So, you’re getting into resin 3D printing. Whether you’re an FDM veteran or a 3D printing novice, resin 3D printers come with unique abilities, challenges, and messes. To get the best quality out of your prints and to make your life easier, you’re going to need several tools and accessories.

Luckily for you, we’ve put together this list of the 15 most essential items that you should gather before your resin 3D printer arrives. Collect all of these accessories, tools, and post-processing equipment and you’ll have 3D prints good enough to sell or display in no time!

We’ve organized the list into three categories: Accessories, Tools, and Spare Parts. In Accessories, you’ll find essential items that you’ll need to get started with your first print. Tools are what you’ll reach for as needed to aid you in the cleanup and post-processing of your resin and prints. Finally, consumable items are listed under Spare Parts.

Let’s get started!

Accessories

A part isn’t done the second your printer finishes; you’ll need some accessories to have a model that’s ready to show friends or clients.

Safety Gear

Take your safety seriously when you’re printing with resin. Before your 3D printer arrives, pick up some safety goggles, an air purifier, an apron or lab coat, and plenty of nitrile gloves.

This safety equipment protects your skin from coming in contact with the resin and reduces exposure to resin fumes. It’s important to always work with this material in a well-ventilated area, and an air purifier can help reduce the resin smell and toxins. While some manufacturers may include an air purifier with their 3D printer packages, you’ll need to purchase one as an add-on if your printer comes from more affordable consumer brands like Anycubic or Elegoo.

Resin will stain your clothes and never come out, hence the need for an apron. In direct contact with your skin, it could cause a rash or irritation, so don’t be stingy on the gloves. A box of 100 costs around $10, so you can replace them whenever a pair rips or after a print.

The worst-case scenario is resin splashing into your eye without safety goggles, giving you irritation at best, followed by an emergency hospital visit. Spend a few dollars to get a good pair of goggles instead. In all likelihood, your printer may not come with all the PPE to have you covered, so stock up!

- Cost: ~$40 for essential safety items; extra for air purifier

- Task: Keeping your skin safe and lungs healthy

- Examples: 3M safety glasses, lab coat, nitrile gloves, Nexa3D Air Purifier, Anycubic AirPure, Elegoo Mini Air Purifier

Silicone Mat

A silicone mat will be the base of your workstation to catch spills or drips while setting up to print, after washing, or during post-processing. You’ll be surprised how often drips happen, and you certainly don’t want resin to get cured onto your furniture.

You can also keep your resin-contaminated tools on it at any stage of the printing process or rest your prints on the mat between stages of printing and post-processing. It’s also the perfect place to dry your prints after they’ve been washed and are ready to cure.

Silicone is especially easy to clean and resin doesn’t stick to it. Just place the mat out in the sun to cure any resin residue, then bend it to pop off all the dried pieces. High-end machines tend to include this type of mat with the printer but don’t waste time looking for one included with a budget printer.

- Cost: $10-$40

- Task: Protecting your workspace from resin

- Examples: Bczamd, MatterHackers Workstation Mat

Cleaning Solution/Isopropyl Alcohol

Unless you’ve specifically bought water-washable resin, you’ll need isopropyl alcohol (IPA) or a branded cleaning solution. Fresh prints should be washed in a cleaning bath to remove any excess resin before it’s fully cured so the model can look its best.

One benefit to isopropyl alcohol over a 3D printer manufacturer’s specialty branded wash solution is that it doesn’t foam up if agitated. Other solutions can foam (like suds from soap) as they wash your prints and they can clump together, reducing their effectiveness at removing every extra uncured particle and creating new issues.

Isopropyl alcohol also evaporates quickly from the surface of 3D prints, reducing the time you need for cleaning. You’ll go through quite a bit and don’t expect it to come with your printer, so consider investing in a jug or multipack.

- Cost: ~$30 per gallon of IPA

- Task: Cleaning prints and resin residue

- Examples: Maxtite, Liqcreate Resin Cleaner

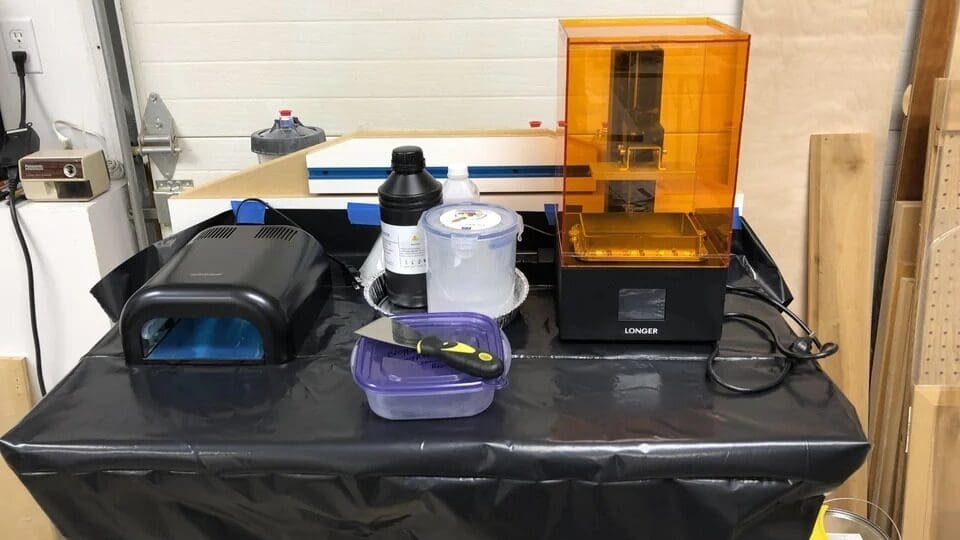

Wash & Cure Station

Once your resin prints finish on the 3D printer, it’s time to put your gloves back on and get started with the post-processing. Resin prints require more than fused-deposition modeling (FDM) makers are accustomed to.

The most important post-processing steps are washing and the final curing of your prints. Conveniently, there are devices that can do the dirty work for you. There are a variety of options, from purchasing a 2-in-1 wash and cure station, opting for separate wash and curing boxes, setting up a solar turn table with a UV light, or going full DIY with a pickle bucket to wash your prints and amplify sunlight with aluminum foil for the final curing.

You’re on your own to figure out what works best for you because these devices won’t come with your printer. If going the DIY route, it’s essential to make sure every single surface gets cured. Don’t forget crevices, the bottom, or the back of prints – thus the turntables in 2-in-1 machines. Always check your resin bottle or manufacturer for advice on curing times.

We recommend not cheapening out on this accessory as it has a huge impact on the quality and detail of your resin 3D prints. No matter what, resin 3D prints need to be washed and cured before you use them out in the world.

- Cost: $100-$800 for commercial all-in-one devices

- Task: Washing and curing prints

- Examples: Anycubic Wash & Cure Plus, Formlabs Form Wash, Prusa CW1

Tools

A collection of helpful and essential tools you’ll want to keep within arm’s reach of your 3D printer for when things go right – or wrong.

Print Removal Tools

Perhaps the least fun part of resin 3D printing is removing the print from the build plate. Just like with FDM printing, a variety of tools can come in handy here.

A plastic putty knife is good for removing parts without the risk of scratching the build plate. It’s also safe to gently run along the FEP film to remove failed prints sitting in the resin vat. That’s a task where you don’t want to use anything sharp or metallic!

When the print’s grip on the build plate is too strong for a plastic putty knife, the palette knife is next up for the job. The blade is thin enough that it should be able to slide underneath the print and create leverage to peel it off the build plate.

If you can’t pry the print off the build plate with a blade, the last resort is a pair of pliers. You can grab your print right off the supports, though be careful not to snap the model in half. While you’ll probably find a plastic putty knife or spatula in your printer box, you’ll have to source your own pliers.

Silicone Spatula

Just like the plastic putty knife, the silicone spatula’s a great tool for gently removing failed prints in the resin vat. It’s also helpful for mixing your resin in the vat without scratching up the FEP film.

Like with the silicone mat, the easy-to-clean silicone is ideal for working with resin. If any dries or cures on your spatula, you only need to bend it and the resin will come clean off.

While you shouldn’t expect one of these to be included in your printer, some people have 3D printed their own spatulas to use on future prints, though the material you’re likely to use isn’t quite as nice as silicone. Otherwise, pick one up at your local grocery store.

Flush Cutters

Resin 3D printers are perfect for highly detailed prints and figurines, but detailed prints and figurine limbs or accessories often need support. Once the supports make your print a success, it’s time to cut them off.

Flush cutters are the perfect tool for the job. Supports can be small and spindly or thick and robust, requiring a tool both strong enough to cut through the brittle resin and delicate enough to strip off the small supports without damaging the print’s intricate details. The flat edge of flush cutters allows you to cut close to the print surface and prevent nubs from sticking around that require sanding.

Luckily, this essential tool is often included with resin 3D printers, even budget-friendly ones.

Soft Bristle Toothbrush

Cleaning off every drop of uncured resin is an important post-processing step for resin 3D printing. Especially when you have detailed prints, you need to get rid of the excess resin from all the lines and tight spaces. Washing it often isn’t enough, and leftover resin could alter the shape and texture of the print once your curing station’s done its job.

A toothbrush makes cleaning all the crevices much easier. Be careful not to scrub too hard or you could damage the print’s small details. Hard bristle brushes can leave marks behind on your prints. So pick up a soft-bristle toothbrush next time you run errands!

- Cost: ~$5

- Task: Cleaning prints

- Examples: Amazon Basics

Funnel

Just like with FDM 3D printing, you’ll sometimes want to switch materials for your next print. To save costs with resin 3D printing, you can reuse the leftover resin in the vat by pouring it into a bottle or container until you’re ready to print with that material again.

To prevent resin from getting all over your silicon mat, you’ll need a funnel. Insert the bottom of the funnel into the bottle’s top and pour the resin out of the vat, scrapping along with your silicone spatula to ensure the vat is free from cured chunks.

Like with most other resin 3D printing accessories, funnels are typically silicone or stainless steel. If you’re lucky, one of these will be included with your printer. You could also print one yourself.

Mesh Strainer

When it comes time to switch resins, you shouldn’t pour the used resin directly back into the bottle because you may be contaminating your supply with small pieces of cured material that can ruin a print. Large cured chunks can get in the way of your build plate movement, while small chunks can shield UV light from getting to where it needs to go on your model. Either way, it’s an easy to avoid mistake.

Since it can be difficult to spot these cured chunks through thick and opaque resin, a mesh strainer inserted into the funnel can filter out any leftover bits. This way, you know all of the resin going back into your bottle is good quality.

If one of these doesn’t come with your printer (which it may), you have options such as paint strainers or metal mesh strainers depending on how much you’re willing to spend. Paint strainers are cheaper and disposable, but can warp as the resins are poured into them. That said, if you’re just starting out with resin 3D printing, the metal mesh isn’t a mandatory investment.

- Cost: ~$12 for 100 disposable strainers

- Task: Filtering used resin

- Examples: 3DMaterials, Boao

Spare Parts

When something goes wrong, these are the spare parts you’ll want to have around for a quick fix to avoid printer downtime.

Resin

It’s awfully hard for your resin 3D printer to produce prints without resin. When you run out of the manufacturer’s small sample, you’ll want to have extra bottles ready on standby.

Resins are available from a wide assortment of brands in different colors with various properties like elasticity, flexibility, rigidity, fluorescence, and many more. Experiment and try out a variety of options to see what best fits your needs.

Premium resins can cost a bit more, but they’re worth it for any parts that require specific mechanical properties. Your choice is particularly important if you’re printing functional parts instead of prototypes. You certainly don’t want your drone’s wing to snap mid-flight!

- Cost: $30-$80+ per kg

- Task: Printing!

- Examples: Anycubic Standard Resin+, Elegoo ABS-Like Resin 2.0, Nova3D Water-Washable Resin, Prusament Resin Tough

Paper Towels (Lots)

If you’re new to resin 3D printing, the inclusion of paper towels might surprise you, but resin printing veterans know there’s nothing you’ll go through more of. It’s key to always have spare rolls of paper towels nearby.

Not only will you need paper towels for cleaning up the resin from the resin vat, the funnel, around the bottles, the silicone mat, and your other tools, but you also need paper towels to help dry your 3D prints after washing them.

You could theoretically use any old rag for cleaning, but it won’t take long for cured resin to cover the entire rag, making it closer to a paper board. Since you also have to consider that you shouldn’t be washing cloths and rinsing resin residue down the drain, it’s easier to stock up on disposable paper towels.

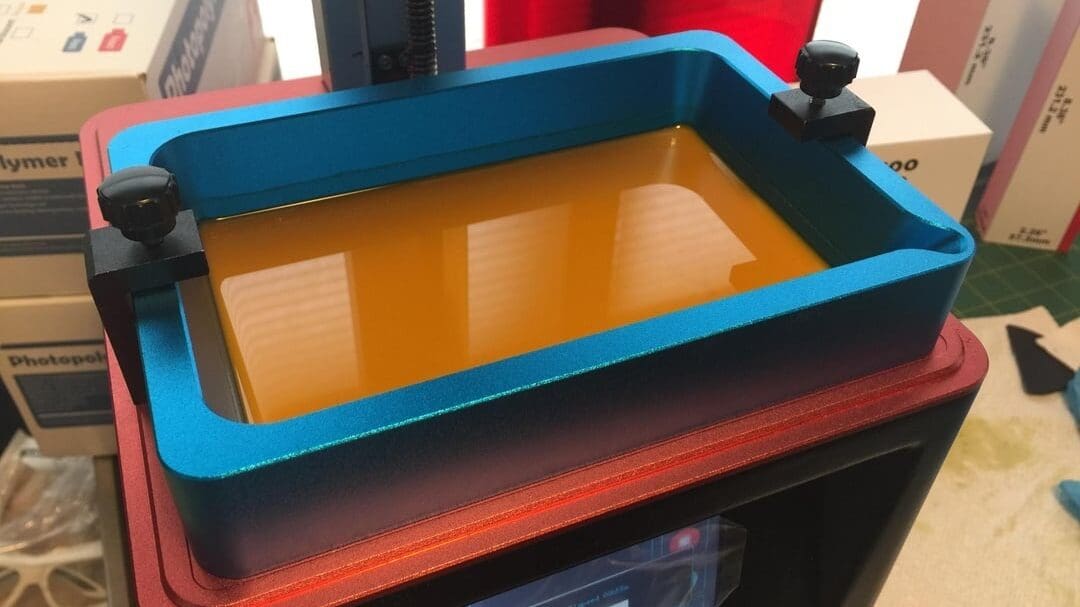

Vat

It’s not often that you’ll need to replace your resin vat or tank, but it happens. For example, Formlabs recommends replacing vats every 1,000-3,000 layers of printing. That’s a wide range and other manufacturers don’t explicitly state their vat lifespans, so keep an eye on damage or deterioration.

Vats are consumables that will naturally wear out over time, but certain causes shorten their span. For example, cured resin sticking to the vat’s edges can prevent the build plate from fully descending or block the light source from being able to reach your model as intended.

In addition to failed prints, vat damage can cause resin leaks and spills that seep into the 3D printer’s circuits causing major damage. LCD printers are particularly sensitive to contamination while DLP printers are prone to voxel distortion around the edges that contrast with their high precision centers. In both cases, it’s essential to monitor the wear and tear on your resin vat to give your prints their best chance at success.

If the resin hardens past the point of cleaning, a new resin vat is needed. It’s always wise to contact manufacturers directly for replacement parts as you won’t get any replacements along with your printer.

- Cost: $40-$80+

- Task: Holding resin

- Examples: Elegoo, Anycubic Photon Mono X

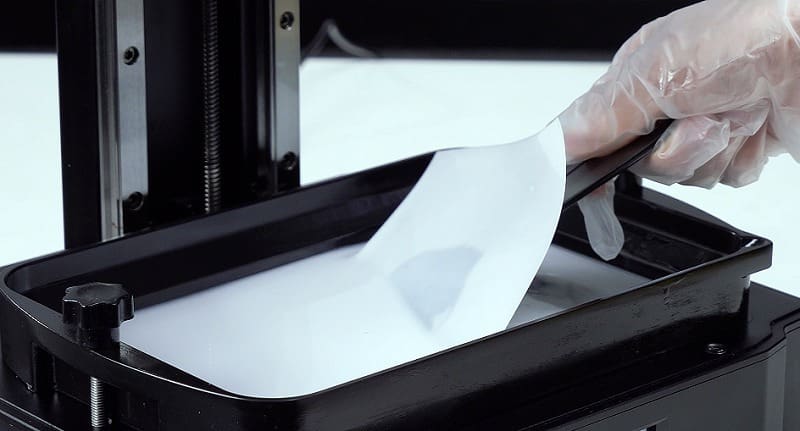

FEP Film

Your FEP film is the most likely piece to break (or at least scratch) on your 3D printer, so it’s never a bad idea to have backups of this thin film. It’s a part that’s easy to overlook once attached to the resin vat, but it plays a key role between your resin and the LCD screen. Damaging it means that light won’t be reaching your model quite as intended, which could result in print failure or defects.

A good FEP film could last as long as your 3D printer if you’re careful with it. Because you’ll only get one with your printer, it’s not a bad idea to go for a higher quality sheet for such an essential part if you’re looking for a replacement, but for those of us that aren’t careful enough, you can also buy in bulk at many online retailers.

- Cost: $3-$20 per sheet

- Task: Protecting LCD screen

- Examples: 3DMaterials, Epax, Phrozen

LCD Screen

The LCD screen displays inverted images of each slice of your 3D model under the resin vat to mask the light source in the correct spots. It also masks the resin around the edges of your print to keep the unused resin from curing. DLP printers similarly use a digital screen to project the light that cures one layer at a time.

If the LCD screen or DLP sheet malfunction or wear out, you won’t have any successful resin 3D prints. It can also be damaged by resin if the above FEP films or resin vat fails. If you can’t clean it off, you’ll have to replace the screen so your resin 3D print knows what shape to take.

According to Nexa3D, LCD screens are considered a consumable part that will need to be replaced after around 3,000 hours of printing or when wear affects print quality. Like with the resin vat, it’s always wise to contact manufacturers directly for replacement parts as there won’t be a spare included in the box.

- Cost: $90-$500+ depending on your printer

- Task: Masking UV or LED light during printing process

- Examples: Anycubic Photon series, Peopoly Phenom Noir

License: The text of "Top 15 Resin 3D Printer Accessories & Spare Parts" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.