Pushing Out the Competition

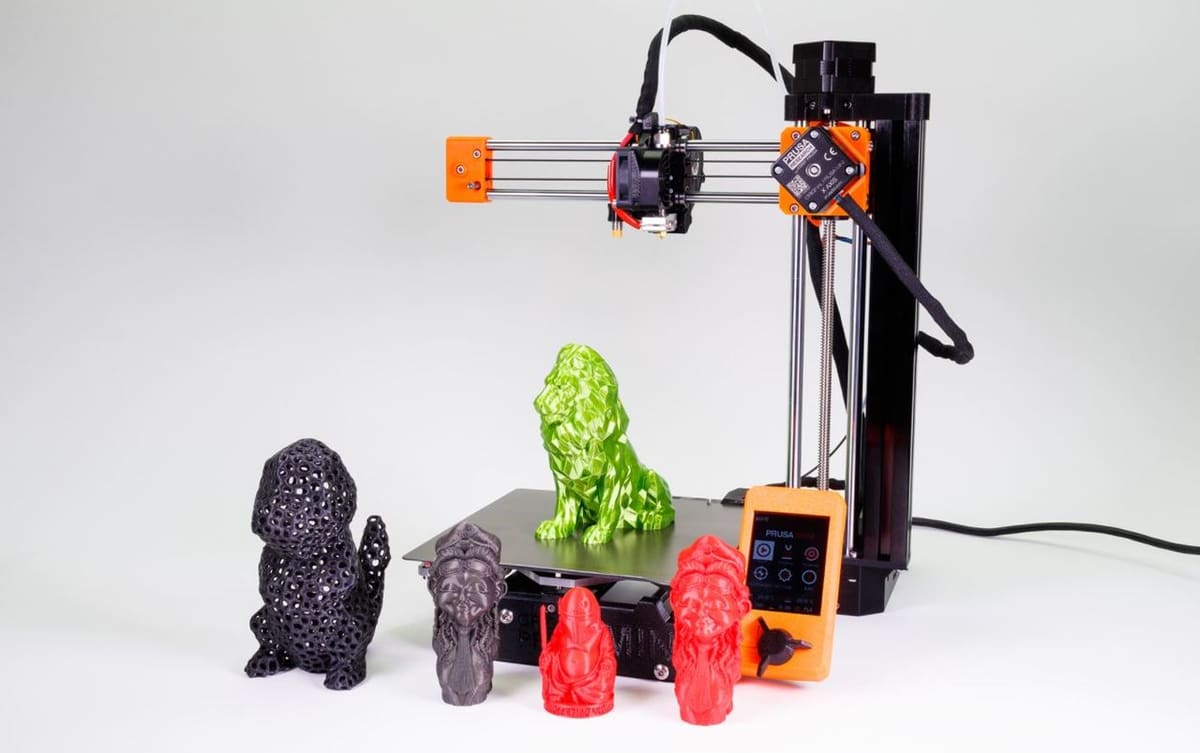

Prusa Research is one of the leading 3D printer companies in the world right now, having sold over 100,000 machines. Prusa has created numerous 3D printer models over the years, each made using 3D printed parts among other hardware. Their printers are generally well-liked in the 3D printing community for being reliable, precise, and affordable.

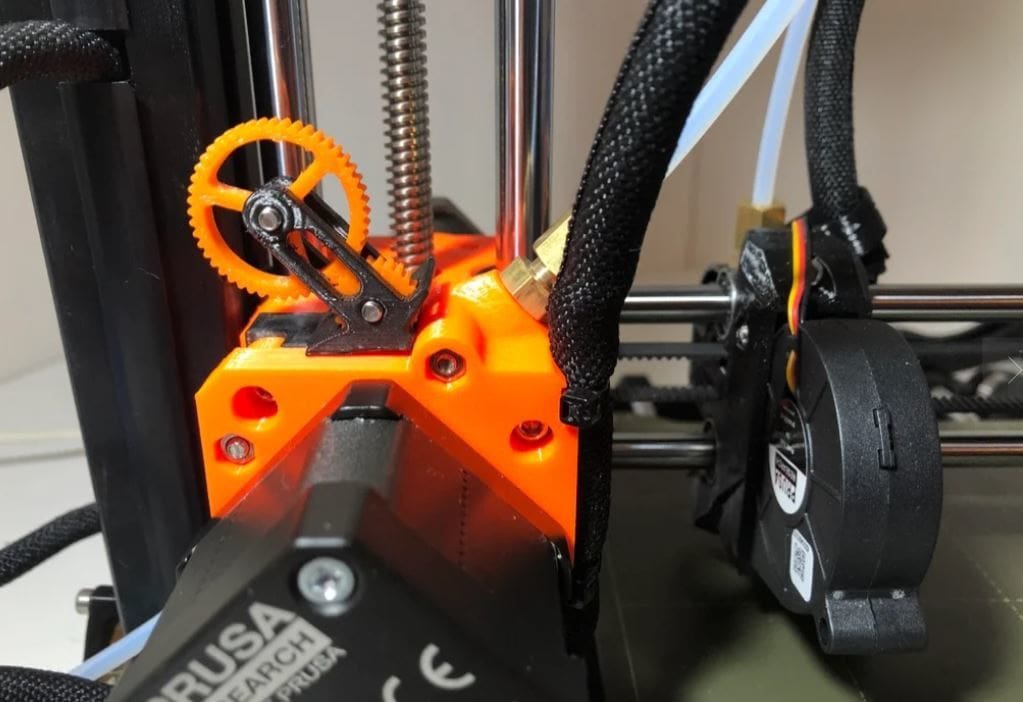

While the Prusa Mini has many good qualities, it’s not without its flaws. The Mini, unlike the other Prusa printers, uses a Bowden extruder.

The extruder is the brawn of the printer, pushing filament through the hot end to enable the machine to print. On a direct drive printer, the extruder is right on top of the hot end. On the other hand, printers with a Bowden setup have the extruder pushing filament through a tube that connects to the hot end.

In this article, we’ll take a closer look at the Prusa Mini’s extruder and present some alternatives and upgrades for it. Of the four upgrades, two of them are purchasable extruders and two are free 3D printable upgrades.

Features

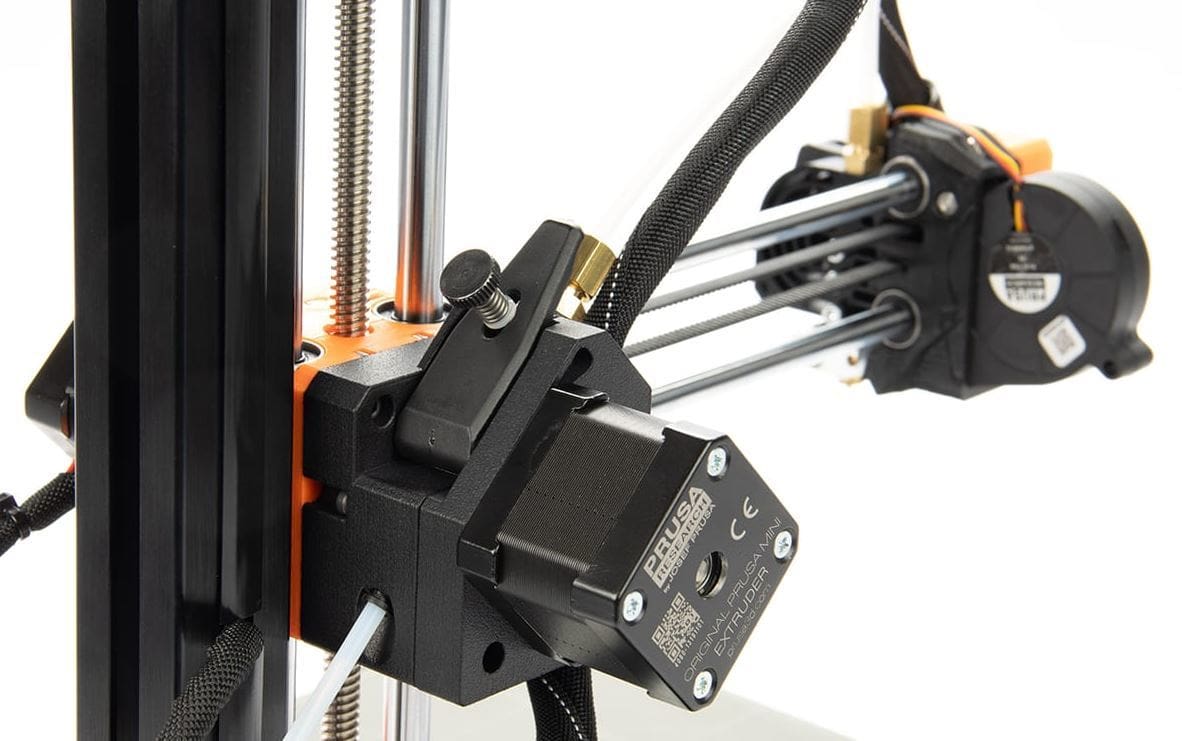

As mentioned previously, the Prusa Mini uses a Bowden extruder to print. With a Bowden setup, the filament gets pushed from the extruder through a Teflon tube to reach the hot end. The Prusa Mini’s extruder is a geared extruder with a 3:1 drive gear ratio that’s meant for 1.75-mm filament.

On the Prusa Mini, the extruder is attached to the Z-rod and moves up and down with the hot end. Having a Bowden system means less weight for the X-gantry because the extruder motor isn’t on top of the hot end. Too much weight on the gantry can lead to sagging and an unlevel bed as well as print quality issues such as ringing.

While other Prusa printers have direct-drive setups, they also have two Z-axis frames that offer more support for the X-gantry along the Z-axis. The Prusa Mini only has one Z-axis frame on the right side, so it’s not capable of handling the heavier payload of a direct drive setup as well as other Prusa models.

Now that you know all about the standard extruder for the Mini, let’s discuss some alternatives!

Alternative: Bondtech Dual Drive Extruder

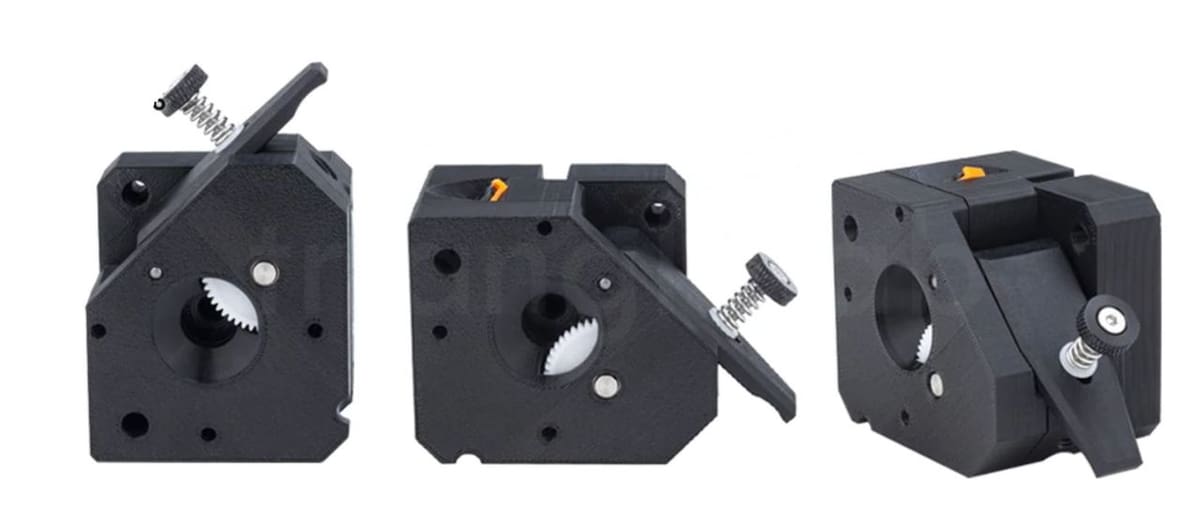

The Bondtech Dual Drive Extruder for the Prusa Mini will, according to the manufacturer, seamlessly fit on your printer with little assembly. Dual drive means that instead of one gear that moves the filament and an idler that rolls with the filament, the extruder has two gears that both push the filament. Bondtech also claims that its extruder will allow your Prusa Mini to print faster and higher quality parts.

This kit uses hardened steel gears and utilizes dual-drive motion for more extruding power. The tension of the extruder on the filament is adjustable through the use of a thumbscrew. Bondtech’s extruder also has a quick-release lever that allows you to change materials quickly.

The extruder housing is printed with SLS technology, while the hinge is an injection molded part.

Cost: $65

Pros: Dual drive, hardened drive gears, fast printing with higher quality, quick-release lever, adjustable tension

Cons: Expensive, plastic body (PA12 and injection-molded plastic)

Alternative: Trianglelab Dual Drive Extruder

Our second alternative, the Trianglelab Dual Drive Extruder, is basically a clone of Bondtech’s design. Trianglelab states that the extruder easily fits on a Prusa Mini and that they test each extruder before shipping them.

The extruder uses CNC-machined, hardened steel, and nickel-plated extruder gears. The manufacturer claims that because of this, the gears are more durable and push filament more smoothly. Other than the gears, the extruder uses 3D printed parts made out of PETG.

Cost: $35

Pros: Dual drive, hardened steel gears, easy fit on printer, pre-tested

Cons: Expensive, 3D printed frame (weaker)

Upgrade: Extruder Motion Flag

As mentioned before, this extruder design and the following model aren’t alternatives, but free 3D printable upgrades for the Prusa Mini’s extruder.

This one functions as a motion indicator for the Prusa Mini’s Bowden setup extruder. A minor flaw of the Prusa Mini is the tight and crammed placement of the extruder on the Z-axis, making it difficult for users to see if the extruder is moving or not.

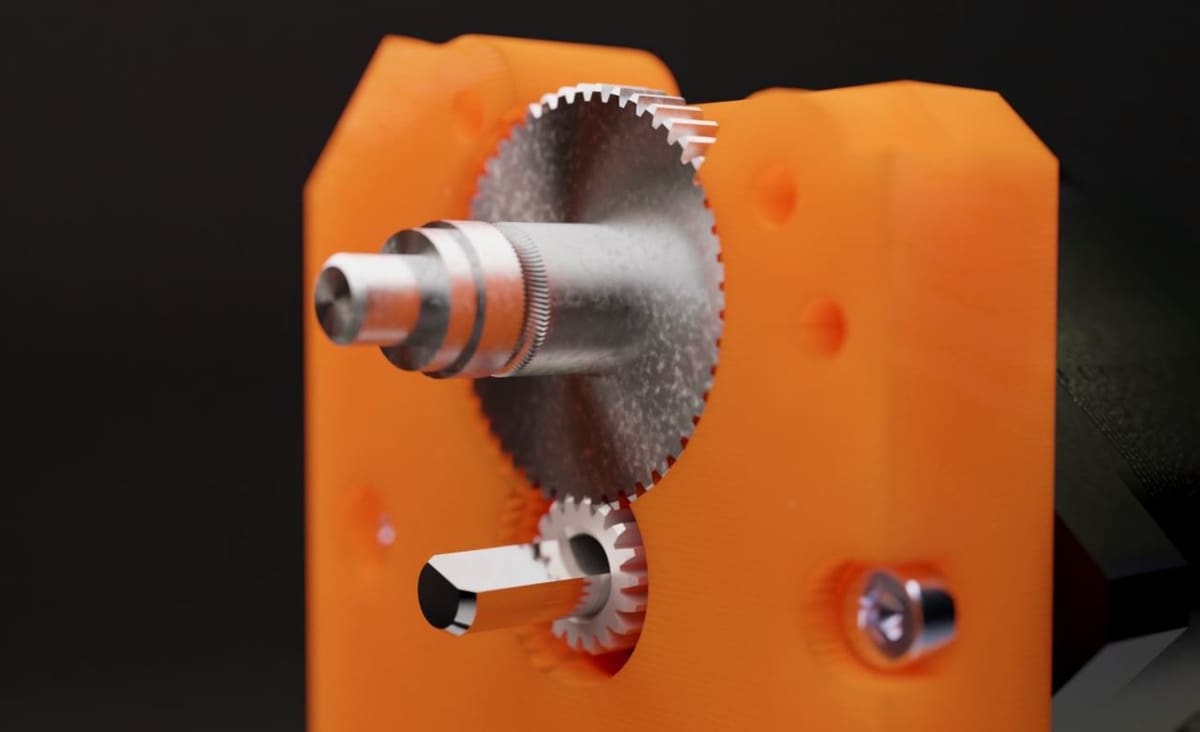

The upgrade attaches to the stock extruder and has idler gears that connect to the spinning extruder gear. When the extruder gear spins, you can easily see it as the large idler (flag) will also rotate. When there’s a jam in the extruder, the idler will stop spinning, allowing you to detect exactly where the jam is.

The maker suggests printing it in either PLA or PETG, in an upright position, and using supports only on the lower part. You’ll also need two M3x16 screws.

Who made it? A-make-designs

Who printed it? This extruder enhancement design has 220 downloads.

Where to get it? Thingiverse

Upgrade: BMG Printable Extruder

If you’re interested in getting a dual drive extruder without the high price, this upgrade is the answer. This extruder uses purchasable Bondtech drive gears along with 3D printed frame parts to create a tight, dual drive extrusion system for the Prusa Mini. The upgrade also has a filament runout sensor mount and uses a 3:1 gear ratio.

The design was remixed from another Bondtech BMG extruder design and altered to fit the Prusa Mini. At the same time, a 3D printed extruder will most likely be less durable than the real Bondtech BMG due to material differences and layer lines (which causes weaknesses in parts).

The model has had two revisions so far to improve the functionality of the upgrade. The extruder now has designated holes for zip-ties (for wire organization), increased Z-axis space, and more.

Supports and rafts aren’t necessary for these prints. The designer suggests printing the parts with a 0.2-mm layer height and using either PLA or PETG.

Who made it? FL62

Who printed it? This extruder design has 1 recorded Make as well as 149 downloads.

Where to get it? Thingiverse

Lead image source: Tom Nardi via Hackaday

License: The text of "Prusa Mini Extruder: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.