3D printing is one of those terms often associated with sci-fi stories or cutting-edge institutions like NASA. But the technology is already a reality for many people, with hundreds of new users starting their 3D journey every year.

This article will provide an overview of 3D printing technologies, including the different types of processes available, the materials, and some of the current and potential applications.

We’ll also discuss how someone can get started with 3D printing, whether you’re a professional, a hobbyist, or just curious about the technology. But let’s start from the beginning.

What Is 3D Printing?

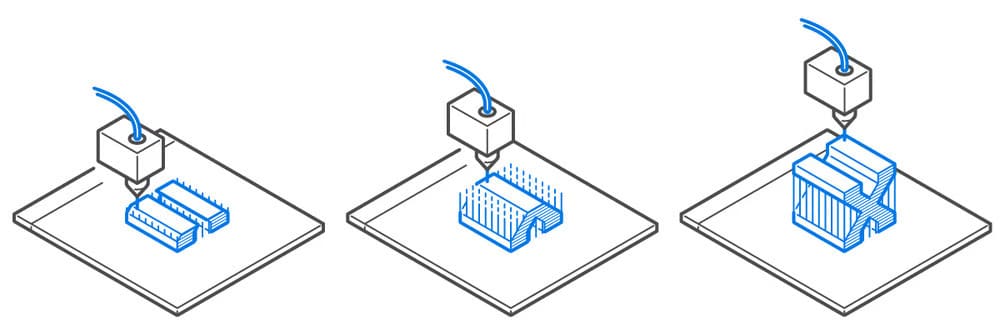

In a few words, 3D printing is a type of manufacturing process in which a machine creates a three-dimensional object by building up successive layers of material.

This process is also known as additive manufacturing (AM) since it contrasts with traditional manufacturing methods such as subtractive manufacturing (machining) or formative manufacturing (casting or molding), which typically involve cutting away or shaping materials to create the final product.

While there are different 3D printing technologies, many aspects of 3D printing make it special compared to other traditional fabrication techniques.

For instance, additive manufacturing can produce shapes and parts that are either difficult or even impossible to create using other fabrication methods while also providing an unprecedented level of flexibility to production systems.

But hang on: we’ll explore more of 3D printing’s advantages further on in this article. First, let’s take a closer look at the more home-friendly 3D printing processes, also known as desktop 3D printing.

Desktop 3D Printing

The term “desktop 3D printing” refers to the use of personal and relatively inexpensive 3D printers that can be used at home or in a shared office. These machines are typically smaller and less complex than industrial 3D printers, being specifically designed for prototyping and small-scale production.

Desktop 3D printing was made possible by the RepRap project, which was started in 2005 by Dr. Adrian Bowyer to create a low-cost machine that could replicate itself and make 3D printing accessible to everyone.

The RepRap project has turned into a community and has been very successful in terms of democratizing access to desktop 3D printing machines, particularly filament machines based on fused deposition modeling (FDM) technology.

Today, desktop 3D printers are typically FDM or resin-based machines and are becoming more and more accessible as their costs decrease, the amount of online information increases, and the overall technologies improve.

3D Printing vs. Additive Manufacturing

So, while “3D printing” is more often used to refer to non-industrial machinery and processes, such as small office printers based on filament and resin materials, what is meant more specifically with “additive manufacturing”?

Both terms refer to the same general process of creating a physical object by adding layers of material, but they’re conventionally utilized for different kinds of processes.

Additive manufacturing is a broader term that encompasses a variety of technologies that are used to create objects by adding material. The different technologies under this umbrella term are defined by ISO/ASTM standards, which include technologies like powder bed fusion and binder jetting.

Having gotten a clearer idea of what we’re referring to, let’s clarify how a typical 3D printing process works.

How It Works

Regardless of the specific technology, 3D printing processes typically follow a general workflow that involves these steps:

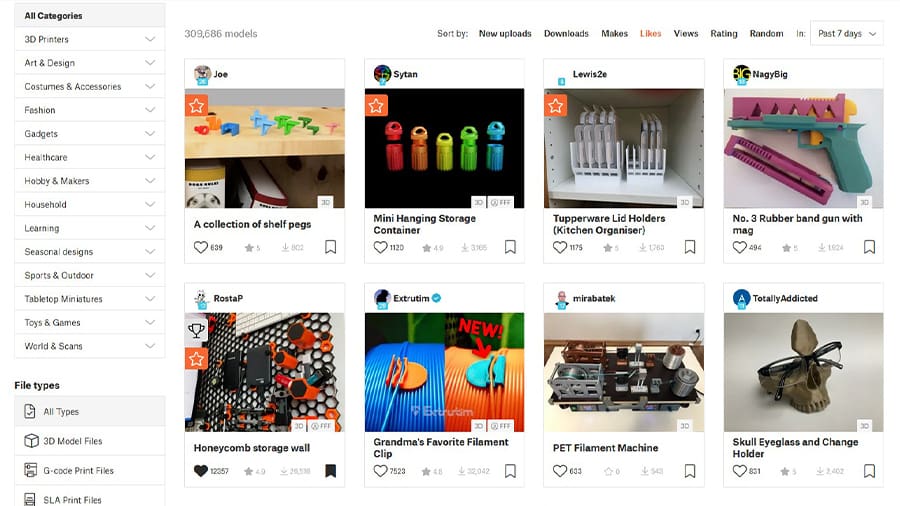

- Digital design: The first step in a 3D printing process is to create a digital model of the object through 3D modeling or computer-aided design (CAD) software. The 3D model can be designed from scratch or copied from an existing object via 3D scanning techniques, or it can be downloaded from a model site. The latter case will more than likely be limited to non-commercial use.

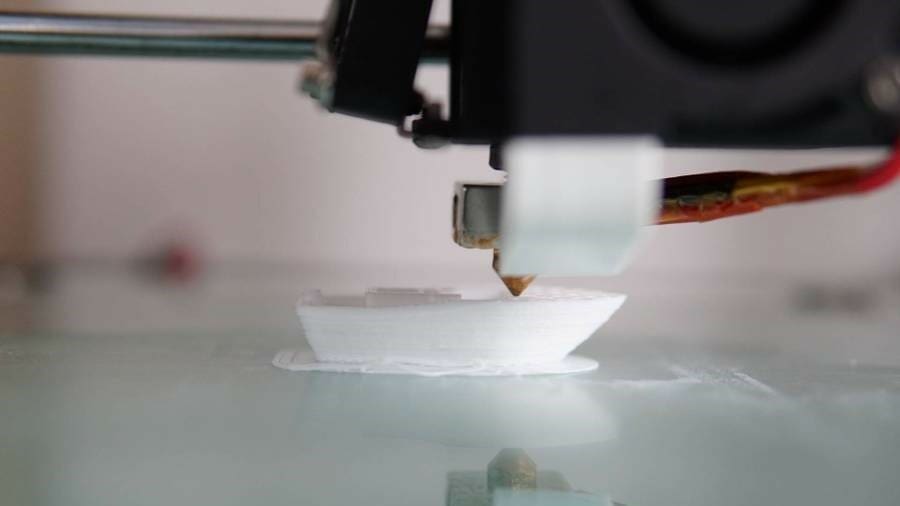

- Preparation: Once the digital model is complete, the file is then prepared for 3D printing based on the specific machine and technology. The 3D model is split into several thin layers, in a process known as 3D slicing, and a machine code (G-code) is generated to instruct the 3D printer how to create the object.

- Fabrication: The prepared digital file is then sent to a 3D printer, which interprets the code and creates the object by adding material layer-by-layer.

- Post-processing: The printed object then goes through post-processing, which can include finishing steps such as cleaning, curing, painting, or the removal of additional structures created to support the fabrication. The specific type of post-processing and adjacent requirements will depend on the specific technology and material(s) used.

Materials

While additive manufacturing technologies work with a wide range of materials – including steels, titanium, plastics, and ceramics – desktop 3D printing has a rather limited range of materials.

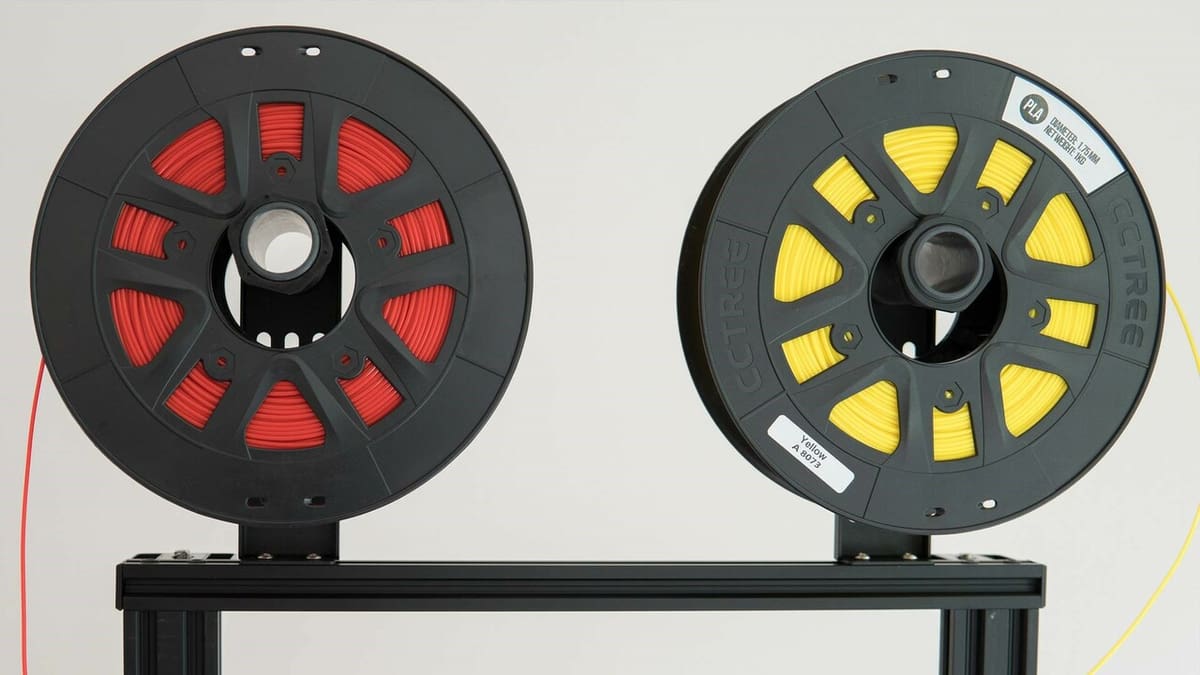

The materials for FDM 3D printing are all different kinds of thermoplastics and typically come in spools of filament that are fed into the 3D printer’s extrusion system.

The most popular FDM materials include PLA, a natural polymer made with starchy crops such as corn and sugarcane, and which is very easy to 3D print with; ABS, a strong and durable plastic used by industry in general, notable for producing Lego bricks; and PETG, a PET variant plastic known for its durability and heat resistance.

Other less popular FDM filaments include traditional plastics such as nylon, TPU, polycarbonate (PC), and other specialty and exotic materials such as those with carbon fibers, wood, and even metals.

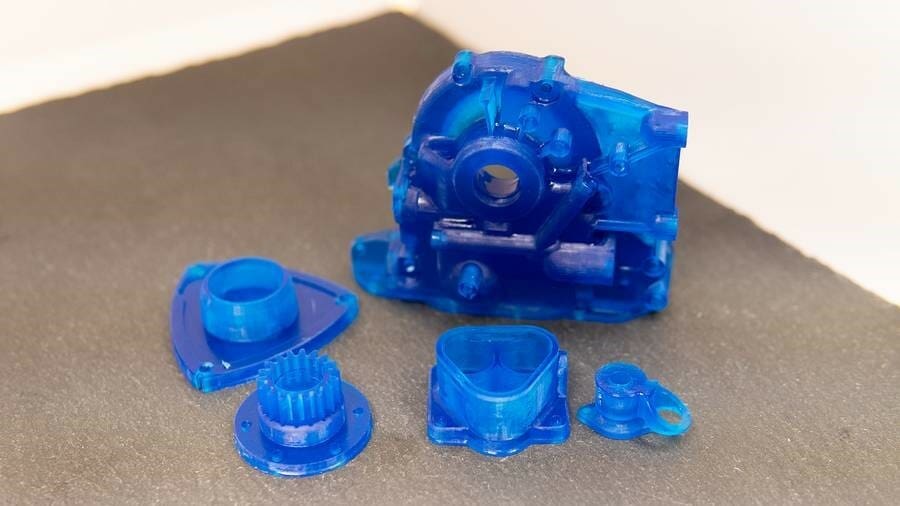

Resin 3D printers, on the other hand, use a liquid resin material that is cured by UV light to create successive layers of the object. While this technology is mostly known for its high resolution and detailed parts, it also offers a good range of materials for different applications.

The so-called standard resins remain the most common material for resin 3D printing, and they are mostly the same regardless of the specific technology (LCD, DLP, SLA). There are also specialty resins available, such as flexible, rigid, and even castable resins to create molds for casting processes.

Applications

As desktop 3D printers became more and more accessible, both individuals and small businesses started incorporating these machines into their daily routines. Today, there’s a wide range of applications for desktop 3D printing, but here are the most prominent for both professionals and hobbyists:

Professional Applications

- Prototyping: One of 3D printing’s main benefits is the ability to quickly and inexpensively create mockups and functional prototypes, speeding up product development processes and reducing the associated costs.

- Architecture: Architects and interior designers can easily 3D print models of buildings and interiors to help them communicate their vision to customers. 3D printing allows the creation of architectural models much quicker and cheaper than with traditional methods.

- Jewelry and fashion: 3D printing allows jewelry and fashion designers to create unique and intricate pieces that would be either impossible or not cost-viable to be fabricated using traditional manufacturing methods. 3D printing also allows the small-batch production of such design pieces.

- Education: 3D printing is already widely used as an educational tool in classrooms and universities, and not only for STEM learning. For instance, ancient artifacts can be 3D printed for history classes and topographic maps for geography studies.

Personal & Hobbyist Applications

- Home decor: Unique home decor items can be easily created with 3D printing, such as vases, planters, sculptures, and wall decorations. There is an endless amount of ready-to-print decor 3D models available in online repositories for free.

- Spare parts: With some 3D modeling knowledge, home users can design and 3D print replacement parts for broken items such as utensils, toys, cabinetry, and electronics housings. Replacement parts can also be created for lost board games pieces, for example.

- Tabletop gaming: Home 3D printers, especially resin-based ones, can create beautiful pieces for tabletop gaming, such as miniatures and terrain tiles. This is an immensely popular application for desktop 3D printing and the reason why many people get into the hobby in the first place.

- DIY projects: Last but definitely not least, 3D printing can be used for a huge variety of DIY projects, especially with electronics such as microcontrollers and single-board computers. The best part is that not much experience is needed since many shared projects online offer detailed instructions for all user levels.

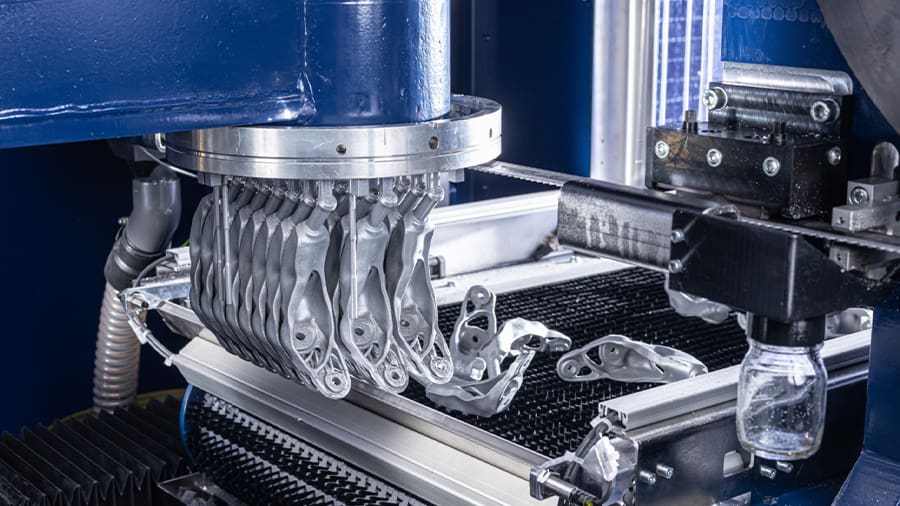

There are, of course, plenty of other applications for industrial 3D printers, particularly in the medical, aerospace, automotive, and construction industries.

Pros & Cons

Compared to century-old manufacturing techniques like traditional machining and injection molding, 3D printing is a more contemporary technology. This generates both new exciting possibilities and many challenges for the manufacturing industry.

Pros

- Geometric freedom: The layer-by-layer additive technology of 3D printing can produce highly complex geometries and internal structures that are either impossible or cost-prohibitive to create with traditional manufacturing methods.

- Customization: 3D printing allows the customization of industrial products with no additional cost, as the digital model file can be easily modified and there’s no need for special manufacturing tooling like molds and fixtures.

- Low volume production: Unlike traditional manufacturing processes, the unit cost of 3D printed parts is fixed regardless of the number of parts produced. This makes the production of small batches of parts economically viable, although some outsourced services may have minimum requirements.

- Rapid prototyping: 3D printing allows for the quick and cheap production of physical prototypes to test and validate products before ramping up production. This drastically reduces product development times and allows designers and engineers to create better products altogether.

- Production flexibility: The digital nature of 3D printing technologies and the no-tooling requirements provides a flexible production environment. Additive manufacturing is also possible with a wide range of materials, including plastics, metals, ceramics, and even edible and biological materials.

Cons

- Lower production speed: 3D printing is generally slower than traditional manufacturing methods for producing high volumes of products.

- Higher costs: As of the time of writing, 3D printing machines and processes can be more expensive than traditional methods for certain parts, especially when using high-end materials.

- Post-processing: 3D printed parts often require additional finishing steps, such as sanding, polishing, or painting, to achieve a smooth surface finish and manufacturing tolerances.

- Quality control: This remains a very challenging task for 3D printed parts, especially for larger or more complex parts.

- Limited scalability: 3D printing is generally limited to small-scale production, as larger-scale production would require multiple machines and a significant increase in costs. This makes traditional manufacturing methods still more cost-effective for larger production runs.

Getting Started

If you’re interested in 3D printing, there are a few things you need to know to get started.

Choosing a 3D Printer

The first step is to choose a 3D printer. FDM printers are the most common type of desktop 3D printer and are well-suited for beginners. There is a wide variety of machines for every budget and abundant filament manufacturers available.

Resin 3D printers, on the other hand, can be a little messier in terms of operations due to the post-processing steps, such as cleaning the prints in alcohol solutions and post-curing. Yet, they are very rewarding in terms of the part’s detail and surface finish.

Regardless of the 3D printing technology, it’s always a good idea to ensure that your future 3D printer is popular and has an invested user base that will support you through your 3D printing journey.

Learning the Ropes

Once you’ve chosen a 3D printer, you’ll need to learn how to use it. This involves setting up the machine, loading and unloading materials, and performing basic maintenance and troubleshooting.

You’ll also need to download and learn how to use 3D printing software, most importantly your 3D slicer program. While many machines come with proprietary slicer software, most desktop 3D printers are compatible with free third-party slicers that usually offer more functionality and performance.

You should also be aware of the particularities of each 3D printing material. It’s definitely a good idea to start with easier materials, such as PLA for FDM and standard resins for resin 3D printers.

Getting 3D Models

Once you’re trained and accustomed to your machine, the next step is to find or design the 3D model to print.

The easiest way to get started is by finding ready-to-print files in online repositories. There’s a huge availability of models online, ranging from free to paid models, and there’s probably a model somewhere that suits your needs if you put in the time to look.

However, that’s not always the case, and sometimes you might need to create the models yourself. There are different ways to create a 3D model, but they usually involve some kind of design software such as computer-aided design (CAD) and 3D modeling programs.

Designing your own files requires more effort than simply downloading a pre-made one, especially if you have no previous experience with it. However, it’ll definitely be worth it in the long run, and there are many beginner-friendly 3D modeling software with great tutorials.

Practice Makes Perfect

It all might sound a bit overwhelming at first, but rest assured that it’s not all that complicated. Time and practice are your best friends here, along with proper tutorials, troubleshooting guides, calibration tips, and community support.

With a little patience and perseverance, you can become a 3D printing specialist in no time!

The Future

3D printing has always been promising and hyped. As the technology matures, the more accessible, versatile, and efficient it becomes.

While the big dream of having your own personal factory at home is still far away, there’s no denying that owning a production machine is extremely attractive. In the same way that personal computers and smartphones have empowered billions of people, 3D printers might do the same for manufacturing.

A lot of 3D printing enthusiasts say that 3D printers will soon be an integral part of every household, shifting the balance between manufacturers and consumers. Others say the technology is not there yet, and that its true value lies exclusively in the industrial sphere.

What Could Hold 3D Printing Back?

There are several arguments against the widespread adoption of home 3D printing. Operating 3D printers still requires technical knowledge that ordinary consumers simply don’t want to bother themselves with.

The same goes for 3D modeling and CAD software, where the learning curve may be even steeper. While users will always be able to download pre-made designs and make quick and easy changes to them, they’ll always be tied to what’s available online.

Another big limitation of desktop 3D printers is the material availability. While the range of materials is constantly growing, they’re most often restricted to plastics. Similarly, multicolored and multi-material 3D printing — while possible on a handful of machines today — isn’t nearly widespread enough.

What About Industrial 3D Printing?

The field of additive manufacturing has already overcome many of the challenges associated with being a new and innovative technology. Different industrial 3D printing technologies are now an integral part of production systems and operations, with notable examples like aircraft parts production and custom prosthetic limbs and implants.

One of the biggest challenges additive manufacturing is facing is in the field of mass production. 3D printing is already in use for low-volume production, but as the technology matures, it should also become a viable option for scale production. This could lead to more companies using additive manufacturing technologies to improve the performance of existing products, such as automotive parts.

The field of materials is also evolving rapidly, with new ones being developed and existing ones being combined to produce new material properties. The use of innovative materials will definitely open up new possibilities for industrial 3D printing.

A Bright Future

From households to the factory floor, the future of 3D printing is very exciting. New technologies, applications, and materials are on the way! It has the potential to completely change the way products are designed and manufactured, and the future looks extremely bright. So much that we might all need some 3D printed sunglasses real soon!

License: The text of "What Is 3D Printing? – Simply Explained" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.