Solid Edge and SolidWorks are both professional computer-aided design (CAD) and computer-aided engineering (CAE) software tools used for designing and modeling parts and assemblies in three dimensions. They have a lot in common, but let’s see what sets them apart so you can make the best software choice for your needs.

Both SolidWorks and Solid Edge use parametric modeling — creating 3D models by defining their parameters and constraints. This approach provides flexibility and efficiency in design and allows for easy modification and updates. Change a dimension or parameter, the software adjusts the model accordingly, helping designers and engineers iterate on their designs quickly.

Although most young designers won’t have a choice of which CAD tool they’d prefer to use since it’s typically dictated by your company or engineering team, if you are in a position to choose for your organization, in this article we detail all you need to know about these two robust systems.

Ultimately, the choice between SolidWorks and Solid Edge often comes down to user preferences, specific project requirements (automotive, consumer products, electronics, etc.), and the overall workflow and size of your engineering team.

* Yes, we’re comparing Solid Edge “Classic” to SolidWorks “Professional”. Why? There are four levels of Solid Edge and three levels of SolidWorks and their feature sets do not align directly. The closest alignment of features is Classic to Professional. In fact, the most basic level for each of these (Solid Edge Design and Drafting vs. SolidWorks Standard) have comparable more features but they are not true representations of what these packages can do or how must people use them.

Prices & Licensing

Which one is cheaper isn’t a clear differentiator in this case because each software has various versions, add-ons, options, and licensing configurations. But before we get into all that, there is one clear choice if you’re looking for which one is free. That would be Solid Edge, which is free if you’re a student, educator, or qualified startup business. Solid Works, on the other hand, comes at a steep discount for these categories of users, but it doesn’t beat free.

Solid Edge & SolidWorks Overview

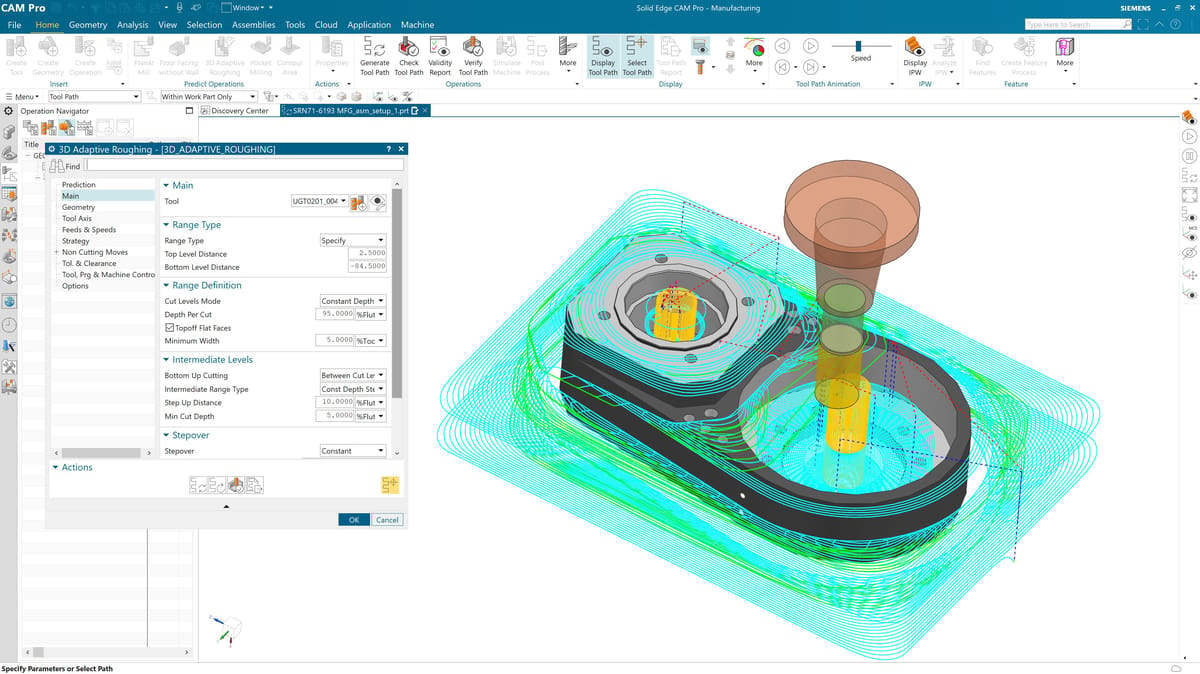

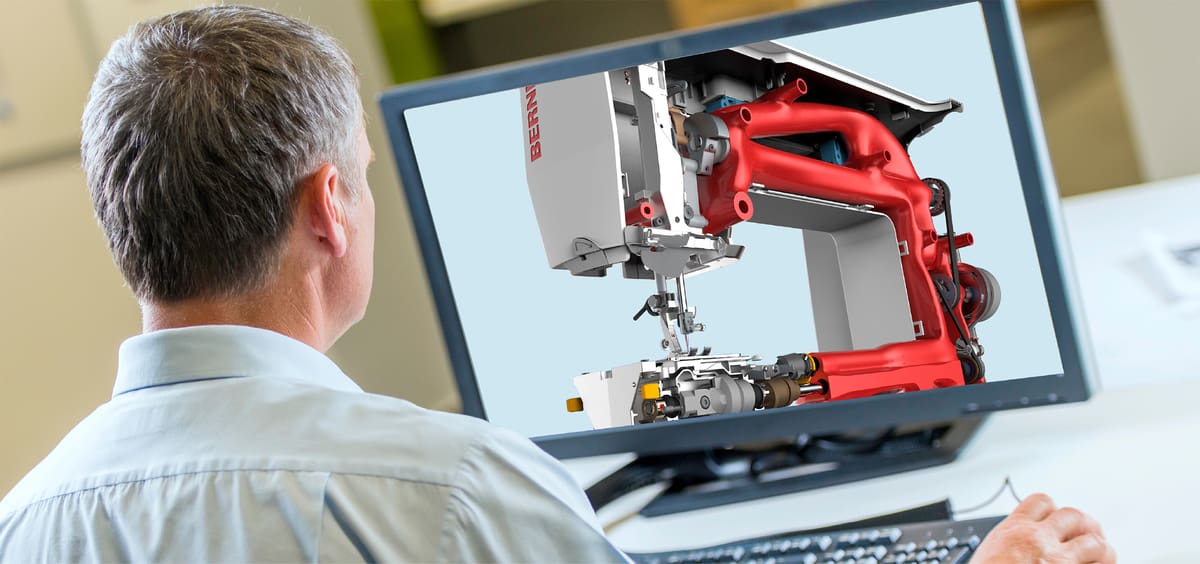

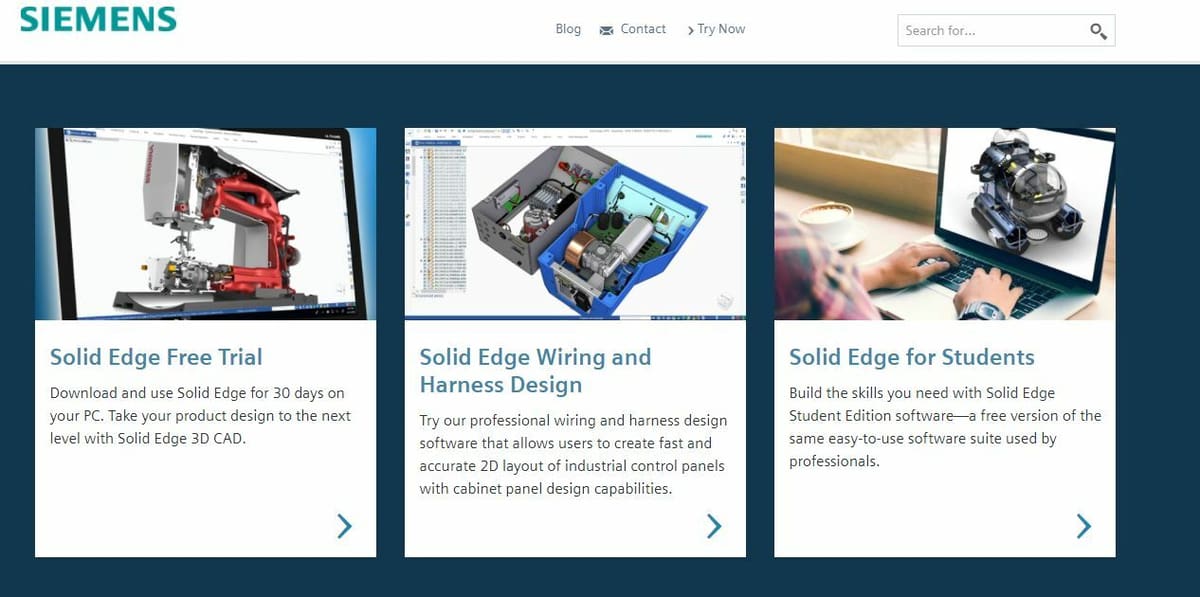

Solid Edge is developed by Siemens, the German engineering giant that offers a wide range of software products across various industries. In addition to Solid Edge for computer-aided design (CAD), Siemens provides solutions in manufacturing, automation, simulation, and product lifecycle management (PLM).

Sort-of the big brother to Solid Edge is Siemens NX, a comprehensive suite of integrated CAD, CAM, and CAE applications covering a broad range of product development processes, including design, simulation, and manufacturing. Where Solid Edge could lack some features and functions compared to SolidWorks, these would be found in NX.

SolidWorks is created by Dassault Systemes, a renowned French software corporation whose portfolio includes software like CATIA, a CAD and CAE solution with a product lifecycle management (PLM) suite, and Simulia, the robust simulation tool. SolidWorks has many components and complements you can buy for added functionality. In fact, like Siemens, Dassault Systèmes emphasizes the integration of its solutions to provide a holistic and collaborative approach to product development. Its software products are used in industries ranging from aerospace and automotive to manufacturing and life sciences.

How Much Does Solid Edge Cost?

Siemens is very upfront and transparent about what Solid Edge will cost you. It can be purchased as a monthly or annual subscription online, or you can buy a perpetual license through a reseller partner, many of which offer training. At the Siemen’s Solid Edge site you can access a handy chart comparing the features and functions of the four main subscription types: Design & Drafting, Foundation, Classic, Premium. There are volume discounts for each of these versions.

- Design & Drafting ($110/m, $983/y): This version is the base level with “basic” 3D part and assembly design, basic animation, 3D drafting, data import and reuse and access to cloud-based collaboration.

- Foundation ($268/m, $2,407/y): This version has “advanced” 3D part and assembly design, synchronous technology and convergent modeling to accelerate design and make revisions faster, along with a variety of features for sheet metal design, surface modeling, and jig and fixture design, plus cloud-based collaboration.

- Classic ($330/m, $3,012/y): Siemens says this is its most popular version featuring everything in Foundation plus 3D print preparation, generative design, basic motion simulation, basic stress and vibration simulation, advanced photorealistic rendering, and cloud-based collaboration.

- Premium ($481/m, $4,322/y): This is the “ultimate” Solid Edge package featuring everything in Classic plus advanced simulation, more design tools for applications, such as gears springs, beams & columns, PCBs, and electrical routing.

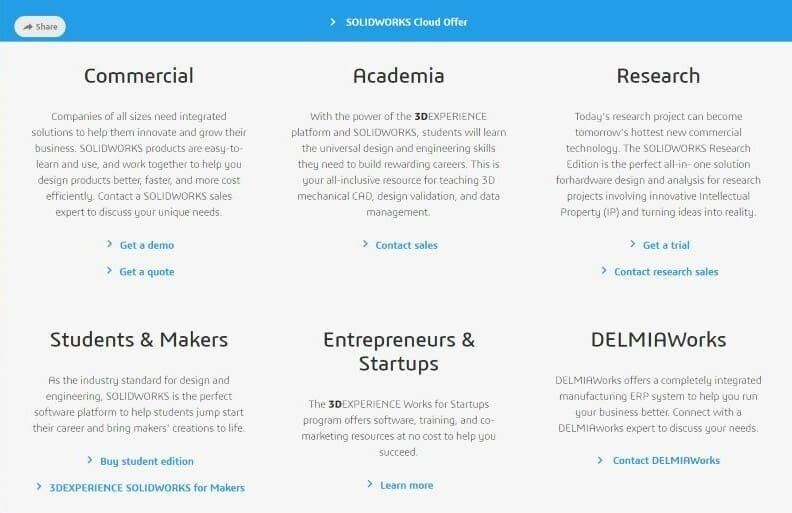

How Much Does SolidWorks Cost?

Unlike, Siemens, Dassault Systems keeps their prices behind a sales force wall, usually requiring you to create an account in order to be contacted by a sales person who will then divulge the prices. We can save you the trouble, see below.

Of course, the folks at Dassault Systems are not trying to hide the prices, and in fact working with a sales person is a good idea (for both brands) in order to really ensure that the subscription tier and type (Perpetual, Term, Standalone, or Network) and add-ons you’re buying will cover all that you need to do with the software and that you don’t over-buy features you really don’t need. So it can really save you money to work with a vendor.

Just like Solid Edge, SolidWorks has versions offering levels of features: Standard, Professional, and Premium available for subscription and perpetual license only through an authorized distributor, no online download. These distributors compete against each other to offer you a licenses, renewals, and tech support, so shop around and you’ll find discounts, bundled training and support, and other perks. In fact, be sure you like your vendor, you may be working with them a lot for training and support. Because of this competitive market and a lot of other factors that could ultimately affect the price you pay, our prices here are approximations.

- Standard (~$5,000/y plus ~$1,600 annual service charge): This entry version offers CAD, design reuse and automation, collaboration, design for manufacturing and productivity tools.

- Professional (~$8,000/y plus ~$2,000 annual service charge): This level includes everything in Standard, plus handy CAD libraries, a design for cost tool, CAD standards checker, reverse engineering tools, and some more time-saving features.

- Premium (~10,000/y plus ~$2,300 annual service charge): The top tier of SoldWorks includes everything in Professional, plus time-based motion analysis, static analysis for parts and assemblies, electrical cable routing, advanced surface flattening, and more.

You’ll notice there are no simulation tools. SolidWorks Simulation is another piece of software you’d need to add on. It is also available in three tiers — Standard, Professional, and Premium — depending on what and how you would like to simulate a part’s function.

Note that both Solid Edge and SolidWorks are only available for Windows, and their requirements are similar. Keep in mind that you’ll be working with heavy sets of graphics and operations, so a modern and capable computer will be fundamental to running either program in an efficient way.

UI & Layout

Solid Edge and SolidWorks have a somewhat similar UI. Both of them have all the necessary tools available at the menu on top, and you can find a listing of all existing objects in the viewport on the left side. In both programs, you’ll find the application button in the top left corner of the window, which can be used to access a complete menu of functions. Just next to the application icon, you’ll find a quick access toolbar.

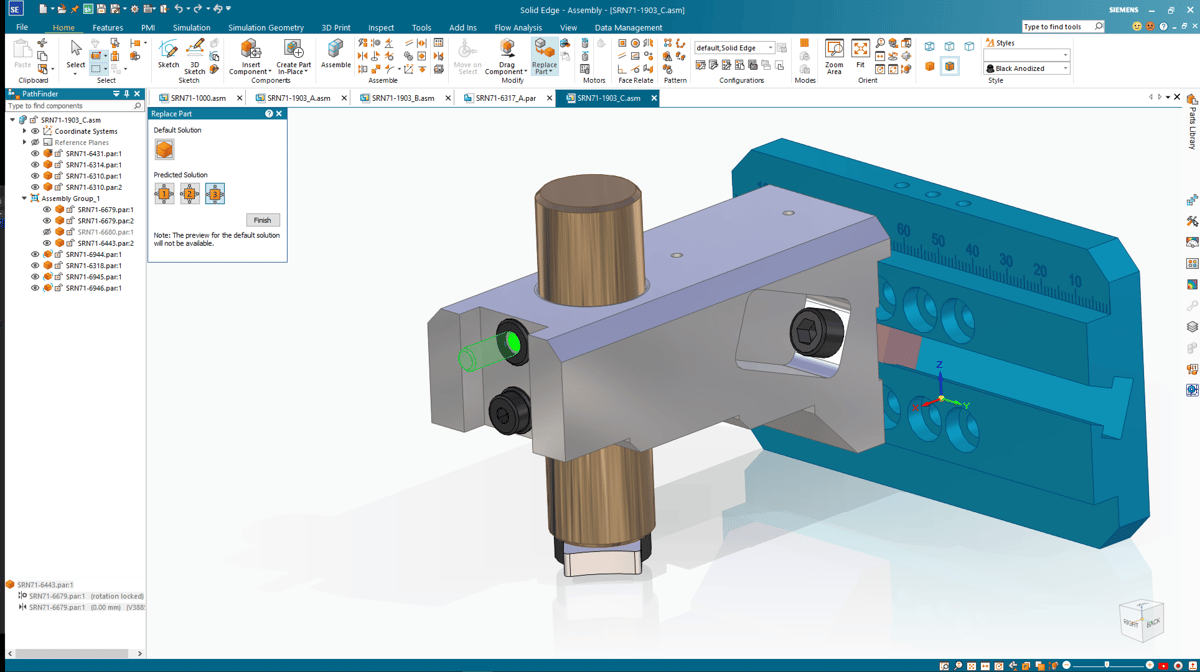

Solid Edge

At the very top of the Solid Edge window, you’ll see the Quick Access Toolbar, which includes standard commands such as save, undo, redo, as well as an option to customize it. Solid Edge has document tabs to easily switch between open projects, basically displaying tabs like you would in Google Chrome. This makes it easier to work with multiple files and is a slight advantage over SolidWorks, which doesn’t have it.

Much of the window is occupied by the viewport, also called the graphics window, which is where you see the model you’re working on. Above it, you can find a ribbon that includes all the program’s main features. On the bottom right of the graphics window, there’s the Quick View Cube to change the point of view from which you’re looking at the model.

On the left side of the window, you’ll see the PathFinder where all features relevant to a part are listed. Additionally, in this section, you can see and edit the model’s material.

On the right is the Learn Window, which offers tutorials and documentation. You can use the Command Finder at the bottom of the Solid Edge window to look up commands. The program will point you towards where to find them. This doesn’t exist in SolidWorks and gives Solid Edge a slight edge for new learners.

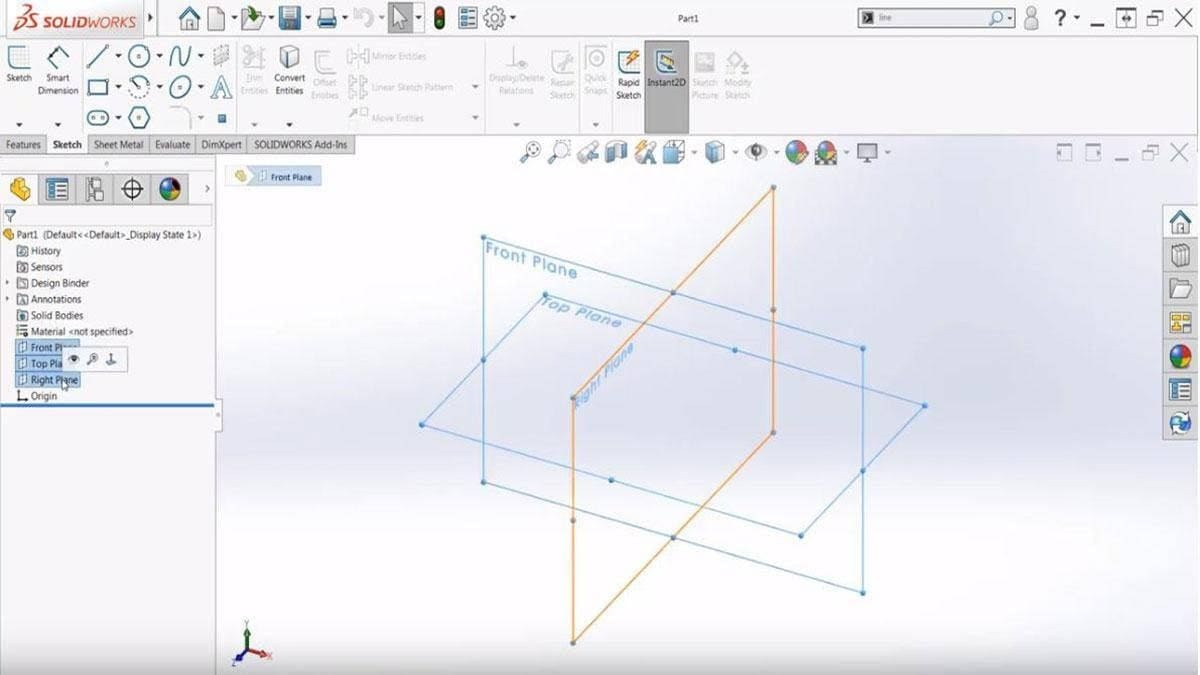

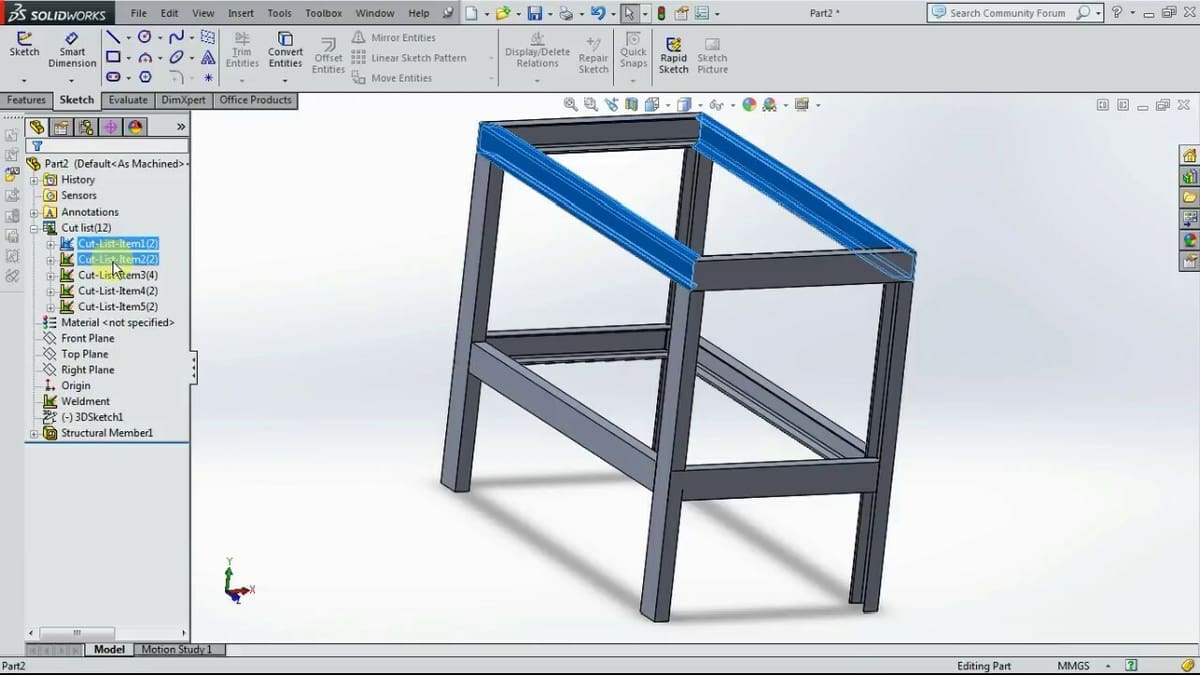

SolidWorks

SolidWorks lets you open multiple files at once. It doesn’t have a Documents tab, so you have to directly use the Window’s taskbar or use the hotkey “Ctrl + Tab” to switch between open files. A toolbar of document-level commands can also be found at the top of the SolidWorks window, and it includes the commands new, open, save, rebuild, and settings and customize.

Similar to Solid Edge, SolidWorks’ viewport – referred to as the graphics area – occupies the main space of the screen. On top, you’ll see the ribbon of main features, which is called the CommandManager in SolidWorks. In it, you can find commands such as sketching tools, features, surface modeling, inspect, among many others.

The left panel in SolidWorks is called the Manager Pane, and it’s organized in tabs. One of which is a features list that’s called the FeatureManager Design Tree. It’s definitely a mouthful, but this section is much more powerful than Solid Edge’s PathFinder. In SolidWorks, not only can you go back in time to undo some features and easily redo them, but you can also suppress features. As in Solid Edge, you can also see and edit the part’s material.

On the right of the graphics area, you can find extra functions like the Toolbox, which contains standard parts, or the orthogonal views if you’re in the drafting environment. Finally, in contrast to Solid Edge’s Quick View Cube, you can switch views in SolidWorks by using the floating menu – Heads-up View Toolbox – on the top of the graphics area.

Features & Functions

Solid Edge and SolidWorks share some features, but each shines on its own in different ways. In 3D CAD, sketching is the process of creating a 2D drawing that can be transformed into a 3D model using operations. Both programs allow you to go back and forth between 2D sketch and 3D model, creating new sketches as needed, to achieve a final 3D model.

Both programs are organized in environments, which are default layouts to either design parts, create blueprints, or create assemblies. For example, Solid Edge and SolidWorks both have dedicated drafting environments, allowing for the creation of 2D technical blueprints, which are necessary for building or assembling design parts.

Let’s go over more specific features available in each program.

Solid Edge

Solid Edge allows users to customize keyboard shortcuts and mouse movements for each environment, independent of the others. This makes the design pipeline more efficient.

The program has a 3D Print feature where you can prepare your model to be printed and send G-code directly to a 3D printer. If you don’t have a printer connected, the file can be exported for later use.

It also has weldment, metal sheets, and 3D sketching tools. You can import and export STL and STEP files, both of which are neutral file types. You can also export blueprints by using the “Print” option.

If you’re a beginner, there are “Heavily Assisted” and other assistance settings that walk you through the use of the program. This will certainly help you get started.

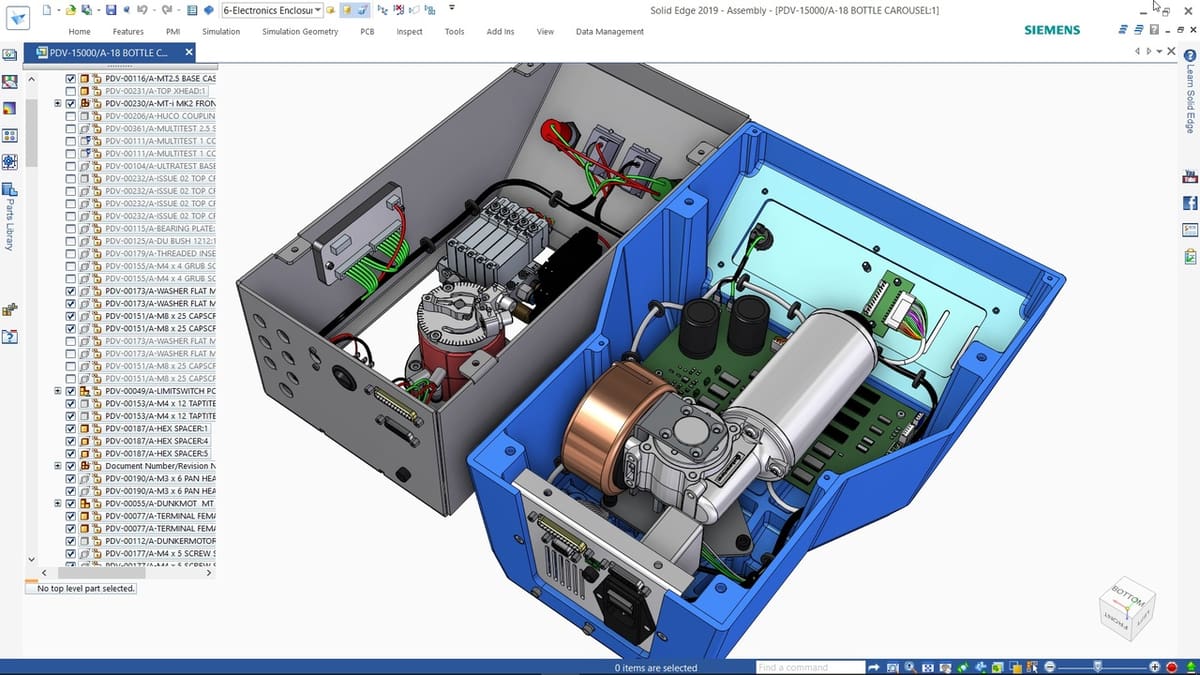

Though it’s not a feature per se, users rave that Solid Edge has a reliable performance even when working on complex and heavy assemblies.

SolidWorks

In SolidWorks, you can also customize the keyboard shortcuts and mouse movements and do so independently in each environment. In the drafting environment, you can generate PDF blueprints by clicking “Save As”, then selecting “PDF” as the file type.

Advanced features like weldments, metal sheets, and 3D sketching tools are included, and the program also supports importing and exporting STL and STEP files. Thanks to the Print3D feature, you can print models directly from the program and export files, among other functions.

A great advantage and one of SolidWorks’ selling points is the ability to work with multi-body parts. In just one part file, you can have multiple independent parts inside the part environment, which can be very powerful when modeling.

Although SolidWorks doesn’t have an assisted work mode, it does have symbols accompanying each feature name to illustrate what it does.

Use Cases & Applications

According to some in the community, Solid Edge isn’t as popular in professional settings, although there are certainly cases where it’s the default software used by a company. SolidWorks, on the other hand, is especially popular at an industrial level because of its comprehensive suite of weldment, metal sheet, beam suit, and tools to indicate beam cuts and weldments.

Solid Edge

Solid Edge’s features make it a great program for 3D modeling structural profiles, diecasts as well as hard surface modeling. It even has FEA simulation. The program is also great when you have to work in a team setting because it has a better team center than SolidWorks.

Solid Edge’s website features customer stories, which include both reviews and use cases. Some cool examples include an electric vehicle charger, a camper van, an entire cruise ship and a robot bartender.

SolidWorks

Thanks to the aforementioned suites, SolidWorks is a very effective and time-efficient tool to create machines, illustrate how it will be manufactured with blueprints, and even model structural sets to locate the machine. The program also works well for normal modeling, which can be used for simulations, exported as an STL for 3D printing, or other uses.

SolidWorks also has a site of customer stories. GATE Space used the software to design a satellite thruster, Australian manufacturer Swoop Aero developed the first end-to-end drone logistics platform capable of delivering vital payloads to remote areas, and Vuala created an innovative food waste container.

Company & Community Support

Even though there are plenty of community resources out there for both programs, it becomes harder to find information online (and even in formal educational settings) when you get to the truly advanced stuff. You usually end up learning the advanced features by word of mouth from other people more experienced in the field who also learned it from other people at some point.

Still, both programs have learning resources available, both official and unofficial.

Solid Edge

Searching for Solid Edge tutorials on YouTube is guaranteed to throw some useful results, and it’s also a good idea to check out the Subreddit where you can ask questions or participate in design challenges.

As for official support channels, Solid Edge has regional hotlines for technical support. The support page offers resources for education, documentation, training, and more, but you need to have a Siemens account and an active license to be able to access it.

SolidWorks

The same principle works for SolidWorks: A YouTube search will bring up a lot of tutorials and other resources, or you can access the Subreddit and connect with the community there.

As for official support channels, Dassault Systems has a hotline for technical troubleshooting and an online support page where you can find updates, tutorials, training and certification resources, and more.

Final Thoughts

Even though SolidWorks has a better history mode setting and allows multi-body parts, there’s not a significant difference in what one program can do over the other. You most likely won’t feel limited with either option.

At the end of the day, the choice will probably depend on budget, the software your educational institution provides and teaches, or what your company is asking for. If you’re interested in learning one of the programs to build up your professional skill set, a good idea might be to check which software is being used in companies that interest you, then invest in that one.

License: The text of "Solid Edge vs SolidWorks 2024: The Differences" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.