The rise of online 3D printing services and beyond has made it possible for hobbyists, consumers, investors, and businesses, big and small, to take advantage of all the features that come with on-demand manufacturing. Two key companies in this industry are Xometry and MFG.com, both of which make it easy to turn your 3D model (or other project) into a reality.

Not only do Xometry and MFG.com narrow the gap between customers and manufacturers, but they also help update how parts are designed, made, and sent to customers. Both companies are heavily involved in the digital marketplace and have their own global network of partners, but they do have some differences in how they operate and in their business models. These platforms have experienced remarkable growth in the past few years, exerting their significance in the current landscape and beyond.

In this article, we’ll take a look at how these two companies stack up in terms of services, materials and finishes, pricing, and more. Let’s get started!

Consider Craftcloud

Before diving further into our comparison, we would like to introduce Craftcloud, a global 3D printing marketplace.

Craftcloud is your gateway to a comprehensive portfolio of 3D printing service providers around the globe. With Craftcloud, you can choose from over 20 different technologies and more than 100 different materials and finishes. By simply uploading your digital file, you’ll instantly receive real-time quotes from our thoroughly vetted partners. From these options, you can choose the least expensive provider, or perhaps you need the fastest delivery or a combination of both. The choice is up to you!

With personalized, efficient processes, Craftcloud allows users to save time and resources when it comes to seeing their 3D printing projects come to life.

Background

Before we cover Xometry and MFG.com’s services, let’s take a look at each company’s business model and history.

Xometry

Xometry was founded in 2013 by Randy Altschuler and Laurence Zuriff. As mentioned, the company is a key player in the custom manufacturing landscape. From small businesses to large enterprises, the platform extends its services to various industries to help produce prototypes, low-volume orders, and manage large-scale manufacturing projects. It helps buyers accelerate production cycles, produce reliable design iterations, and quickly verify design concepts.

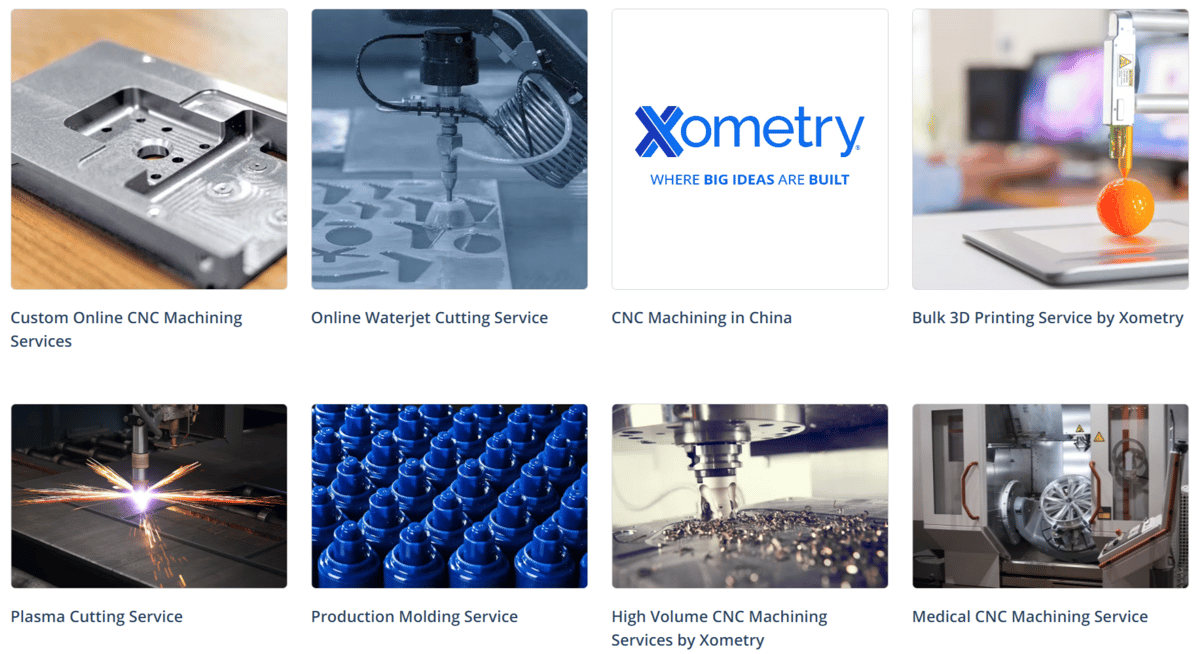

The platform offers a wide range of manufacturing services, including CNC machining, 3D printing, sheet metal fabrication, and injection molding, among others. The versatility of the services offered ensures Xometry reaches a wide array of industries, including aerospace, medicine, automotive, and consumer electronics. Reporting over 10,000 global production partners across the US, Asia, and Europe, Xometry claims to be the largest network of its kind. Partners undergo a stringent qualification process to meet the industry’s established standards. These pre-qualified manufacturers provide access to a diverse array of expertise across the globe, from small machine shops to large-scale manufacturers.

MFG.com

Much like Xometry, MFG.com is a global marketplace with a network of over 100,000 suppliers capable of addressing extremely specific requirements for a project. Founded by Mitch Free in 1999 and acquired by Shapeways in 2022, their network has expanded to become a platform that streamlines the sourcing process for buyers. They allow businesses to submit detailed specs to registered suppliers to view and competitively bid on. The platform acts as an intermediary and a meeting place between customers and suppliers, helping buyers make decisions for their specific needs.

MFG.com reports over 100,000 monthly visitors to their platform, claiming to be the number one online marketplace for custom manufacturing. Thus, MFG.com can deliver special projects and complex commissions, whether it’s for intricate aerospace components or medical-grade equipment. Customers facing unique manufacturing challenges can leverage MFG.com and its impressive roster of go-to solutions. Overall, their available services go beyond what is readily available in similar online manufacturing platforms.

Similarities & Differences

When comparing Xometry and MFG.com, several similarities and differences emerge. Both Xometry and MFG.com operate within a digital marketplace, connecting buyers with service providers around the globe, along with a vast library of services and materials.

While they both operate in the same market, they do have some differences. While Xometry has an instant quoting tool, matching customers with a service provider within seconds, MFG.com has a bidding environment where potential customers can submit project details and receive a quote within a few days from suppliers. MFG.com’s platform allows direct communication between buyers and a vast pool of suppliers through the use of their RFQ-based model.

Thus, Xometry’s model is more suitable for quick turnaround and project management support. MFG.com fits well with more complex projects, offering a broader supplier network and direct communication with manufacturers.

We’ll now take a closer look at each platform’s services, materials and finishes, pricing and lead times, and customer support.

Services

Both Xometry and MFG.com offer a variety of manufacturing processes. Choosing the right process for your project comes down to your specific part, how you want to make it, and how many you want to make. Here’s how each company’s services compare.

3D Printing

Xometry’s 3D printing processes include fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and Multi Jet Fusion (MJF) for plastics and their composites. They also include metal 3D printing solutions enabled by metal binder jetting, direct metal laser sintering (DMLS), and selective laser melting (SLM). In addition, Xometry offers PolyJet 3D printing for high-definition color parts, Nexa3D’s Lubricant Sublayer Photo-curing (LSPc), and Carbon’s Digital Light Synthesis (DLS) for high-performance models.

In comparison, MFG.com offers FDM, SLA, MJF, SLS, and a wide range of other additive manufacturing technologies depending on the manufacturer. Although not specifically stated, MFG.com features some 3D printing technologies for construction, gaming, modeling, and more. Since it’s a bidding marketplace for specialized projects, it’s safe to say that there are many different 3D printing services offered on their website and a manufacturer ready to work with you to meet your needs.

CNC

Computer numerical control (CNC) involves the automated supervision of tools through computerized systems. This technology is employed to manage various tools including drills, lathes, mills, grinders, and routers. Both companies offer ISO 9001 certified parts, with MFG.com presenting a specified directory of suppliers for each desired standard. MFG.com can offer milling, turning, and wire EDM, as illustrated by the types of CNC machines they have access to.

Xometry offers fast and custom CNC machining services from its vast network, including turning, milling, and drilling.

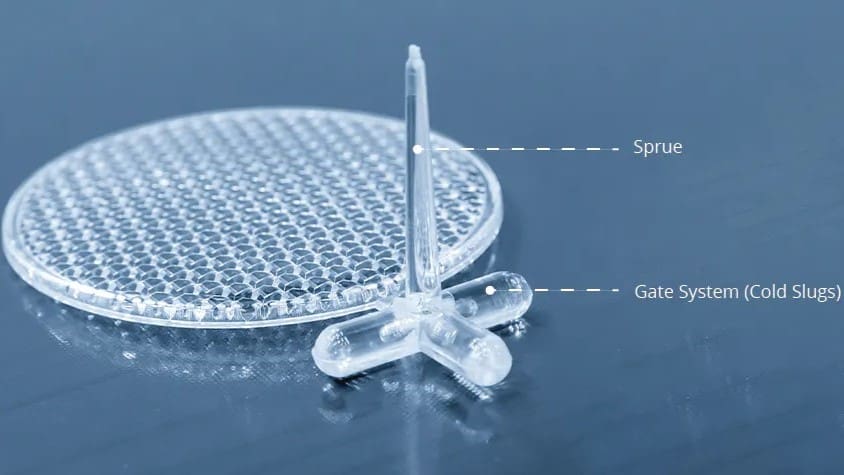

Injection Molding

Injection molding is a manufacturing technique used to create components by injecting liquefied material into a mold. Xometry’s injection molding services address large segments of the industry with different class molds. Some of their processes include insert molding, die casting, overmolding, metal injection molding, gas-assisted injection molding, and medical injection molding.

In comparison, MFG.com’s platform delivers the main injection molding services, including overmolding, insert molding, micro-molding, and gas-assisted injection molding.

Sheet & Tube Fabrication

High-precision and durable sheet metal parts can be produced through Xometry’s sheet and tube production solutions. They offer cutting and forming for aluminum, copper, bronze, steel, stainless steel materials, and more with a variety of different finishes. Processes offered include sheet, laser, waterjet, and plasma cutting, along with tube bending and laser tube cutting.

MFG.com offers an assortment of sheet metal fabrication solutions, including laser, plasma, and water-jet cutting. They also offer different assembly processes for cut sheet metal components, such as bending, cutting, punching, and welding.

Additional Services

Xometry has much more to offer customers outside of the main technologies mentioned. The size of their network allows them to expand their roster to include urethane and silicone casting, metal extrusion, metal stamping, plastic extrusion, die-cutting, electrical discharge machining (EDM), micro-molding, and micro-drilling. These technologies can be for part production or as a post-processing step to achieve the desired final aesthetics, surface finish, and performance.

The MFG.com platform also provides access to several versatile and effective stamping techniques that include blanking, bending, piercing, and forming. Some of the additional processes available in their manufacturer’s directory include design services, extrusions, blow molding, forging, investment casting, printed circuit fabrication, thermoforming, and woodworking.

Materials & Finishes

On-demand manufacturing requires an equally impressive selection of materials and finishes. Here, we highlight some of the main options available from these two companies.

Keep in mind that the number of available materials for each platform depends on the location and bid request. For example, Xometry Europe offers a wide selection of over 130 common metals and plastics. However, other locations in the US and Asia can offer a greater variety of custom and unique finishes.

3D Printing

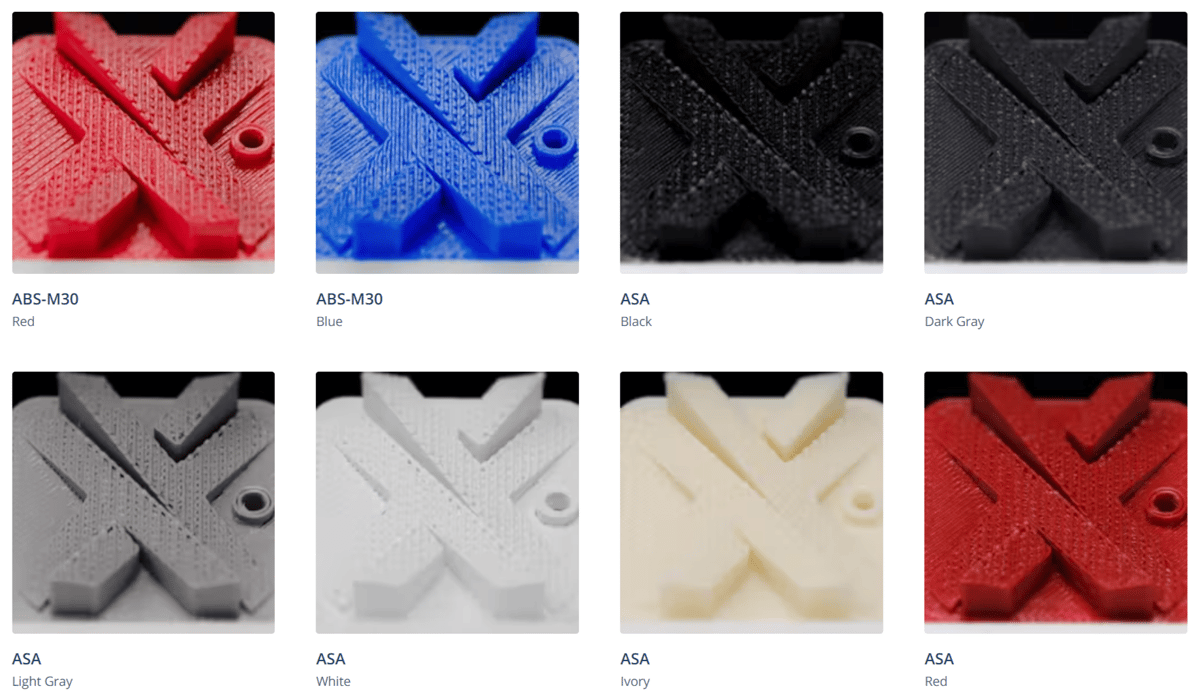

Xometry’s plastic 3D printing services are capable of producing parts made from nylon, ABS, ASA, Ultem, and other photopolymers like resins. Aluminum, stainless steel, Inconel, titanium, and more alloys can be produced through their metal 3D printing suppliers.

Xometry provides vapor smoothing, color dying, and nickel plating as three of the most commonly requested finishes. Additional options include sanding, polishing, and clear finishing for plastics, and CNC machining, polishing, and sandblasting for metals.

In comparison, materials available in MFG.com’s directory include ABS, nylon, and polycarbonate, in addition to other thermosets and thermoplastics. The metal library lists titanium, stainless steel, aluminum, and various alloys as options. For certain applications like jewelery, customers can order parts made from brass, bronze, copper, and precious metals such as gold, platinum, and silver. Many more options can be requested when creating the RFQ on their website.

CNC

Xometry offers plastics, composites, and metals for their CNC services. Plastics and composites include materials such as ABS, acrylic, Garolite (composite), nylon, PEEK, PTFE (Teflon), PVC, and Ultem. Some metals offered by the platform are aluminum, copper, bronze, stainless steel, titanium, and zinc, but there is also a wide range of available alloy options suitable for even high-end applications.

Some of the featured CNC material finishes include bead blast, anodized type II and III, electropolishing, electroless nickel plating, silver, gold, and zinc plating, among others. In addition, customers can communicate whether they require a specific, custom finish in the quoting system.

Their roster of available materials on MFG.com includes different classes of materials, metals, plastics, and even ceramics. Common metals like alloy steel, aluminum, copper, and titanium are readily available in addition to more specialized materials like Inconel, carbon steel, and beryllium copper. Thermoplastics and thermosets orders can also be submitted along with ceramics like tungsten carbide.

Their submission portal has a wide range of finishing options, such as anodizing, electroplating, powder coating, sand and shot blasting, galvanizing, and heat treatment.

Pricing & Lead Times

Pricing and lead times can vary significantly between Xometry and MFG.com. Xometry’s instant quoting process helps reduce the amount of time to production significantly, whereas MFG.com needs bids from suppliers to be submitted, approved, and then commissioned. However, MFG.com’s RFQ-based model can potentially reduce the price from available suppliers compared to Xometry.

Generally, several factors affect pricing and lead times, including the chosen process, material, and location, in addition to other factors such as desired finishes and certifications. The manufacturing process has a direct influence on both pricing and lead times. For example, technologies like 3D printing may be done with a single part while others like injection molding usually have a minimum order amount that affects delivery time and costs.

For a clearer comparison, we compared pricing on the platforms with a 3D Benchy model, as shown in the image. We set the same parameters to FDM, 100% infill, ABS material, and standard finish. Xometry quoted $19.83 for the part. On the other hand, MFG.com had a wide price range from different suppliers. The lowest price was $4.20 and the highest was $56.18. This is expected, as suppliers can be from different regions, large or small, and use different machines for the same technology.

In terms of lead times, Xometry reports three to five business days. MFG.com allows users to submit expected delivery dates for suppliers to view and bid on. Hence, MFG.com does have different options that rely heavily on the chosen quote and supplier. Lead times typically range from one to five business days.

Minimum orders differ, depending on the chosen process. Xometry asks for a minimum of 50 pieces for injection molding, but users can submit a single part for other technologies, such as FDM. The minimum for MFG.com again depends on the supplier. However, both platforms offer access to batch discounts and provide a chance to negotiate.

Platform Interface

When ordering your parts, it helps to have a website that’s easy and intuitive to use. Xometry and MFG.com both provide quoting portals to help simplify the process from design submission to final delivery.

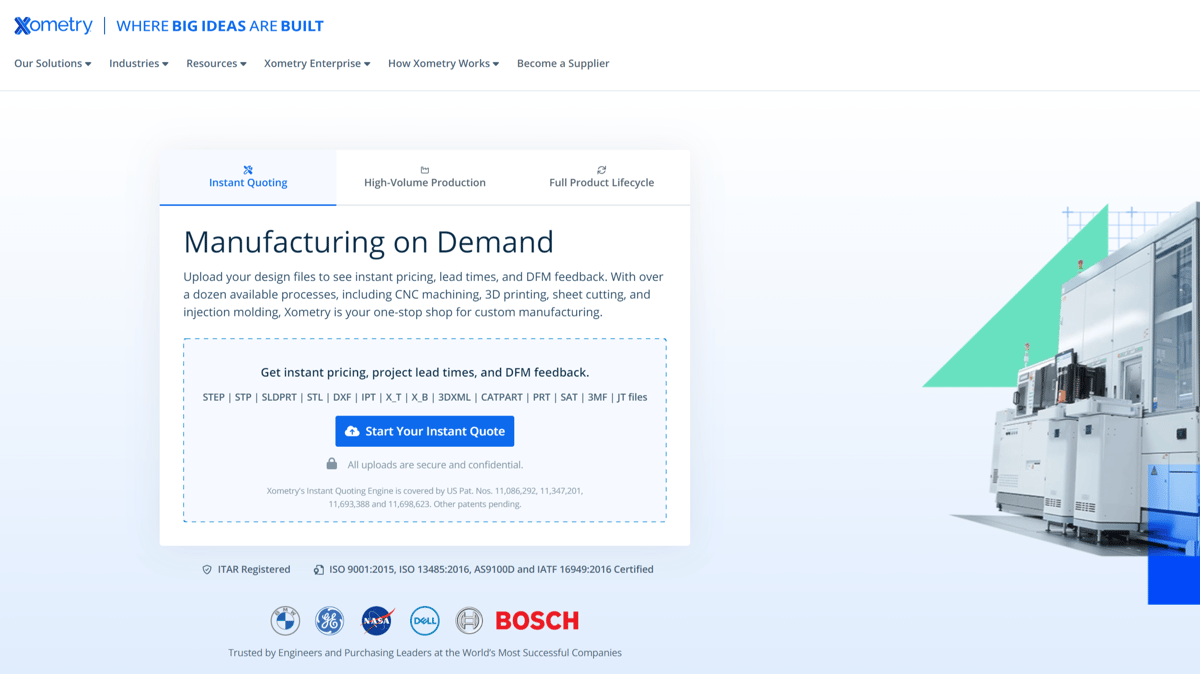

With Xometry, users can easily access the instant quoting tool from the top of the homepage. When submitting a file, the platform analyzes and suggests an ideal material and technology suitable for the specifications. The design for manufacturing (DFM) feedback feature automatically checks certain aspects, such as confined hollow, floating parts, large parts for process, large parts requiring manual quote, model fidelity, and part volume.

As for finishes, users can manually input their desired finish from Xometry’s gallery. Xometry also provides different site extensions to select areas, so users can refer to these to order parts from their desired region, including the USA, UK, Europe, Turkey, and Asia.

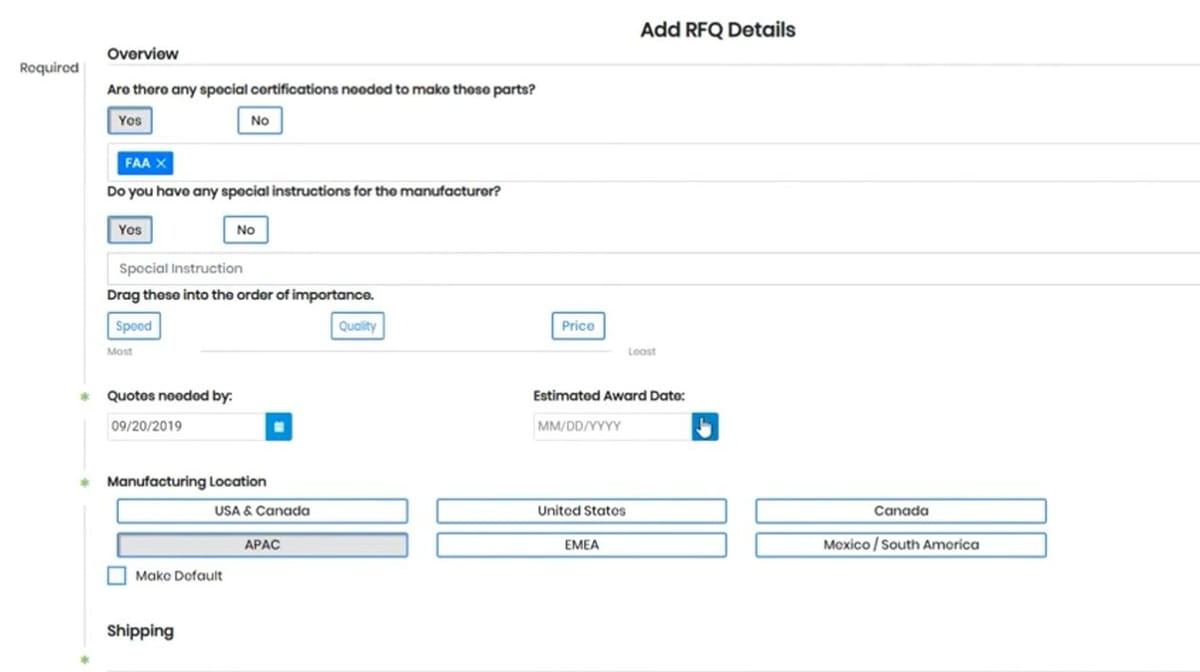

MFG.com also makes it easy to connect with manufacturers, right from their homepage. They accept all file formats, and users do not need to submit CAD files or other drawings to start a project if it requires an initial design phase. To begin the RFQ process, the platform will ask users to submit any pertinent files and then choose standard or custom NDAs with single or double confirmation. The extensive library of options accommodates projects for sensitive areas, such as aerospace, defense, and pharmaceuticals. The certifications options can be viewed in the manufacturer directory under certifications.

After the RFQ is created, suppliers can submit bids for users to review, showing their location, affiliation, contact person, quote date, and action bars. When satisfied with a quote, users can then choose to Award Part to start the process. The platform makes it simple for suppliers and users to communicate directly.

Customer Support

Xometry allows users to leverage several resources, providing the best experience for them and their projects. Customers can refer to Xometry’s knowledge hub for more information about different aspects of the quoting process. Additionally, users can utilize the help center and other resources on the website that focus on topics like design tips, materials, processes, and FAQs.

In comparison, MFG.com provides several resources to help potential customers use their platform. Key components that help customers include a manufacturer directory, a blog, a FAQ page, and a dedicated forum. You can also always contact them directly if you want more information. Moreover, MFG.com provides additional resources with featured case studies.

Both platforms have regular community events, with Xometry being more active in contests, design awards, and innovation competitions. They also each have a social media presence, but only MFG.com provides forums for users to engage in. Overall, the two companies offer dedicated resources to take the guesswork out of the ordering process.

License: The text of "Xometry vs MFG.com: The Main Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.