Too long, didn’t read: 3D printed Organoids can reduce animal testing drastically and help scientists develop faster. Meet the “Body on a Chip”.

The “Body on a Chip” project is a pioneering medical researching effort that suggests the 3D printing of human tissue based “organoids”, which function similarly to real organs on a very small scale. The main purpose of the project is to develop an alternative for the in-vivo testing methods that would be quicker, more efficient, less costly and wouldn’t involve real, living animals.

The $24 Million “Man”

The project is federally funded by the US government (with $24 million) and is lead by the Wake Forest Baptist Medical Center’s Institute for Regenerative Medicine. Other participants and contributors include Brigham and Women’s Hospital in Boston, University of Michigan, The U.S. Army Edgewood Chemical Biological Center, Morgan State University, and The Johns Hopkins Bloomberg School of Public Health.

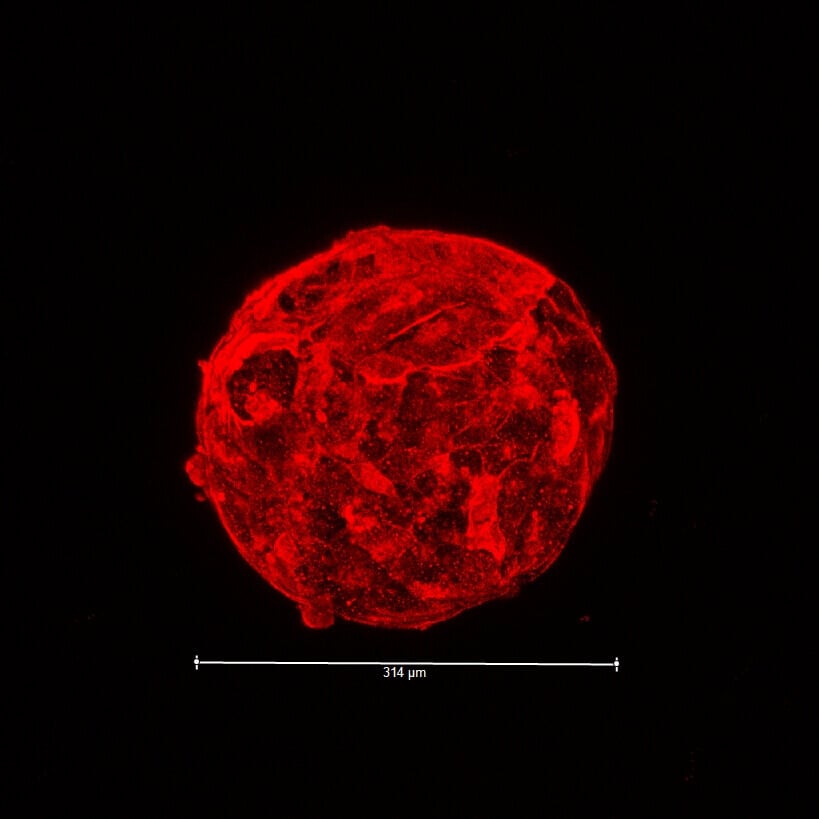

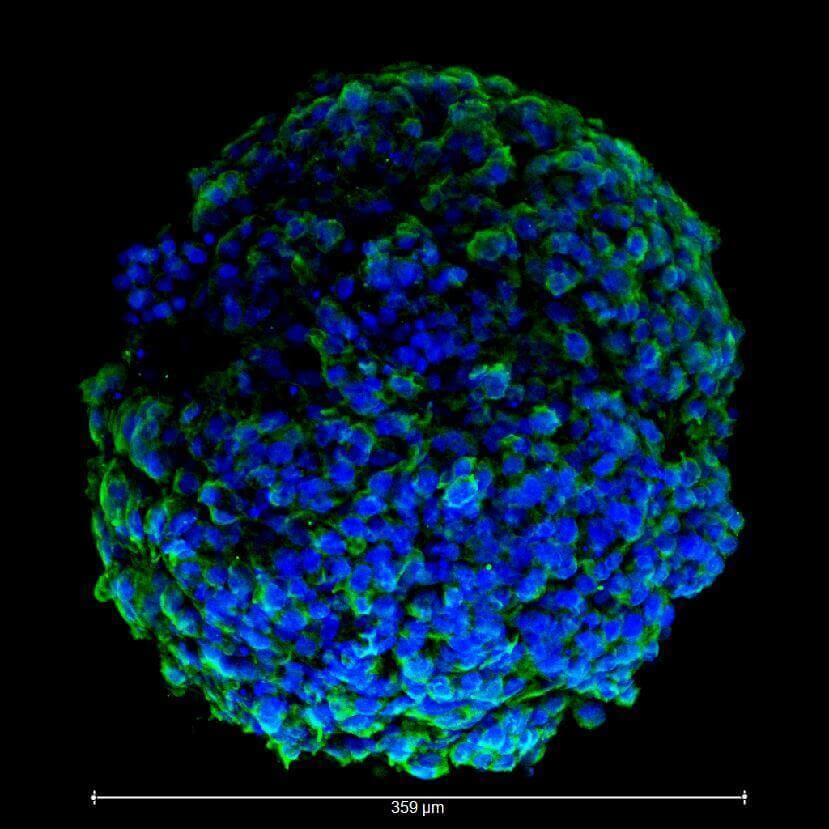

The special 3d printer that is used is still undergoing heavy testing. But the latest developments in micro-tissue and micro-fluidics have allowed scientists to take first steps into the field of bioprinting; with the 3D manufacturing of “tiny human organs” that are able to imitate the functional and cellular characteristics of the real ones. The idea is to create less complex tiny organs that would be interrelated with a moving fluid serving as an artificial blood substitute.

Testing 1, 2, 3…

Between the organ plates, scientists can insert monitoring sensors to acquire measurements of key data in real time, while also being able to take note of any interactions, data relations and bio-mechanic properties of the system as a whole. This is especially important as current in vivo testing methods allow scientists to only determine how a drug or virus affects a particular cell family/organ.

Besides the fact that the testing will be more effective and complete, it will also be significantly quicker, which is critical when dealing with a new toxin or dangerous biological agent. That is exactly the reason why the US government is the main financial supporter of this project, as “Body on a Chip” will hopefully bring great enhancements in their biowarfare defense abilities and will greatly decrease the time and cost to develop medical countermeasures.

Like a the 3D Printer You Have at Home

The 3D printer used to build the Body on a Chip components follows standard additive manufacturing methods, printing the “organoids” layer by layer at a cellular level. An artificial scaffolding is automatically generated and added to keep the cells in place and hold the organ structure intact. When the printing is completed, the organs are kept “alive” by circulating fluids that travel through tiny channels carrying nutrition, drugs, chemicals or whatever else is needed for each testing session.

The whole system is placed in a 2-inch chip that contains the sensors that will measure temperature, oxygen levels, PH and other factors. The organs that can be printed so far using this method are the heart, liver, lungs and blood cells that constitute the core of the human body and are enough to draw safe conclusions from testing. The question that the project is called to answer is how well all this will work as we pass from theory to practice, but since so many people and institutions are involved, and the money is in place, the answer can’t be very far from today.

License: The text of "3D bioprinted body-on-a-chip project is “alive”" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.