New innovation in 3D printing takes inspiration from nature; 3D Cocooner copies spiders and caterpillars to spin threads into complex shapes.

German industrial control and automation company Festo have created the 3D Cocooner, a “bionic technology” platform that can spin complex yet stable shapes using thread coated with resin.

The cool thing about the 3D Cocooner is that Festo has taken inspiration from nature. Whether in the form of a net to catch prey, or a cocoon for protective, spiders and caterpillars are able to create amazing shapes by spinning threads.

In turn, the 3D Cocooner is able to build objects freely in space using a special combination of resin and UV light, with no supports needed for the resulting structures.

How Does the 3D Cocooner Work?

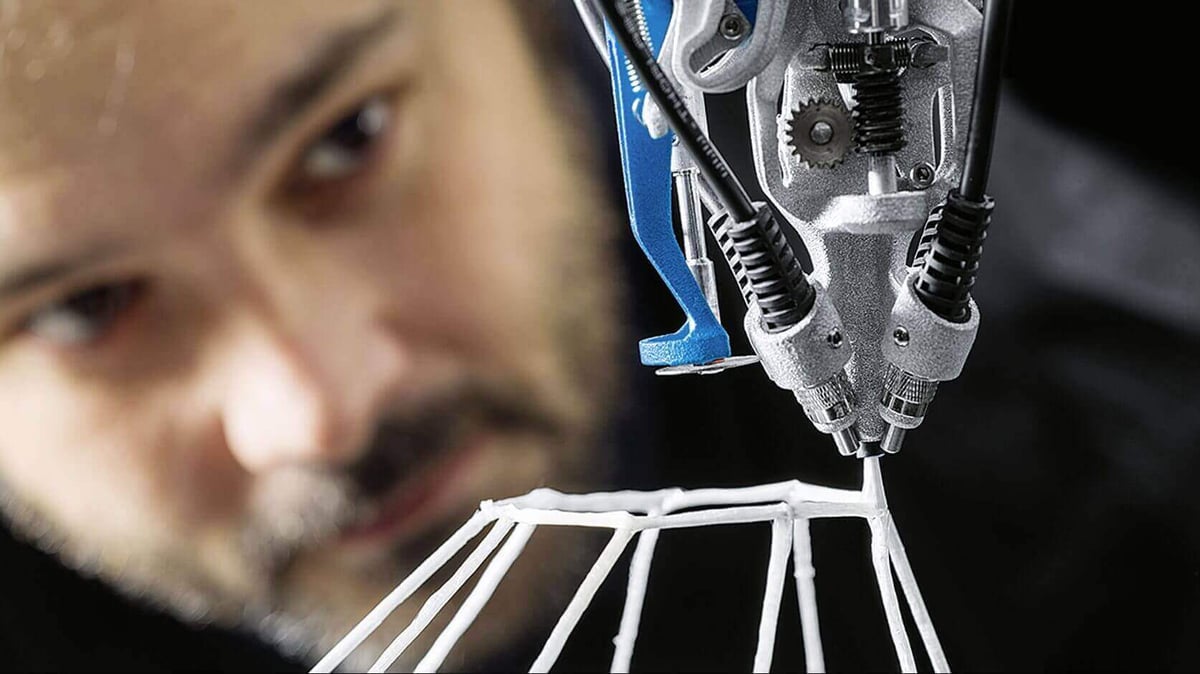

The soft thread is covered with a special resin so that it can be converted into a solid lattice structure. Once it has been extruded from the mechanical spinneret, a UV light cures the resin-soaked fibre with pinpoint accuracy, and hardens it into a sturdy little rod.

During the process, the thread can be reset at any point on the lattice structure, where it continues to build. This means it’s possible to construct even complex shapes in three-dimensional space without any supports.

Even if you change your mind about your print, a built-in saw can slice the resin when you want to reposition the print head. The special resin can also be softened at any time. This allows beams to be angled or connected to other parts of the 3D cocoon during the printing process.

Something else that makes the 3D Cocooner so special is speed; it can print at a rate of 10mm per second, meaning you won’t be waiting around for hours to finish your project.

What do you think? Is 3D Cocooner going to be the future of manufacturing? Let us know in the comments.

(Via Futurism)

License: The text of "3D Cocooner Spins Shapes Inspired by Nature" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.