While some filaments aren’t as popular as others, that doesn’t mean they’re not worth a try. Take PVB, for example. PVB stands for polyvinyl butyral, and even though it isn’t as popular as the likes of PLA or PETG, this filament offers some unique characteristics, namely that it can be easily smoothed. In fact, PVB is perfect for aesthetic prints since a wipe of isopropyl alcohol (IPA) will make the print glossy and shiny.

The best part is that PVB is easy to print, and it’s become more popular in the last few years. More companies have now started producing it and offer a rainbow of colors to choose from.

In this article, we’ll dive deeper into the properties of the material, looking at its relative pros and cons. We’ll also cover how to print and post-process it to obtain the best results possible, along with a few examples. So, let’s dive into it!

Material Properties

We’ll start by taking a look at the unique material properties of PVB.

Appearance

PVB is slightly transparent, and that makes this filament perfect for creating vases, lampshades, or other art pieces. Keep in mind that as for all transparent filaments, the results won’t be as clear as glass, but it will allow light to pass through pieces without problems. That being said, the transparency of the print will vary greatly between filament manufacturers since some brands sell more opaque PVB. Additionally, transparency is influenced by print features. For example, more walls and a higher infill lead to less clear parts.

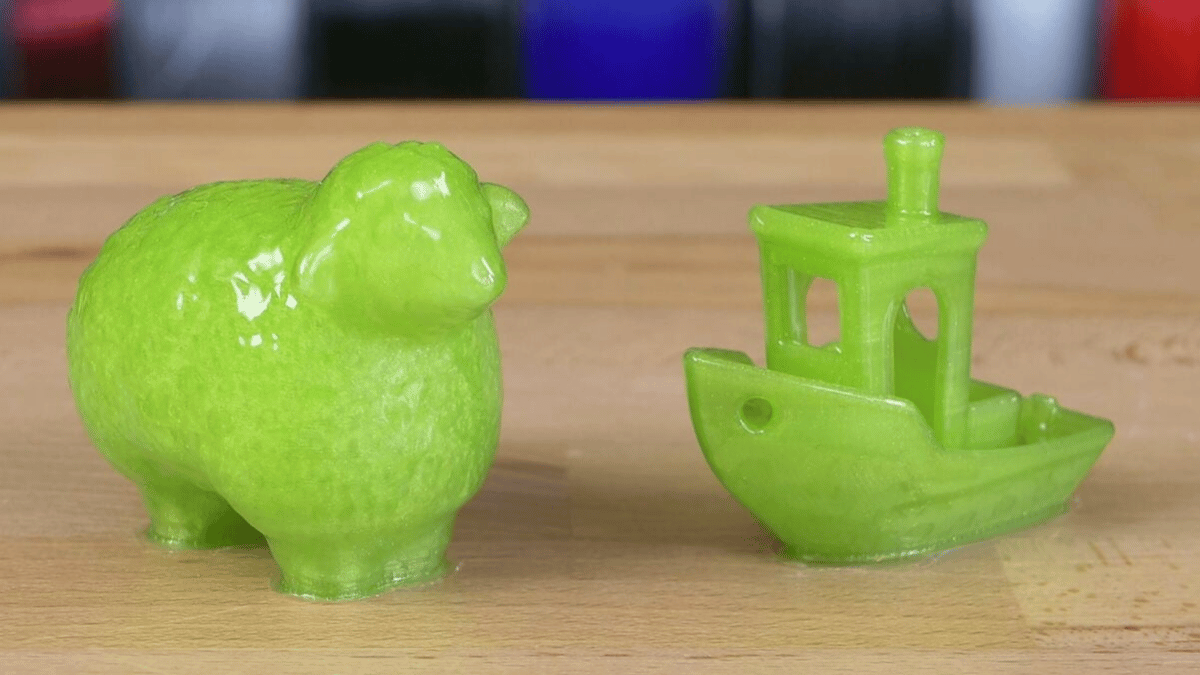

As mentioned, the most loved property of this filament is the glossy surface that you can obtain on prints after the smoothing process. PVB is soluble in isopropyl alcohol (IPA), making it possible to obtain glossy parts and easily bond pieces together, similar to the acetone smoothing of ABS. We’ll go into more detail on post-processing later on.

Strength

Although the best use case for this filament is aesthetic prints, PVB also offers some nice mechanical properties compared to more well-known 3D printing materials.

Prusa Research has created a detailed comparison table that presents the properties of different materials. Compared to ABS and PETG, PVB has a higher tensile strength and impact resistance, meaning that it withstands more force before breaking. That’s connected to the nature of PVB: this filament is slightly more flexible than ABS and PETG, although it’s rather rigid compared to TPU and other flexible filaments.

It’s also worth mentioning that the glass transition temperature of PVB, the temperature at which a material transitions from a glassy or brittle solid to a more rubbery, flexible one that is easier to deform is 60°C. This is rather low compared to PETG and ABS but is similar to PLA. For this reason, it’s recommended to avoid using PVB parts in applications where temperatures may get elevated, such as inside a car.

The main weak point of this filament is the poor layer adhesion, which may be attributed to its high hygroscopy.

Hygroscopy

Unfortunately, PVB is prone to absorb moisture and it is greatly affected by it. When a hygroscopic filament absorbs water, a series of problems can arise during printing, such as bubbles or blobs in the part, along with stringing. From there, extruder clogs and bed adhesion issues can present themselves.

For this reason, PVB should be stored in a dry space, ideally in a sealed bag with silica gel. Consider using vacuum storage bags or dry boxes with silica beads to be even safer. These two solutions allow you to create a dry environment thanks to the desiccant. Before printing, the filament should dry for at least four hours at 60 °C in a filament dryer.

Due to absorbed moisture degrading PVB’s properties over time, PVB is generally better suited for aesthetic parts than functional ones. Moreover, if you’re looking for a material for outdoor applications, popular options like PETG or ASA would be a more durable choice.

Printing

We’ll now take a look at the best print settings to use with PVB and how to post-process the filament.

Best Settings

PVB is basically as easy to print as PETG. The major advantage of PVB is the ease of printing: it doesn’t need an enclosure and isn’t as prone to warping as ABS. Another point in its favor is that it doesn’t require a hardened nozzle to be printed since it isn’t an abrasive material, like filaments blended with fibers or wood particles.

The nozzle and bed temperature are usually similar to those used for PETG: 215 °C for the hot end and 75 °C for the bed. To avoid problems with bed adhesion, PVB should be printed on a smooth PEI or satin sheet rather than on a textured PEI. You can also print in vase mode for nice, aesthetic results.

Although you can generally print PVB parts at whichever layer height you prefer, to obtain the best results you should consider using a smaller layer height, such as 0.12 mm or 0.16 mm with a 0.4-mm nozzle. Talking about nozzles, a point in favor of PVB is that you can print it with larger nozzles without worrying about the part finish since the smoothing process will hide the layer lines. Using larger nozzles like 0.6 mm or 0.8 mm can be great for fast print jobs.

Finally, as we highlighted previously, keep in mind that to obtain the best results with this filament, you should dry it thoroughly before printing.

Post-Processing

Not only can solvent be used to smooth PVB, but it can also be used to bond pieces together. PVB is slightly soluble in IPA, so placing a few drops of IPA on a PVB joint will turn it soft and sticky. Then you can simply press the other PVB part onto the sticky surface, secure the parts together, and let them dry. This works great for projects that are made up of numerous parts, especially if it’s a display piece.

Now let’s talk about the smoothing process. As we’ve said, we can use IPA to make PVB prints shine and there are a few different approaches to take to achieve great results.

The easiest and fastest path to smooth your PVB parts is to use a smoothing station, which automatically vapor smooths the piece while turning it on a plate to distribute the chemical agent evenly. One of the most appreciated smoothing stations on the market is the Polysher by Polymaker. You can take a look at it in this video from Polymaker.

If you’re looking for a cheaper way to smooth your parts with a finish that resembles the machined version, you can spray the IPA directly onto the piece, like this Reddit user who used an airbrush gun with 99.9% IPA.

Another option is to immerse the piece in an IPA bath or wash it multiple times in 30-second intervals. Finally, you can use a brush to spread the isopropyl alcohol on the piece, but when doing this, it’s important to be particularly careful to avoid making marks on the piece.

Regardless of the process that you’ve chosen, remember that smoothed pieces need to be allowed to dry for a day or two at room temperature. Once it’s dry, you can also think about painting it, as this Reddit user. How cool is that?

Examples

Now that we’ve covered all the most important aspects of this filament, let’s briefly talk about some of the best PVBs that you can try for yourself:

Prusament

Prusament offers one of the widest listings for PVB in the filament manufacturing world. It produces lots of different high-quality filaments, and PVB is not lacking. Users are really happy with the quality of Prusament PVB, reporting that their spools are easy to print and smooth. If you’re looking for a transparent PVB, Prusament is the right choice for you.

Polymaker

If you’re in the US, there’s a high chance that you have tried at least one spool of Polymaker. This is one of the biggest filament companies in the United States and China. Their Polysmooth line offers high-quality PVB, with a whopping 14 colors available! With over 300 positive reviews on Amazon, you can’t go wrong with this filament.

Fiberlogy

Let’s move on to another famous European manufacturer. Fiberlogy produces premium filaments with amazing tolerances. We’re talking about ±0.02 mm for the diameter and only ±0.01 mm for the oval tolerance! With their FiberSmooth line, they have decided to bet on the quality of the filaments rather than the mechanical properties, giving it one of the best finishes out there. They have also published a guide to teach you how to smooth PVB prints for wonderful results.

License: The text of "PVB Filament: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.