The Uniqueness of Silicone

Most of today’s silicone seals, joints, wearable technology, robotic grippers, and the like, are made with injection or compression molding. It’s a process that requires a model, then a mold made from that model, then silicone injected into the mold.

3D printed silicone removes the model and mold steps entirely and simply prints the final part. This clearly saves an enormous amount of cost and time: up to 90% faster than injection molding, according to 3D printer maker 3D Systems.

However, 3D printing with a tricky material like silicone has challenges that the additive manufacturing industry hasn’t fully overcome. Only a few specialized 3D printers can produce pure silicone parts, but where 3D printing silicone is really growing, is with “silicone-like” materials. Let’s take a closer look at both.

Silicone & Silicone-Like 3D Printing Materials

One of the challenge of 3D printing silicone, is that, unlike solid polymer filaments that are malleable when heated and solidify once again when cooled, silicone, once solidified, can’t be made pliable again. It’s also unlike photopolymer resins that are hardened with light, because silicones are highly resistant to UV light and cannot be cured in their pure form.

Silicones require an additive to render the material sensitive to light or heat — the two conditions used in 3D printing — to act as a trigger to initiate the polymerization reaction within the material (in other words, solidify it).

This material complexity means that silicone requires special 3D printers.

However, if your application doesn’t need 100% pure silicone, you have more options with silicone-based and silicone-like materials, which are more widely available today and work on many existing resin 3D printers.

When silicones are used on resin 3D printers, such as from Carbon or B9 Creations, the silicone material is blended with other polymer resins and thus loses a few of its distinguishing characteristics while still being ideal for a wide range of applications.

Despite the complexity, there are many reasons to turn to 3D printing with silicone (and silicone-like), especially for unique or low-volume parts.

Applications of 3D Printed Silicone

Application-wise, 3D printing with silicone is not intended for mass production. Small to medium-size batches, product prototypes, unique shapes only possible with 3D printing, or one-of-a-kind and patient-specific products are where silicone 3D printing has the greatest application and advantage.

- Medical implants: 3D printed silicone implants are being explored for meniscus implants and other medical devices.

- Prosthetics: 3D printed silicone prosthetics and prosthetic liners offer a comfortable, customizable alternative to traditional prosthetics.

- Soft robotics: 3D printed silicone is ideal for creating soft robotic components, such as grippers, that are able to grasp and manipulate delicate objects.

- Medical models: Silicone can have the feel and response of human tissue, making it ideal for medical models and surgical practice aids.

- Wearables: 3D printed silicone is used to create customized wearables for research and prototypes of consumer wearables, such as smartwatches and fitness trackers.

- Textiles: 3D printed silicone can be used on flexible and stretchable fabrics for potential applications in fashion and athletic wear.

- Electronics: 3D printed silicone is being explored as a potential material for flexible and stretchable electronics.

- Biomedical research: 3D printed silicone is used as a scaffold for tissue engineering, creating structures to grow cells for studies and experimentation.

- Acoustics: 3D-printed silicone is used to create acoustic materials such as noise barriers, sound absorbers, and vibration dampers.

Recent Advances in Silicone & Silicone-Like Materials

With developments in material sciences and manufacturing processes, silicone has slowly but surely entered additive manufacturing. Although hobbyists shouldn’t expect to print silicone in their garages any time soon, silicone 3D printing for industry, especially manufacturing and healthcare has definitely evolved.

In late 2024, Elkem, a Norwegian producer of silicone-based products, launched new silicone materials specifically for 3D printing. AMSil 20503 and AMSil Silbione 24503 provide a longer shelf life for easier handling and are available with Shore A hardness from A10 to A70 with well-known properties of 100% silicones for LDM (liquid deposit folding), a specialized 3D printing process used mainly for high-viscosity materials like ceramics and pastes. Potential applications for Elkem’s silicone formulations include industrial parts such as seals, gaskets and valves, and healthcare products including hearing aids, anatomic models and prosthetics.

Filament2, a company specializing in innovative 3D printing materials, announced the launch of what it calls the world’s first silicone filament compatible with standard FDM 3D printers in late 2024. This development promises to expand the capabilities of additive manufacturing across various industries by removing the necessity for specialized equipment. As of this article’s publication, it is still not available.

Also, late last year, 3D printer manufacturer Axial3D announced a new silicone materials for its resin 3D printer. Developed by Spectoplast, TrueSil-X50 is a 100% pure silicone without any additives, the company says. It is specially tailored for use with the company’s Lumia X1 3D printer that incorporates both laser and projection technology.

Material properties of silicone

- Excellent thermal stability

- Available in different hardnesses

- Water resistance and suitability as a sealant

- UV resistance

- Oxidation resistance

- Compression and shear resistance

- Flame retardancy

- Electrical insulation

- Biocompatibility

- Food safe

- Can be sterilized

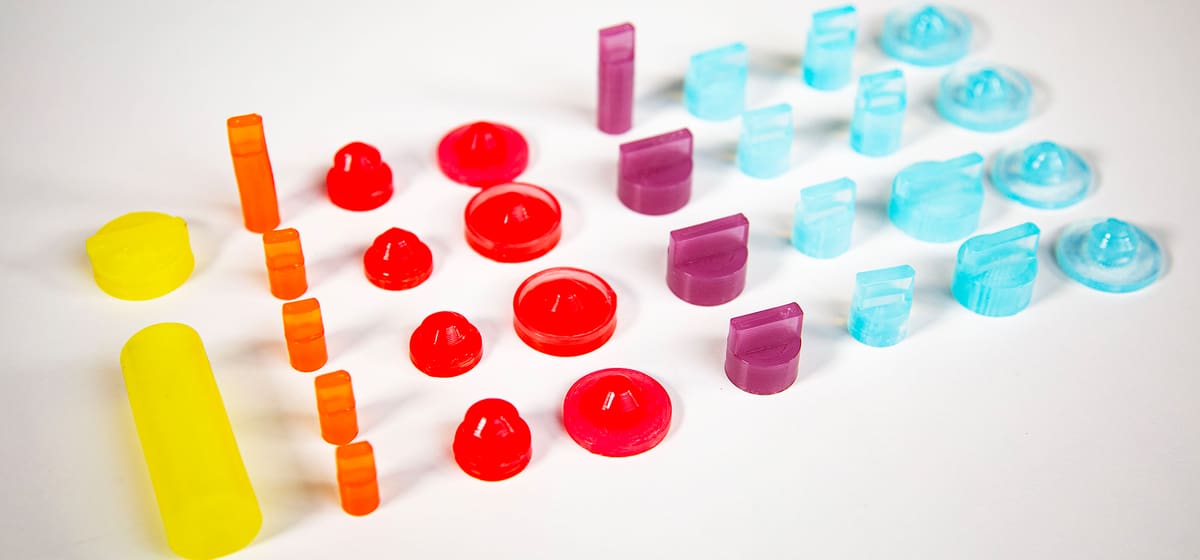

- Color and translucency options

Academics and 3D printer companies, in particular, have advanced a variety of techniques and material variations. The growing demand for innovation has led to several printers and services that we detail below.

Silicone-Like and Silicone-Alternative Materials

Most silicone 3D printers can not print with exactly the same material that’s used for injection molding. In fact, only a few companies, including Spectroplast, Lynxter, Axial3D, and Eklem, claim to be able to 3D print with 100% silicone. A host of others offer silicone-based materials with additives that make them easier to 3D print.

Additives, such as UV curing agents, can weaken the silicone or reduce the quality and lifespan of the final part, so special blends with other polymers make up for this effect. That said, these modified silicones still offer many positive properties and are suitable for a wide range of applications.

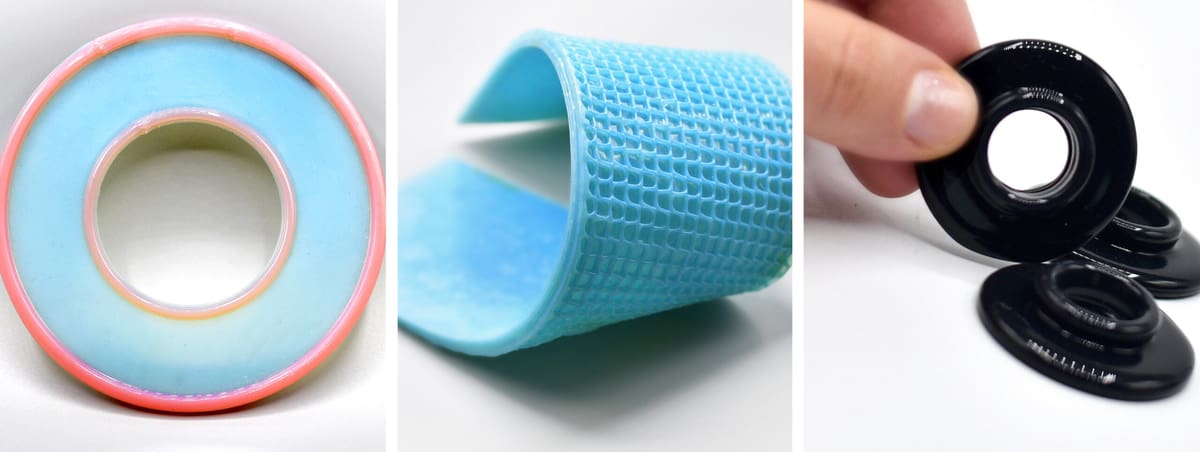

3D-printable polyurethanes are used for gaskets and other applications that need soft rubbery properties but may not need all the benefits of pure silicone. Chromatic 3D Materials, for example, offers 3D printable industrial-strength elastomeric products, including polyurethanes and other thermoset elastomers for applications in transportation, industrial seals and gaskets, textiles, medical devices, and defense. Chromatic’s RX-AM materials and technology platform is based on Reactive Extrusion Additive Manufacturing, a type of deposition 3D printing that uses chemical reactions.

How & Why to 3D Print with Silicone

In the last five years, a number of companies have developed novel approaches to 3D printing silicone. Some use a material jetting approach with an inkjet print head deposition and UV light. One version of this called drop-on-demand, 3D prints silicone by planting one voxel of silicone solution (silicone plus UV activating binder) at a time. After each layer, a UV light source activates the binder and then the next layer is planted. Although this seemed like a promising approach from a company called Aceo, its parent company Wacker Chemie completely abandoned it in late 2021.

Liquid Additive Manufacturing (LAM) is a term coined by a company called German RepRap to describe its process of extruding liquid silicone that’s then cured with heat from a halogen lamp. LAM was developed in collaboration with Dow Chemical Company and these LAM-based 3D printers are now under the InnovatiQ brand after it acquired German RepRap.

Other methods use a vat photopolymerization approach. Here, silicones are blended with other photosensitive resins so they can be used in the same 3D printers that process other materials, as is the case with 3D printer makers Carbon and Desktop Metal.

All approaches produce parts comparable to injection molding. Several printers on our list can print with more than just silicone, while other are specialized for silicone only.

Software, Supports & Post Processing

As you might guess, you’ll need special slicing software that can account for the limits and attributes of this unique material. Each printer solution below offers custom slicing software.

As with many 3D printing methods, support structures can be necessary for complex geometries and overhangs. Some silicone methods use just one material, but others enable the use of a dissolvable support material along with the silicone material.

Post-processing involves support material removal and often additional curing to further solidify the silicone part. It’s also possible to color silicone parts during printing. Because silicone parts have good surface finish quality after curing, extensive post-processing is not generally required.

Silicone 3D Printers

If you’re looking for a 3D printer for pure silicone, currently, there are only a handful of machines on the market, but if your application is suited to a silicone-like soft-touch material, your options open up dramatically as many top vat polymerization printer makers offer these non-silicone, but very flexible materials.

For these non-silicone resin 3D printers, check out our guide to professional resin 3D printers linked below:

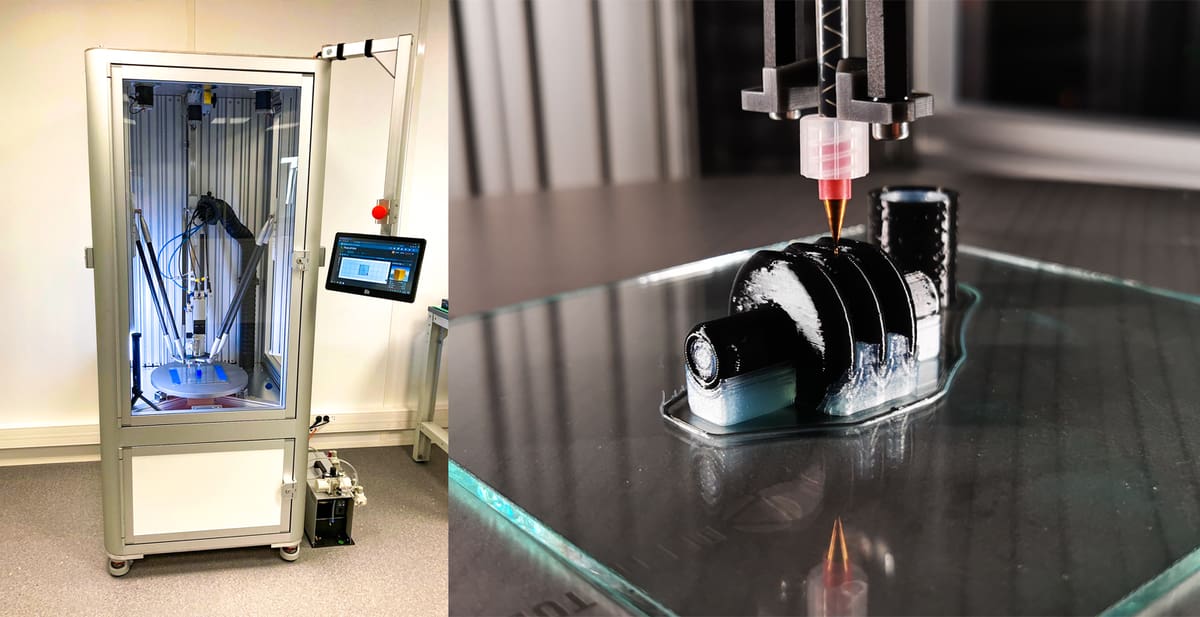

InnovatiQ LiQ 320

The LiQ 320 3D printer from the German company InnovatiQ , part of equipment giant Arburg, prints components from liquid silicone rubber. Both prototypes and functional parts can be produced in comparable quality to injection molding, the company says.

Once your digital file is sent to the 3D printer, a layer of high-viscous silicone material is extruded from the print head onto the print bed. Then, the built-in halogen lamp generates heat to activate cross-linking of liquid elements at the molecular level. This process is repeated until the desired part is created. After the printing process, the finished components are immediately functional and ready for use without any post-processing.

For material, the LiQ 320 works with InnovatiQ’s Silastic 3D 3335 Liquid Silicone Ruber (LSR), which is a material created to combine the performance advantages of silicone elastomers with the design and processing advantages of 3D printing.

Silastic 3D 3335 is UV and ozone-resistant, which makes it particularly suitable for all types of seals, joints, shoe components, housings, and other products in the medical sector.

As an option, you can add the company’s Smartcoloring kit to additively manufacture your parts in color. InnovatiQ acquired the printer and technology from German RepRap in 2020 then was acquired by Arburg.

Min layer thickness (mm): 0.22 – 0.9

Lynxter S300X

Another 3D printer maker relatively new to the silicone scene is France-based Lynxter. The company offers the S300X silicone drop-on-demand 3D printer and the larger S600D.

High-capacity material cartridges make it possible to print large parts or several small parts in complete autonomy with fewer material cartridge changes. The S300X features a large, 300 x 250 x 200 mm, print volume, and can produce parts to a minimum 100-micron layer height.

The S300X prints in a range of medical and industrial grade silicones (RTV2 silicone 5, 10, 25, 40 ShA, 45shA) and polyurethanes (from 50 to 85 ShA) and is ideal for producing customized masking parts for post-processing (painting, sanding, plasma treatment, etc.), dampers, seals, orthoses certified for skin-contact and textiles with additional functionality, the company says.

As a dual-extruder IDEX 3D printer, the S300X is fitted with a single-component tool head to print the supports and a two-component tool head to print the parts. This also paves the way for combining materials and the printing of parts with different physical properties in one single print.

Formlabs

Printer maker Formlabs launched a silicone material in September 2023, Silicone 40A Resin.

Formlabs says it invented a patent-pending “Pure Silicone Technology” that relies on Formlabs’ standard stereolithography (SLA) ecosystem to “produce 100% silicone parts” in-house, in a matter of hours. There are no details released on the new technology but the silicone resin product is compatible with the Formlabs Form 3+ printer.

Silicone 40A Resin parts feature a 40A Shore durometer, 230% elongation at break, and 12 kN/m tear strength. Ideal applications include anything requiring pliability and durability even through repeated stretching, flexing, or compression. Parts made with Silicone 40A Resin have a rebound resilience of 34%, chemical and thermal resistance (-25°C to 125°C), and can have fine features as small as 0.3 mm and complex shapes that are challenging to achieve with traditional manufacturing methods.

The biocompatibility of Silicone 40A Resin is still being evaluated.

Axtra3D Lumina

3D printer manufacturer Axtra3D announced in 2024 a new compatibility with silicone via the material TrueSil-X50 by Spectroplast, a 100% pure silicone material specifically formulated for use with the company’s Lumia X1 3D printer.

TrueSil-X50 will enable Lumia X1 users to meet a broad range of needs, the company says, from high-surface-quality sealants, gaskets, and keypads to high-performance sanitary solutions. Potential application areas include food processing, household appliances, and automation, enabling reliable, waterproof, and electrically insulating parts.

Axtra3D’s Lumina X1 3D printer features what the company calls Hybrid PhotoSynthesis (HPS) technology. This patented method of resin 3D printing combines SLA (laser) and DLP (projection) technologies in one platform to take advantage of the strengths (resolution and speed) of both. The laser is used for surfaces with a 45-micron resolution, while the DLP technology is used for the mass of the part enabling large resin prints faster than traditional SLA.

The company plans to make TrueSil-X50 available soon.

B9 Creations Core 5 Series Med XL

3D printer and material maker B9 Creations launched its BioRes Silicone ($345 per 1 kg bottle) in January 2022 for use with the company’s B9 Core 5 Series Med XL 405 and 385 3D printers. The materials, which offers high surface finish, tear resistance, and precision, is also ISO 90993-certified for prolonged skin contact of up to 30 days. BioRes works on most other photopolymer resin-based 3D printer platforms.

B9 Core 5 Series Med XL 385 (with a 385-nanometer light engine) is a resin-based DLP machine that enables customers to 3D print translucent, white, and specialty materials, such as silicone, with 25-micron effective resolution. It boasts IEC 60601-1 and IEC 60601-1-2 medical equipment compliance and CE certification.

Carbon3D

Well-known 3D printer maker Carbon formulates all of the materials that work on its vat polymerization platform. The company’s silicone material, SIL 30, is a soft, biocompatible, and tear-resistant silicone urethane elastomer that is ideal for skin-contact applications, the company says. The exact composition of SIL 30 is not released but its technical data sheet covers its mechanical properties and chemical compatibilities.

SIL 30 is only for use on Carbon’s resin 3D printers, which use a technology the company calls Digital Light Synthesis (DLS), which is a type of vat polymerization.

Delta Tower Fluid MT

The Fluid MT and Fluid ST, from Swiss start-up, Delta Tower are multi-tool and single-tool 3D printers with precision volumetric dosing systems for viscous, one or two-component fluids and pastes, such as silicone.

Using drop-on-demand technology, the smallest possible extrusion amount is 0,0208 µl, the Fluid printers enable the build up with fluid materials without deformation, the company says

The MT multi tool version can use up to 6 tools can be used in one print process.

The company has partnered with Elkem Silicones, which just launched a new support material, AMSil 92100, for silicon 3D printing. The material is water-soluble and can be washed off during the post-processing phase. Elkem Silicones provides 100% silicones from ShA 10 to ShA 70 for use with several types of DOD-based 3D printing systems. Besides their use in medical and industrial applications the range now also allows the use in Food Grade applications.

Rapid Liquid Print Levity

Rapid Liquid Print’s 3D printer isn’t even out yet, but it’s worth mentioning for its innovation.

Scheduled for release in 2026, the Levity 3D printer’s proprietary process enables the creation of large-scale flexible-materials products without the need for support structures or extensive post-processing, the company says. Parts are printed within a reusable gel suspension, which holds the material in place as it cures, resulting in minimal waste and reduced production times.

Levity is compatible with industry-standard materials such as foams, rubbers, and silicones, making it suitable for producing soft, pliable, and complex geometries across various industries, including medical, automotive, and consumer goods.

Prayasta Silimac P250

India-based start-up Prayasta introduced the Silimac P250 silicone 3D printer in 2023 that’s specifically aimed at implant-grade silicone for making personalized soft-tissue implants and prostheses.

Prayasta says the Silimac P250, with its 250 x 250 x 250 mm build chamber, is a production-ready machine that can manage large-volume silicone part production. The printer includes an in-built UV sterilization for the print chamber and a contamination-free support system that facilitates ideal hygiene for the 3D printing of implants, the company says.

Print resolution is 50 microns and materials include silicone elastomers from NuSil and others.

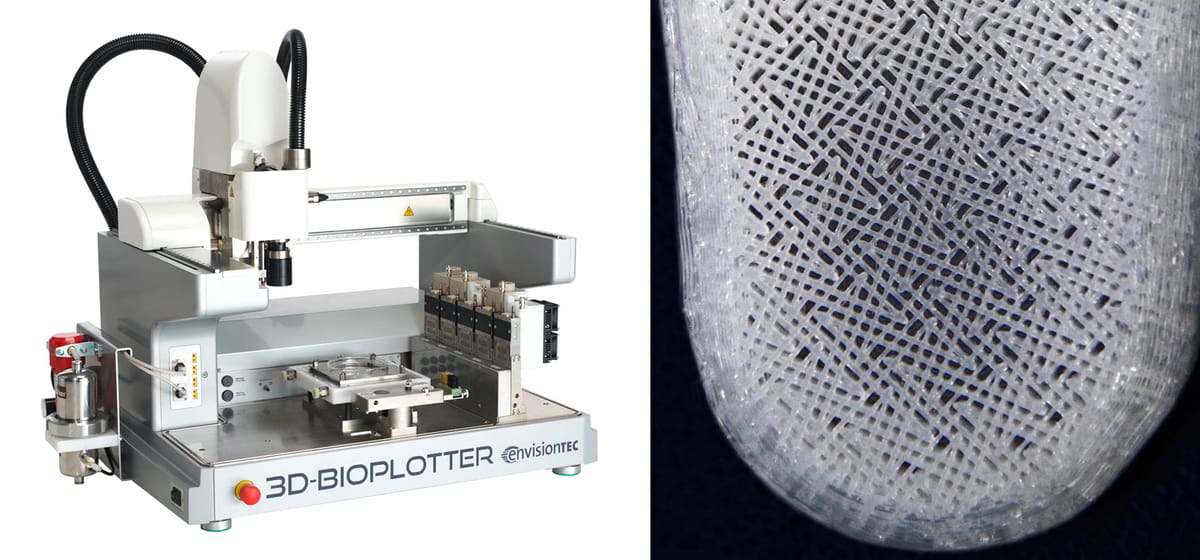

Desktop Health Bioplotter

Of particular interest to the medical industry, US-based company Desktop Health, a division of Desktop Metal that’s in the process of being acquired by Nano Dimensions, offers a bioprinter that also prints with two kinds of silicone.

Launched in 2000, the 3D-Bioplotter comes in three levels of functionality — Starter, Developer, and Manufacturer. It processes open-source biomaterials and silicone using air or mechanical pressure to a syringe. The silicone is dispensed from a material cartridge through a needle tip to create a 3D object that’s then cured with UV light. All models have been designed for use in a sterile biosafety cabinet, meet standards for clinical trials, and offer build sizes up to 192.4 cubic inches.

The 3D-Bioplotters offer users complete control of all printing parameters (temperature, pressure, speed, etc) through the software.

In addition to thermoplastics and cellulose materials, the 3D-Bioplotter prints with 3D-Bioplotter Silicone TG, a technical-grade silicone that 3D prints objects with medium hardness, and 3D-Bioplotter UV Silicone 60A MG, a medical-grade silicone that 3D prints objects with medium hardness.

San Draw S053 & S300

Taiwan-based San Draw offers four silicone 3D printers, the S053 ($7,000) and the larger S300 among others. The machines use drop-on-demand technology with San Draw’s proprietary two-part silicones, which are biocompatible (ISO 10993 certified), flexible, and high-temperature resistant (up to 250℃).

THe S02 53 has a build volume of 200 x 150 x 100 mm and is compatible with third-party materials, including hydrogel, ceramic gels, food gels, and more.

The S300 is another two-part silicone printer that can also print with a water-soluble support material at the same time, so it’s suitable for free-surface and thin-wall parts.

The company says it focuses on medical applications, including medical trainers, simulators, surgical trainers, pre-surgery simulation models, and medical devices.

Ordering Silicone 3D Printed Parts

If you’re not in a position to purchase a silicone 3D printer, there are still many opportunities to order your custom-made parts in silicone. 3D printing marketplace Craftcloud has more than 200 manufacturing partners and offers two kinds of silicone rubber AR-G1H (Shore A65) and AR-G1L (Shore A35). Upload your part file for a free quote.

Spectroplast is another on-demand service. In fact, the company has printed nearly a million silicone parts and says its core business is silicone-as-a-service. All parts are made in Spectroplast’s production facility in Switzerland and shipped worldwide, but the company plans to open a US facility in the coming years. US-based service provider Protolabs recently announced a partnership with Spectroplast to 3D print customer parts.

Norway-based silicone material maker, Elkem, also offers a silicone 3D printing service. Elkem Silicones has developed a production process based on extrusion principles called Liquid Deposition Modeling (LDM). This process allows using a new series of customized silicone materials: the AMSil series. You can design high-performance parts with 100% silicones with complex geometries and overhangs that are impossible to achieve using traditional die molds and machining to create elastomeric parts or objects by direct printing.

3D Alchemy is a UK-based additive manufacturing service company that offers “100% pure LSR silicone” with ISO certification for 3D printing. Their Silicone 3D printing process allows for complex geometries using a separate soluble support material which is then washed away post-build.

Lead image source: The LiQ 320 silicone 3D printer from InnovatiQ Arburg

License: The text of "Beyond Plastics: the Rise of Silicone 3D Printing Materials, Methods & Machines" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.