Reexamining the Wheel

Generally speaking, reverse engineering is learning how something works for the purpose of recreating it. There are several different uses of this process, including basic understanding, interfacing with existing products, reproduction, and determining patent infringement.

Since the rice of additive manufacturing (and subtractive manufacturing before it), reverse engineering has taken on a whole new meaning. Now, almost anyone can reimagine existing products to get longer life out of them using 3D printing.

In this article, we’ll take a look at common reverse engineering applications, especially from a maker-centric point of view, as well as the basics behind the process. We’ll then check out a couple specific examples before ending with a point on commercial use cases.

Applications

For an individual maker, common reasons for reverse engineering a product or software fall into one of three categories:

- Recreating inaccessible hardware/software

- Proprietary, inaccessible software or hardware can be recreated in an accessible form. This is the concept behind some open-source software and open-access designs.

- Reimagining existing designs to improve them

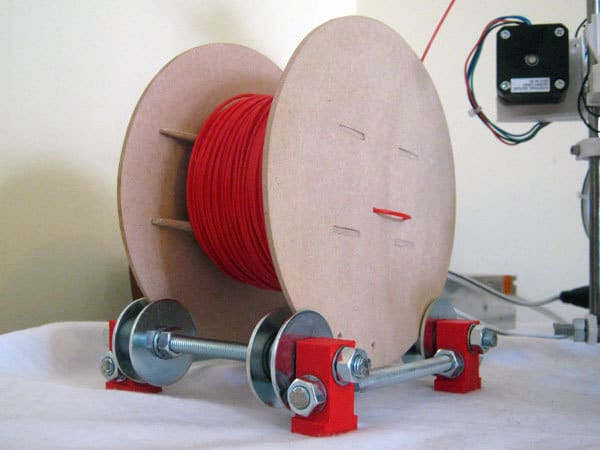

- In the world of 3D printing, this is quite common, especially on many 3D model sites. For example, many of the most popular models have remixes and recreations. One generic example is the humble spool holder. Although some of the designs differ slightly, the general theme is the same, with some simple versions as well as complex auto-rewind spoolers.

- Interfacing with an existing product

- Oftentimes 3D printing and machining are done to bring an existing product back into a useful state by creating a part that can function as a bridge between old and new technology. This is quite often done in software that uses an older computer language or with hardware when an old device is decommissioned.

Measuring & Scanning

A common goal in reverse engineering is to recreate the physical dimensions of an object.

Measuring & Modeling

For simple geometries or objects that require tight clearances or tolerances, a common approach is to physically measure an object, using simple measuring tools like calipers and rulers, and model it, using a CAD tool. Say, for example, one wanted to replace a broken foot on the bottom of a sofa. Using one of the intact pieces, assuming a simple geometry, one could model the part. Simple CAD tools, like Tinkercad, allow even novices to produce basic objects.

Naturally, the more complex the object, the more modeling experience one needs to use this method.

3D Scanning

The next best option for recreating an object is to scan it. A 3D scanner is a device that uses either a camera or laser light to photograph an object from different angles in order to reconstruct a 3D model of the device.

There are several factors to pay attention to when it comes to 3D scanning for reverse engineering:

- Scan volume: Generally, you’ll want your scan volume to be at least as large as the maximum volume your printer can print. In that case, you’ll be able to use the full capabilities of your 3D printer with your scanner. Many consumer-level printers start at around 200 x 200 x 200 mm, which is around the same size that many 3D scanners can scan.

- Resolution: This really depends on what you’d like to scan and recreate. For larger objects, such as a jewelry box, a low scan resolution on the order of 0.5-1 mm is generally fine to still give an accurate representation (from a 3D printing perspective). On the other hand, if you’re trying to recreate small parts, like a Lego brick or smaller, you may need a much higher resolution.

- Note that, for FDM printers in general, the best resolution you can achieve in the XY plane is about the same as the nozzle diameter (0.4 mm for most printers). Therefore, for detailed parts, you should try to have a scan resolution that’s less than your best printable resolution (less than 0.4 mm). You may not see significant improvement below that, unless the functional part of your print is printed with the Z-axis (i.e. where resolution can be much smaller at 0.1 mm or less).

- Technology: There are many technologies in use for 3D scanning today, but the two most popular are laser triangulation and structured light. Generally, laser triangulation methods tend to be more accurate, however, there can be a disadvantage with using a laser if the part you’re trying to scan is highly reflective or absorbs the laser light.

- Cost: Cost for 3D scanners varies widely. Professional scanners can cost several thousands of dollars, whereas consumer-level options, such as an Xbox One Kinect can be as low as $99 with a resolution of 0.5 mm.

Advanced Scanning

One thing to note about 3D scanning is that scanners generally only scan the surface of a part and therefore miss internal geometries and features that are not easily visible from the outside.

For commercial reverse engineering, often the internal structure of a device is also important to the final functionality. So to scan the internals of an object, a different type of 3D imaging called computed tomography is used. This generally uses X-rays or other forms of penetrative radiation to see through an object, recording internal geometries as well as external surfaces. This type of scanning can be particularly useful if the disassembly of an object would destroy it.

Tantalizing Examples

Lego Bricks

Lego bricks have not only been reverse-engineered and posted to 3D websites, but there are even legal issues surrounding the reverse engineering of Lego using 3D printing. This covers not only the concept of recreating a product but also the improvement of a product through the successful interfacing of Lego bricks with other types of construction sets.

G-Code to STL File

Oftentimes, to prevent a digital object from being reverse engineered, the file format is released in a format that isn’t easily convertible. For example, a 3D printer can print a G-code file, but G-code files are not particularly known for their ability to be loaded and edited in 3D modeling software. Yet, a couple methods of reverse engineering G-code back into an STL file do exist, bringing about the recreation of an editable digital object.

Further Use Cases

You might think reverse engineering is just making small changes or replicating an existing object, but it has profound implications for our world far beyond making cool new Lego bricks. There are many companies dedicated to the process of reverse engineering an existing product to understand how it works.

Commercial Uses

Commercial reverse engineering services go far deeper than simply 3D scanning an item to recreate it. As the company Arrival3D puts it, “reverse engineering requires some understanding of the original designer’s thought process.” What they’re talking about is the concept of tolerancing and figuring out how parts fit and move together when they are intended to be used rather than how a particular part may look or function.

An individual part may have flaws or artifacts that do not affect the design in any noticeable way that would be expensive or difficult to replicate. Their business provides reverse engineering services for things like patent drawings, machining, and molding parts.

For military applications specifically, companies like PHT Aerospace provide reverse engineering services for things like motors, radar systems, and power supplies for obsolete military equipment. This type of reverse engineering is crucial for national security purposes, as it allows extremely expensive defense systems to be updated to modern electronic and software specifications without the costs and time associated with building new systems.

Overall, reverse engineering is crucial to our world from the mundane home use cases to things like national security. As the old adage goes, “If it isn’t broken, don’t fix it.” Hence reverse engineering will continue to be useful far into the future.

(Lead image source: pinshape.com)

License: The text of "What Is Reverse Engineering? Meaning and Definition" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.