high stability also plays an important role in functional parts. Its dimensional and geometric stability, allied with its high heat resistance, makes POM parts able to work under high temperatures while also keeping their original dimensions.

POM is used for piping applications due to its low moisture absorption rate and chemical stability to solvents, hydrocarbons, and neutral chemicals.

Other Applications

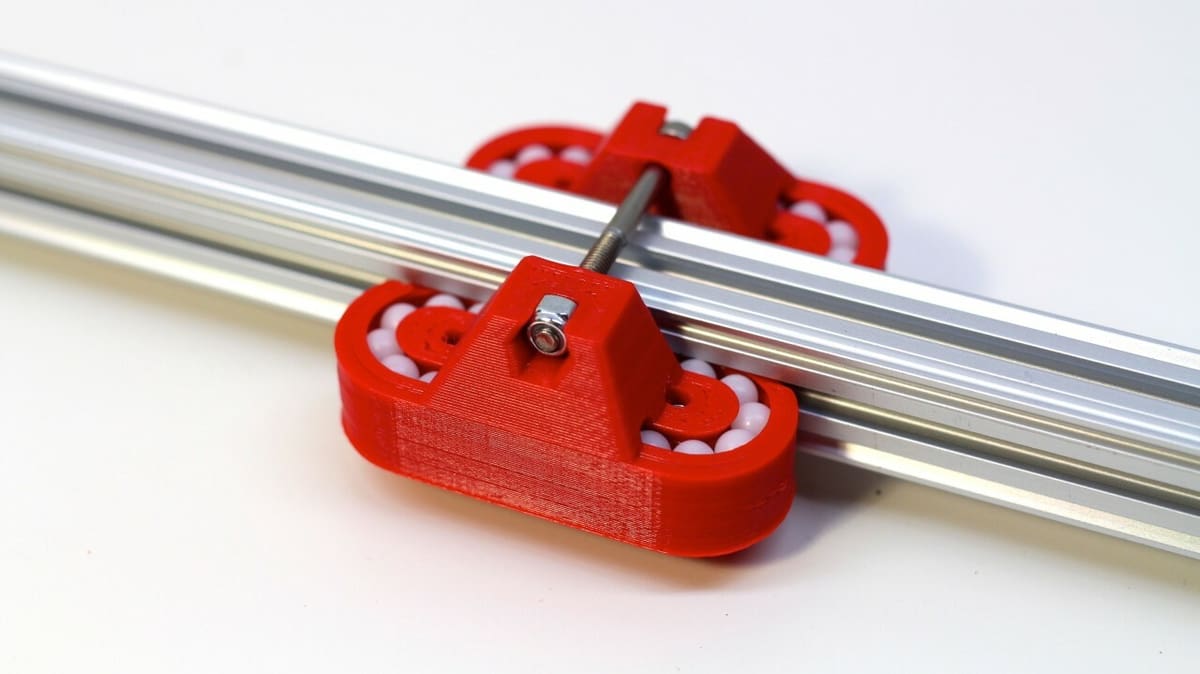

As far as other applications go, POM is used in safety restraints and rollers. In fact, the rollers used in many V-slot 3D printers, such as the Ender 3, are made from a POM material.

Printing

To get started with 3D printing POM, take a look at the filament manufacturer’s recommendations for the print settings. Here are some general guidelines:

- Nozzle temperature: 210-230 °C (unless otherwise noted by the manufacturer)

- Bed temperature: 100-150 °C (unless otherwise noted by the manufacturer)

- Bed surface: Wood, cardboard, or sketching paper

- Enclosure: Highly recommended

- Print speed: 30 mm/s or lower

- Print fan: Off

Nozzle Temperature

We do not recommend increasing it beyond 220 or 230 °C, depending on the formulation. This is because, above these temperatures, POM begins to degrade, releasing dangerous fumes. If you smell these fumes, it’s a good indication that you are printing too hot, so decrease the nozzle temperature immediately. (We’ll address this further in the section on safety.)

Also, keep in mind that this temperature of degradation will vary from brand to brand and between homopolymers and copolymers.

Heated Bed & Fans

Along with a heated bed, it’s a good idea to also have an enclosure. POM doesn’t like to stick to the print bed, or to itself, so the heated bed helps the first layer adhere better, while an enclosure raises the ambient temperature to prevent layer delamination. You might get away without an enclosure, but the ambient heat is definitely helpful.

On a similar note, you’ll want to decrease your print speed and turn off your print fan. POM is stiff and can harden quickly, so this will ensure that layers have a chance to firmly stick to each other and prevent further delamination.

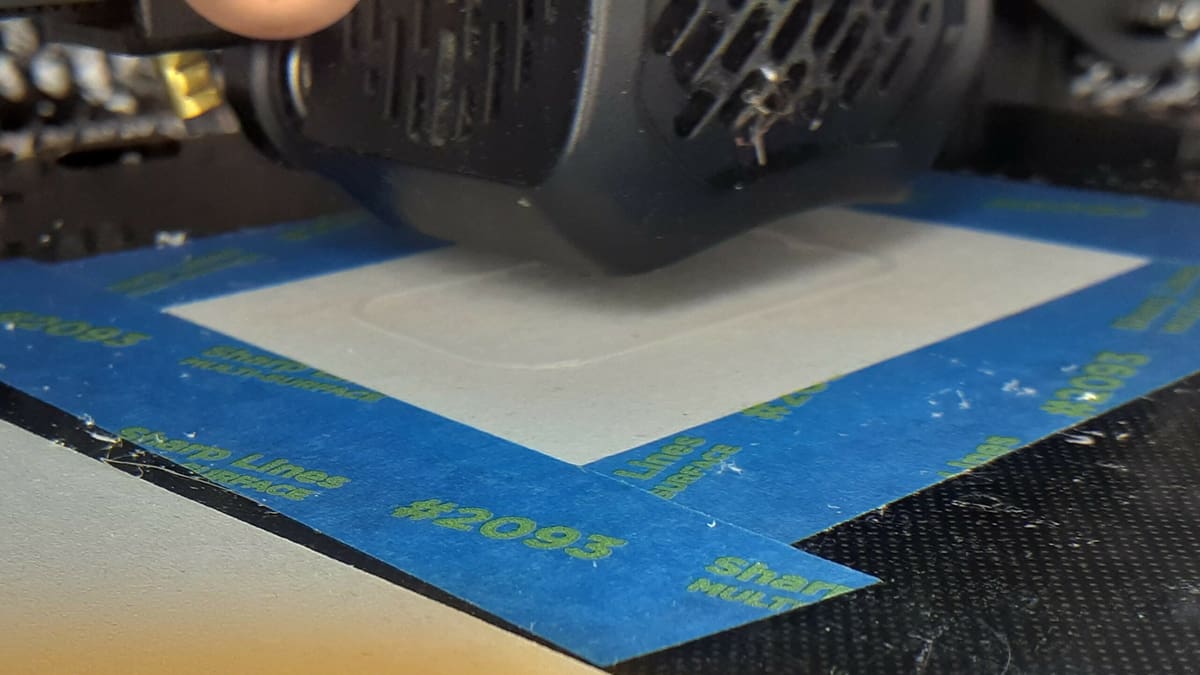

Bed Surface

Whereas other materials might work with a glue stick, hairspray, or PEI, POM works better with wood, cardboard, or sketching paper. These are the few materials that POM will like adhering to, increasing the odds of success for your first layer. You can try clipping, gluing, or taping a sheet of wood, cardboard, or paper onto your print bed; just take care not to damage it.

With that, you are armed with the tips and tricks for succeeding with POM. As with other materials, your experience is going to vary on a case-by-case basis, but these guidelines should set you on the right path. Next up, we’ll explore how to properly store your POM when you aren’t using it.

Storage

We’ve already mentioned that POM boasts low moisture absorption, but you should still take care when storing your material. This is especially true when you’re not planning on using it very often.

As with other materials, we recommend storing filaments in a cool, dry environment to minimize degradation in the long run. A sealed box with some desiccant packs will do the trick, though we have more methods described in our full guide to filament storage.

POM is definitely more forgiving in this respect than other materials, but it’s better to be safe than sorry. As with other materials, your experience will vary with the environment that you’re printing in.

In the case that your POM ends up absorbing moisture, consider drying it out for the best printing and mechanical properties. Though this is almost never necessary for the material, you can refer to our drying guide if the need arises. The guidelines there for nylon should serve you well.

Toxicity & Food Safety

The main health risk associated with 3D printing POM is degradation from printing at too high of a temperature. When this happens, POM begins emitting large amounts of formaldehyde fumes, which can irritate the eyes, nose, and throat. The exact temperature at which this happens varies from brand to brand, but is usually between 220 and 230 °C.

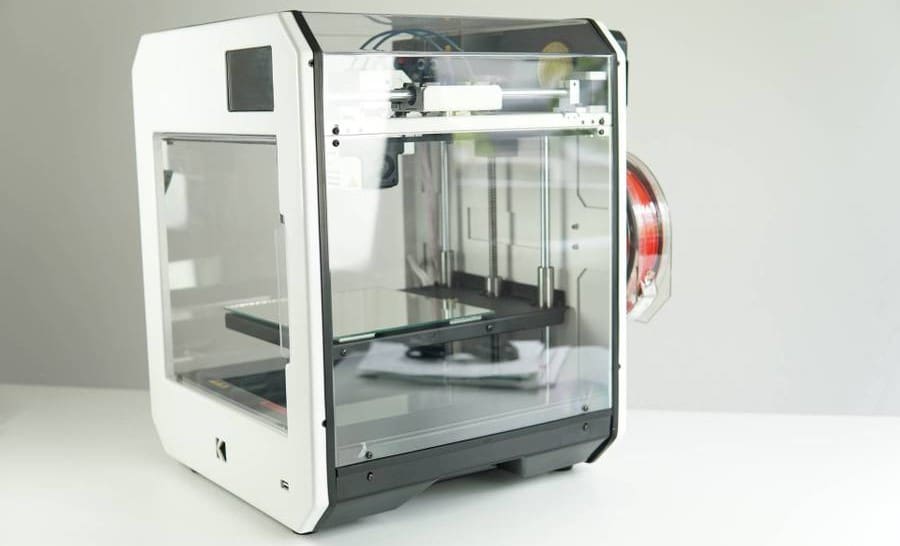

We recommend printing in a well-ventilated area, as small amounts of formaldehyde might be released even if you aren’t exceeding the proper temperature range. For the safest option, print in an enclosure with a filter, as pictured above, to minimize fumes.

Regarding food safety, certain grades of POM have been approved by the FDA for food contact. When 3D printing, however, the grade you’re buying isn’t always clear, so always check with the manufacturer.

License: The text of "POM 3D Printing (Acetal/Delrin) – All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.