The Problem: Size

If you didn’t know already, waterjet cutting machines are capable of cutting materials that are both thick and hard. That’s nice and useful, but the tradeoff is that these waterjet cutters are usually big and heavy. They would look out of place anywhere but in a factory next to an automotive assembly line.

Luckily for those of us with smaller workshops, WAZER is making a machine that fits on a desktop, packing the raw power of waterjet technology into a manageable form factor.

WAZER: The First Desktop Waterjet

Beginning as a Kickstarter project, WAZER has already raised over $1.3 million in funding. If you pre-order one today, the company expects to get it to you by December 2018. With a price tag of $5999, including the water pump (the stand is an additional $250), this machine is a bigger investment than a 3D printer or CNC mill, partly because of its rarity but mainly because of its capabilities.

For starters, the WAZER packs the same power of its bulky, floor-stranded cousins in an elegant, compact package that fits on a tabletop. And because it’s the first of its kind to do this, it doesn’t take cues from any competitors, another factor contributing to its price.

Consider also that this waterjet cutting machine can slice the same kinds of materials as its giant brothers, from steel to ceramics to carbon fiber to stone. That’s impressive. The mere 3′ x 2′ cutting assembly and the 2′ x 1′ pump allows you to cut materials up to an inch thick.

And that’s the other factor that hikes up the price: the cutting power. This thing is a definite upgrade over your average kitchen knife or hacksaw.

How Well Does It Perform?

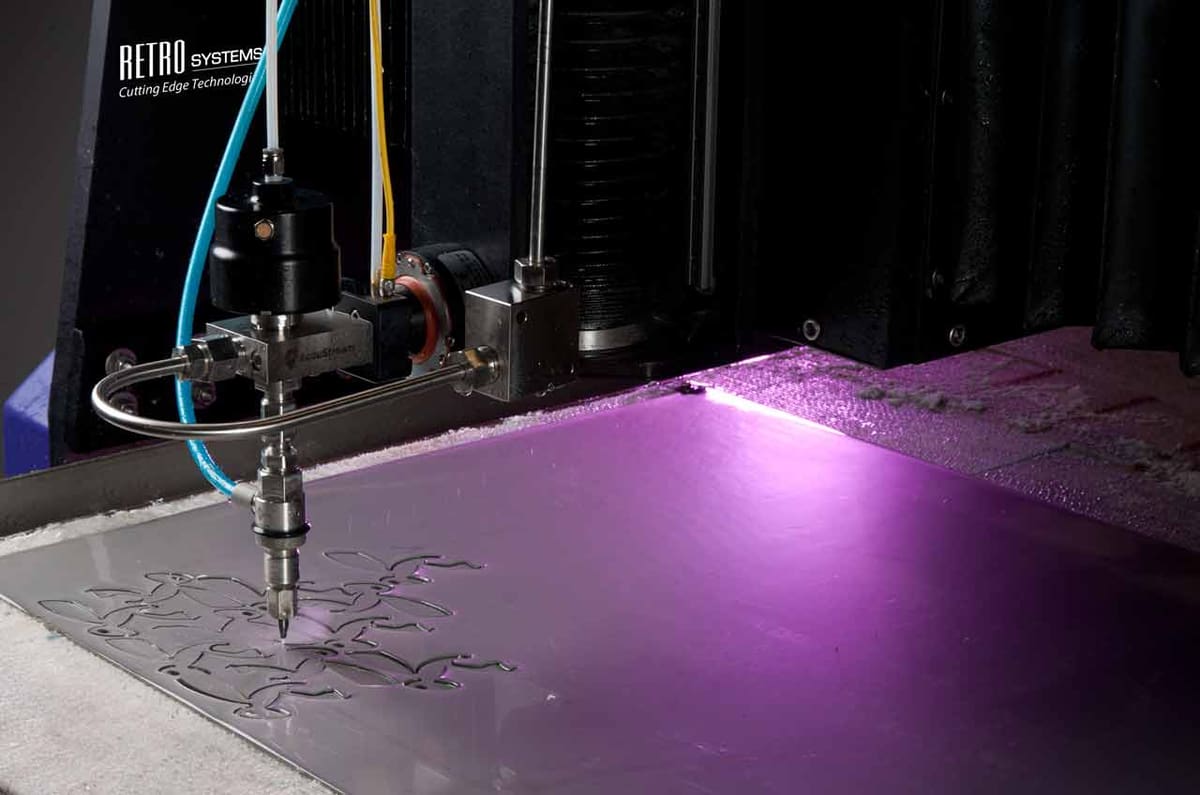

The company advertises WAZER being used for cutting many materials that would otherwise be difficult to cut in the precise shapes shown using other methods. This waterjet cutter machine consistently cuts glass, ceramics, china, steak, CDs, and all kinds of other things in lots of intricate designs. It’s been used to make a necklace out of pennies, floor tiles in custom shapes, bicycle belt gears, custom knives, and the list goes on.

Notice, however, that the objects are cut in a sheet-like, 2D nature. The stream of water that does the cutting slices right through the object to the bottom, so the layered cutting effects that could be achieved by, say, a CNC mill on a block of wood, would not be possible here.

Speaking of wood, you probably shouldn’t cut wood with this waterjet cutting machine as the combination of water and sawdust can make a mess. Not to mention the wood can be damaged by all that direct water exposure.

Also, if you feel like cutting some diamonds you have lying around in the garage, to make that tunnel boring drone, you’ll probably need to look elsewhere for a cutter. (We don’t currently have access to diamonds to test this, but it’s an educated guess).

How Does It Work?

To get this waterjet cutting machine running in your workshop, you’ll need electricity, a water outlet, a drain, and a bench or table that can support up to 136 kg, the weight of the machine when full. You could, of course, use the company’s own stand, which has generous space for the pump and cutting unit.

Most importantly, you’ll also need some consumable abrasive particles. Yes, it’s not just water doing the cutting. Garnet — more simply, crushed rocks — is combined with a stream of pressurized water to slice through whatever unlucky piece of material that happens to be under the nozzle.

But a good cut starts with a design and some software. WAZER provides their own proprietary software (shown above), which prepares the cutting instructions for their machine, using any .DXF or .SVG file as the input. It appears to be intuitive and gets the job done.

What's the Catch?

Obviously, this waterjct cutter machine has some limitations compared to its industrial cousins, which usually cost around $100,000. As explained on their FAQ page, the team at WAZER has managed to provide formiddable cutting performance with a much cheaper water pump that operates at a lower pressure. This means that although traditional, large industrial waterjets can cut two-inch steel 20 to 100 times faster, as the WAZER team puts it, “you probably don’t have to.”

Consider the fact that bigger waterjets also require trained operators, expensive maintenance, and sound like a herd of elephants operating chainsaws. Immediately you can see that WAZER really is a machine in its own class. The condensed form factor and more accessible design considerations of this machine makes waterjet cutting an option for many people when it ordinarily wouldn’t be possible at all. Still, it’s technically slower and not as capable as the bigger, more expensive machines.

In addition, you have to remember that the abrasive particles needed to cut things are a consumable and cannot be reused. However, the team does plan to offer the option of cutting only with water in the future.

But the biggest issue with the WAZER right now is that you can’t get your hands on it yet. Pre-orders are expected to ship in December 2018, which means that if you have a pressing need, you’ll have to find another temporary solution.

Other than that, there’s really nothing bad to say about this machine as it’s the first of its category. It wouldn’t be fair to compare it to industrial waterjets, and we’ll need to wait until we can test one ourselves before listing any complaints.

Last thing: Fun Facts about WAZER

Perhaps the most exciting thing about this waterjet cutting machine is that the company plans to make the hardware open source. That means that this desktop waterjet technology could manifest itself in many more machines, driving down price and increasing availability rapidly, as open source did for consumer 3D printing.

Something else to appreciate is the sound produced by this machine is, thankfully, not loud at all. The team even had a live demo of it operating onstage during a presentation at a Techcrunch event, proof of its compatibility with a livable human environment.

Furthermore, it’s nice that you don’t have to worry about pets or small children falling into the path of the all-powerful waterjet, since the machine is fully enclosed and immediately stops when the lid is opened. The company claims it’s impossible to get near the active waterjet while it’s cutting, which makes it quite safe for any workplace.

A Happy Conclusion

In theory, WAZER does a lot of things right: The concept of a desktop waterjet cutting machine is an exciting opportunity that many people will appreciate. We’ll have to see how flexible, capable, and reliable it really is after the first few batches ship, but early fans should have no trouble pre-ordering this innovation.

After all, it’s a remarkable achievement in itself that such a large system could be shrunk down to this desk-sized version. And the very real possibilities that emerge with such a machine will keep us happily tinkering for a long time.

License: The text of "WAZER – The First Desktop Waterjet Cutting Machine" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.