DIY Bioprinting is a great, cost effective way for smaller labs get started in Biotech. Here’s an overview of what’s happening in the open source 3D bioprinting scene.

A Bioprinter? What’s that?

https://youtu.be/ueo2KhKP0P8

A bioprinter is a 3D printer that creates parts using materials called “hydrogels” that contain live stem cells. These can be used to create human skin, tissue and, one day, organs.

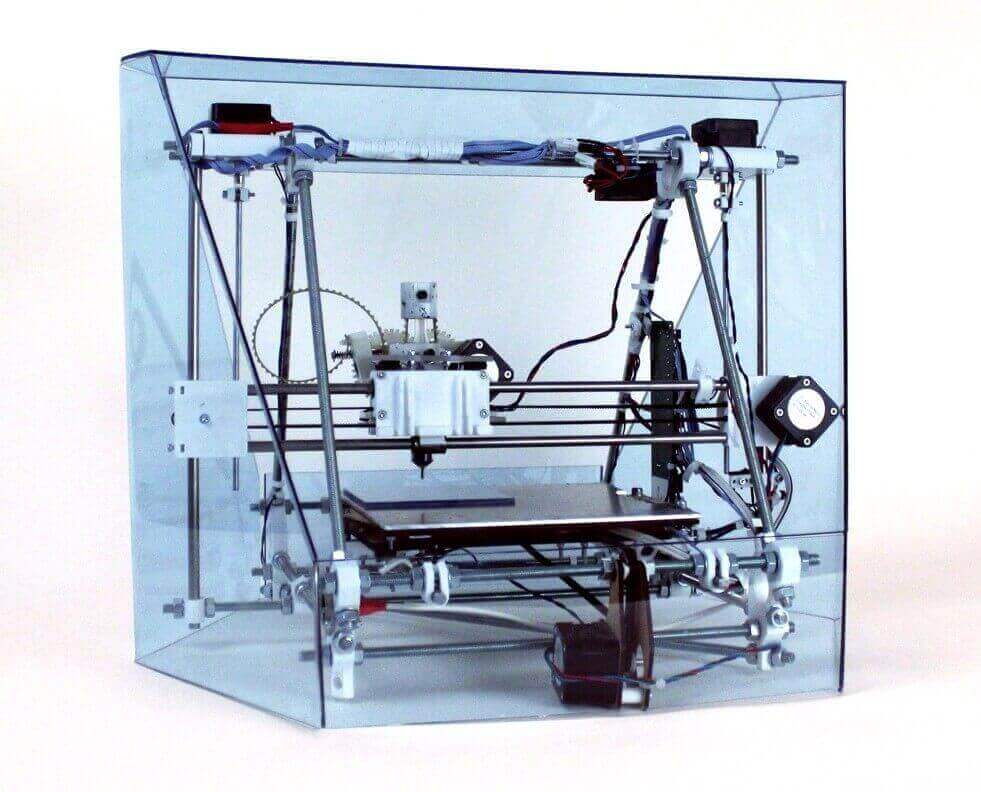

Past week Stephen Gray from Ourobotics presented, during a meet-up at MIT, the first publicly available model for a RepRap 3D bioprinter. It can be built and assembled for less than $1,000 in components.

How can such an advanced system be built for less than the cost of a semi-professional photo camera?

That’s because of the implications of 3D printing and specifically open source RepRap 3D printing. This new manufacturing technology is not just a technology but an entirely new way of making things, including biological things. Additive processes can assemble matter digitally. So they can do with biological matter. A bioprinter is nothing other than a standard RepRap 3D printer which uses a pneumatic syringe instead of the common filament extrusion.

For $900, You Can Print All Sorts of Cells

Then main difficulties of bioprinting isn’t in the actual 3D printing process. It’s in the handling of materials, which, incidentally, is the most complex issue in any type of 3D printing. How do we cure and solidify them? How do we extrude them without killing the living cells? And how do we maker sure that once the biological part has been built it can survive and the cells inside it grow and multiply?

These are all the matters that scientists are researching. They will be able to do so even more intensively now that they will have access to a truly low-cost 3D bioprinter.

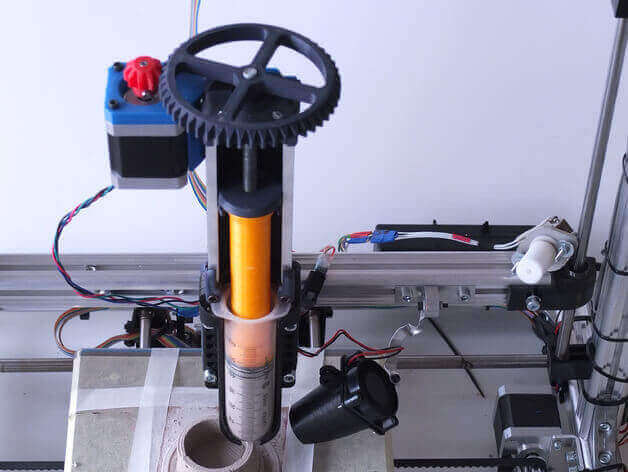

The one presented by Ourobotics was designed by Raunaq Bose. He used the now famous Universal Paste Extruder by RichRap as its main extrusion system. That’s because hydrogels behave like most gelatinous and paste materials: they contain the cells and a large amount of water and they can generally solidify (by UV curing or by temperature shift) after being deposited.

DIY Bioprinting: Where Can You Get The Tools and Infos?

RepRap has a small bioprinting wiki assembled, which you can find here.

A RepRap isn’t the only way to a DIY bioprinter. You can even hack an an old inkjet printer to become one. There’s an Instructable right here for you to download. All you need is an old printer, some spare time and a bit of tinkering knowledge.

A quick look at Thingiverse will yield a number of other freely available bioprinter components.

Designer Sidertis released a Triple-Lumen BioPrinter Head, while Italy’s piùLAB released a 60 ml Syringe Extruder for a process they named Liquid Deposition Modelling (LDM). A quick look at the Bioprint tag on Thingiverse will also show other accessories, while a look at “bioprinter” will give you yet one more accessory.

Free, Open Source Medical Research Components on Thingiverse

That brings us to the subject of open source development applied to scientific research. One of the main authorities on the matter is Professor Joshua Pearce from Michigan Tech University. His research group studies RepRap 3D printing and sustainability. Prof. Pearce has also published a great book on this subject, Open Source Lab, which accurately details dozens of expensive lab tools that can be manufactured for a tiny fraction of the cost using open source designs and 3D printing technologies.

In the book Pearce describes dozens of these in his book, along with clear instructions, diagrams and photos on how to build devices such as a phDuino, a laser cut Open PCB, a DremelFuge (Dremel+3D printed centrifuge), 3D printed rapid fluid filers, PCR tube racks, forceps, and many more items for just a handful of dollars.

“Historically, you, I and the rest of the scientific community had no choice. We had to buy proprietary tools to participate in state-of-the-art research or develop everything from scratch. Thus, we had to choose between paying exorbitant fees or investing a lot of our own time as even the simplest research tools like a lab jack are time-consuming to fabricate from scratch. No more! Now the combination of open-source microcontrollers and 3D printers enables all of us to fabricate low-cost scientific equipment with far less-time investment than ever possible in the history of science,” Pearce writes as a premise.

DIY Bioprinting: The Bottom Line

The bottom line though is that, although open source 3D printing many seem like a threat to traditional manufacturers of lab equipment this is not true. In fact the use of open source in scientific research is a win-win situation. That’s because if a University is able to save hundreds of dollars on the most basic lab equipment. That’s not how scientific research works. Instead they will use that extra money to hire a new researcher, give more scholarships or buy more advanced lab equipment.

This means that the large producers of lab equipment stand to earn even more money than before due to the higher rate of research and discoveries.

There is no inherent limit as to how fast science can go. Pearce once demonstrated that a single open source mechanical pump design can generate savings for up to 800 million dollars in the long run, with hundreds of labs throughout the world using it and upgrading it. Now that concept is about as disruptive (and constructive) as it gets.

License: The text of "3D Bioprinting For Just $1000" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.