Marlin is open-source firmware for FDM 3D printers, CNC machines, laser cutters, pen plotters, and a few more. It’s owned and maintained by the community, and it’s entirely free for anyone to use and modify under the GPLv3 license.

Marlin has its origins in the RepRap community, with its first standalone release dating back to 2011. Since then, Marlin has experienced steady growth within the 3D printing world, and today is perhaps the most known firmware amongst hobbyists and professional-grade FDM 3D printers.

In this article, we’ll go over 10 reasons why Marlin is so popular and why it should be a top contender for the firmware running on your 3D printer.

Hardware Simplicity

Coming from the RepRap project, practicality is one of Marlin’s core values. Here, simplicity is often a good thing, and fewer parts and components in a 3D printer make for a cheaper and easier-to-maintain machine.

A handful of 3D printer firmware requires additional hardware or software to be able to perform its basic operations. For instance, the RepRap firmware needs to be paired with host software, and Klipper invariably demands an additional Raspberry Pi board, adding significant costs considering the current electronic shortage and high prices of this board on the market.

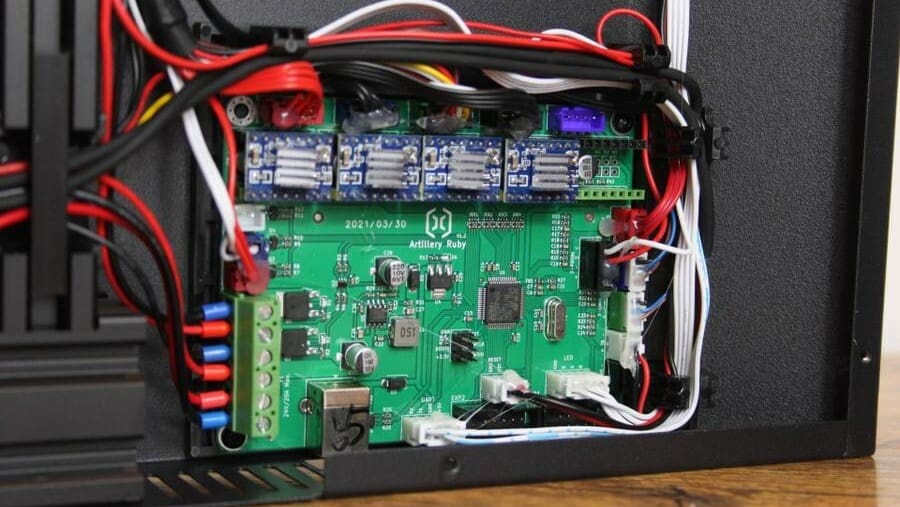

In this respect, Marlin is one of the lightest firmware. For hardware, it only requires one single control board, which is the printer’s mainboard (both 8-bit and 32-bit).

In terms of operation, while most 3D printers come with a display for at least starting the 3D printing jobs, Marlin can get away with just using its Autostart feature. Sure, operating your 3D printer with a display is more convenient, but at least you have the option of running your machine without it.

Well Documented

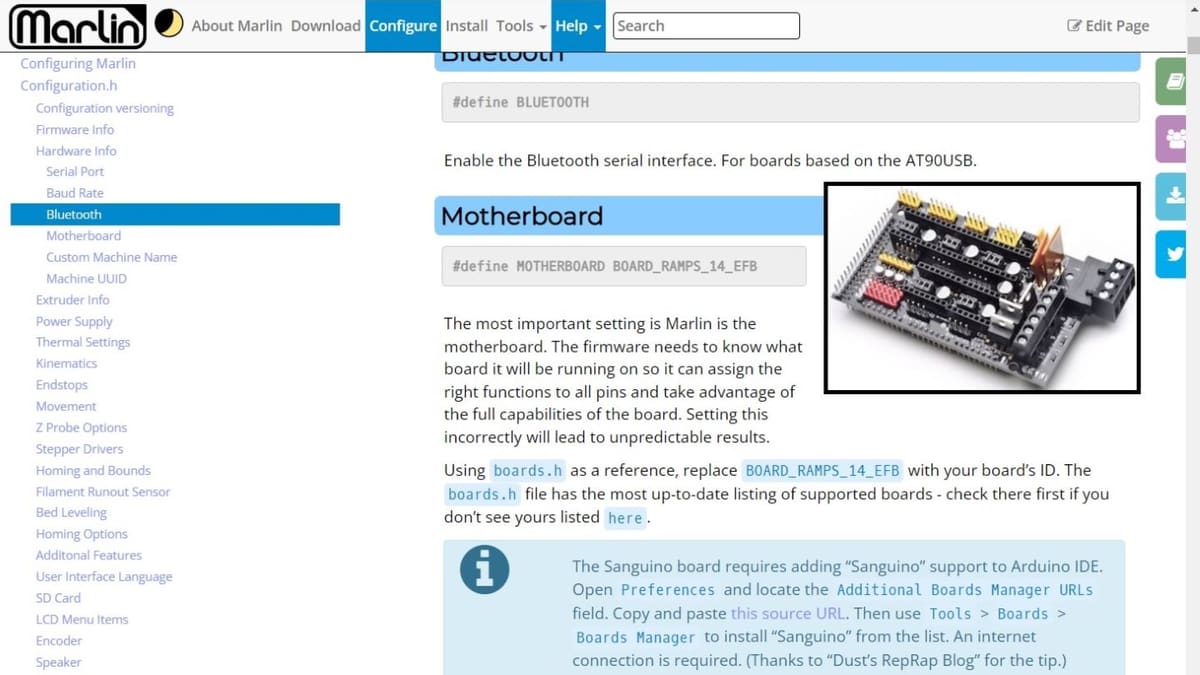

3D printing firmware, which can be intricate and complex, can be somewhat daunting for everyday people (e.g. non-software engineers) to configure and customize. While it’s true that open-source firmware is usually well-documented, it’s often done from a development point of view.

To benefit from all the customization and flexibility involved in open-source 3D printing, the end-user must be able to understand at least the high level of the code and be able to make subtle configurations to suit specific needs.

Here, Marlin does an excellent job of providing additional jargon-free documentation. The information that covers the firmware configuration is extensive, highly detailed, and yet very approachable for us, mere mortals.

Easy Implementation

Firmware is often considered the heart of a machine, and that’s also true for our desktop 3D printers. Without firmware, the printers are simply a bunch of parts held together by screws.

Yet installing or replacing the firmware on your printer is much easier than a heart transplant procedure. With Marlin, that’s even more simple, with most of the time being just a matter of flashing the new or updated firmware into the 3D printer mainboard.

While it’s true that some old 8-bit mainboards may require firmware flashing procedures that may look like open-heart surgery, in most modern boards, it can be done via a USB connection to a PC or even with an SD card loaded with the firmware file.

The software options used to compile and flash Marlin using a USB connection are usually Arduino IDE or, for 32-bit boards, PlatformIO tied to VSCode, with both programs free with plenty of tutorials online (including Marlin’s own guide).

If you’re lucky enough to find reliable, pre-configured, and already compiled firmware that matches your 3D printer, the process is even simpler.

Improved Safety

3D printers can be dangerous machines if not maintained and operated correctly. They deal with high temperatures in the hot end and high electrical current for heated beds, potentially leading to a fire hazard. You’ve probably heard some cases of 3D printers catching fire as in the image above.

While there are isolated cases in which multiple factors cause incidents, we must always be cautious when using FDM 3D printers. In this sense, Marlin firmware has several features to monitor and prevent electrical issues.

The most known feature is thermal runway detection, sophisticated mechanisms that control the thermal progress of both the hot end nozzle and bed temperatures. These protections monitor and automatically shut off the heating components whenever something is off, aborting the 3D printing job and notifying the user about it.

But keep in mind that these features must be enabled in the firmware, and you should ensure it. For instance, Anet A8 printers (with a Marlin fork) were shipped with thermal runway detection disabled by default, which could have possibly prevented many of the fire hazards reported with these machines.

Also be aware that, while providing an extra layer of safety, these Marlin features alone are not enough to guarantee the complete safety of your 3D printing operation.

Flexibility

The 3D printing world is diverse. Even within the confined space of desktop FDM 3D printing, the possibilities are huge in terms of how the printers move the printhead and how they extrude material.

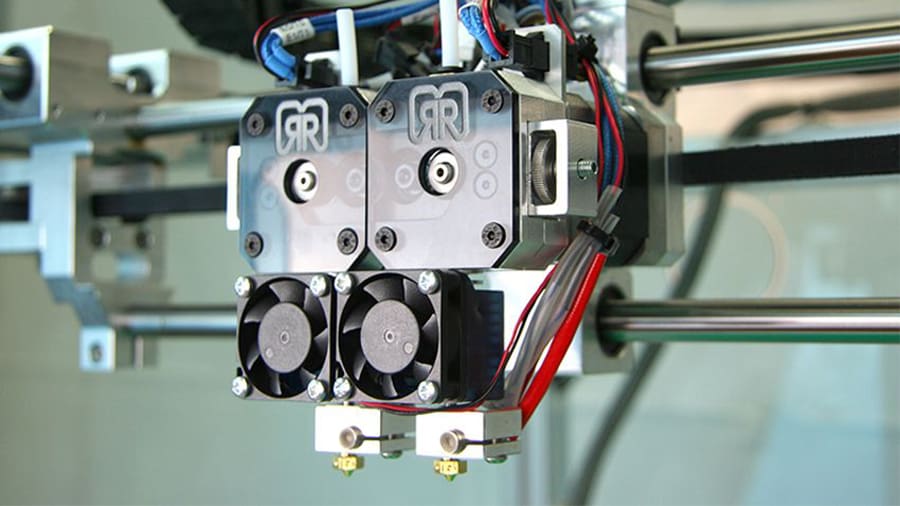

Marlin firmware, through its high customization scheme, allows users to implement any major and minor hardware changes relatively easily. If you’re thinking about making a complete upgrade of your printer – additional extruders, sensorless homing, speed-controlled fans, the works – Marlin’s got you covered.

While it’s true that the whole firmware must be updated to conform to these changes, this is achieved with ease with Marlin, as we’ve discussed already.

The flexibility offered by Marlin also benefits more advanced makers who are creating their 3D printers from scratch since it accommodates different 3D printer styles, such as Cartesian, Delta, CoreXY, and more.

Marlin even goes a step further, being able to run small CNC and laser cutting and engraving machines. This way, one can employ the skills learned by tinkering with 3D printing firmware to configure and customize different kinds of machines.

Linear Advance

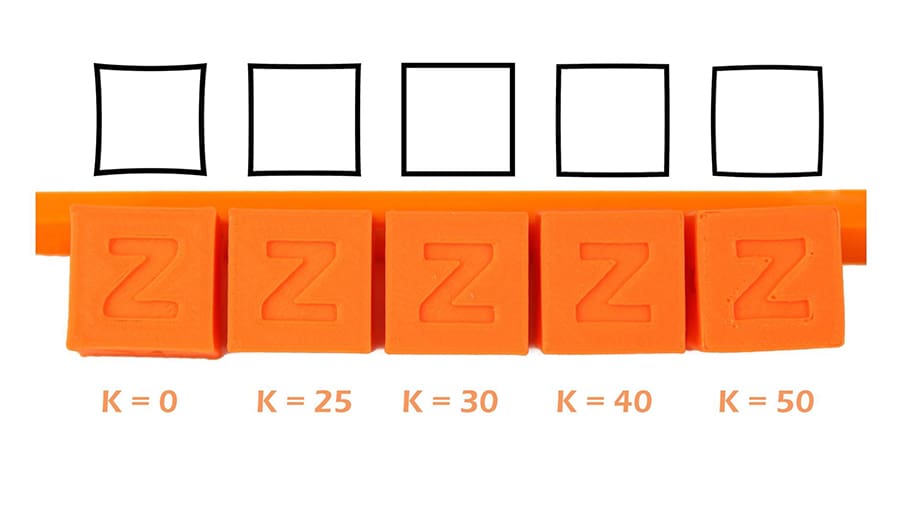

It might not seem like it at first glance, but the extrusion systems of FDM 3D printers are complex things. It’s not just a matter of pushing filament through a heated nozzle, as many physical variables are involved in the process.

One such variable is the filament pressure build-up (or lack thereof) inside the nozzle during extrusion. This is very tricky to control, especially in high-speed printing or in models that require several mid-print retractions, and this can lead to poor print quality and severe extrusion issues.

The famous Linear Advance feature is Marlin’s attempt to solve this issue. It uses a refined compensation method that regulates the pressure inside the nozzle according to the printing speed and nozzle flow, thus making extrusion lines as uniform as possible.

Linear Advance is enabled via firmware and requires some calibration to ensure its accurate functioning, but once that’s done, this feature provides enhanced print quality and precision at both low and high printing speeds.

The release of this feature in Marlin v2.0 was so successful that other popular firmware also developed their own versions of it. Yet it’s Marlin’s Linear Advance that’s currently in use by many commercial FDM printers, including the FDM machines by Prusa Research.

OctoPrint

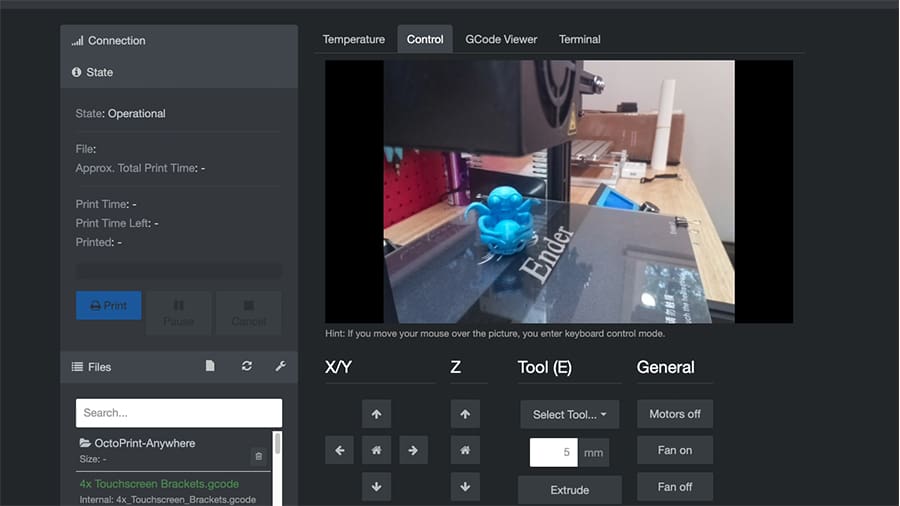

OctoPrint is a popular 3D printing control and monitoring software often considered a must for any FDM 3D printer setup. It runs on a separate Raspberry Pi board that connects to the printer via USB while offering a wireless web interface to end-users to control and track their 3D printing jobs.

While other 3D printing firmware’s also compatible with OctoPrint, the combination with Marlin is considered by many users to be the smoothest, especially when one’s reminded of the huge repository of plug-ins available for OctoPrint.

Klipper, for instance, a reliable firmware that’s currently on the rise, has some issues regarding OctoPrint specifically, as it uses up some of the Raspberry Pi resources required by this firmware to function properly.

With Marlin, you can rest assured that both OctoPrint’s core functionalities and the plug-ins will work as intended by their creators with excellent compatibility.

Popularity

“Everything popular is wrong”, Oscar Wilde once said. He would definitely change his mind if he ever tried messing with 3D printing firmware.

Marlin is undoubtedly the most popular and most recognized firmware for desktop 3D printers. Many commercial 3D printers on the market use Marlin forks as stock firmware, including the Creality Ender 3 series and Ultimaker‘s machines.

Here, popularity comes with great benefits. Marlin’s huge user community allows for much easier troubleshooting and customization. Its official documentation can only cover so many issues, but given the sheer number of Marlin users, you can bet that someone else has probably experienced similar issues and has found (and posted) the solution somewhere.

The community can also be of big help when integrating new hardware into your 3D printers, like newly released bed leveling sensors or custom contraptions for filament monitoring. The chances are someone has already created a solution for Marlin before other firmware developers have had the chance to.

Reliability

Speaking of popularity, one of the reasons for Marlin’s colossal community and constant presence within the commercial 3D printing world is that it’s extremely reliable.

Whether you’re a company using 3D printing for commercial uses or a maker building your own projects for fun, reliability matters when money and effort have been put into 3D printing endeavors.

No company wants to delay a service or product due to malfunctioning equipment or random print failures. It’s bad for business and costs money if you consider the waste of filament, energy, and machine time.

That’s also true for hobbyists and makers: How frustrating would it be to discover that your 30+ hour print job has failed right at the end because of a firmware issue? Very.

Not to say that Marlin doesn’t have its issues and bugs – there are plenty. But given how long Marlin has been around in the 3D printing market without any major issues and how many companies use it in their print farms to produce goods daily, that can give you a hint about its reliability.

Regular Updates

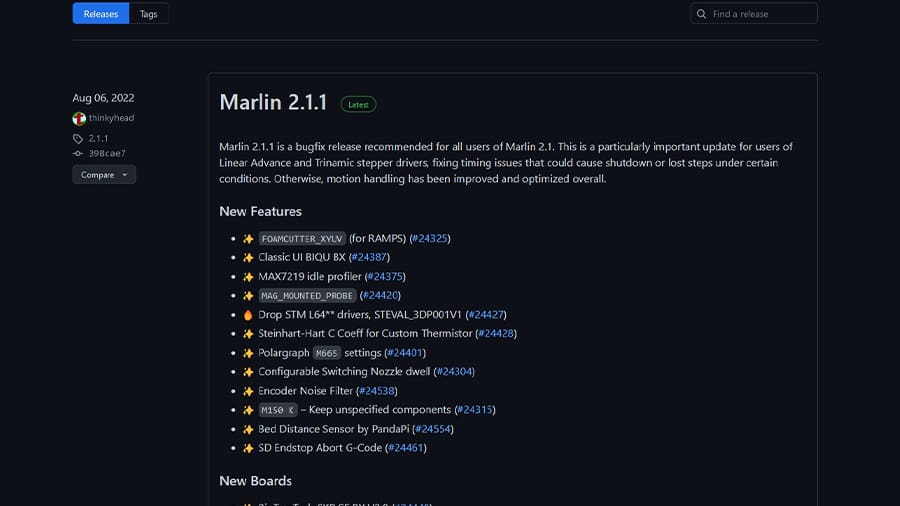

Last but not least, we need to talk about updates. As powerful and useful software can be, it doesn’t matter if it isn’t properly maintained and updated from time to time (erm… Simplify3D…). And in this regard, Marlin also has plenty to show.

So far, there have been five updates in 2022 alone (from v2.0.9.3 to v2.1.1), with every tiny change made being duly reported at Marlin’s GitHub repository.

Every new Marlin release brings new features, improvements, bug fixes, newly supported mainboards, LCD updates, and more.

This also shows how active Marlin’s open-source development team is, so we can rest assured that the Marlin project and firmware will probably outlive our own 3D printing machines where they currently run today.

License: The text of "10 Good Reasons to Use Marlin Firmware" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.