Polyetherimide Build Plates

On an FDM 3D printer, the build plate is the surface where melted filament from the nozzle is laid out. It lays over the print bed structure and is primarily responsible for providing adequate first layer adhesion. Because the first layer of any 3D print can determine the fate of the following layers, the build plate is a vital part to consider.

As the 3D printing industry has expanded, so have the options for build plates, and you can now choose between different materials with various special properties (e.g. flexible, magnetic, etc.). Current popular choices for build plate materials include borosilicate glass, tempered glass, polypropylene, steel, and more.

Another popular build plate surface material is polyetherimide, more commonly known by the acronym PEI. PEI build plates, or sheets, have many useful properties, such as low-maintenance adhesion and excellent thermal conductivity. PEI build plates also come in various forms, each with distinct properties concerning adhesion.

Prusa Research, a widely-known manufacturer of open-source printers like the Prusa i3 MK3S+, has developed a few of their own PEI build surfaces. In this article, we’ll go over the different types of PEI build plates or sheets, focusing on the options available from Prusa Research.

Players & Properties

Before we get into the specifics and differences between each of the Prusa offerings, let’s cover some background. Prusa Research was founded in 2012, dedicated to providing consumers with open-source, low-budget, high-quality 3D printers. Over the years, they’ve developed many innovative machines and 3D printer accessories, including their range of PEI build plates.

As we’ve mentioned, PEI build plates are a type of build plate that uses polyetherimide material. While they come in a few different forms, in general, PEI surfaces are a standout choice for their thermal conductivity, making them a great option for printers with a heated bed.

Most importantly, though, they are known for superior adhesion. Unlike many glass beds, PEI surfaces usually don’t require an additional adhesive like glue or hairspray to function properly. Unfortunately, this benefit also comes with the risk that the PEI surface sticks too much, potentially damaging the bed or print when you try to separate them.

Prusa offers three main types of PEI build plate surfaces: smooth, powdered, or satin. On top of this, they also sell a PEI-Ultem sticker that can be added to an existing plate. Let’s take a look at the options!

Smooth Spring Steel

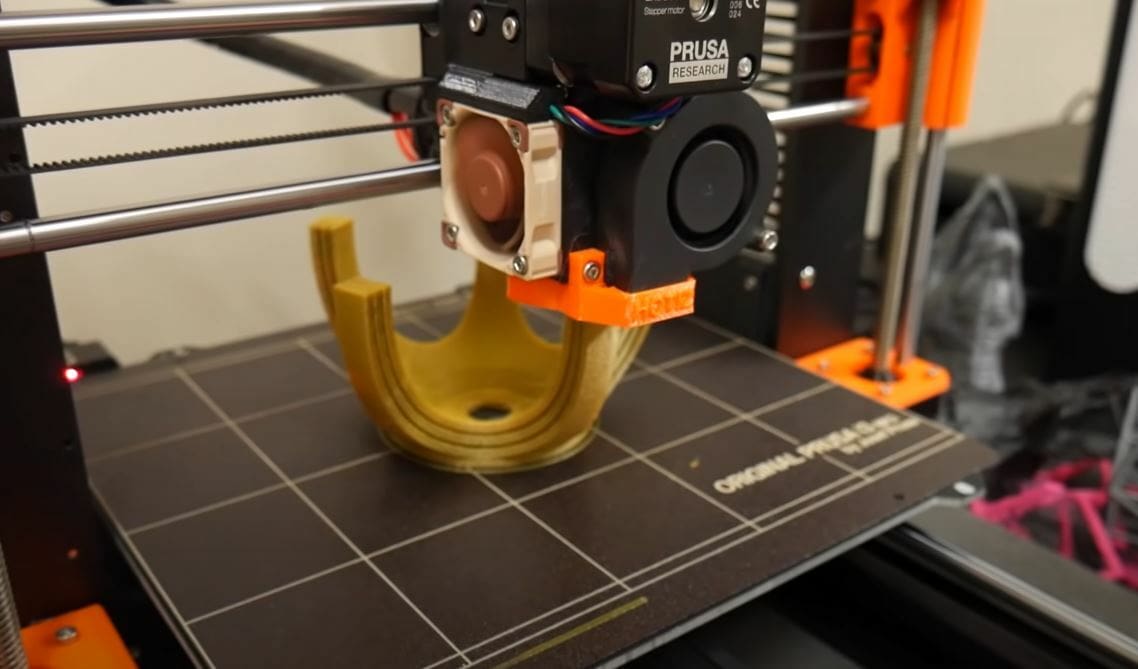

First up, Prusa Research offers a spring steel, double-sided, smooth surface PEI build plate, which is one of their most popular options. While this plate may have many descriptive phrases slapped onto the name, it’s essentially a magnetic, flexible steel sheet with PEI stickers on both sides for a super-smooth surface.

The surface of this PEI build plate will yield an ultra-smooth finish on the bottom of prints (the surface connected to the bed). One user commented on how well PLA parts come out when printed on this surface, and Prusa Research also highlights that this build plate is ideal for printing PLA parts.

Moreover, small details should adhere very well to this type of print bed, meaning the smooth PEI plate is suitable for printing small models, like miniatures. It also allows for small surface areas and sharp corners to stick and stay attached to the surface.

A potential disadvantage of this build plate is that parts won’t pop off as easily as they would from a textured bed. That’s because the bottom layer of prints will fully adhere to a smooth build plate rather than only touching the tops of the bumps of a textured bed. So, while parts are less likely to accidentally dislodge from a smooth surface bed, they will also be harder to remove, especially when printing with highly adhesive materials like PETG.

On this note, Prusa recommends using a glue stick on this surface if you’re worried about prints getting too stuck. Using an additional adhesive will provide a thin barrier that will make part removal easier.

Powder-Coated Textured Spring Steel

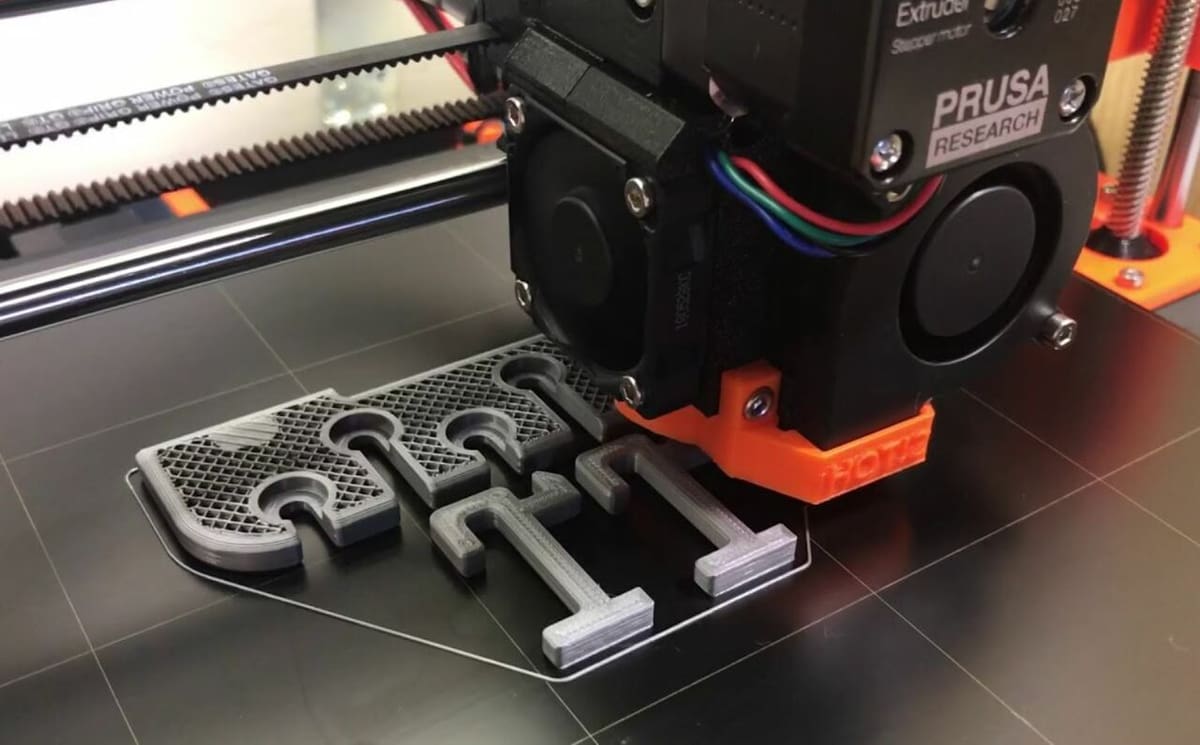

Second, Prusa offers a double-sided, spring steel, textured powder-coated PEI build plate, which is the most textured option in the range. The texture comes from the powder coating on the PEI plate, and this should make it easier to remove prints.

In addition to the flexible aspect of this spring steel bed, you can remove prints without removing the build plate from your printer. That’s because parts pop off the plate when cool due to the rugged texture. Sadly, as one user pointed out, this also means that you probably won’t be able to resume a print in the event of an interruption (like from a power outage) because your print will already be loose from the bed.

This build plate is functional with a wider range of materials without additional adhesives, and users point out that textured beds work particularly great with ABS and PETG. High-adhesion materials like PETG will come off the bed easier, with a reduced risk of damage to either the bed or the print. With this, however, comes the rough texture on the bottom of parts, reflected from the build plate’s powder coating.

Other benefits of this surface include its enhanced durability and scratch-resistance, making it a more long-lasting option. Moreover, textured build plates give you more leeway when setting the Z offset because the uneven surface means you don’t need to be so precise. While these benefits are great, you can’t clean this type of bed with acetone, and PLA also tends to warp, so a brim or raft may be necessary.

- Pros: Flexible, durable, double-sided, the Z offset has some wiggle room, scratch-resistant, great adhesion for PETG and ABS

- Cons: Leaves parts with a rough bottom surface, harder to clean, you can’t resume a print (parts come off too easy when the bed cools)

- Price: ~$40

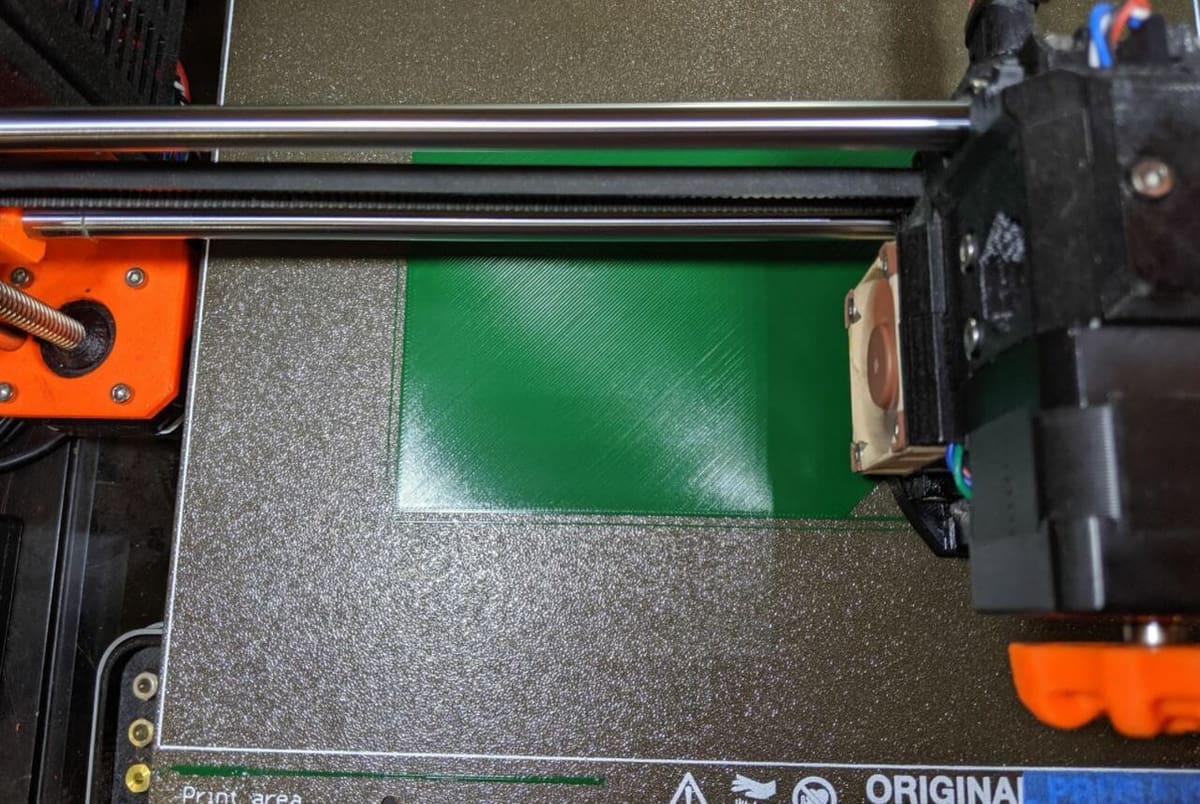

Powder-Coated Satin Spring Steel

Third, Prusa’s satin build plate option finds the middle ground between the previous two alternatives. Prusa’s satin build plate works – without any additional adhesive – with the most materials compared to the other options, including traditionally difficult-to-print filaments like polycarbonate blends.

According to Prusa Research, this type of bed works great for both PLA and PETG, most likely due to its excellent adhesion and easy part removal properties. As you might expect, the finish this plate leaves on the bottom of prints isn’t as smooth as the smooth sheet but is less rough than the previous powder-coated option.

When it comes to the Z offset, this bed falls more in line with the smooth sheet and is less forgiving than the textured surface. Due to the slightly roughened surface, parts should be easy to pop off when the print cools.

- Pros: Good in-between option, great adhesion for many materials, no additional adhesive necessary

- Cons: Pausing prints is difficult, precise Z offset required

- Price: ~$45

PEI-Ultem

Lastly, Prusa Research’s PEI-Ultem sheet is a sticky sheet that you can add on top of your existing build plate. It’s important to note that, while the above PEI options are sometimes referred to as “sheets”, they are more accurately described as plates. The PEI-Ultem option is an actual sheet of PEI film that can replace or add a PEI adhesion layer to a plate.

You can also use these to switch to a PEI surface without completely changing your build plate. For instance, if you like the rigidity of a glass bed but want to have the adhesion of a PEI sheet, you could apply this sheet on top of the glass plate you usually use.

Eventually, the PEI film on the outside of your Prusa spring steel build plate will degrade or wear, and replacing the entire plate would be a waste of materials. So, you can remove your existing PEI film from one side of your Prusa bed and replace it with this PEI-Ultem sheet to extend the life of your build plate. Prusa isn’t the only manufacturer of these types of sheets, and many exist elsewhere if you need a different size. (Prusa only offers PEI-Ultem sheets in 260 x 242 mm.)

According to Prusa, this sheet is made of 3M 200MP adhesive backing, which should allow you to stick this new sheet onto your existing build plate. You can check out the Prusa Knowledge Base for helpful instructional guides to installing the sheet.

- Pros: Peelable PEI, high-quality adhesion, sticker fits on many print beds

- Cons: Temporary, high bed temperatures could weaken the adhesion

- Price: ~$10

Lead image source: GiverOfPotatoes via Reddit

License: The text of "Prusa PEI Sheet: Smooth, Textured, & Satin – The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.