What Is It?

Selective Compliance Assembly Robotic Arm, also known as SCARA, is a unique type of motion system that can be found in robots and even 3D printers. The motion most closely models a human hand with joints.

The word “assembly” in the acronym SCARA hints at the technology’s beginnings – that the “arm” was originally meant for automated assembly, not 3D printing. Indeed, though the technology was invented in 1981 by Sankyo Seiki, only in the past decade has it been used in 3D printers.

SCARA printers belong in the category of fused deposition modeling (FDM) machines and were first introduced into the 3D printing world with the RepRap Morgan, whose design was born out of needing a cheaper way to print expensive parts for FDM machines at the time. The Morgan SCARA printer went on to win the HumanityPlus Uplift Personal Manufacturing Prize in 2013.

In this article, we’ll be looking at SCARA 3D printers and focusing on how they work, how they’re different from standard FDM printers, their benefits, and their drawbacks. Let’s start moving!

How Do They Work?

Now that you know what they are, let’s explore how they work. As we said previously, SCARA printers can be classified as Cartesian FDM printers in terms of their operational coordinate system. This means that they determine where to move using the X-, Y-, and Z-axis (like the Ender 3, MakerBot Replicator, and Prusa MK3S+).

Motion

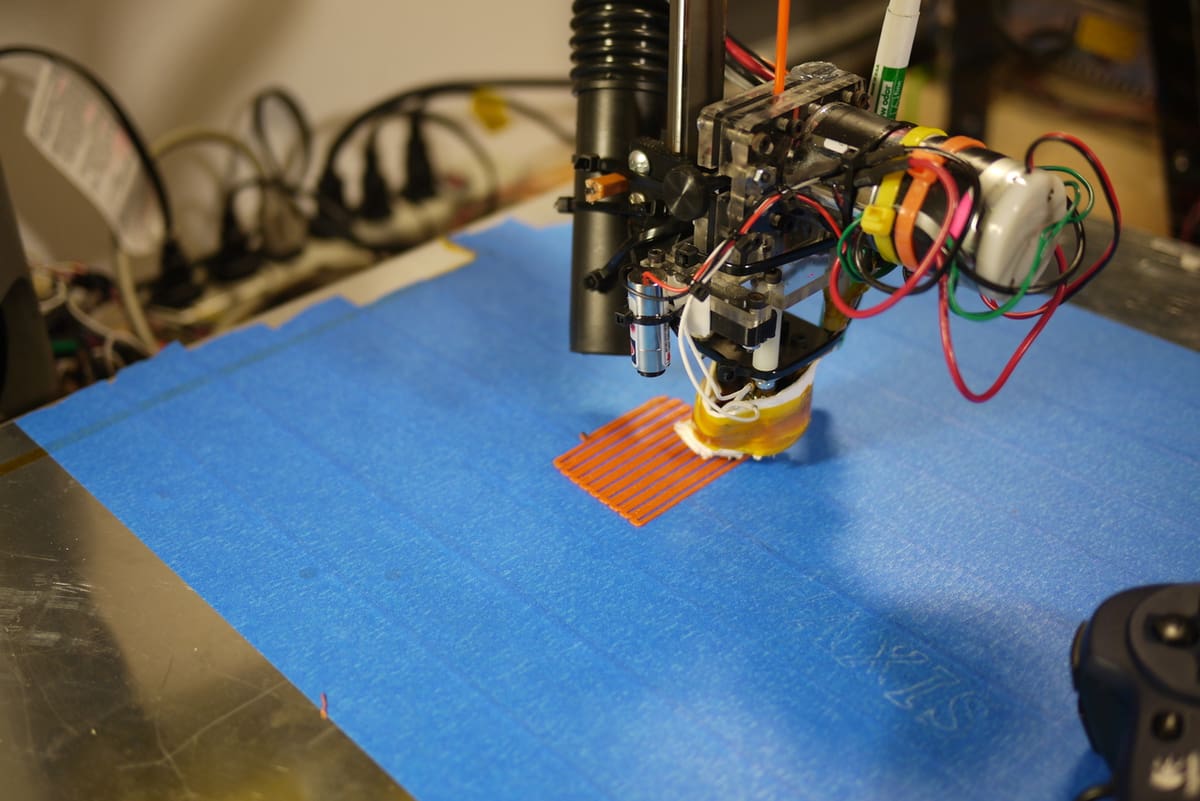

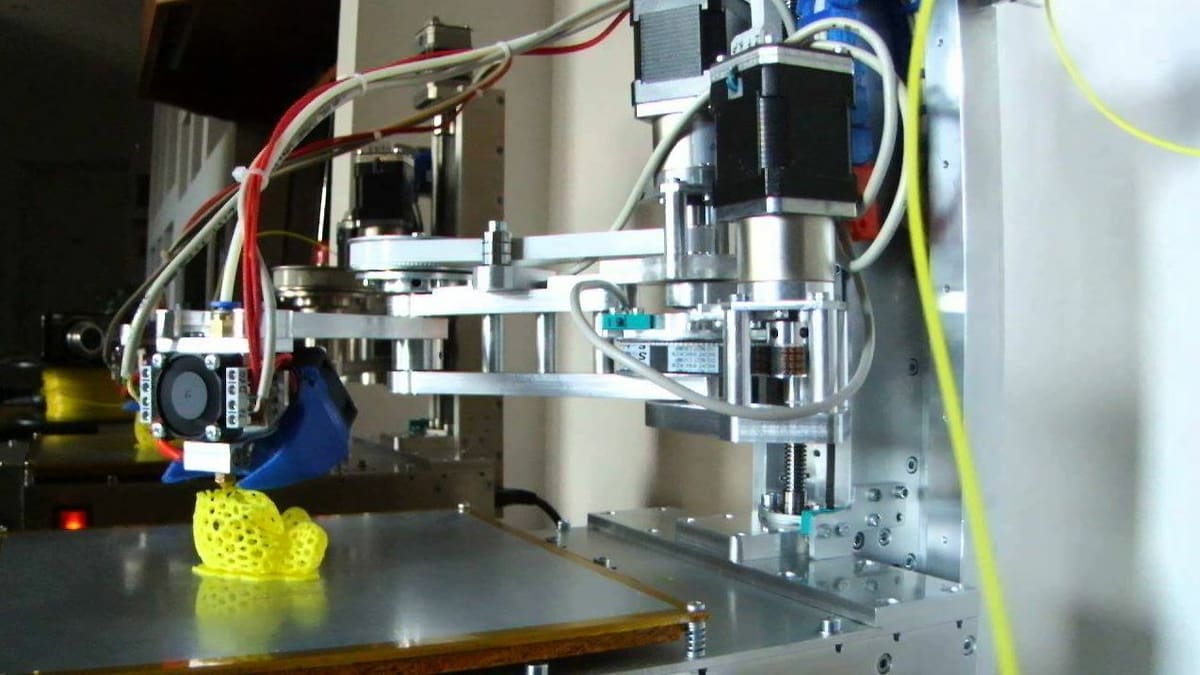

SCARA printers differ in mechanical nature from other FDM printers as their motion system involves the use of multiple controlled arms. These arms enable the printer to move the printhead around the X and Y planes.

The printer’s arms typically use two motors on the same side that are connected through joined arms. This arm motion system incorporates linkage to cover the full range of the print area.

The firmware of a SCARA printer calculates how the motors should move and in what combination to have the printhead move to print the desired part. This arm motion contraption moves up and down typically using a threaded rod along the Z-axis.

Extrusion

SCARA printers use a heat cartridge to heat a hot end and are typically a Bowden extrusion setup. Because the linked arm carriage cannot hold much weight without becoming unstable, SCARA printers don’t tend to have direct-drive systems, which are heavier on the printhead.

Other Essentials

Like other 3D machines, SCARA printers have firmware, a mainboard, a power supply unit (PSU), and most of the other essentials. They’re supposed to print on a flat print bed, and most of the time it’s a glass plate because they’re easy to get.

Most Cartesian printers have a standard build plate size from 200 x 200 to 300 x 300 mm. However, SCARA printers use both rectangular and circular build plates of various sizes. Because they’re often custom-made, there isn’t a common frame or design for the printer, but they use the same main principles.

Pricing

SCARA printers can cost a variety of different prices, but you can get one starting at about $300 or one costing well over $10,000. As a reference point, the popular RepRap Morgan can be purchased for a little over $1,000.

Unique Qualitites

Next, let’s discuss how SCARA printers are different from other types of FDM printers such as Cartesian, delta, and polar FDM printers.

SCARA printers are significantly more complicated than some of the other subcategories in FDM printers, just look at them! They use a complex, dual-arm-linked motion system.

Additionally, SCARA is probably the most non-commercial type of printer out of the numerous subcategories of FDM printers. This means that unlike Cartesian and even delta printers, there are very limited hardware options. You’ll most likely have to make your own printer components; 3D printing the parts could make this process easier.

This also means that there are fewer printer designs and commercialized upgrades for SCARA printers. Despite that, they’re faster than most Cartesian and polar FDM printers. Additionally, unlike Cartesian printers where the frame takes up most of the printer, SCARA printers have a minimalistic frame leaving more room for printing.

As we stated in the last section, the price for SCARA printers can start at just $300. You’ll get a build space of 200 x 200 x 150 mm, which isn’t too shabby for the price. You can also build a fairly inexpensive one such as the MPSCARA for just under $350. This is especially reasonable compared to other Cartesian printer builds such as the HyperCube (~$500 to make). The cheaper price stems from the need for fewer frame materials, which drops the price dramatically.

Pros & Cons

SCARA printers have many unique features and capabilities like the ones we mentioned in the previous sections, but there are a few downsides, too. Let’s take a closer look.

Pros

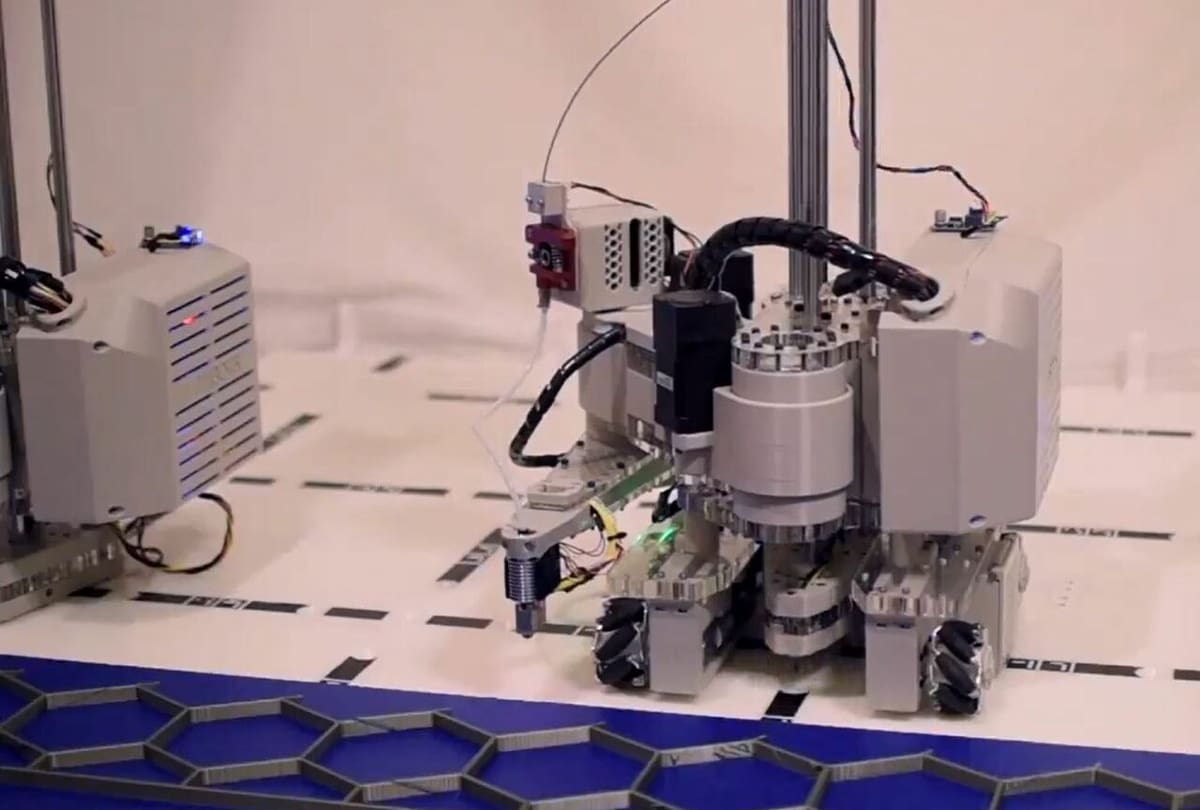

- Capable of auto-bed leveling (also as seen with AMBOTS)

- Faster than Cartesian FDM printers

- Growing and developing fast

- Inexpensive

- Take up less space

Cons

- Requires high-quality joints to maintain accuracy and precision

- Calibration can be tedious

- Microstepping can cause precision errors

- The technology is still in its infancy

- Low payload (the printhead has to be lightweight)

Examples

Advanced 3D printer enthusiasts have built and played around with SCARA machines and you can see some being used and sold in the commercial field right now such as AMBOTS. There are more and more SCARA printer designs being made as the technology develops. Let’s take a look at a few of the most popular ones:

RepRap Morgan Pro 3

The RepRap Morgan was the first SCARA 3D printer to be built. Multiple versions of it have been made that you can buy on their website. With a build volume of 380 x 220 x 220 mm and a hot end that can heat up to 245 °C, this printer has won multiple awards as we’ve mentioned. If you have extra money to spend, add the heated bed option so you can print more materials other than just the recommended PLA.

- Cost: ~$1,095

- Creator: Quentin Harley

- Difficulty: Easy (not a build)

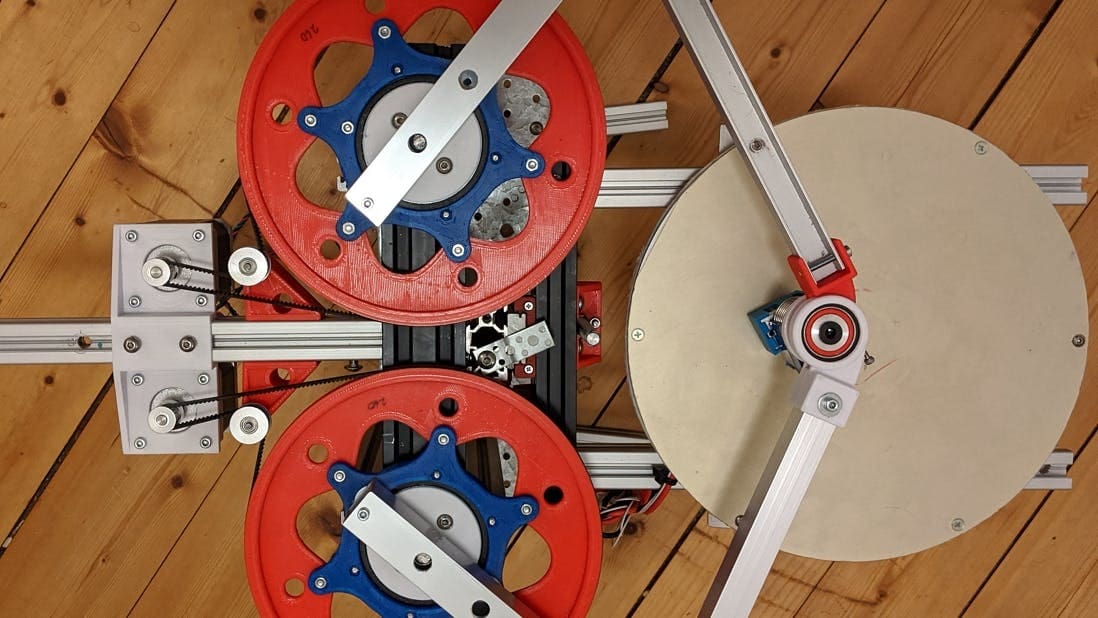

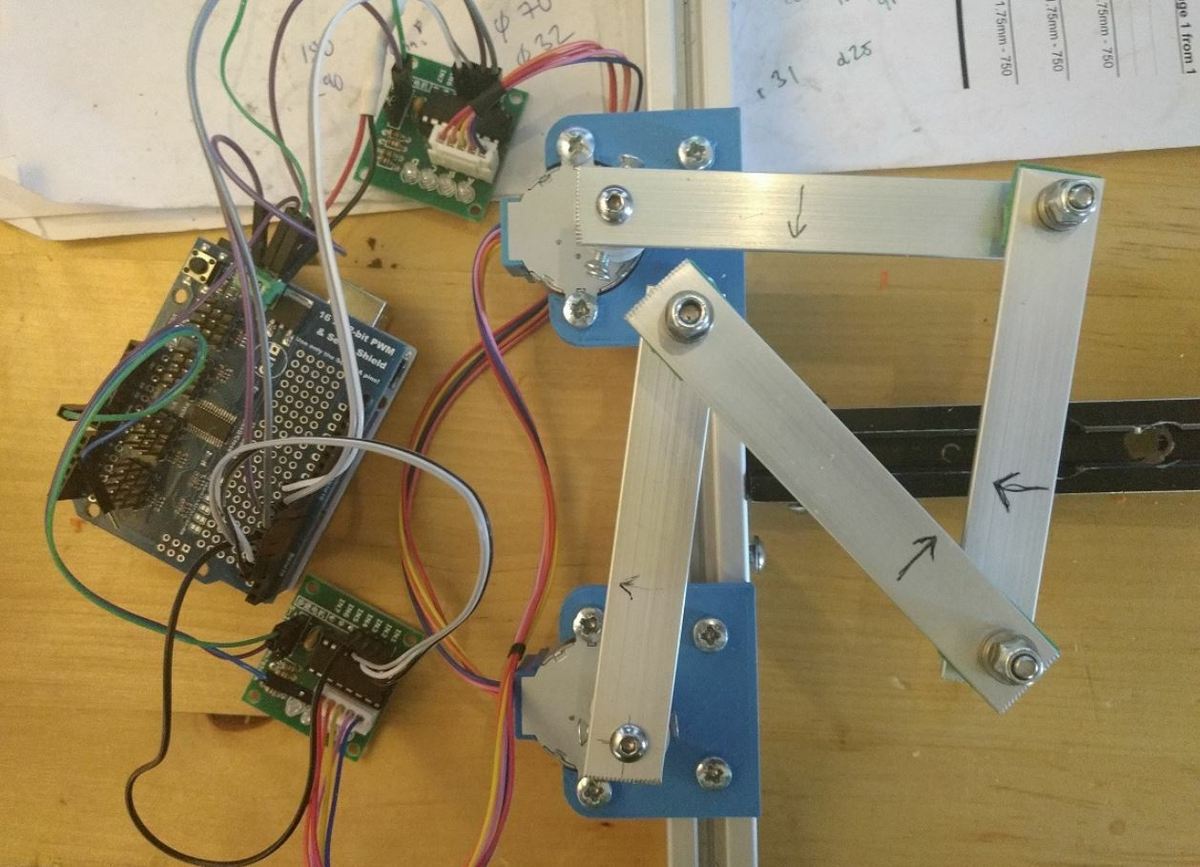

Five Bar Parallel SCARA

The Five Bar Parallel 3D printer is another SCARA printer build that’s made of mostly 3D printed parts. It uses 12-mm rods, bearings, belts, 3060 extrusions, and a lot more to work. It runs on custom-built firmware, as the Duet firmware wasn’t compatible or configured for this type of printer.

- Cost: N/A

- Creator: bondus

- Difficulty: Hard

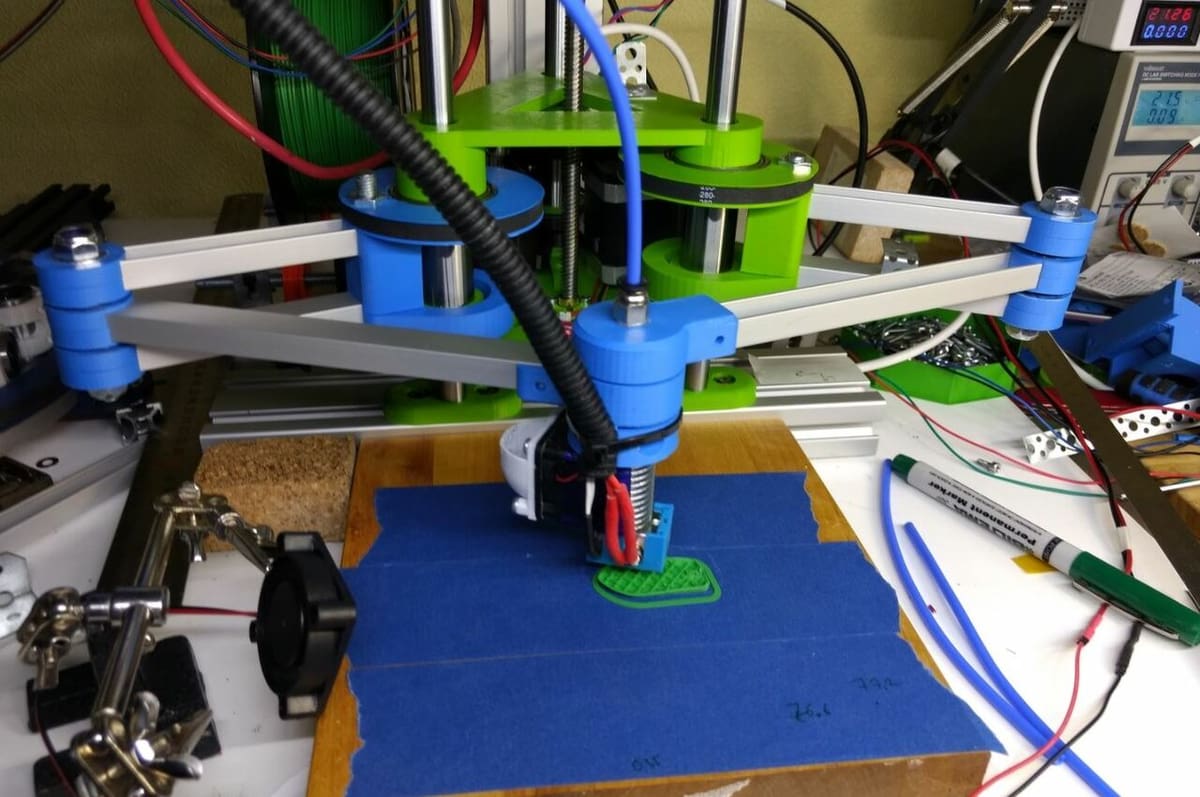

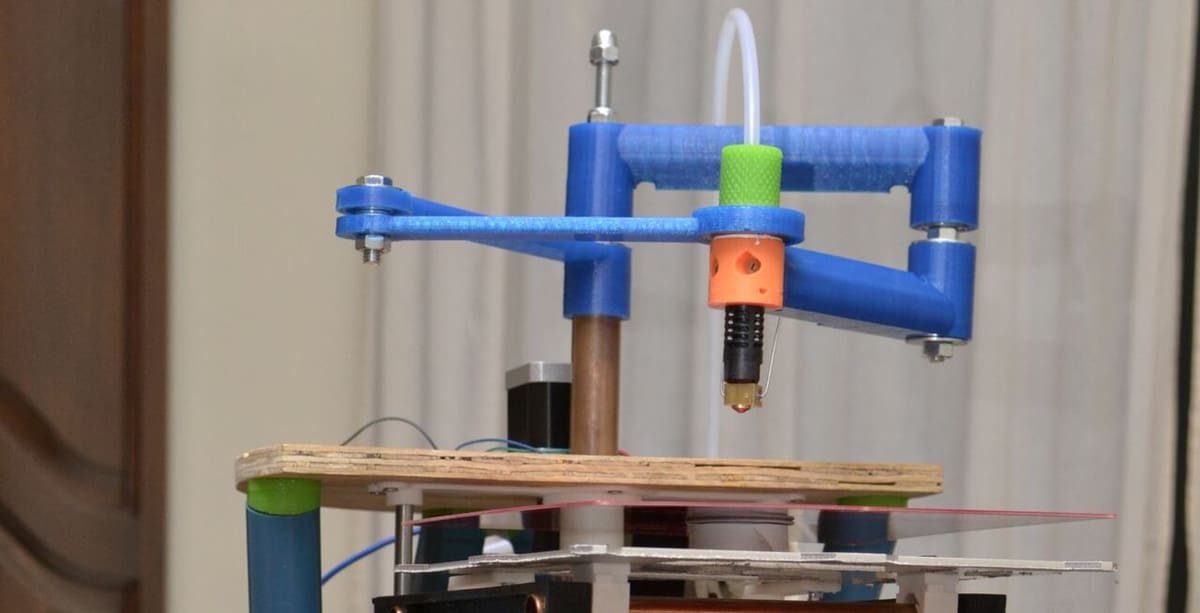

RepRap Helios

The RepRap Helios was made in 2017 and posted on Hackaday. The printer has a build volume of 200 x 200 x 100 mm and also has auto bed leveling and an LCD panel. This DIY SCARA printer requires assembly and the purchasing of many different parts. It also runs on Smoothieware firmware.

- Cost: ~$600

- Creator: Nicholas Seward

- Difficulty: Hard

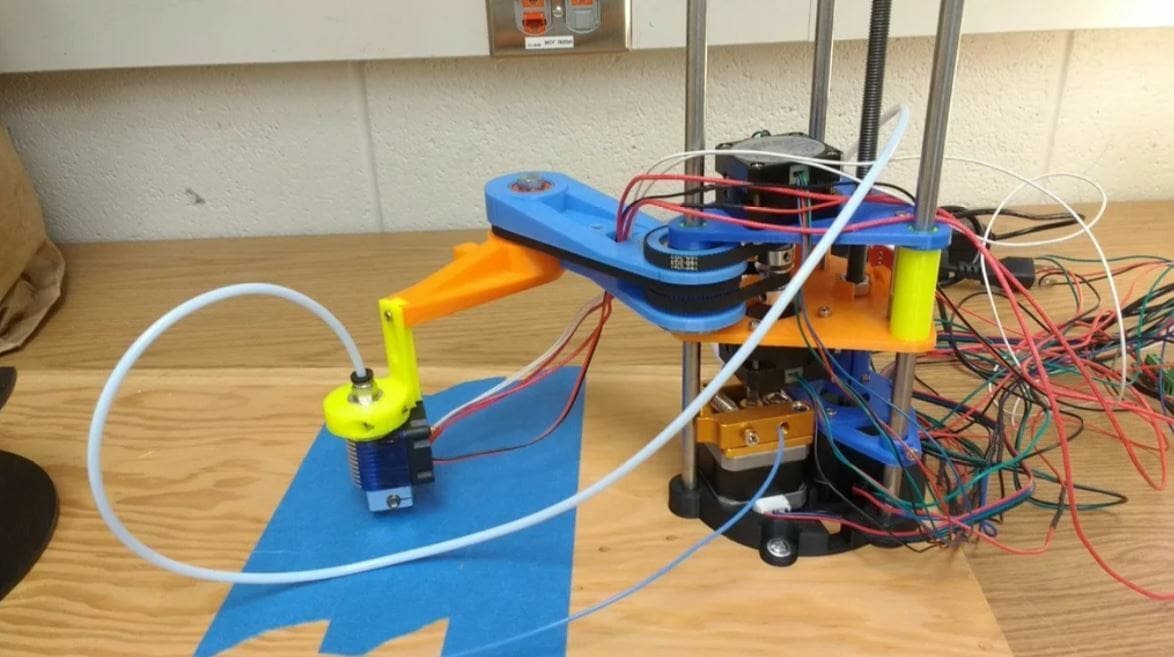

MPSCARA

The MPSCARA is another 3D printer build available on Thingiverse. MPSCARA stands for “Mostly Printed SCARA”, meaning that most of the components to this printer can be 3D printed. Of course, you’ll need to purchase some electronics and hardware. The project page has all the necessary files such as the bill of materials, printable part files, and assembly instructions.

- Cost: ~$350

- Creator: Williaty

- Difficulty: Medium

SCARA Arm

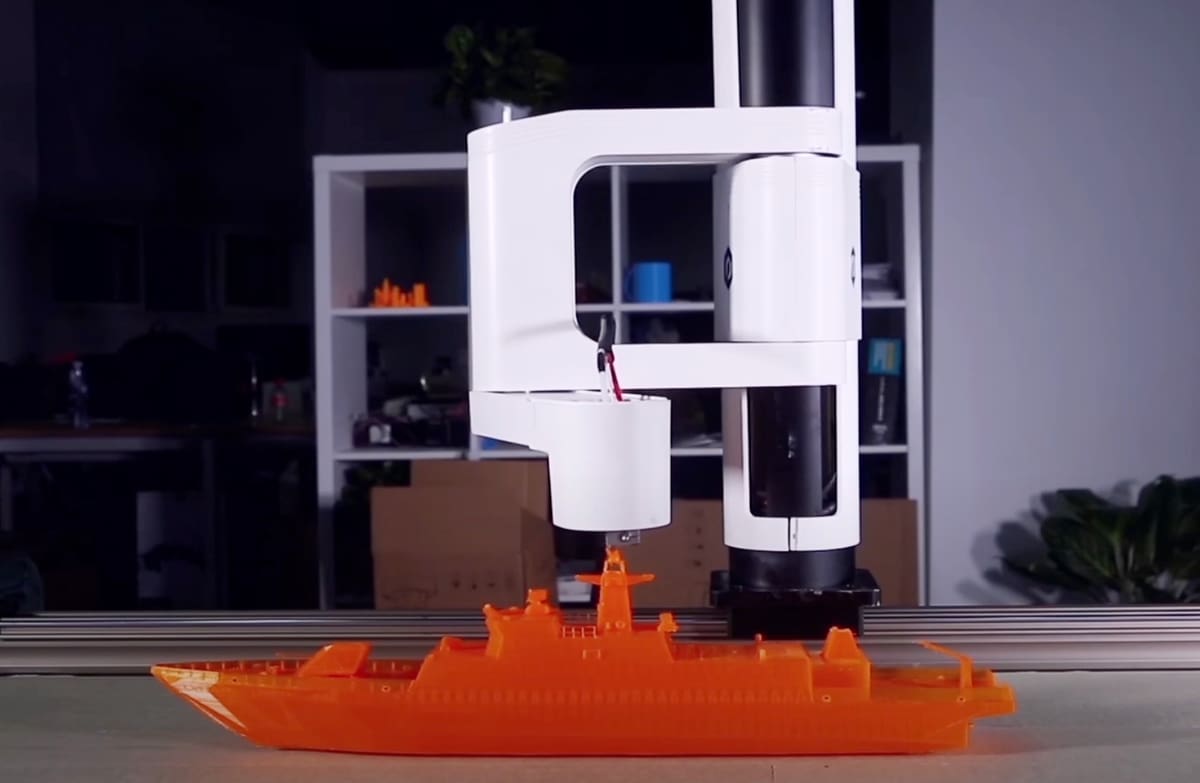

The SCARA Arm 3D Printer is a purchasable SCARA printer that has no attached build plate and a minimalistic frame. You’ll be getting a printing volume of 200 x 200 x 150 mm with a listed maximum printing speed of 100 mm/s, which is crazy fast. Sadly though, it uses proprietary firmware that isn’t open-source. You can watch this printer in action in this YouTube video.

- Cost: ~$300

- Creator: RobotDigg

- Difficulty: Easy

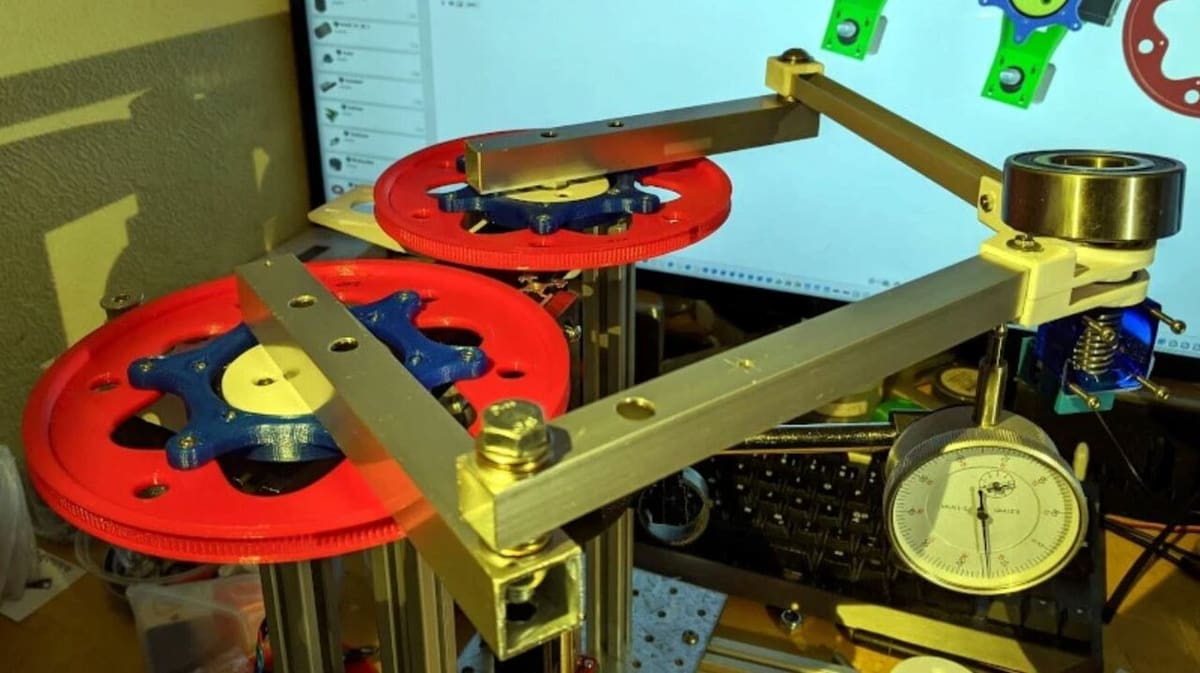

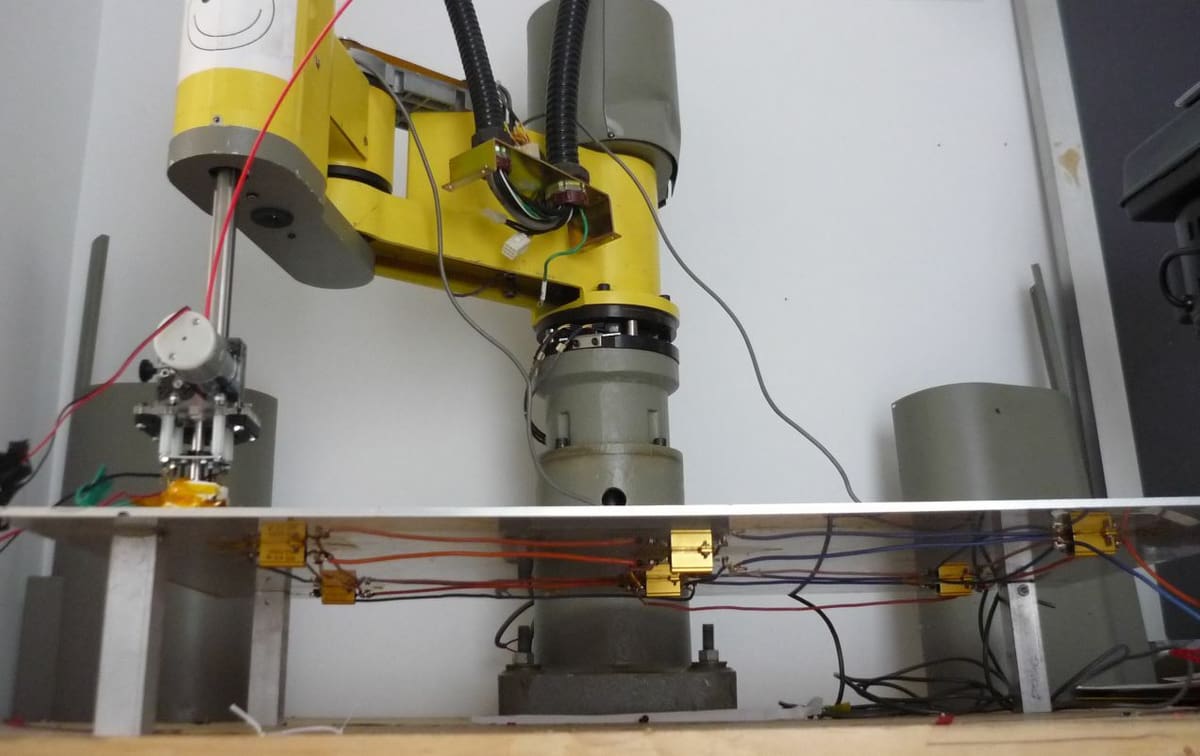

Dobot M1

The Dobot M1 is an industrial SCARA 3D printer that functions as a pen plotter, laser engraver, and an assembly bot too. You can see the Dobot M1 in action on this YouTube video.

This SCARA printer comes with attachments such as a printhead, laser module, grabber, and more. This allows you to change tools on the machine to perform various tasks.

The machine has a reach of 400 mm, a payload of 1.5 kg, and 0.02-mm repeatability. However, it doesn’t use any sensors, which is slightly unsafe. It also runs on Linux software.

- Cost: N/A

- Creator: Dobot

- Difficulty: Medium

Final Thoughts

SCARA technology in the 3D printing world is still very new, so there’s definitely room to grow.

Specifically, these 3D printers still need to improve upon many things, especially reliability, accuracy, and payload. Additionally, SCARA machines are geared towards advanced users. The development of a more plug-and-play-oriented printer (and at a lower price point) would allow more new users to experiment and learn about the technology.

With beneficial changes like these, SCARA might gain more popularity in the 3D printing community. Remember that when Cartesian printers were first invented, they seemed very complicated too, but look how much they’ve developed over the years! SCARA 3D printers still have a long way to go, and hopefully, they’ll continue to become more and more accessible.

Lead image source: Pontus Borg via YouTube

License: The text of "SCARA 3D Printer: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.