How SLA Works

SLA, or stereolithography, is a method of 3D printing that utilizes a laser and resin. Unlike digital light projection (DLP), which uses a projector screen, SLA is distinguished by the use of a single laser directed at particular points to cure the resin and solidify a pattern.

The first 2D pattern becomes the first layer of the print, usually suspended from an upside-down build platform. This platform initially rests on the surface of a reservoir of resin, and is incrementally raised as more layers are solidified. That’s right, with SLA you are essentially 3D printing upside-down.

Most SLA machines will use a UV laser and UV-curing resin, which makes the setup and post-printing processes difficult due to ambient UV light. The resin is often toxic, and can release a harmful vapor with an unpleasant odor.

The laser can be moved in one of two ways. The most popular, efficient and cost-effective way is to use a set of mirrors to play the laser about the print surface, but it’s also possible to use a gantry to move the laser in the same method a hot end is moved on an FDM machine.

The strength of SLA is the ability to print objects much more precisely, as the focal width of the laser can be quite small in comparison with the nozzle sizes on traditional FDM machines.

Looking to have something professionally printed with SLA or SLS? Check out Craftcloud, All3DP’s 3D printing and price comparison service.

How SLS Works

SLS stands for selective laser sintering, and is a more typical method of 3D printing in an industrial environment. In an SLS machine, the laser is used to melt, fuse or sinter a powder together to eventually form an object.

The laser in an SLS printer will vary in power, which determines what materials the machine can print. SLS printers, in addition to printing plastics, are often used to print with metals and ceramics. However, the laser is not capable of creating a completely solid bond in these “exotic” materials, and the part will often need to be further processed in an oven or kiln before reaching full strength.

Print material for SLS printers comes in powdered form, and within the machine is a roller device that continuously deposits new layers of “raw” material on top of partially sintered ones. An advantage of this method is that printed supports are not needed, as the surrounding unsintered material acts as a support throughout the print. As a result, parts can be more complex, both with respect to geometrical structure and interlocking components.

Another strength of SLS printing is a much wider variety of useful materials, printed more accurately than is possible with other methods, resulting in stronger and more reliable parts.

Most SLS machines available today are extremely high-end 3D printers, and therefore cost a good deal of money. To see a few good examples of benchtop SLS machines, check out these 6 Benchtop SLS Printers for Small Businesses.

A Direct Comparison

The main similarity between these two technologies is the use of a laser. Lasers are not only much more accurate, they eliminate the need for heaters and hotends, and there isn’t any problem with prints warping.

Technology

In most SLA machines, the use of a mirror is where the laser becomes a problem. As the mirror is rotated, the laser point becomes slightly ovoid, which can impact the precision of the printer. SLS machines also experience this phenomenon, but to a much lesser extent due to the use of more advanced systems.

The higher power of the lasers in SLS machines make them more dangerous, and as such SLS machines are completely enclosed with no view of the print. In SLA machines, the laser is much less powerful, so tinted glass or plastic is used to allow the user to view prints without any harmful UV light escaping.

Material

The resins used for SLA printing are both expensive and toxic. Post-processing a resin print is also messy, time consuming, and slightly dangerous, as you do not want to touch the resin in its liquid form. In contrast, the powders used for SLS printing are easy to deal with. And while they are still pricey, they’re easy to clean from a finished print before further post-processing is implemented.

Finished Product

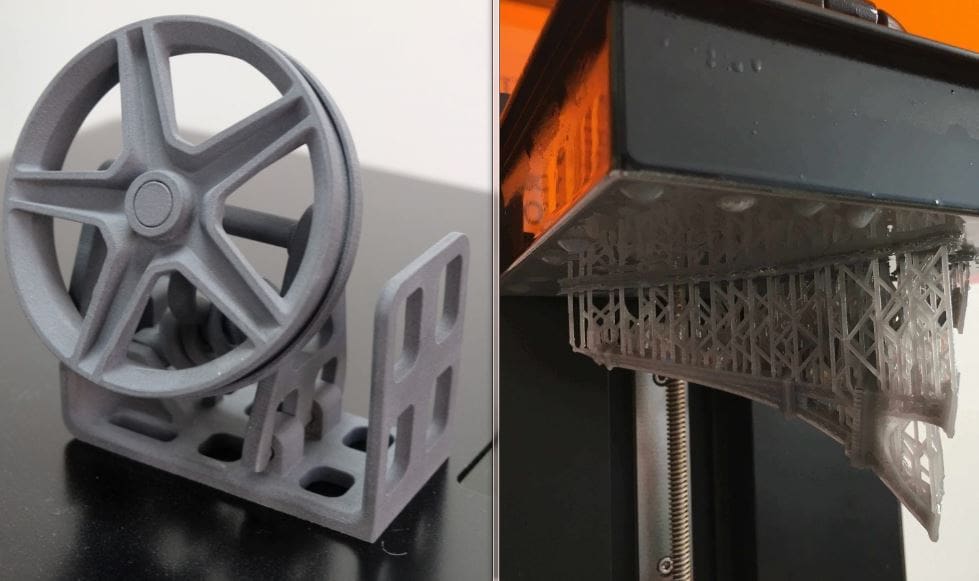

One of the biggest comparisons is the suitability of parts for different uses. SLA printers generally produce parts that are very high in detail, but brittle and not suitable for any mechanical purposes. SLS printers, on the other hand, are capable of creating decently high-detail parts in a number of different strong materials, like metal, that are perfectly suitable for any number of mechanical purposes.

Use cases aren’t the only important feature of printing, however. Another factor is how complexly models can be printed. Here, the lack of supports on SLS prints is definitely a helpful feature, aiding in the creation of increasingly complex models, where SLA would be limited by the need for supports. In both machines, print-in-place mechanisms are possible, but in SLA they are harder to post-process than in SLS. And again, the brittle quality of SLA prints makes them literally much less flexible.

Size

SLA printers are generally smaller, suitable for use as desktop machines. SLS printers, on the other hand, are still limited to “benchtop” models that are both large and require a lot of power. While SLA may be more convenient, SLS printing has the capability to produce larger models — or more small models faster — than an SLA machine. This is due to increased build area and the lack of the need for supports in SLS machines.

Cost

Another factor is cost. SLA and resin-based printers are now available for less than $500 USD, while SLS machines are still well over $5,000 per unit. And in both designs, the cost is compounded over time, as the materials are often proprietary and quite expensive.

Verdict

So how does it all pan out? That depends on what you need and how much you are willing to invest in a 3D printing machine.

If you are on a smaller budget, in need of super-high resolution models, but don’t need mechanical flexibility, then SLA is definitely the better choice. Have a look at our article on the best SLA and DLP printers available today.

If you’re a professional with a larger budget and need to be able to precisely print working models with high-end materials, SLS will be your best option. For a list of the best benchtop SLS printers, see this article on SLS machines for small businesses.

And if neither of these methods fit your needs, have a look at this article detailing all 10 of the 3D printing methods currently existing today.

3D Printing Service

If you’re interested in having something printed in SLA or SLS but don’t have access to the printers, consider using a 3D printing service. Through Craftcloud, All3DP’s 3D printing and price comparison service, you can easily find the best price for your needs.

Using your designs and location, we offer real-time prices from major global and local providers, including Shapeways, Sculpteo, and i.Materialise. In addition to taking the work off your hands, you can benefit from professional quality, a wide range of materials, and round-the-clock support.

License: The text of "SLA vs SLS 3D Printing: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.